Glass edge strip press fitting equipment

A press-fitting and glass technology, applied in the direction of mechanical equipment, material gluing, connecting components, etc., can solve the problems of press-fitting instability, inapplicability, and easy aging, so as to avoid damage and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] Adopting the first automatic press-fitting method for glass edge strips, that is, to simply press the glass edge strips into the gap between the glass and the glass installation groove, so that the glass is stably installed in the glass installation groove, including the following steps:

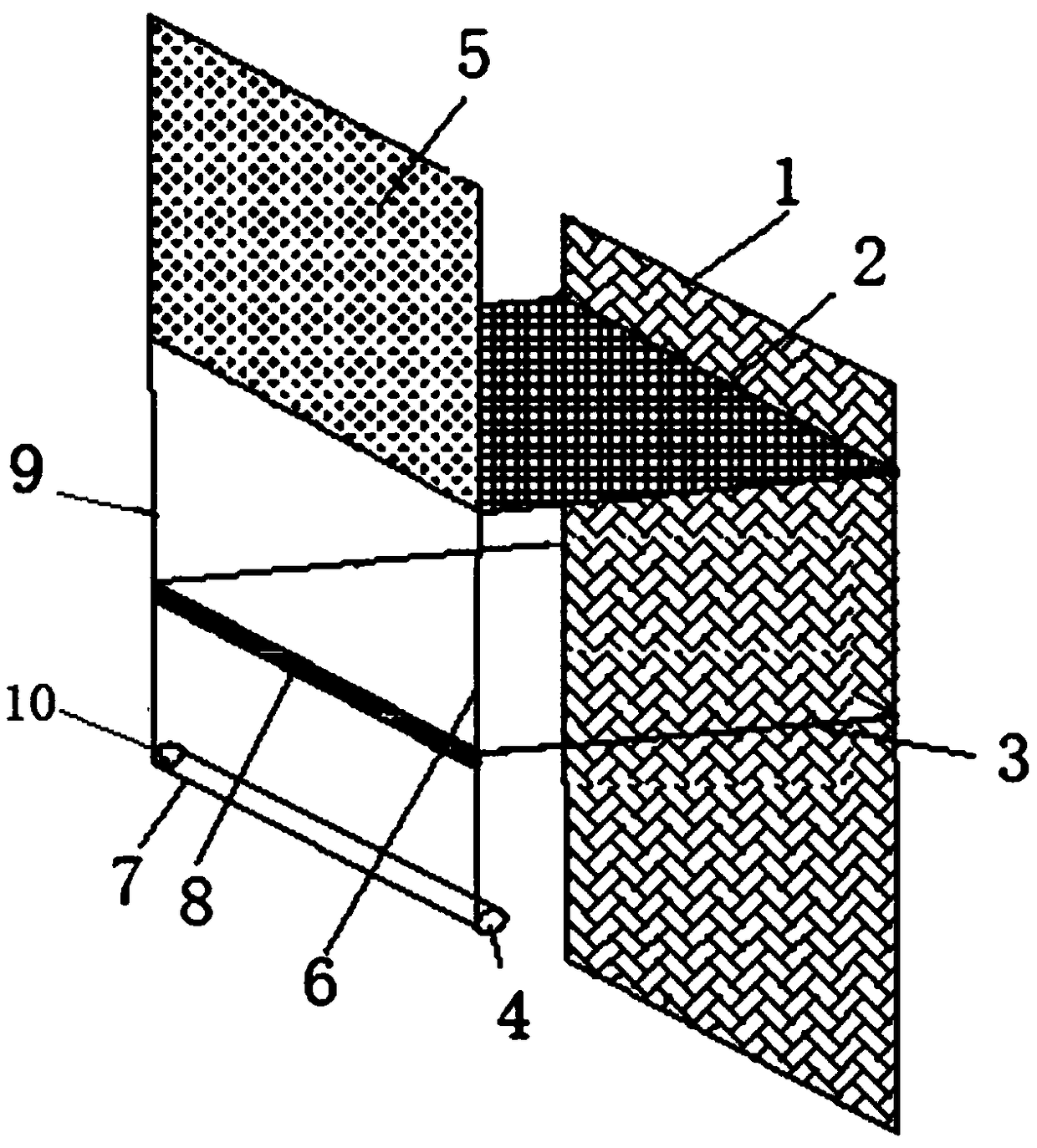

[0030] S1. Assembling the automatic press-fitting equipment, the automatic press-fitting equipment includes an installation frame 1, a press-fitting frame and a power mechanism;

[0031] The mounting frame 1 includes a first track and a second track arranged along the height direction of the mounting frame 1; the first track is parallel to the second track;

[0032] The press-fitting frame is arranged in parallel with the mounting frame 1, and the press-fitting frame includes a baffle plate 5, a first press-fitting guide rail 6, a second press-fitting guide rail 9 and a press-fitting head 8; one end of the first press-fitting guide rail 6 is arranged on the baffle plate 5 The lower en...

