Single-row socket

A single-row socket and socket hole technology, which is applied in the electrical field, can solve the problems of increased production enterprise costs, low material utilization rate, and difficult processing, and achieve the effects of improving the standardization of materials, improving the degree of automation, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

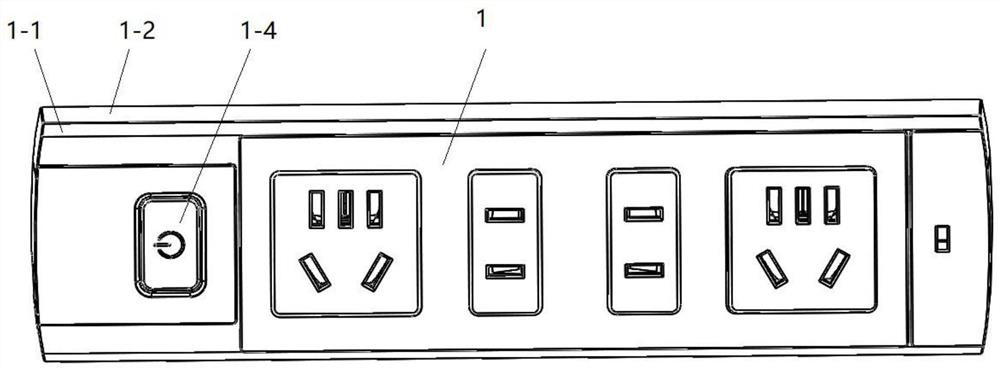

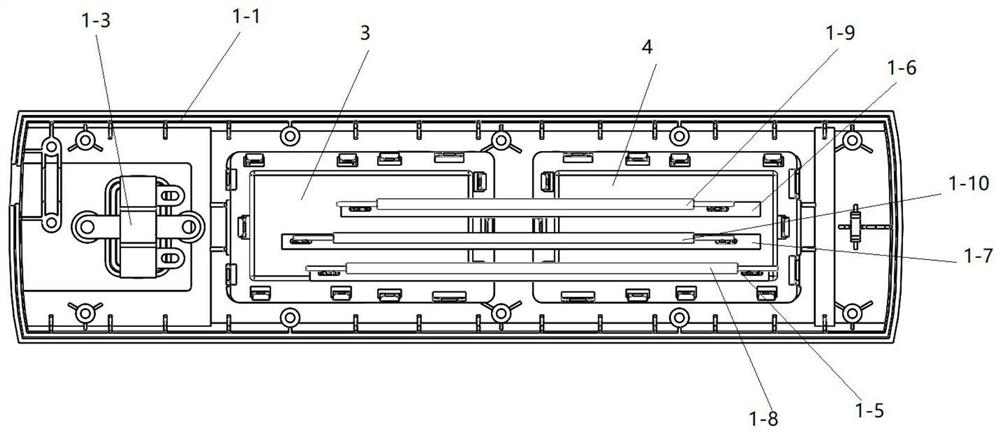

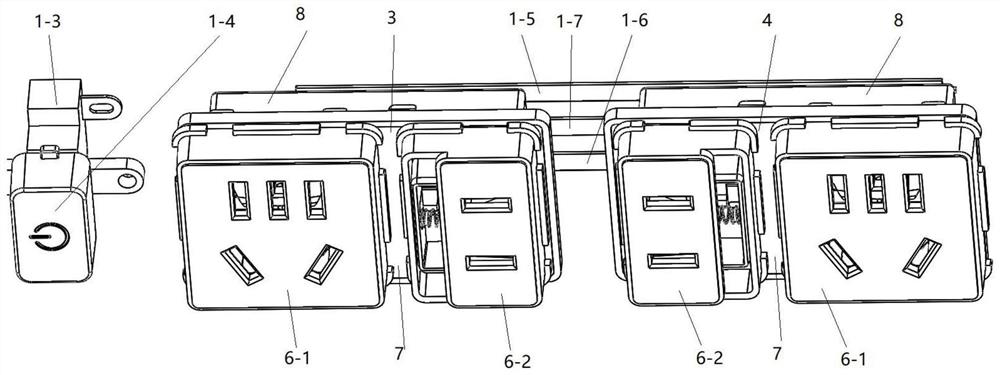

[0040] Such as Figure 1 to Figure 3 As shown in , the 14-hole single-row socket of the present invention includes a housing composed of an upper cover 1-1 and a lower cover 1-2, and a switch 1-3, a button 1-4 for controlling the switch, and a left seven combination are installed in the housing. Hole module 3, right seven combination hole module 4, L pole connection copper strip 1-5, N pole connection copper strip 1-6, E pole connection copper strip 1-7, L pole power line 1-8, N pole Power cord 1-9, E pole power cord 1-10. The straight line where the L-pole welding leg, the N-pole welding leg, and the E-pole welding leg protruding from the left seven combined pass module 3 and the right seven combined pass module 4 are parallel to each other, and the distance between the two 3mm in line with electrical safety requirements. L poles connect copper strips 1-5, N poles connect copper strips 1-6, E poles connect copper strips 1-7 and L poles protruding from the left seven combina...

Embodiment 2

[0048] Such as Figure 10 with Figure 11 As shown in , the 19-hole single-row socket of the present invention includes a housing composed of an upper cover 1-1 and a lower cover 1-2, and a switch, a button 1-4 for controlling the switch, and 2 left seven combination holes are installed in the housing. Type module 3, 1 independent five-combination hole module 2, L pole connection copper strip 1-5, N pole connection copper strip 1-6, E pole connection copper strip 1-7, L pole power cord, N pole power cord , E pole power cord. The straight line where the L-pole welding leg, the straight line where the N-pole welding leg is located, and the straight line where the E-pole welding leg protrudes from the two left seven combined pass modules 3 and one independent five-pass combination pass module 2 are parallel to each other, and two by two The distance between them meets the electrical safety requirements of 3mm. L poles connect copper strips 1-5, N poles connect copper strips 1-...

Embodiment 3

[0053] Such as Figure 15 with Figure 16 As shown in , the 25-hole single-row socket of the present invention includes a housing composed of an upper cover 1-1 and a lower cover 1-2, and a switch 1-3, a button 1-4 for controlling the switch, and 2 horizontal sockets are installed in the housing. Ten combination pass module 5, 1 independent five combination pass module 2, L pole connection copper strip 1-5, N pole connection copper strip 1-6, E pole connection copper strip 1-7, L pole power cord, N Pole power cord, E pole power cord. The straight line where the L-pole welding leg, the N-pole welding leg, and the E-pole welding leg protruding from the two transverse ten-combination pass modules 5 and one independent five-pass combination module 2 are parallel to each other, and two by two The distance between them meets the electrical safety requirements of 3mm. L poles connect copper strips 1-5, N poles connect copper strips 1-6, E poles connect copper strips 1-7 and L pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com