Patents

Literature

30results about How to "Achieving Elastic Contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

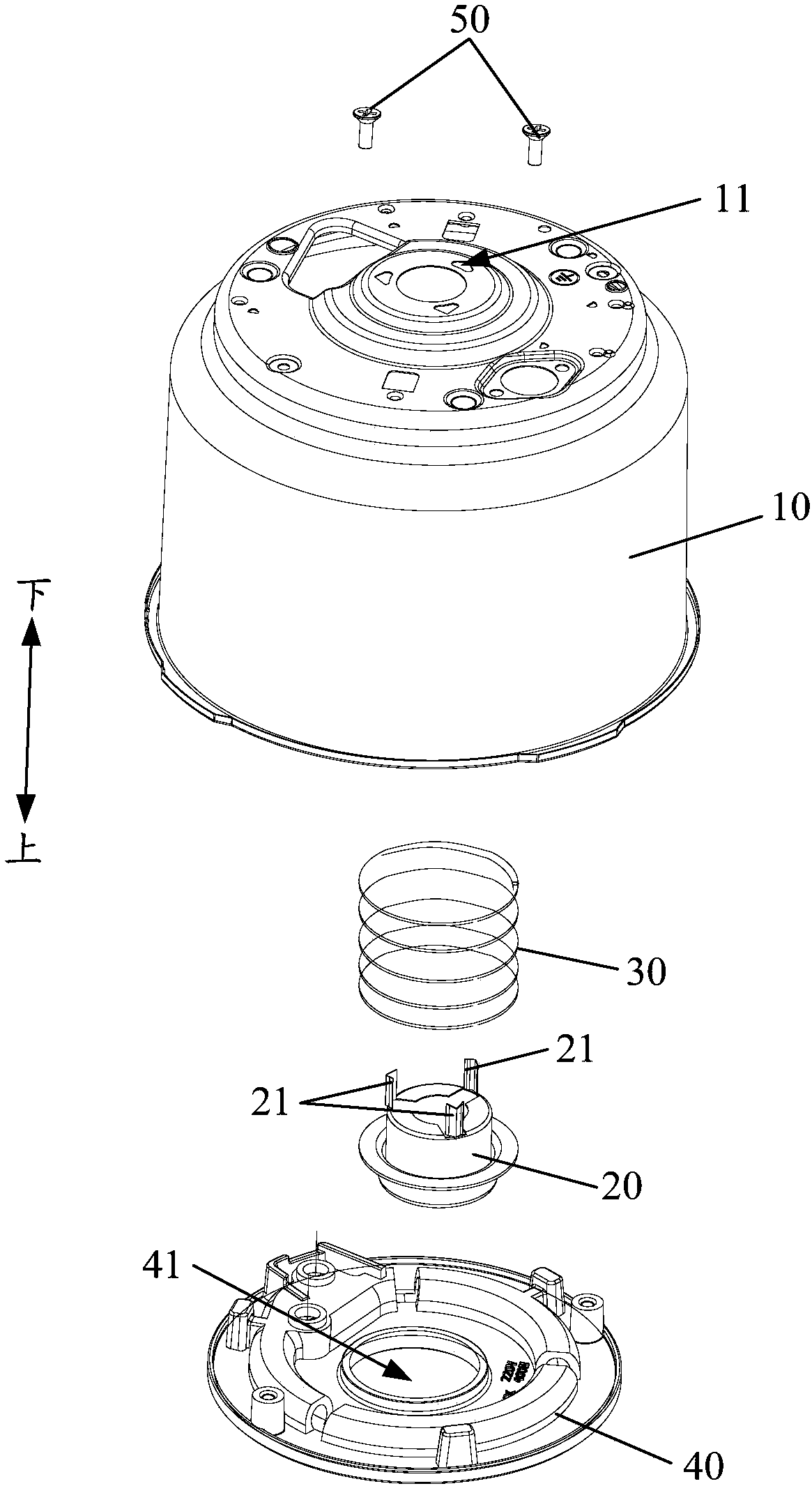

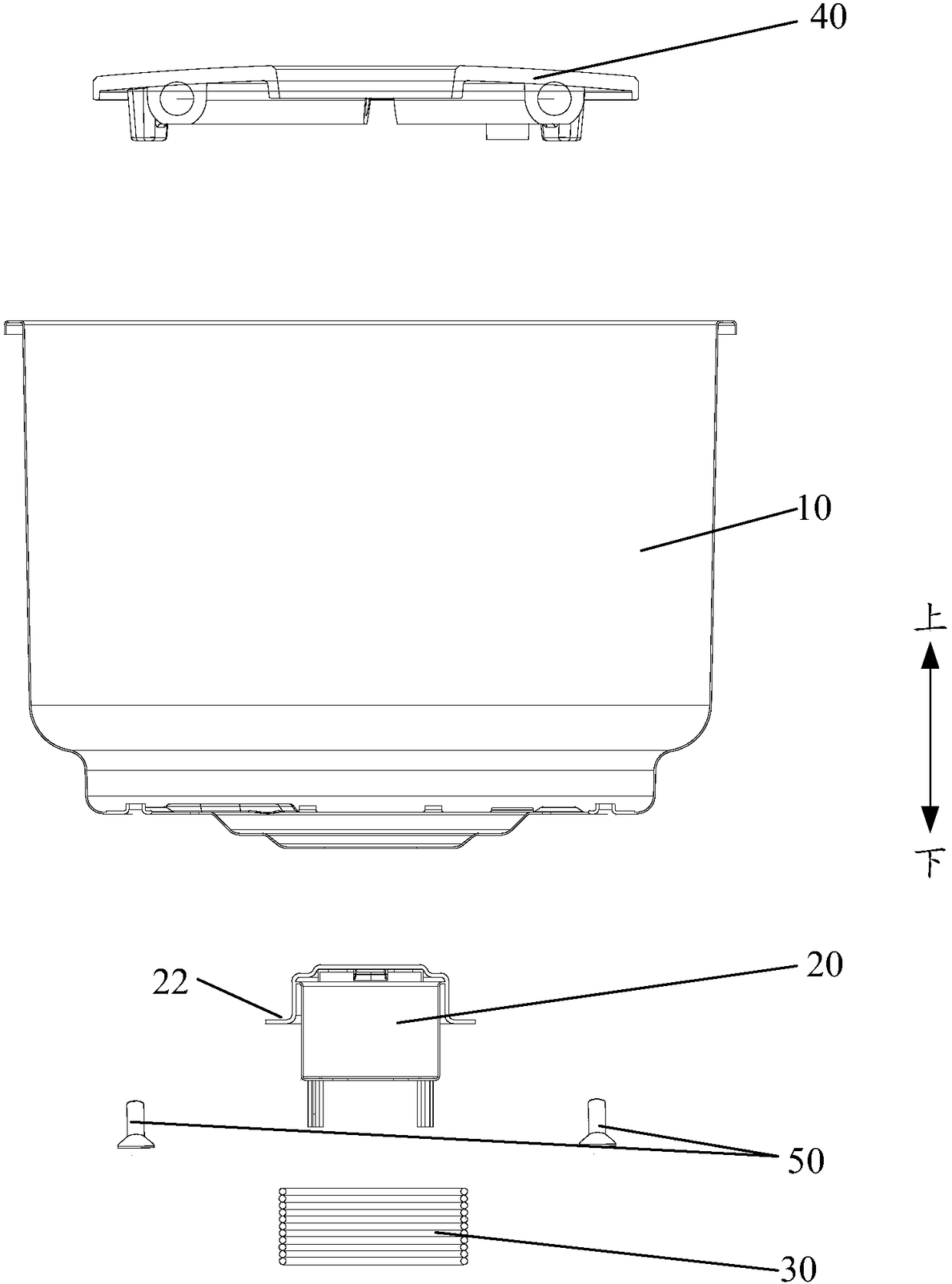

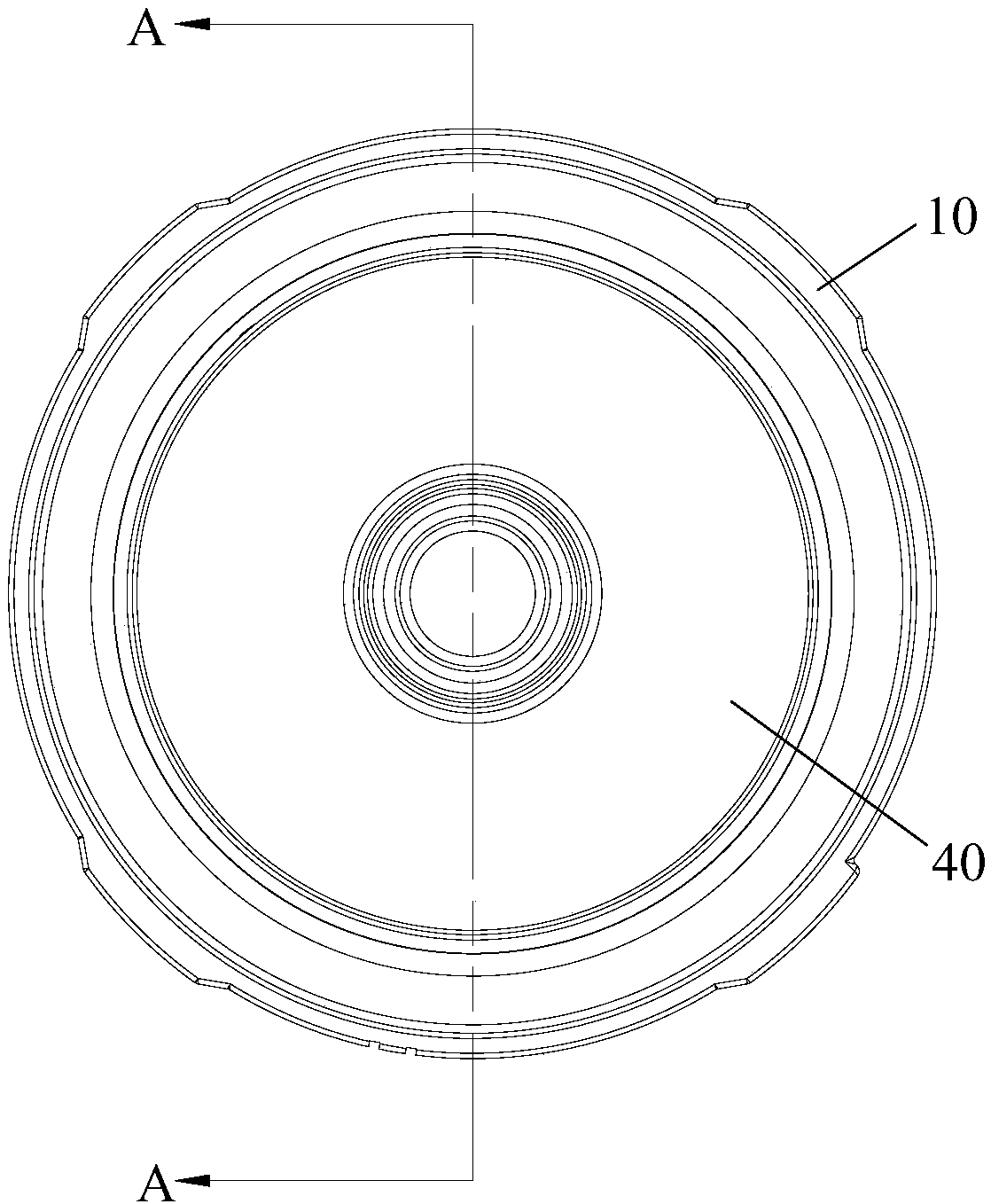

Cooking utensil

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

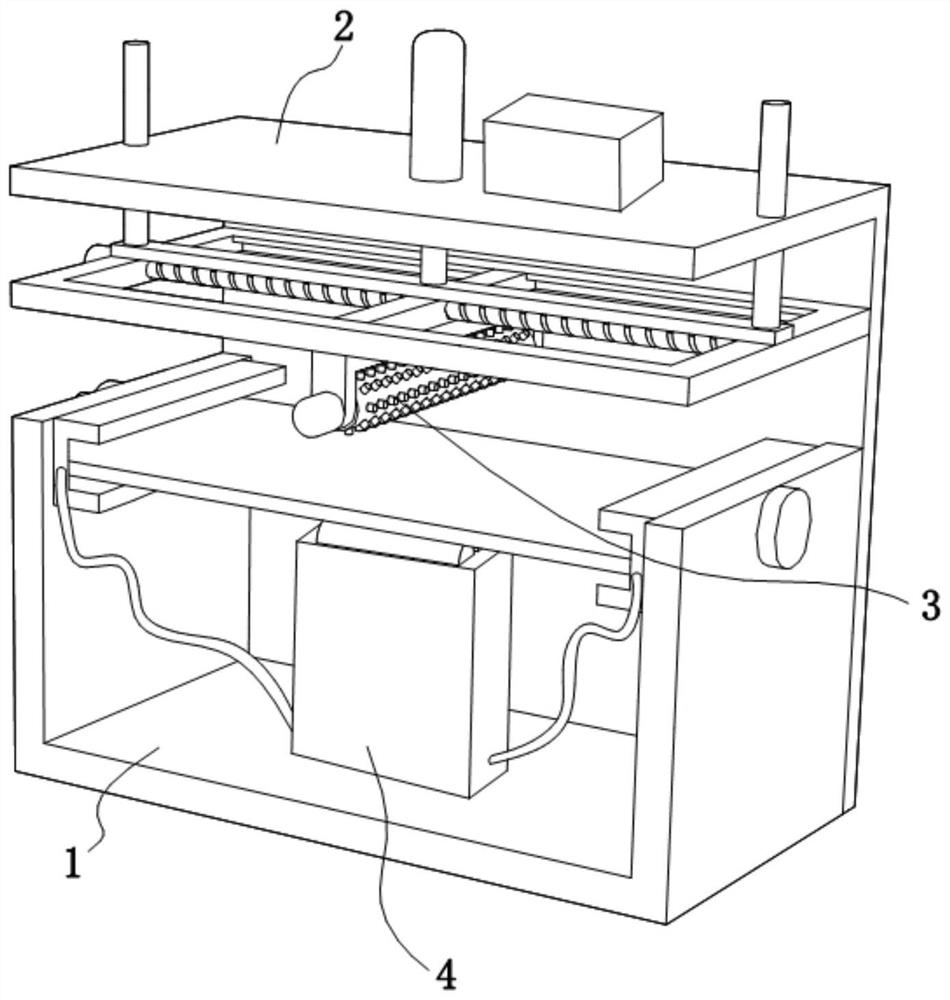

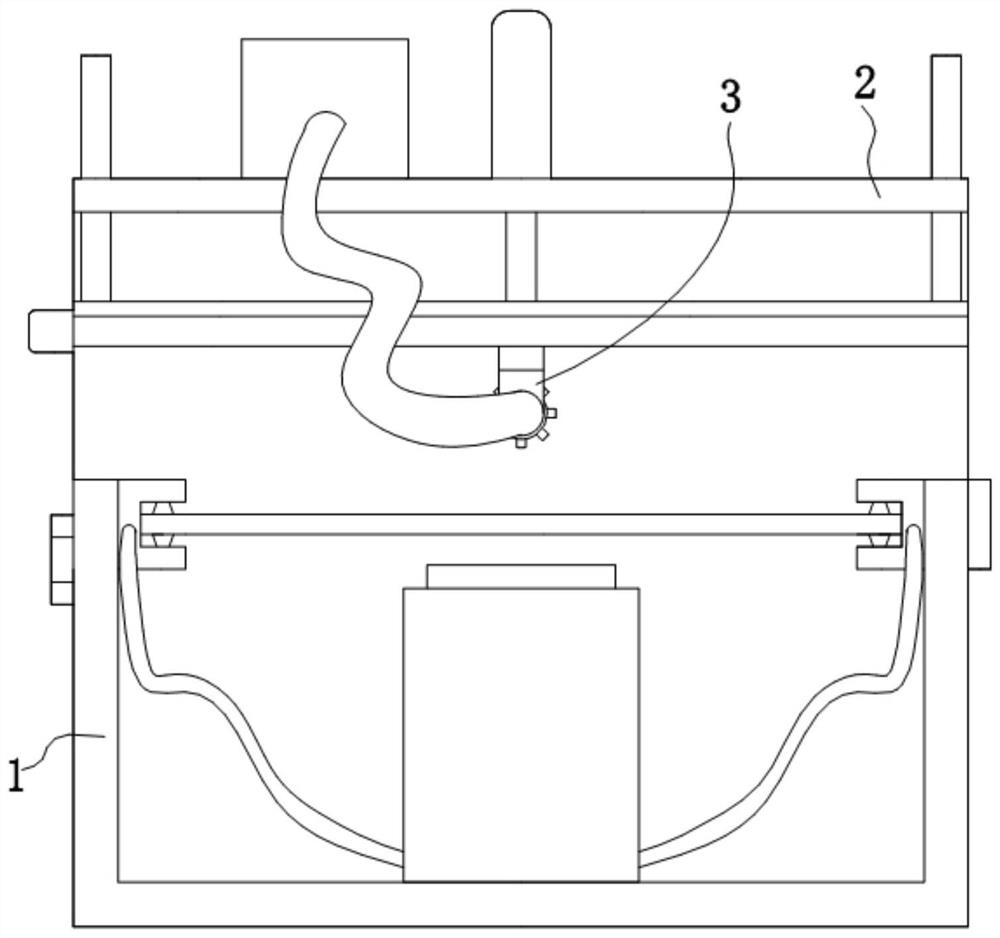

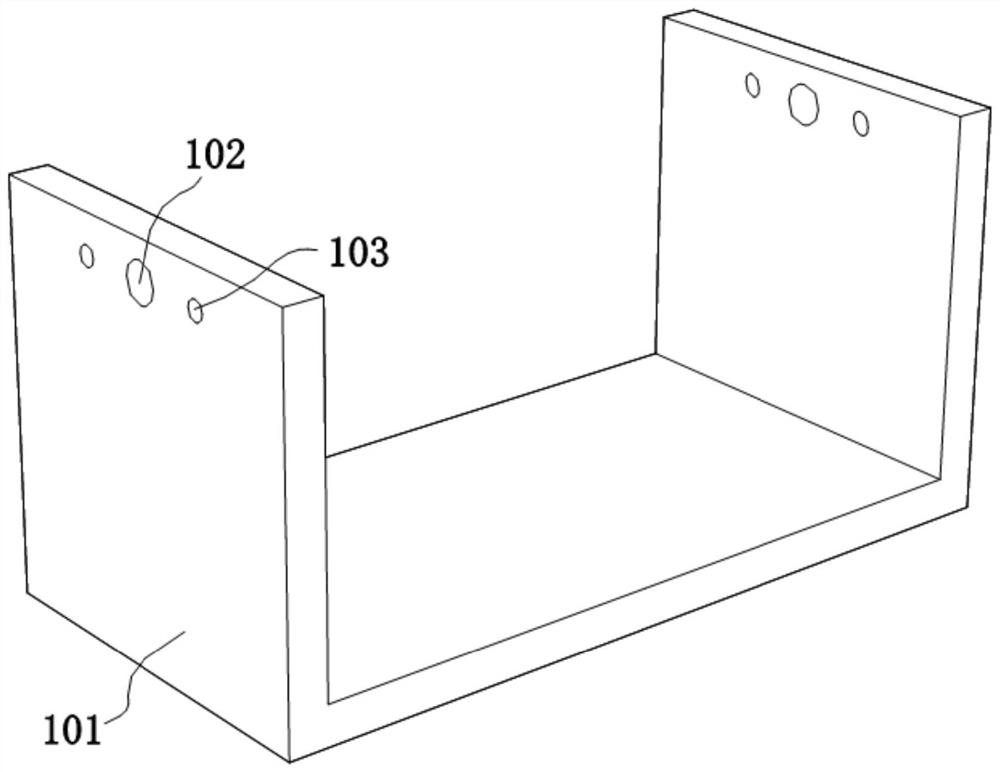

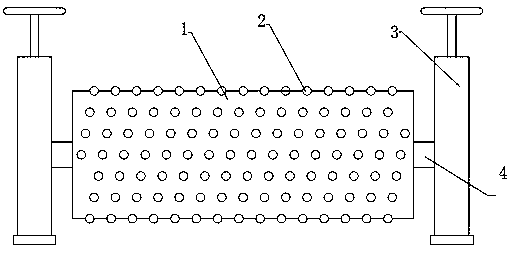

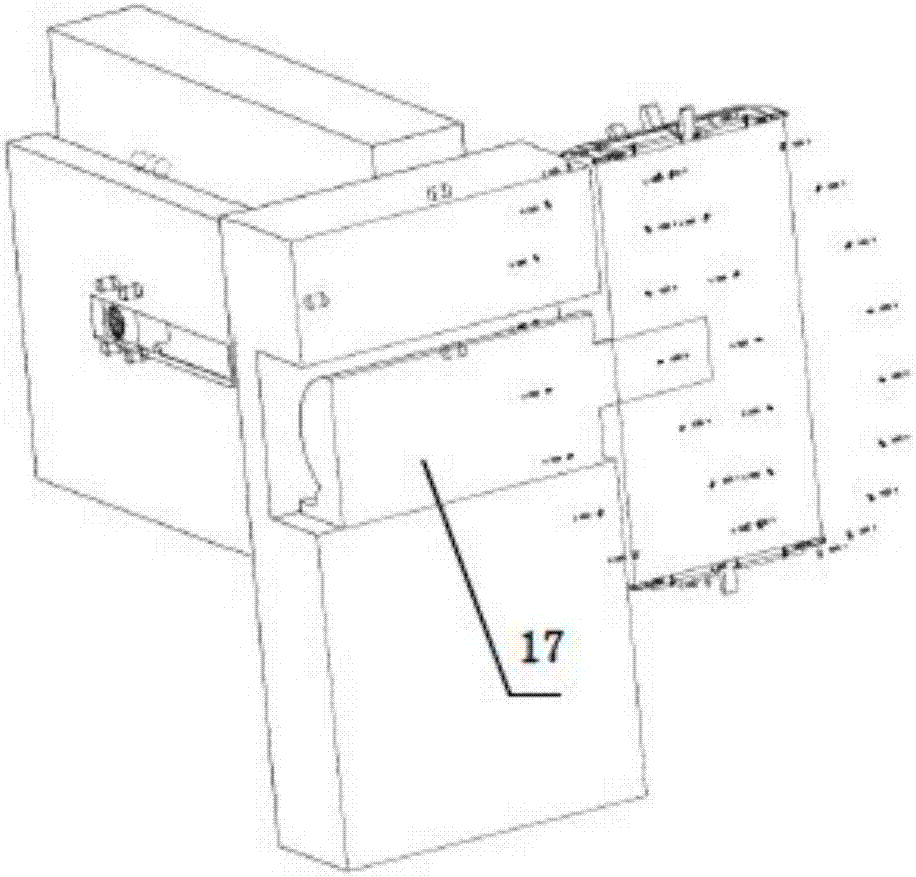

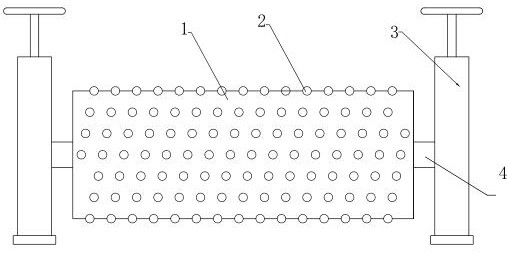

Cleaning device for tempered glass deep processing

ActiveCN112958571ASolve cleaning problemsClean and comprehensiveDrying gas arrangementsFlexible article cleaningEngineeringToughened glass

The invention belongs to the technical field of glass processing, and discloses a cleaning device for tempered glass deep processing. The cleaning device comprises a bottom mechanism, a transmission mechanism is arranged at the bottom of the inner side of the bottom mechanism, a sliding mechanism is arranged at the top of the bottom mechanism, a cleaning mechanism is slidably connected to the bottom end of the sliding mechanism, and the bottom mechanism comprises a supporting frame; and shaft holes are formed in the opposite inner walls of the supporting frame, a rotating shaft is rotationally connected into the shaft holes, a fixed plate is arranged at one end of the rotating shaft, first air bags are communicated with the two sides of the fixed plate, clamping plates are arranged at the other sides of the first air bags, and communicating air channels are formed in the clamping plates. By means of the cleaning device, transmission, clamping, cleaning and overturning of to-be-tempered glass can be simply and conveniently completed, cleaning is comprehensive and free of dead corners, meanwhile, soft contact clamping of the to-be-tempered glass can be achieved by means of the air bags, the clamping effect is good, and wind power drying and impurity removal, impurity liquid flow guiding and recycling and the like can be conducted on the to-be-tempered glass.

Owner:广西荆楚新型建材有限责任公司

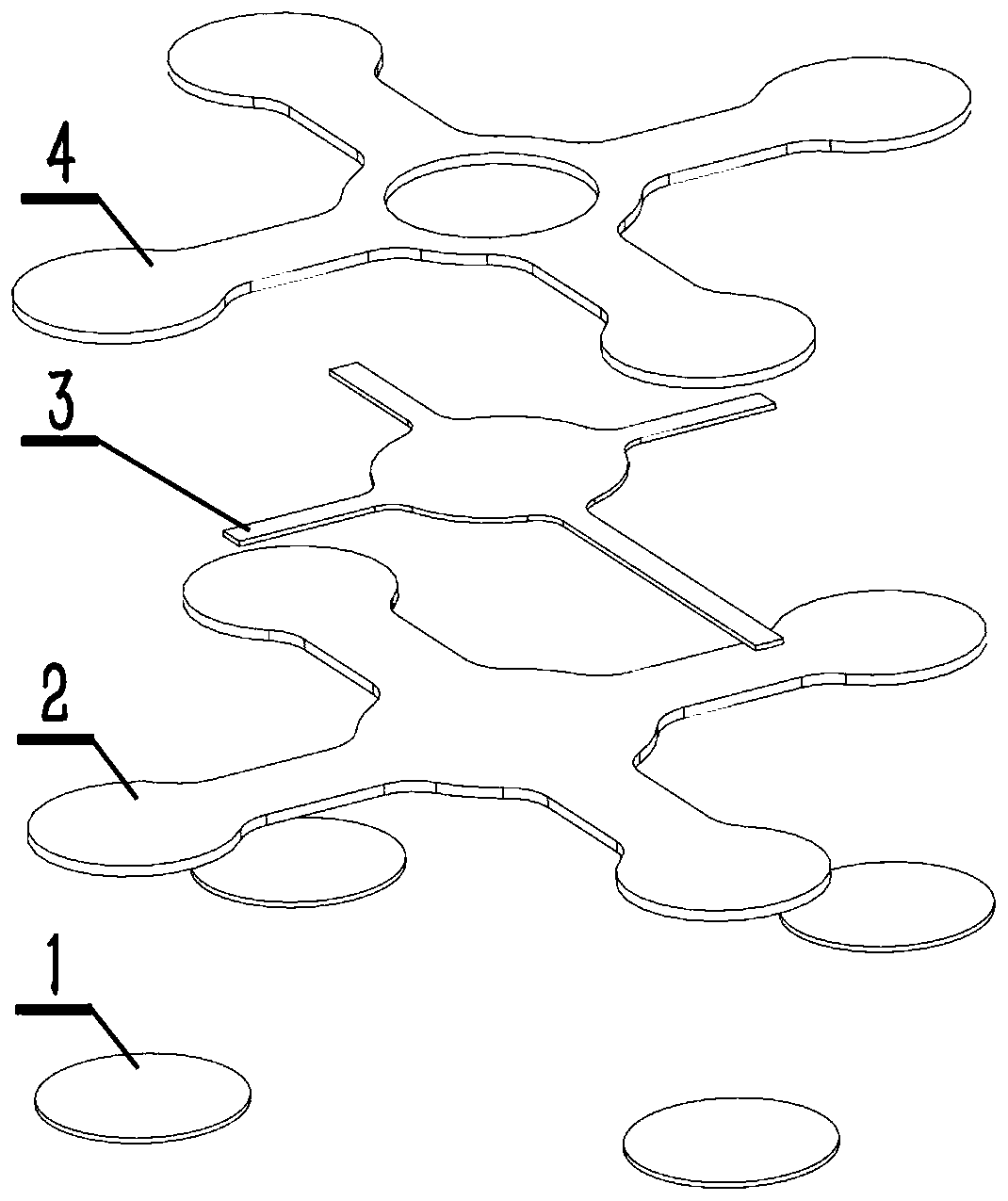

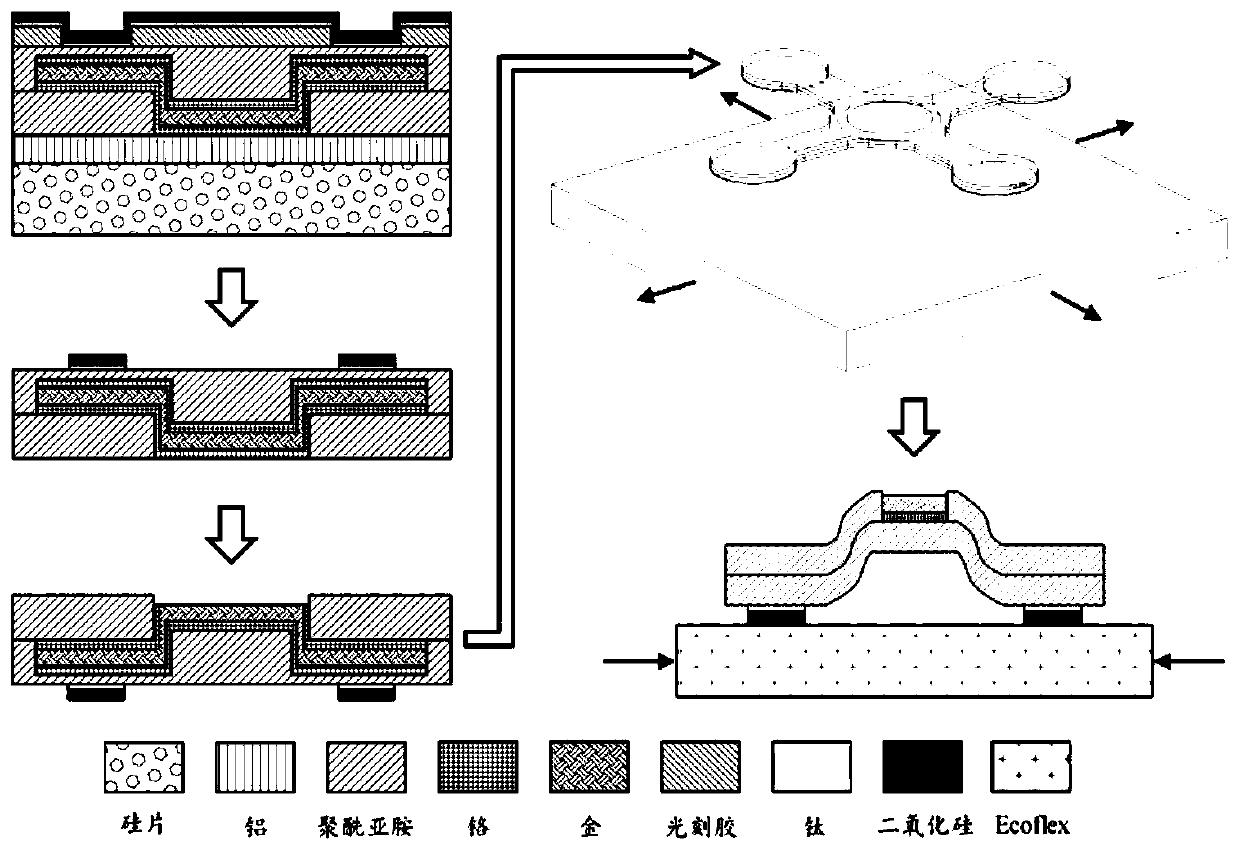

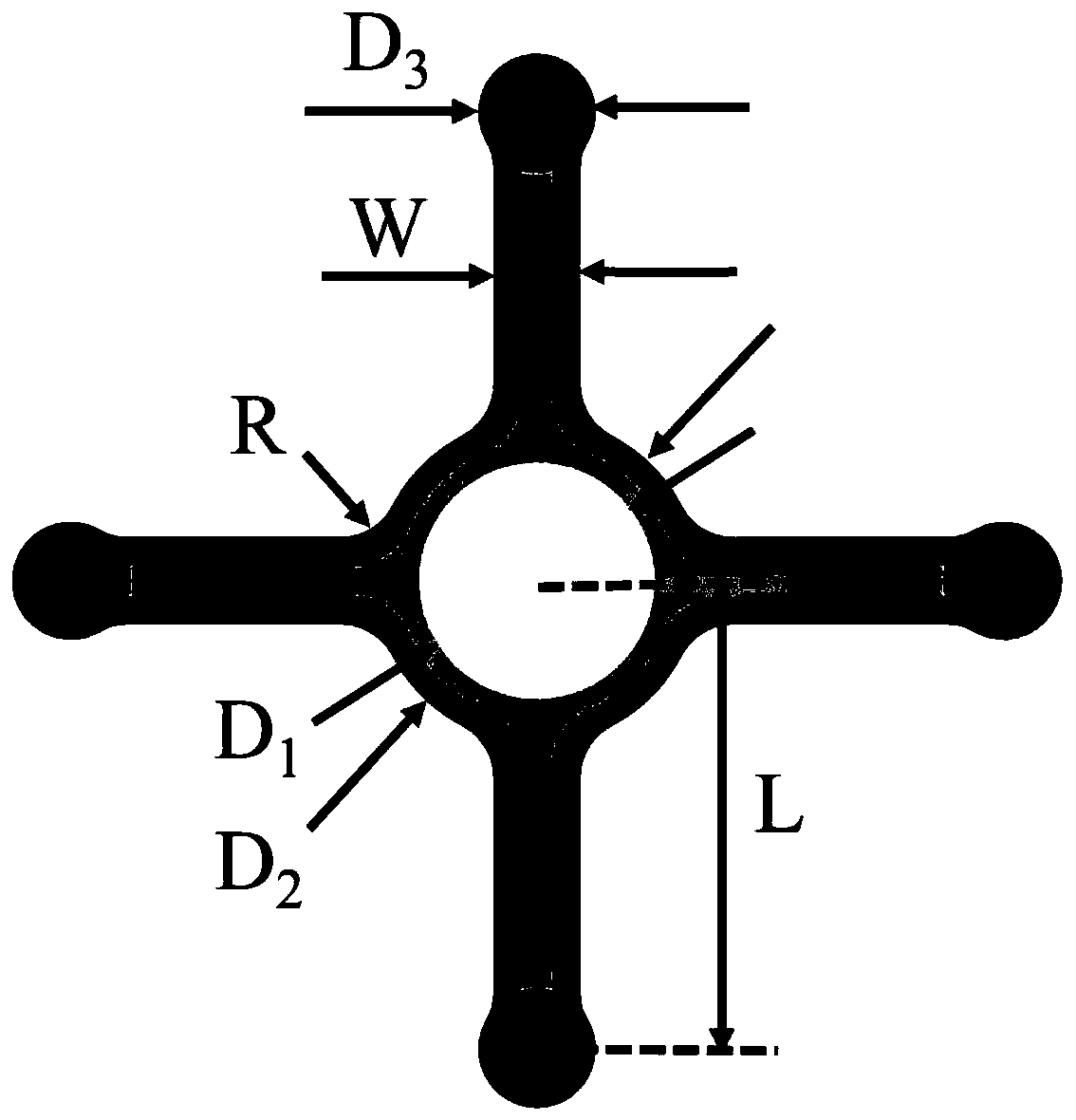

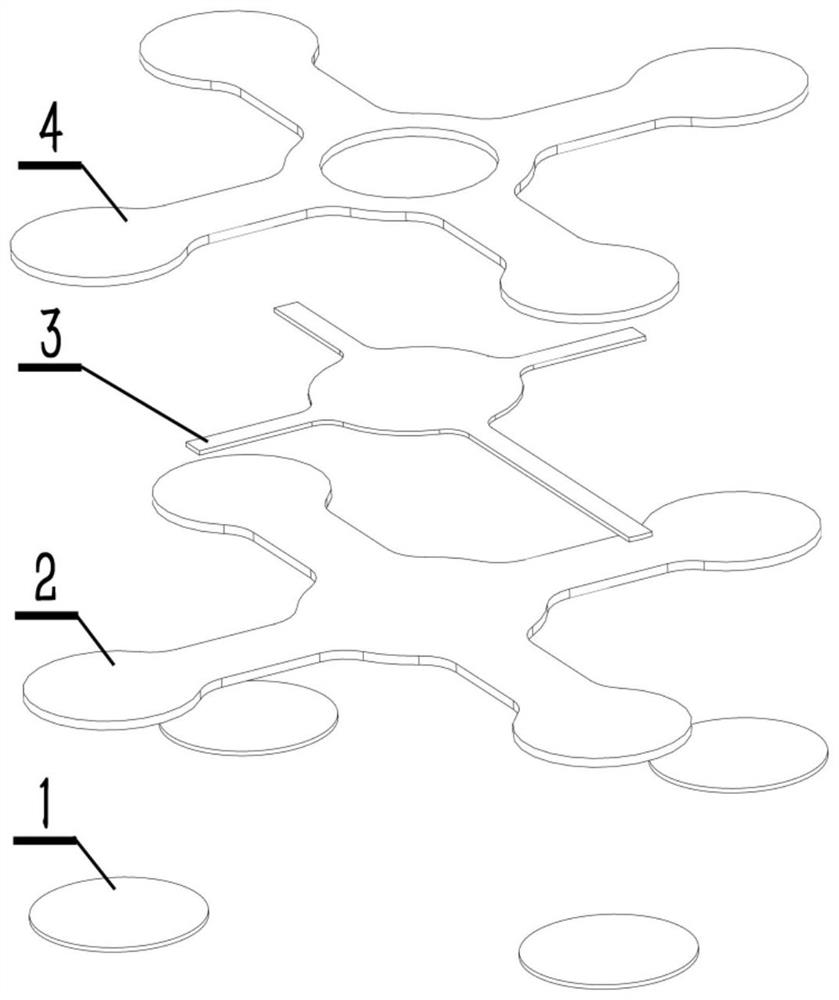

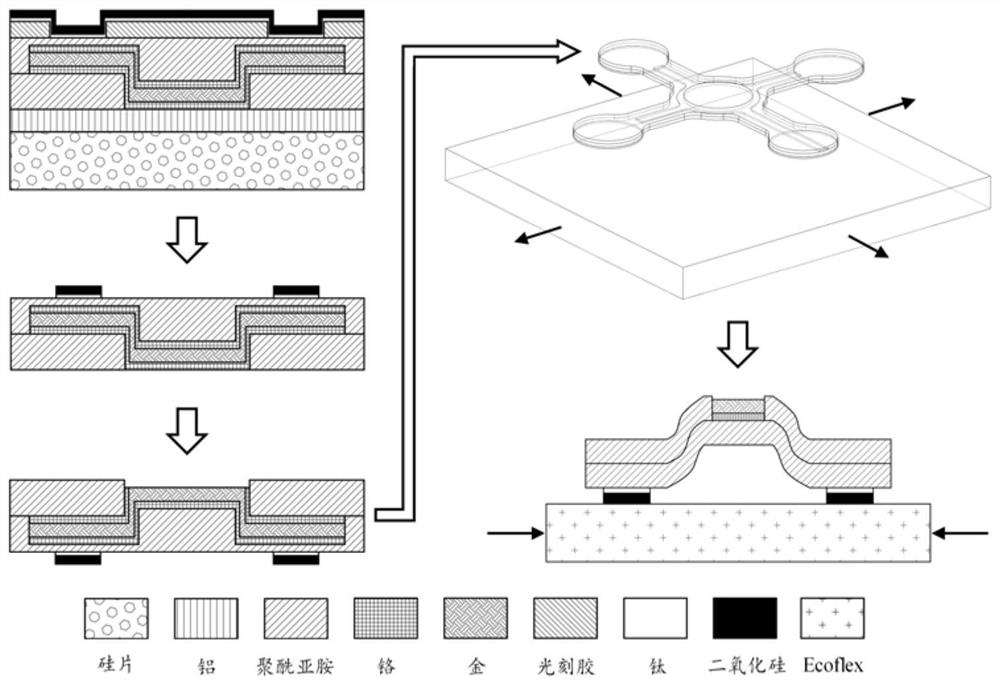

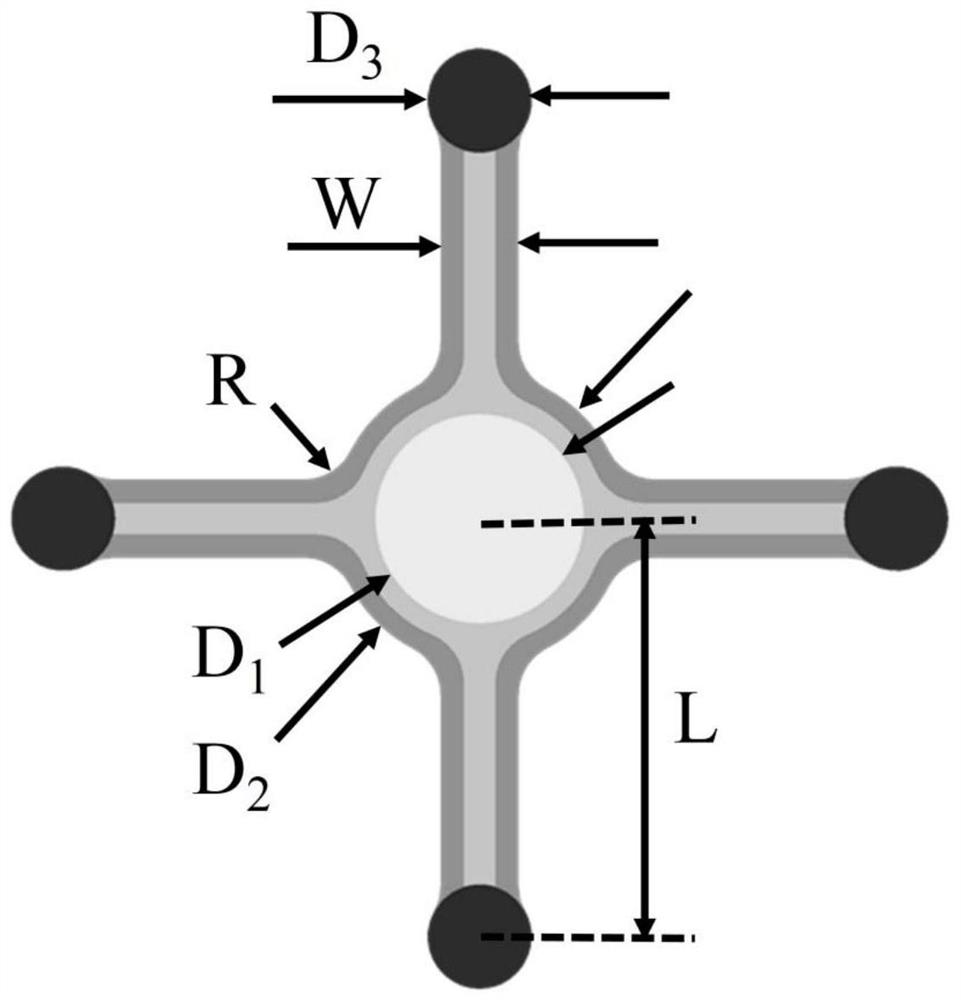

Three-dimensional buckling-structure flexible neural electrode and preparation process thereof

ActiveCN110367978AReliable recordAchieving Elastic ContactDiagnostic recording/measuringSensorsElastic substratePolyimide substrate

The invention provides a three-dimensional buckling-structure flexible neural electrode and a preparation process thereof. The electrode comprises an elastic substrate, an adhesion layer, a polyimidesubstrate layer, a metal electrode layer and a polyimide packaging layer, the metal electrode layer is arranged on one surface of the polyimide substrate layer, the polyimide packaging layer is arranged above the metal electrode layer, and the polyimide substrate layer, the metal electrode layer and the polyimide packaging layer form a two-dimensional planar-structure electrode; the adhesion layeris arranged on the other surface of the polyimide substrate layer and comprises a Ti layer and a SiO2 layer, the Ti layer is arranged on the surface of the polyimide substrate layer, the SiO2 layer is arranged on the Ti layer, strong chemical bonds generated by condensation reaction between the SiO2 layer and the elastic substrate enable the two-dimensional planar-structure electrode to be bondedwith the surface of the elastic substrate, and the elastic substrate deforms to enable the two-dimensional planar-structure electrode to form the three-dimensional buckling-structure electrode underextruding effect.

Owner:SHANGHAI JIAO TONG UNIV

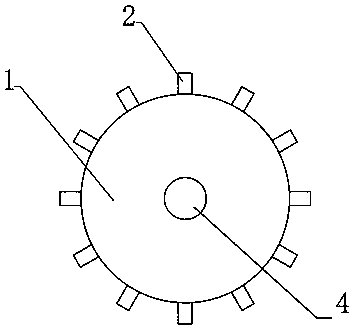

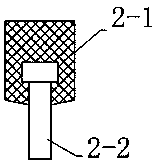

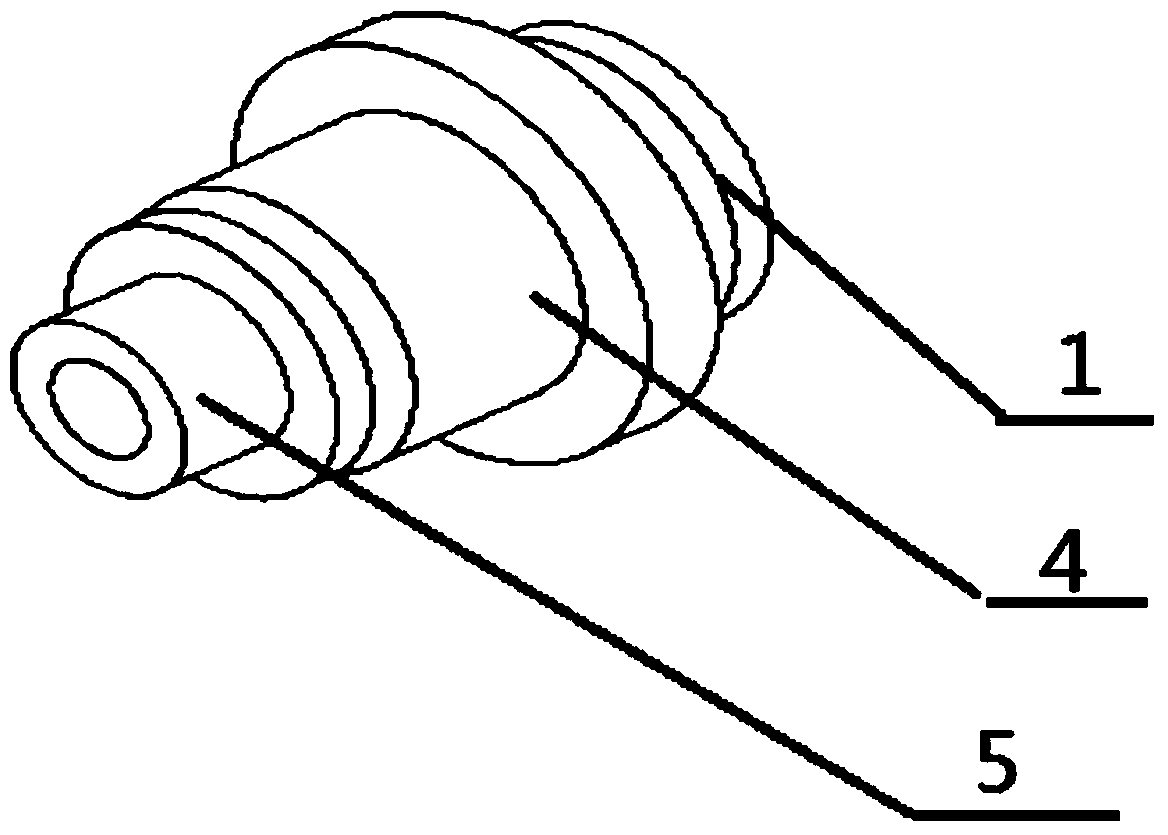

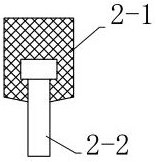

Convex point pressing roller device

The invention discloses a convex point pressing roller device. A convex point pressing roller comprises a pressing roller body and convex points, wherein the pressing roller body is of a cylinder structure, the several convex points are provided, and are evenly distributed on the outer cylindrical surface of the pressing roller body along a spiral line, the tops of all the convex points are located on the same cylindrical surface, the convex points are made through a steel and rubber composite process, and each convex point is composed of a convex point working surface and a convex point connecting portion. The convex point pressing roller device is specially used on a belt blank forming line for a ultra-wide rubber conveying belt for belt blank forming; the convex point working surfaces are made of high-strength high-hardness rubber, elastic contact is realized, and the pressure balance effect can be ensured; through the convex points, the local pressure can be concentrated and the adhesion can be enhanced, so that the local initial viscosity effect is enhanced, and the later vulcanization working procedure is facilitated; through the convex point structures additionally arrangedon the pressing roller, the stress can be dispersed, moreover, the accumulated wrinkle tendency of a cloth layer can be dispersed, then wrinkle caused by pressing is eradicated, the forming quality ofa belt blank is ensured to be stable and reliable, the product quality and the working efficiency are improved, and the rate of finished products is guaranteed.

Owner:LAIZHOU JINGCHENG RUBBER

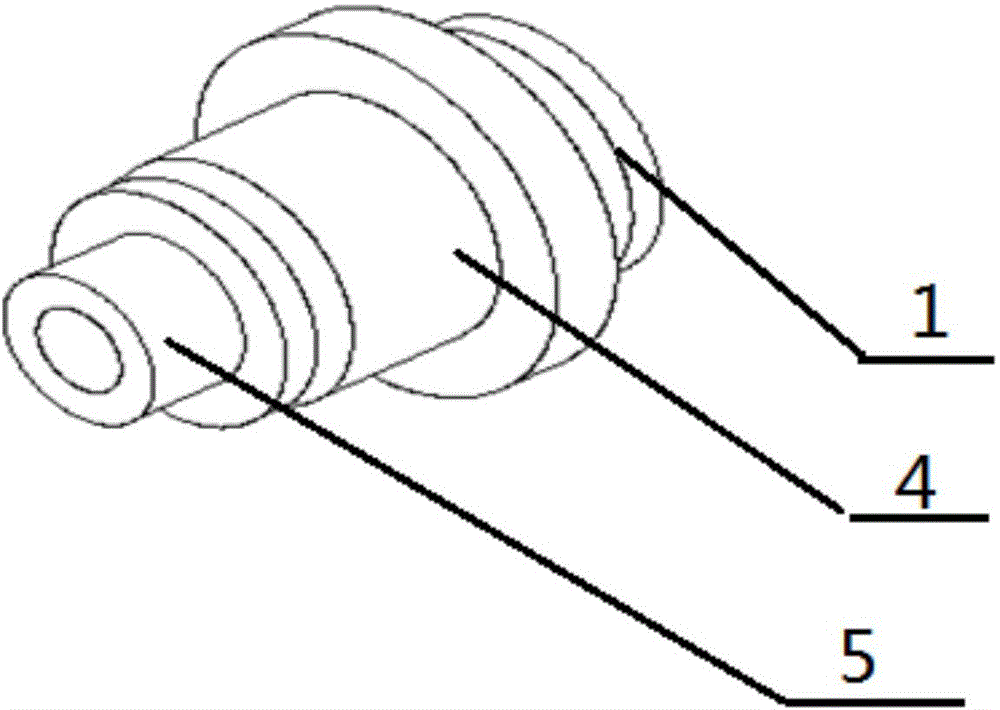

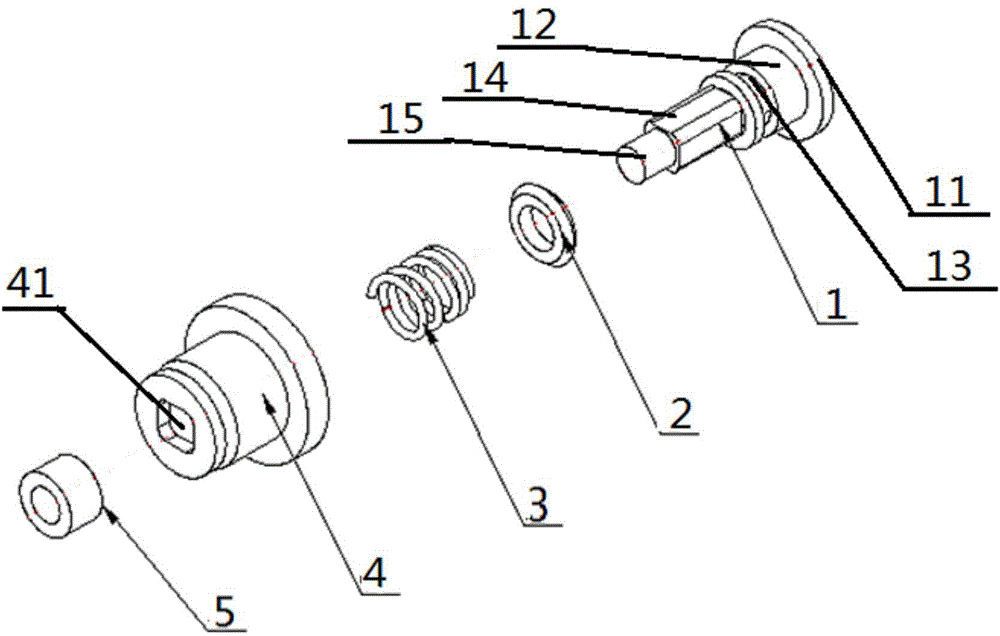

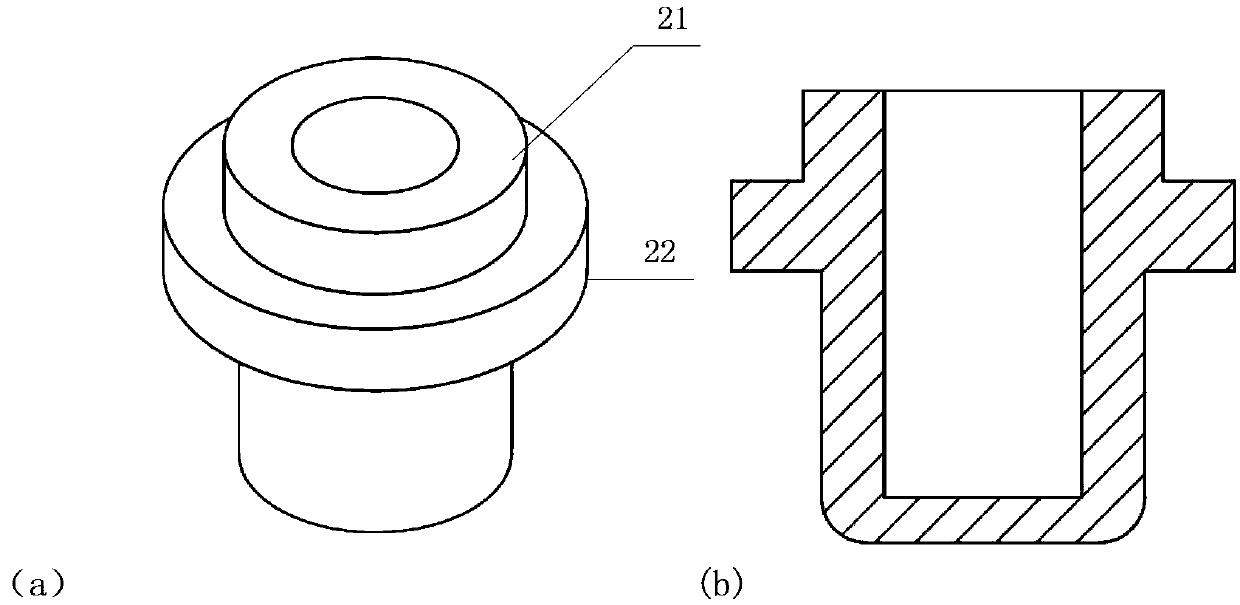

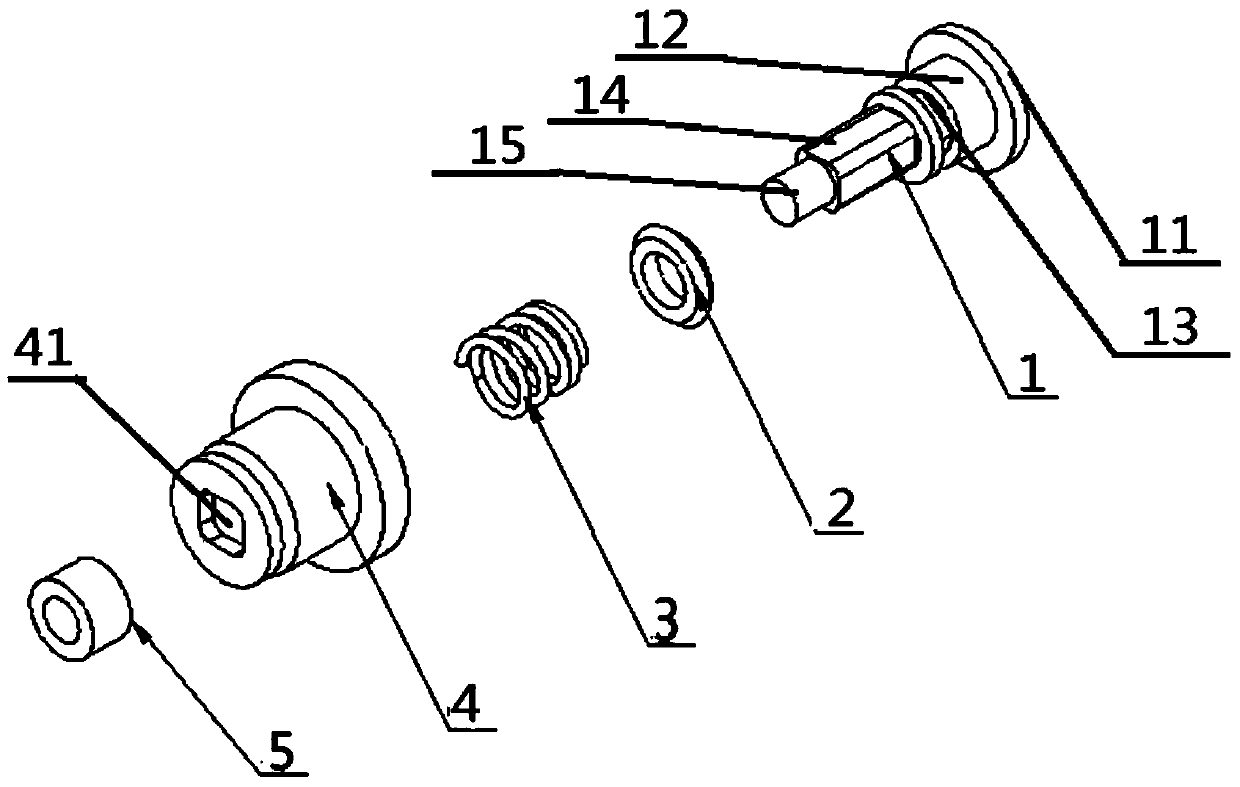