Embodiment 3

[0039] An automatic press-fitting method for glass edge strips, that is, to press the glass edge strips into the gap between the glass and the glass installation groove, and fill it with silica gel. One is to ensure the stable installation of the glass edge strips, and the other is to facilitate the replacement of the glass edge strips. (Pull out the silica gel from the glass installation groove, so that the aged glass edge can be completely cleaned from the glass installation groove) To make the glass stably installed in the glass installation groove, including the following steps:

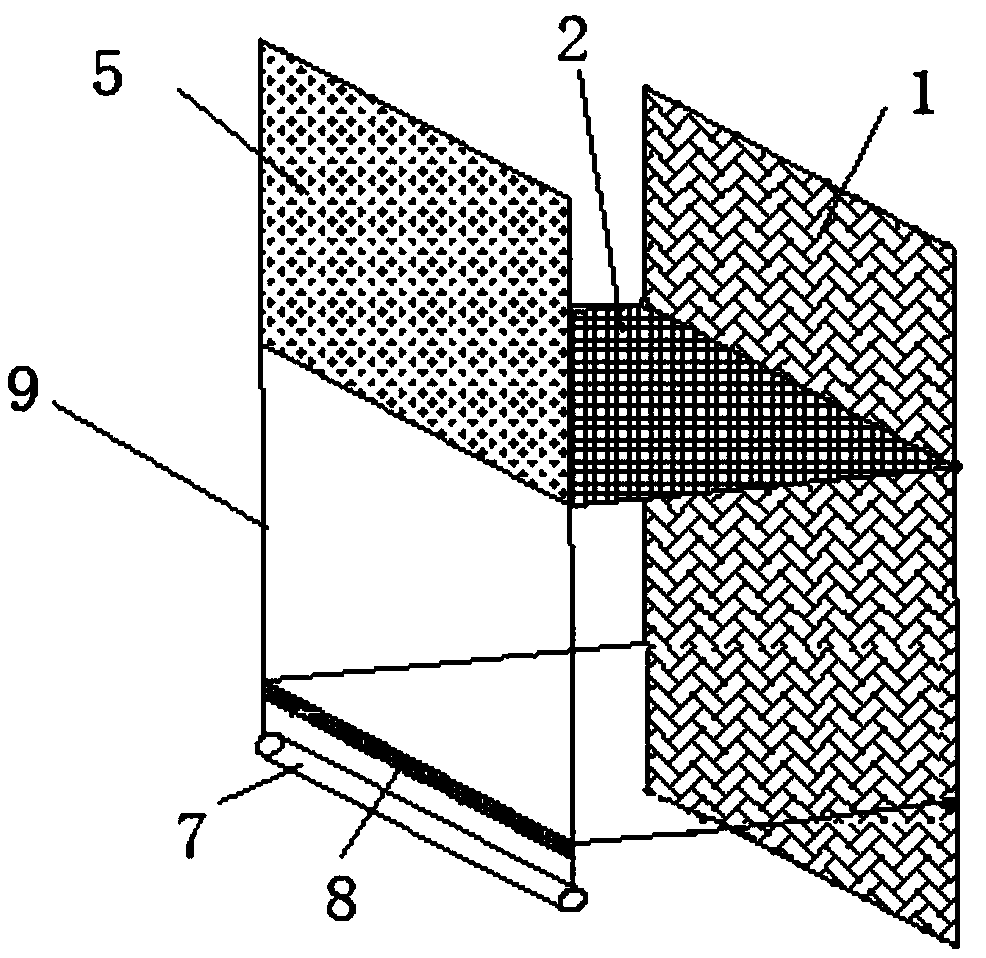

[0040] S1. Assembling the automatic press-fitting equipment, the automatic press-fitting equipment includes an installation frame 1, a press-fitting frame and a power mechanism;

[0041] The mounting frame 1 includes a first track and a second track arranged along the height direction of the mounting frame 1; the first track is parallel to the second track;

[0042] The press-fitting frame is arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap