Method for increasing torsion of aluminum handle

A handle and torque technology, applied in the field of enhanced handle functions, can solve problems such as the influence of handle application stability, insufficient hardness of aluminum material, easy slippage of tooth hole torque, etc., and achieve the effect of novel structure composition, enhanced torque, and unique technical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

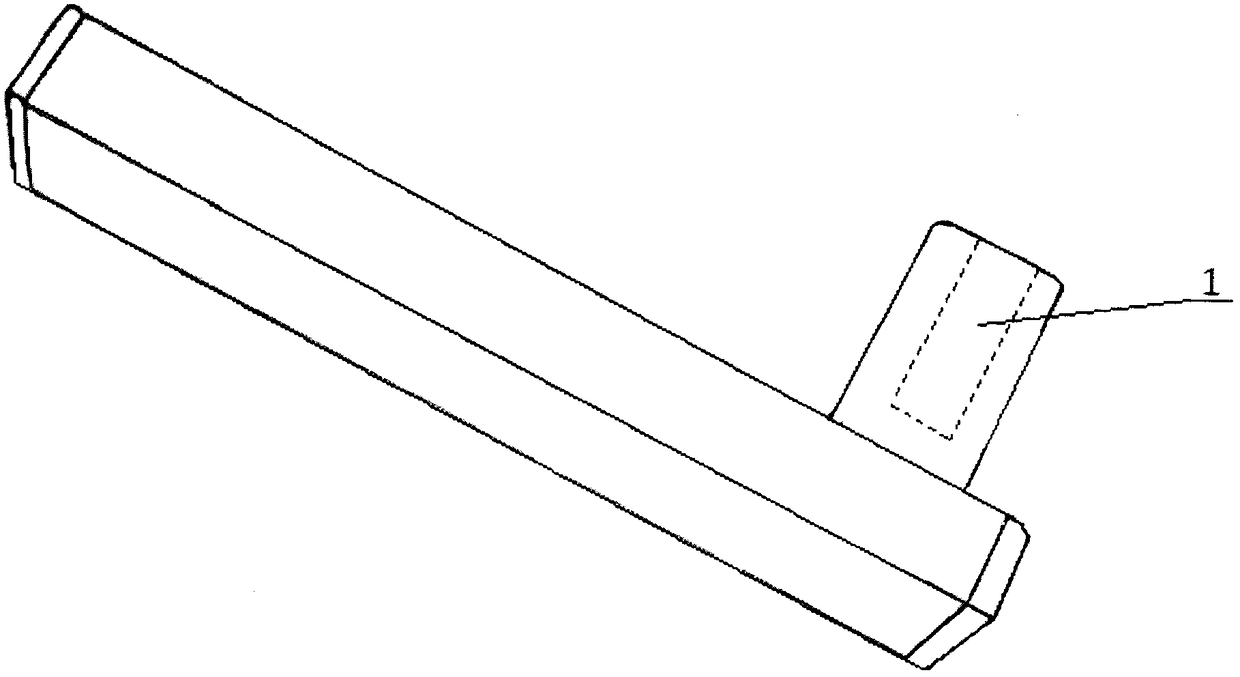

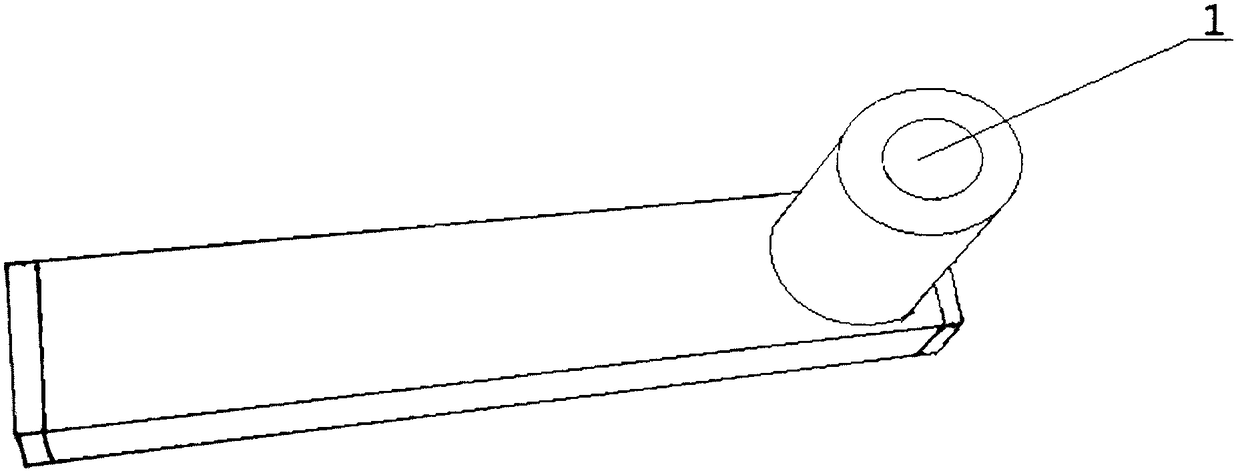

[0035] 1. Perforation: Pierce a process hole (1) in the handle connecting column.