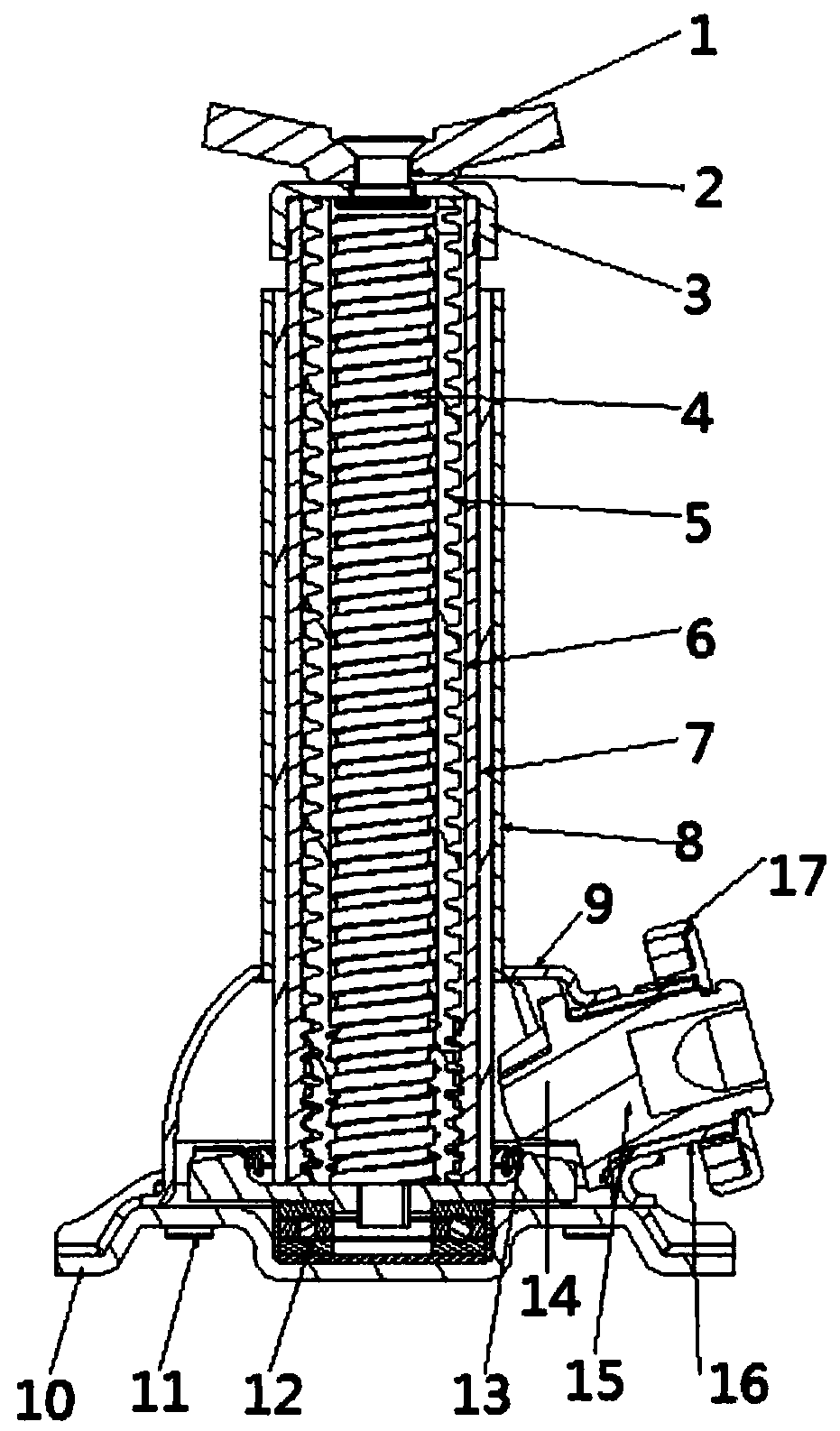

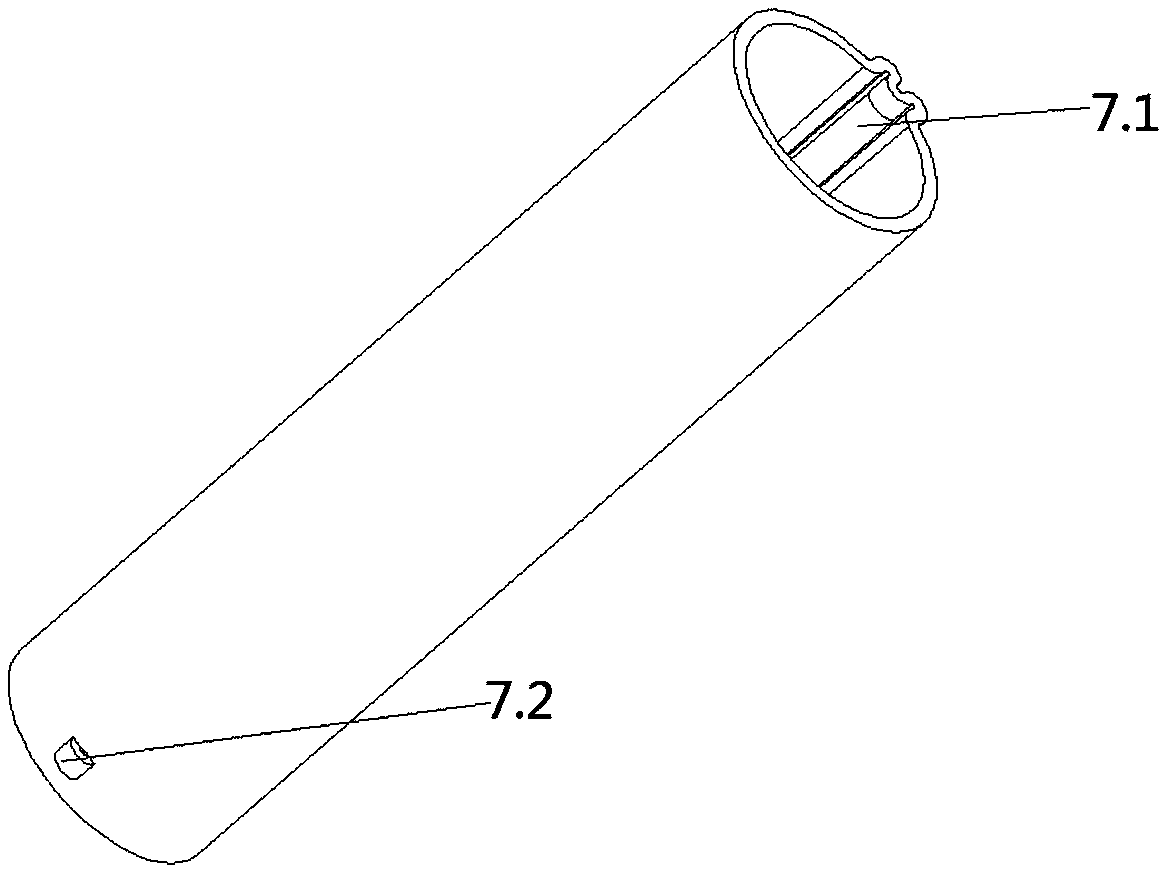

Conductive contact pole of electronic cigarette and elastic conductive contact body

