A method for preparing high-efficiency carbon nitride nanorod photocatalysts by acidification-assisted hydrothermal method

A photocatalyst and carbon nitride technology, applied in the field of catalysis, can solve the problems of cumbersome experimental steps and human harm, and achieve the effect of safe and effective process, strong repeatability, safe and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

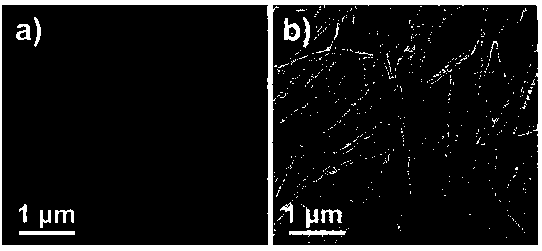

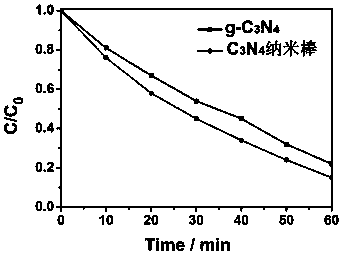

[0033] A method for preparing efficient carbon nitride nanorod photocatalyst by acidification-assisted hydrothermal method, the method is as follows:

[0034] (1) Weigh 20g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, keep it for 4 hours, and naturally cool to room temperature to obtain graphite-like layered carbon nitride;

[0035] (2) Disperse 0.5 g of the prepared carbon nitride powder in 1M hydrochloric acid, continue to stir for 2 hours, collect the carbon nitride powder by centrifugation and wash it with deionized water three times;

[0036] (3) The acidified carbon nitride was placed in a polytetrafluoroethylene autoclave, and 100mL of deionized water was added, kept at 180°C for 3 hours, and then naturally cooled to room temperature;

[0037] (4) Collect the powder of the lower layer, wash it with deionized water three times, and then dry it in a blast drying oven at 60°C for 5 hours unt...

Embodiment 2

[0039] A method for preparing efficient carbon nitride nanorod photocatalyst by acidification-assisted hydrothermal method, the method is as follows:

[0040] (1) Weigh 30g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 1.5°C / min, keep it for 4 hours, and naturally cool to room temperature to obtain graphite-like layered carbon nitride;

[0041] (2) Disperse 0.8 g of the prepared carbon nitride powder in 2M hydrochloric acid, continue to stir for 3 hours, collect the carbon nitride powder by centrifugation and wash it with deionized water three times;

[0042] (3) The acidified carbon nitride was placed in a polytetrafluoroethylene autoclave, and 100mL of deionized water was added, kept at 150°C for 5h, and then naturally cooled to room temperature;

[0043] (4) Collect the powder in the lower layer, wash it with deionized water three times, and then dry it in a blast drying oven at 60°C for 8 hours until ...

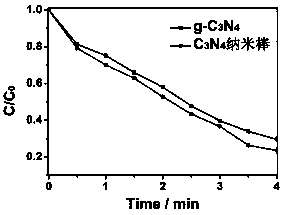

Embodiment 3

[0045] A method for preparing efficient carbon nitride nanorod photocatalyst by acidification-assisted hydrothermal method, the method is as follows:

[0046] (1) Weigh 20g of urea and place it in a ceramic crucible with a lid, raise the temperature to 550°C in a muffle furnace at a rate of 2°C / min, keep it for 4 hours, and naturally cool to room temperature to obtain graphite-like layered carbon nitride;

[0047] (2) Take 0.5 g of the prepared carbon nitride powder and disperse it in 2M sulfuric acid. After stirring for 3 hours, the carbon nitride powder is collected by centrifugation and washed three times with deionized water;

[0048] (3) The acidified carbon nitride was placed in a polytetrafluoroethylene autoclave, and 100mL of deionized water was added, kept at 200°C for 3 hours, and then naturally cooled to room temperature;

[0049] (4) Collect the powder of the lower layer, wash it with deionized water three times, and then dry it in a blast drying oven at 60°C for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com