Three-dimensional piece folding low pressure mask

A three-dimensional sheet-type, low-pressure technology, applied in the field of masks, can solve the problems of reducing the filter area of the filter sheet, the impact force of the airflow on the filter sheet, and the increase of the probability of microparticles passing through, so as to increase the effective filter area and improve the anti-corrosion effect. Air leakage performance, the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

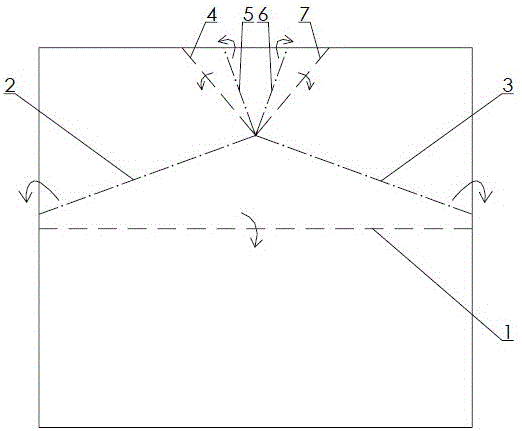

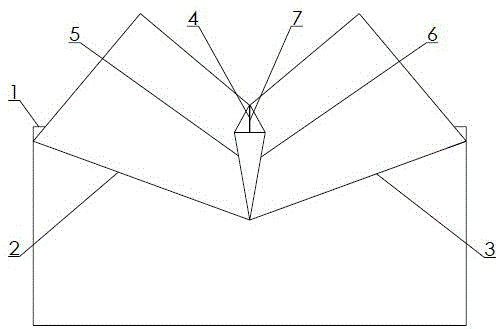

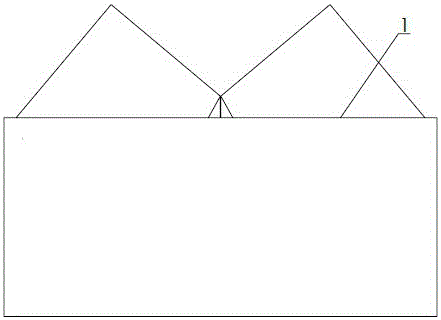

[0027] Embodiments of the present invention are as Figures 1 to 5 As shown, the three-dimensional sheet-type folded low-pressure mask is provided with a mask consisting of more than one layer of filter sheets, and the mask is provided with folds. , 6, and 7. These creases are marked by dotted lines in the figure. The long dotted line is the valley crease, the dotted dotted line is the peak crease, the arrow is the folding direction, and the arrow crossing the dotted line inside the edge is the forward fold. The arrows for the reverse fold, figure 1 From the angle of view, the valley crease is forward folded into a valley, and the peak crease is reversely folded into a peak. The mask is folded forward along the straight line crease 1 and then reversely folded back along the fold line crease 2 and 3. The fold line crease consists of two Line segments are connected, and the folds and creases are distributed on the reversely folded mask starting from the apex of the fold line cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com