A low frequency vibration isolator for high-speed train floor

A technology for high-speed trains and vibration isolators, applied in the direction of high internal friction springs, etc., can solve the problems of large static deflection of the mounting seat and large deformation of the floor, and achieve the effects of good vibration isolation performance, improved riding comfort, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

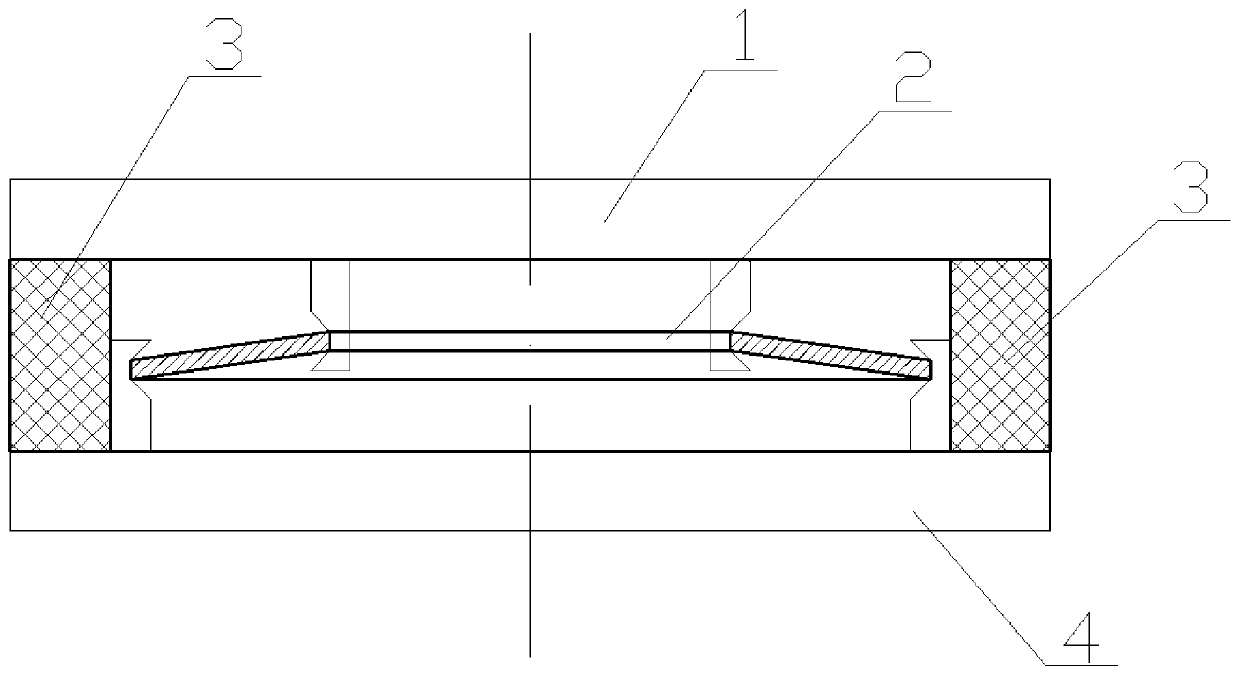

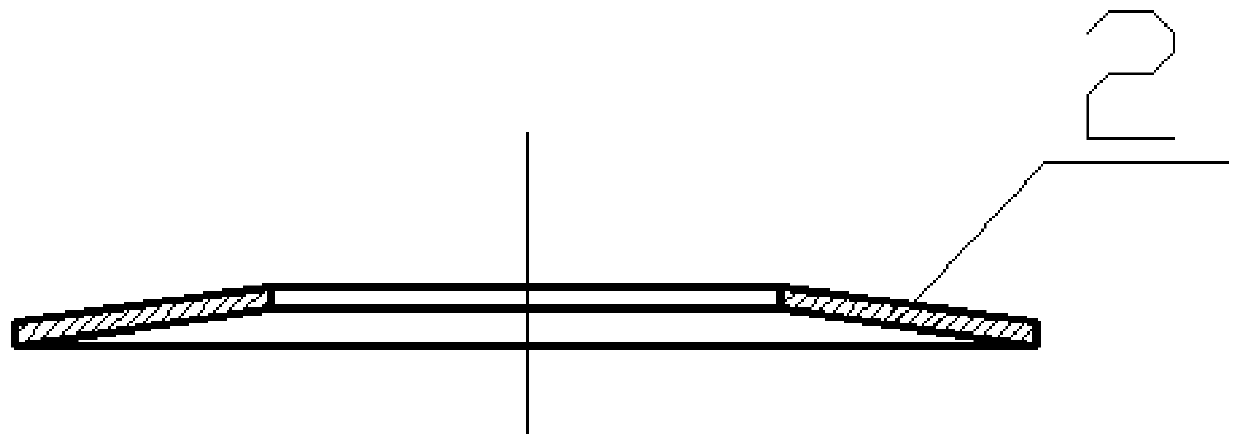

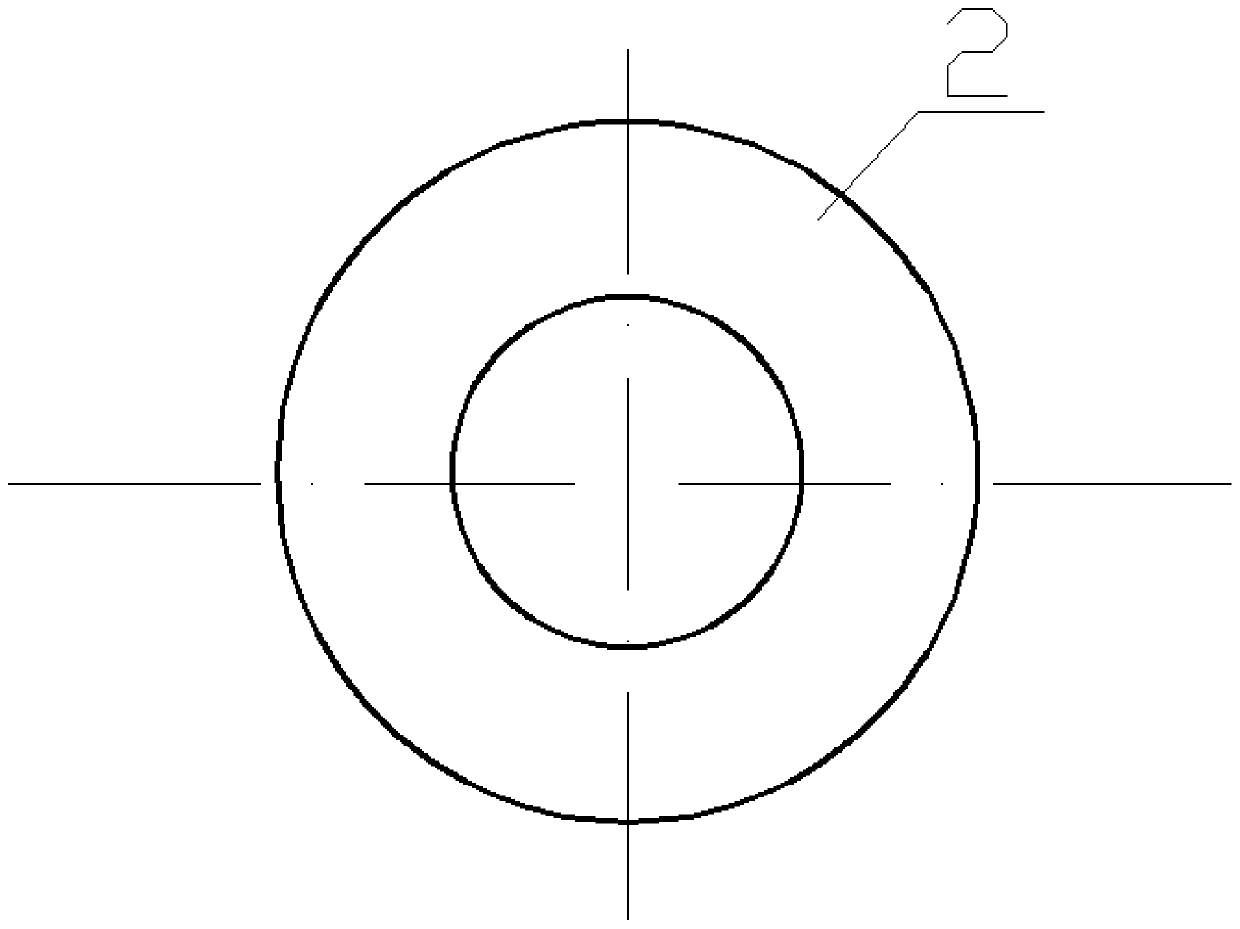

[0031] A low-frequency vibration isolator for high-speed train floors, such as figure 1 As shown, it includes the upper mounting base 1 of the vibration isolator, the lower mounting base 4 of the vibration isolator, the disc spring 2 arranged between the upper mounting base 1 of the vibration isolator and the lower mounting base 4 of the vibration isolator, and the The bushing-type rubber spring 3 on the outside of the spring 2, the upper and lower ends of the bushing-type rubber spring 3 abut against the mounting seat 1 at the upper end of the vibration isolator and the mounting seat 4 at the lower end of the vibration isolator respectively. The inner edge of the upper end of the disc spring 2 is fixedly connected to the outer side of the side wall of the upper end mounting base 1 of the vibration isolator, and the outer edge of the lower end 2 of the disc spring is fixedly connected to the inner side of the side wall of the lower end mounting base 4 of the vibration isolator....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com