Assembly method of fpc components and fpc components

An assembly method and component technology, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components, can solve the problem of difficulty in accurately ensuring that the distance between FPC connectors meets production requirements, and reduce product production defects and improve production. Efficiency, the effect of facilitating the amount of tin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

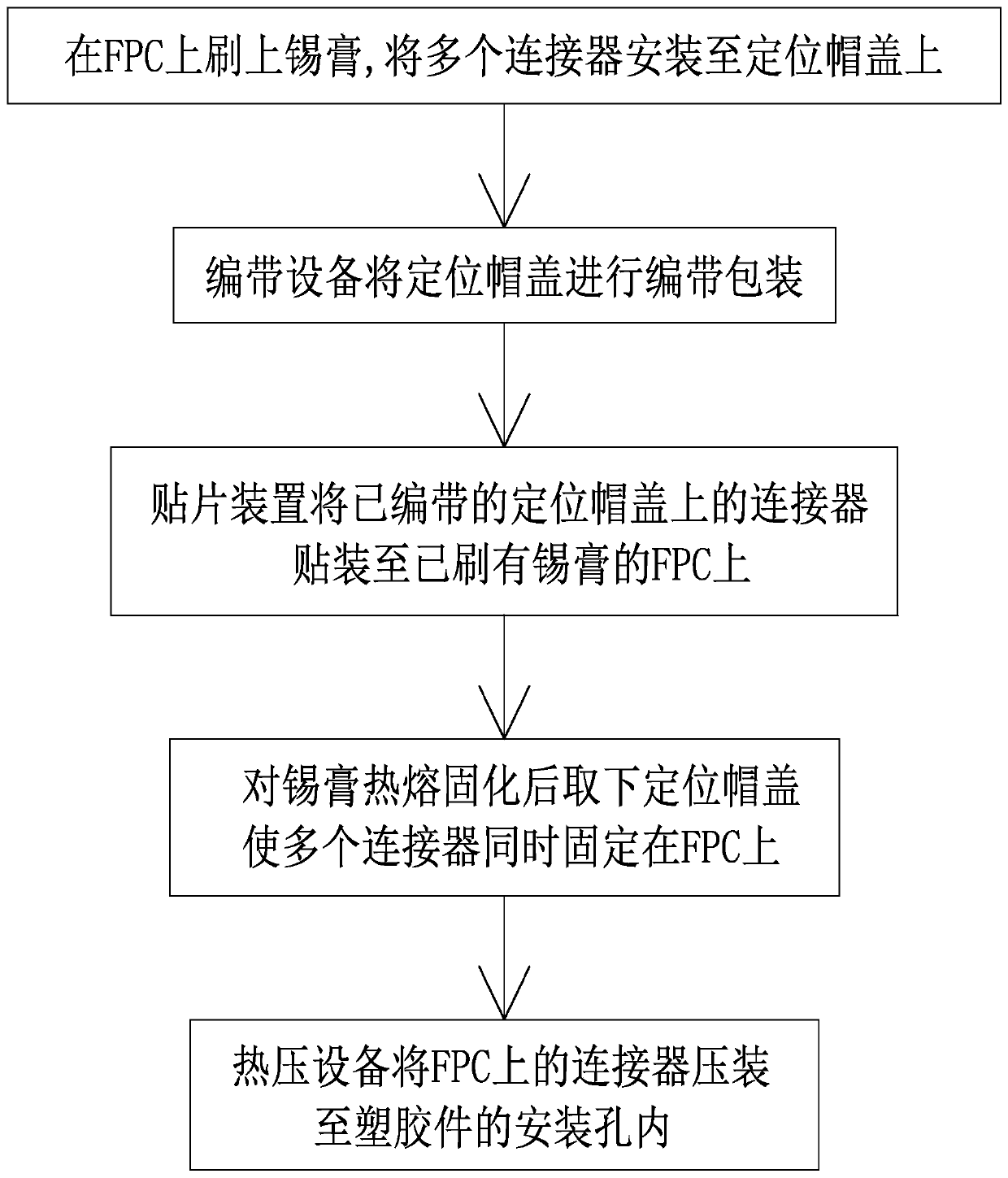

[0035] This embodiment provides a method for assembling an FPC assembly, such as figure 1 shown, including the following steps:

