Flexible cutting system mechanism

A cutting system and flexible technology, applied in metal processing and other directions, can solve the problems of no cutter protection measures, unable to meet different types of cutting needs, affecting the cutting efficiency of the cutting machine, etc., to achieve the effect of protecting the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

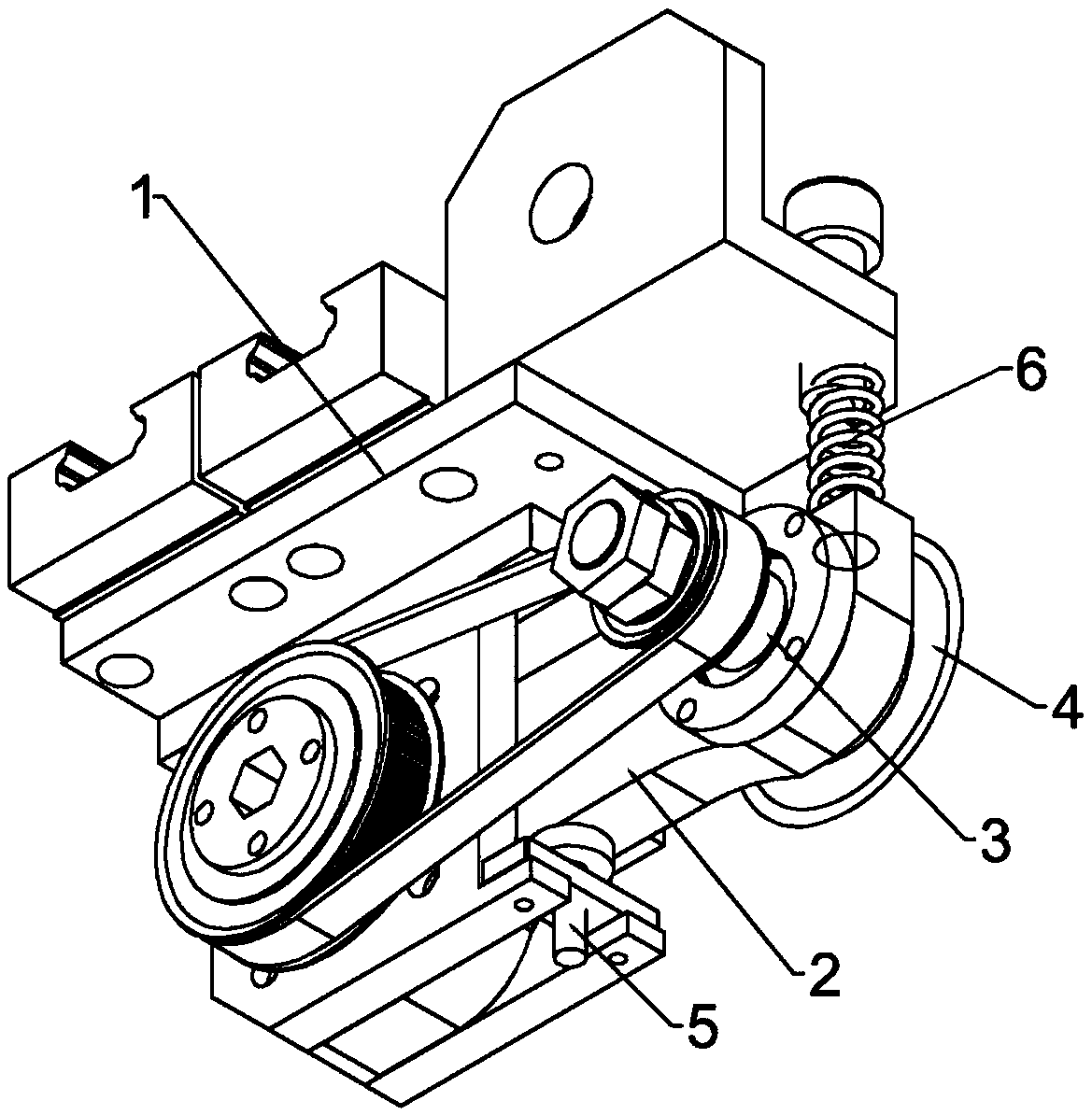

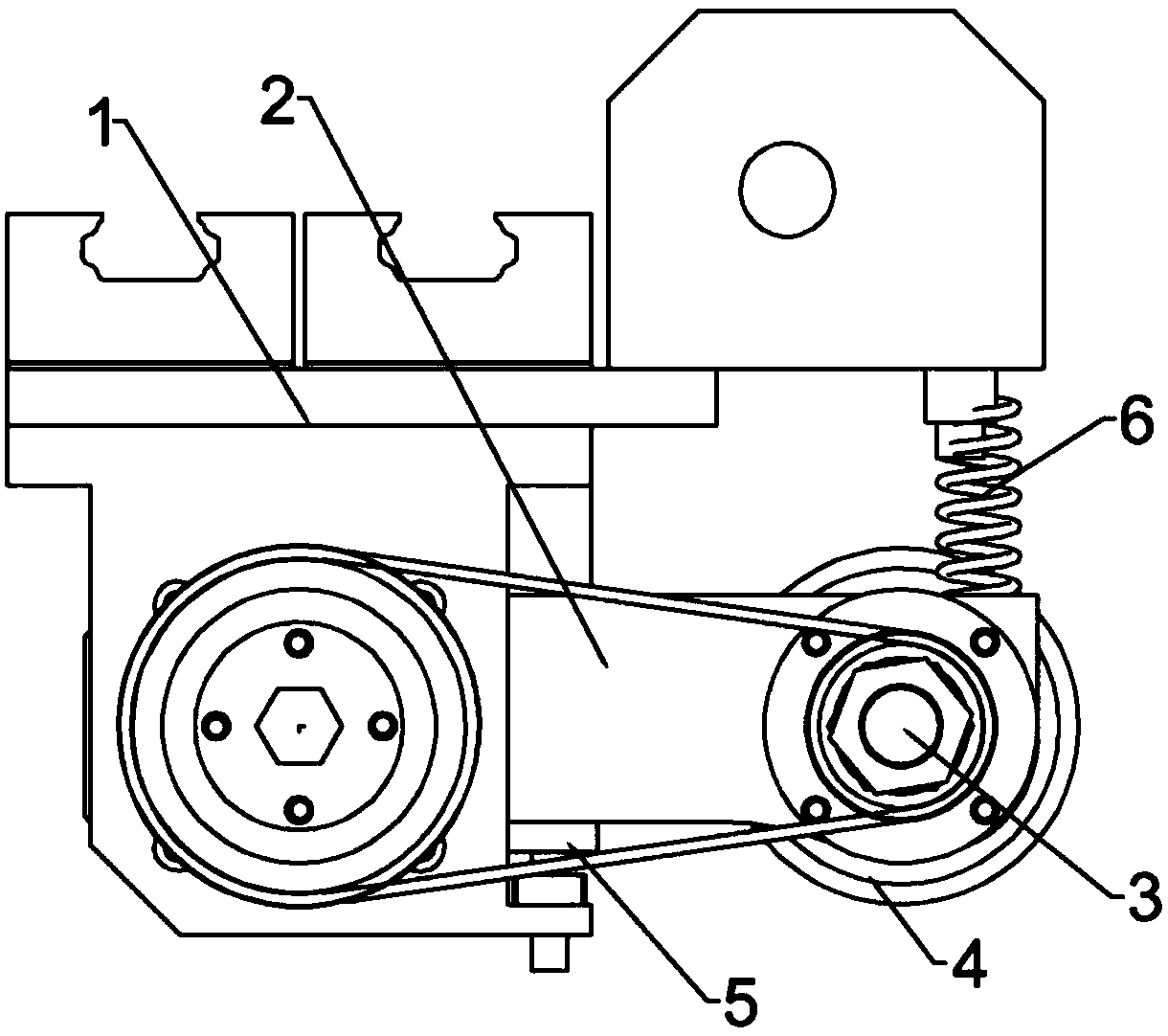

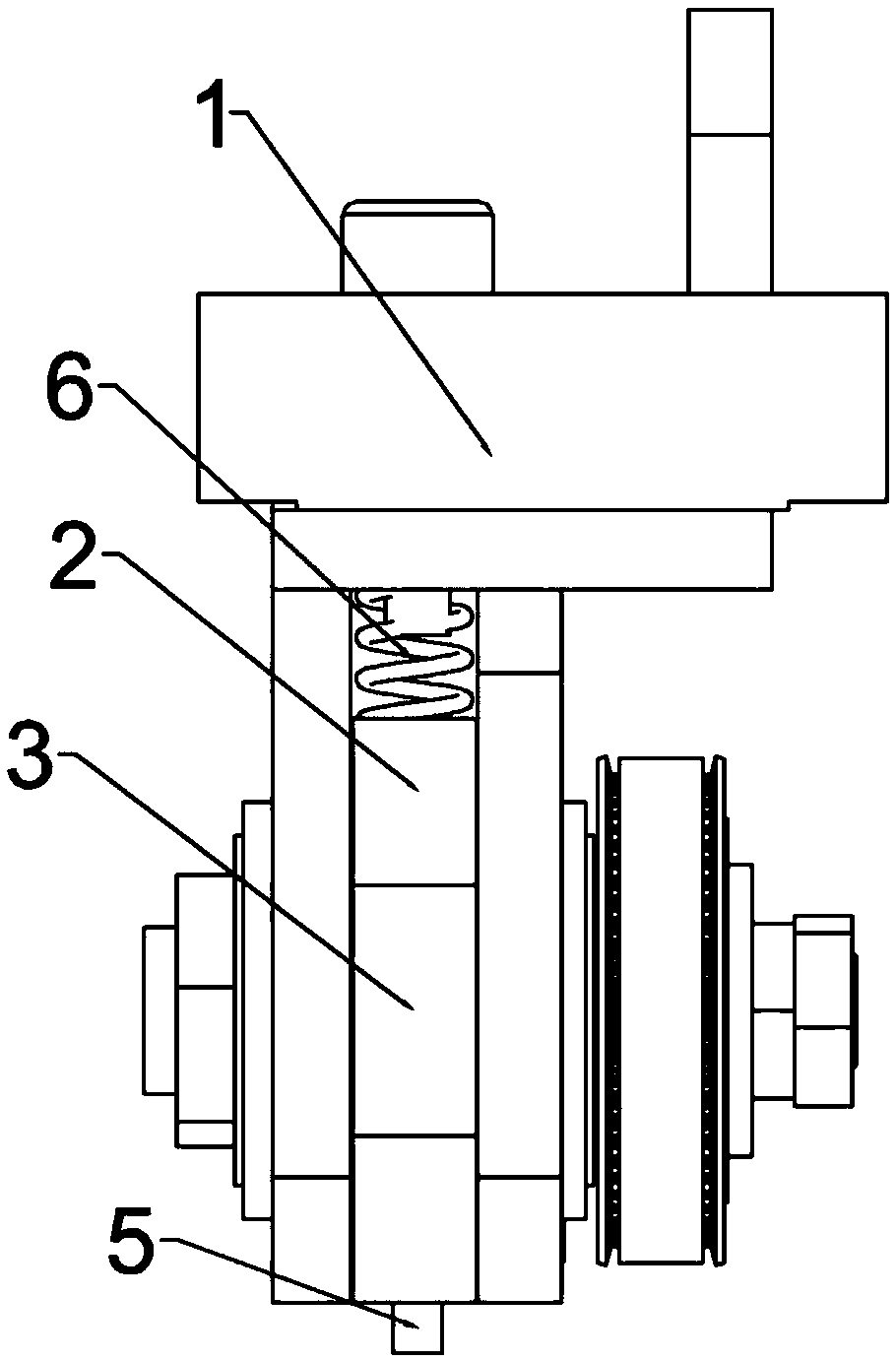

[0018] Example 1: Please refer to Figure 1-4 , a flexible cutting system mechanism, comprising a frame body 1, a swing arm 2 is rotatably connected to the bottom of the frame body 1, and a cutting blade 4 is fixedly connected to the outer end of the swing arm 2 through a positioning shaft 3 connected by rotation, and a cutting blade 4 is fixedly connected by driving the positioning shaft 3 To realize the rotation of the cutting blade 4, and then to cut, the bottom of the frame body 1 is screwed with a limit screw 5 that limits the swing angle of the swing arm 2, and the limit screw 5 limits the maximum swing limit of the swing arm 2, thereby determining the cutting contact. Position, between the frame body 1 and the outer end of the swing arm 2 is fixedly connected with an elastic member 6 that presses the swing arm 2 to move downward. The elastic member 6 enables the swing arm 2 to swing elastically, avoiding rigid cutting during the elastic swing process. Protect the blade....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com