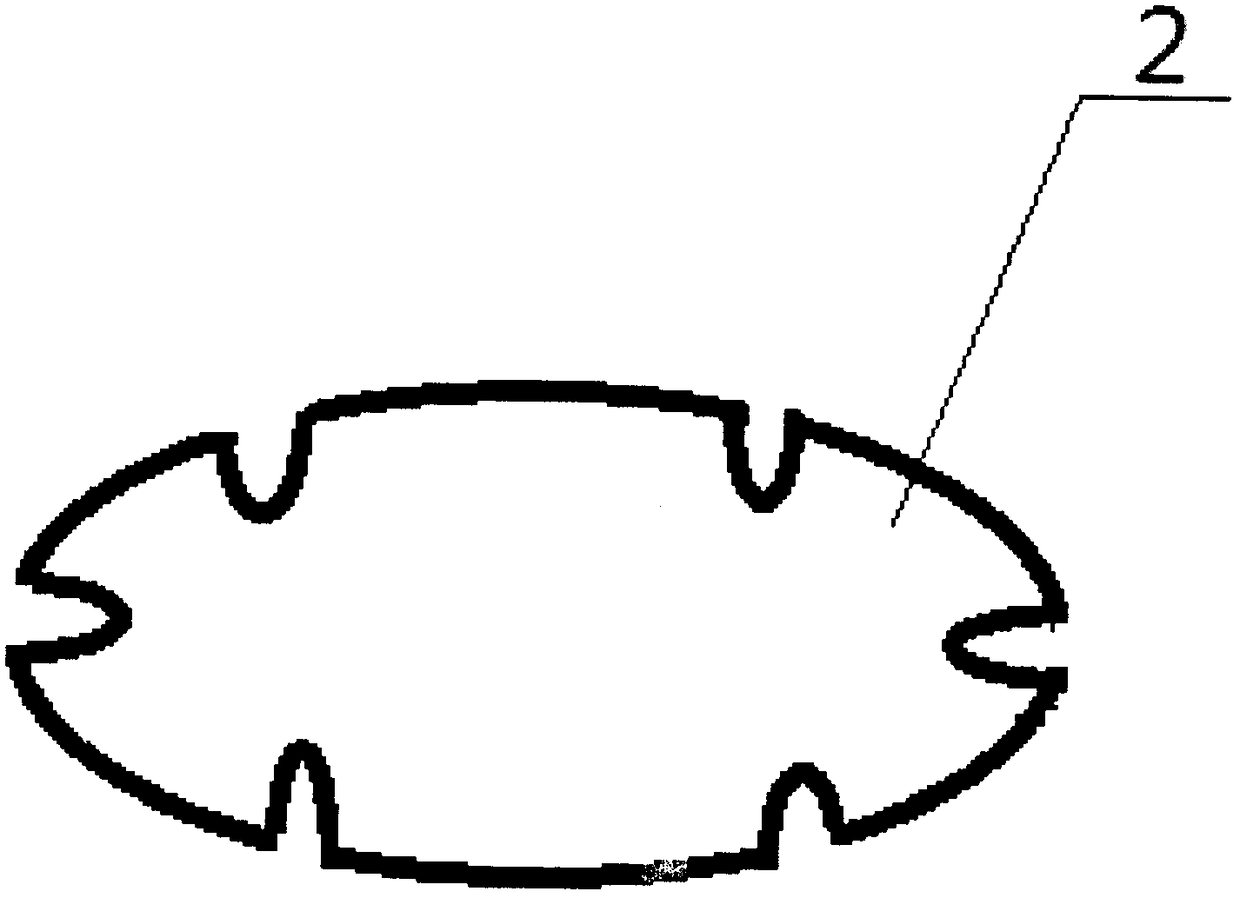

[0036] 2. Prepare the iron sheet: process the iron sheet into a reinforced iron sheet (2) whose diameter is consistent with the process hole (1), and is provided with several gaps.

[0037] 3. Iron sheet: place the reinforcement iron sheet (2) at the bottom of the process hole (1).

[0038] 4. Stamping: Place the handle connecting column on the punching machine, punch out the required hole shape in the process hole (1), and the reinforced iron sheet (2) placed in the process hole (1) will be extra when punched The aluminum material is covered and compacted, and the reinforced iron sheet (2) is provided with a gap, so that the reinforced iron sheet (2) and the aluminum material at the bottom of the process hole (1) are integrated.

[0039] 5. Tapping holes: Punch a hole at the bottom of the craft hole (1) and tap to get the holes (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com