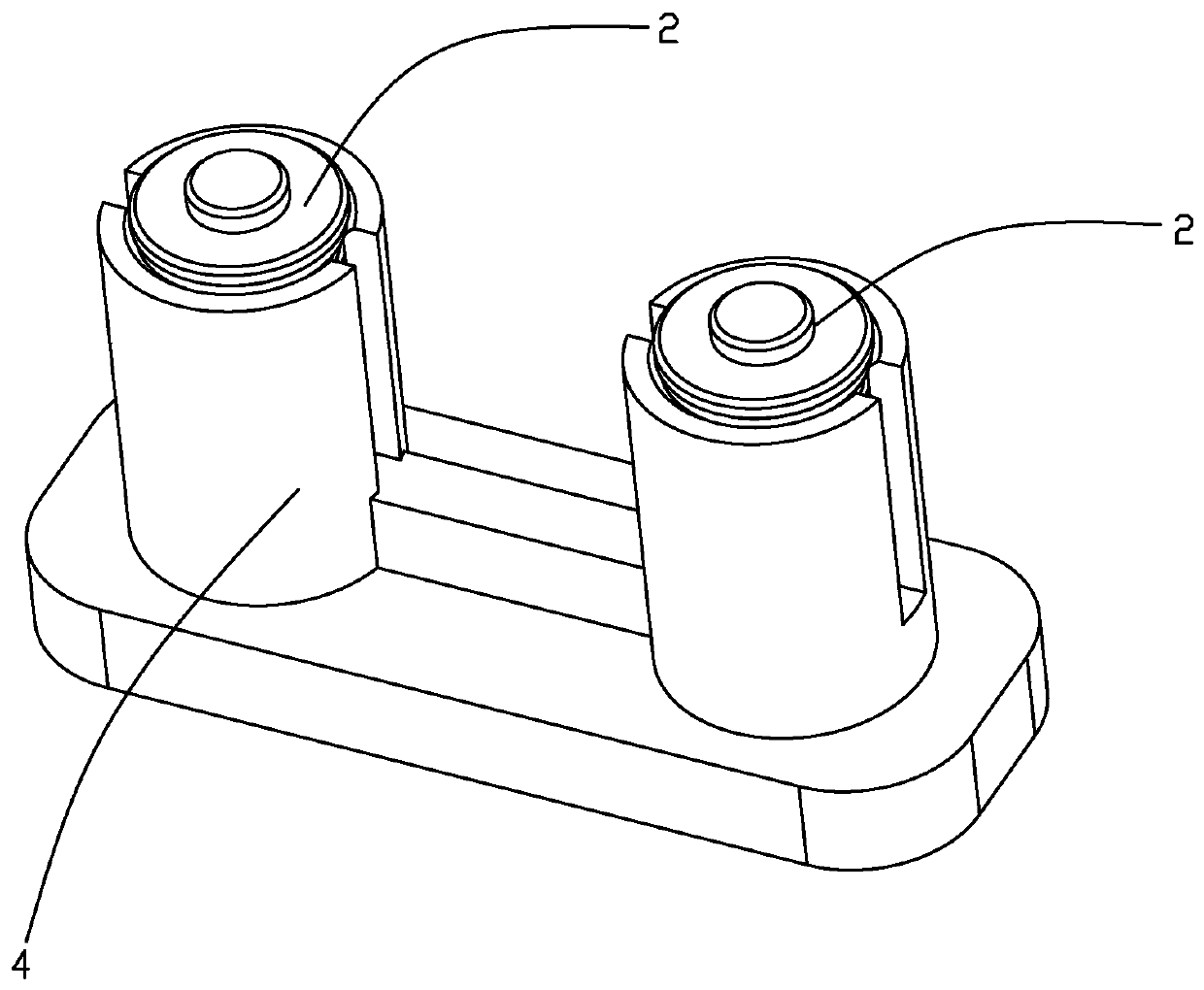

[0036] a. Brush solder paste on FPC1, and figure 2 As shown, a plurality of connectors 2 are installed on the positioning cap 4 so that the distance between each connector 2 is fixed; in this step, the solder paste can be printed on the FPC1 by a solder paste printing machine.

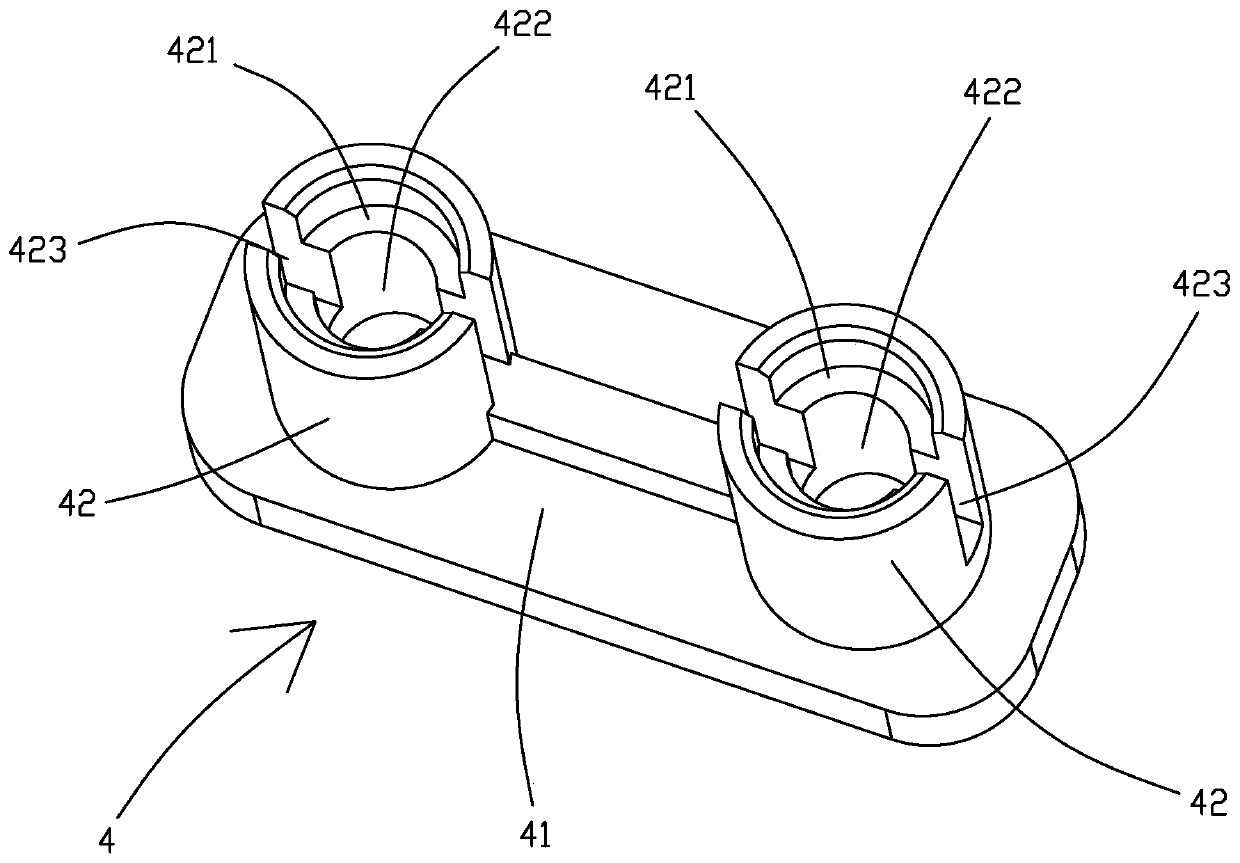

[0037] In the step a, in order to enable the connector 2 to be firmly assembled into the positioning cap 4, as image 3 As shown, the positioning cap 4 includes a base plate 41 and a plurality of positioning cylinders 42 arranged on the base plate 41, and the distance between each positioning cylinder 42 is fixed. Specifically, the positioning cap 4 includes two positioning cylinders 42. cylinder 42, the positioning cylinder 42 is provided with a positioning installation cavity 421 that can be installed in cooperation with the connector 2, and the connector 2 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com