The invention discloses a conductive contact pole of an electronic cigarette. The conductive contact pole comprises a columnar sliding body, which is made from a conductor material, and an insulating base, wherein a disc-shaped electric contact point is arranged at the top of the columnar sliding body; and a radial limiting column body is arranged at the lower part of the disc-shaped electric contact point. The base is a cavity barrel-shaped body which is provided with a bottom limiting hole; the limiting hole is matched with the radial limiting column body of the columnar sliding body, so that radial limiting is achieved; and the columnar sliding body, instead of radial rotation, is capable of doing axial sliding in the limiting hole of the base. A columnar connecting part is arranged at the other end of the columnar sliding body; a fastening ring is arranged on the columnar connecting part; and a seal ring and a reset elastic body are arranged between the columnar sliding body and the base.

Owner:INNOKIN TECH

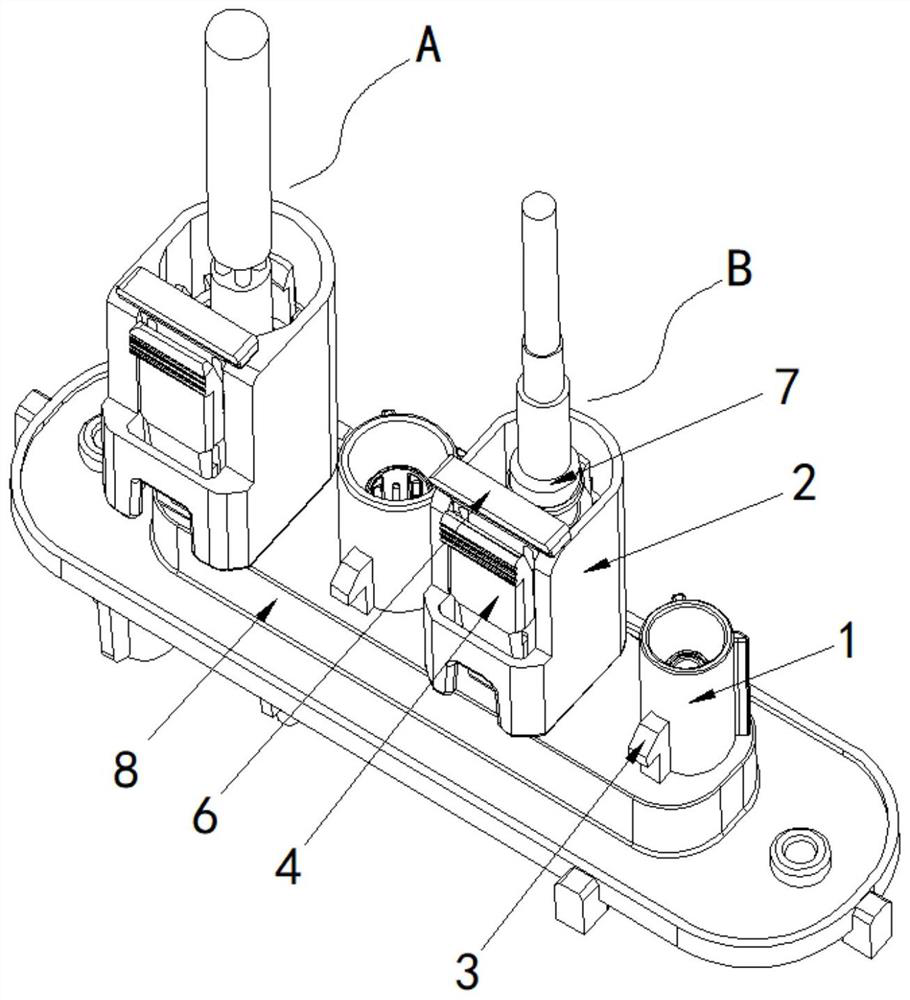

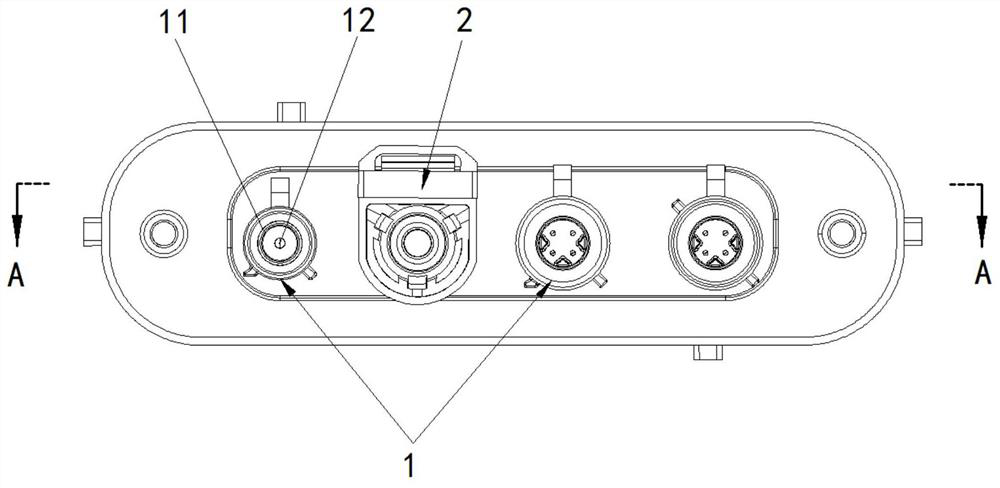

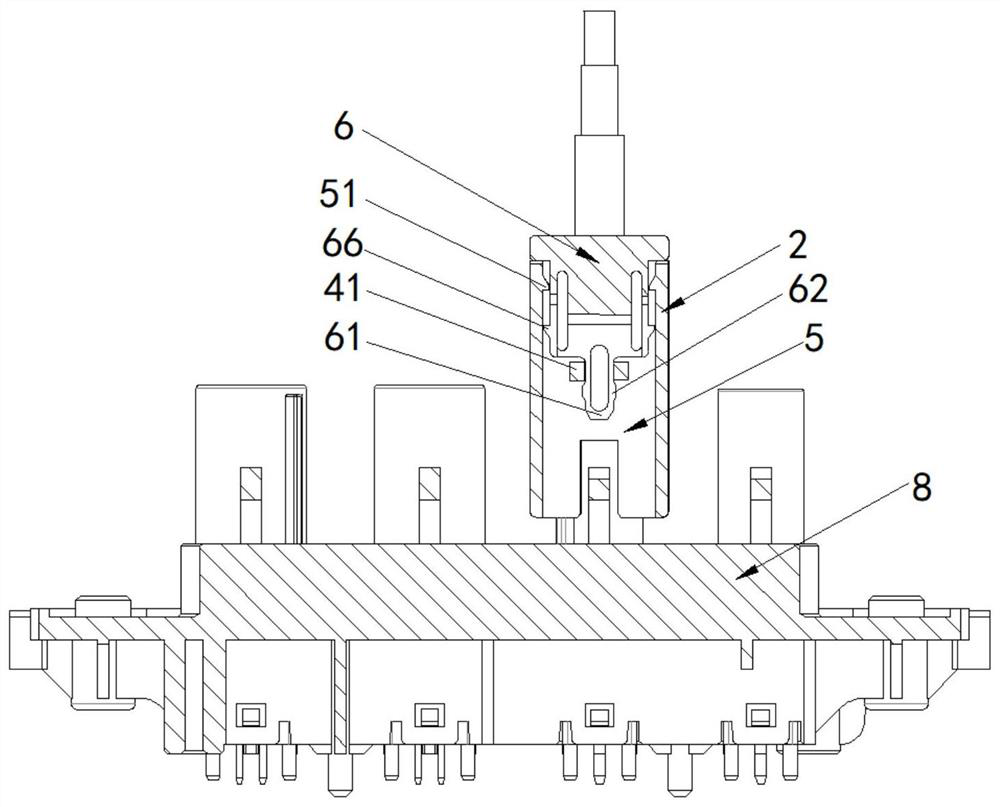

Locking structure of automobile high-frequency data signal transmission device

PendingCN113594788AEnsure safetyPrevent disengagementCoupling contact membersTwo-part coupling devicesData signalStructural engineering

The invention discloses a locking structure of an automobile high-frequency data signal transmission device, which comprises a connector seat end and a connector wire end, wherein the connector seat end and the connector wire end are clamped together through matching of an elastic buckle plate and a buckle boss when the connector seat end and the connector wire end are inserted oppositely, and a slot structure is arranged between the connector wire end and the elastic buckle plate. A mortise lock piece for extruding the elastic buckle plate to limit the elastic buckle plate from being pressed to tilt is inserted into the slot structure, and a limiting structure is arranged between the mortise lock piece and the slot structure. By adopting the technical scheme, the elastic buckle plate is prevented from being separated from the buckle boss when being pressed and tilted towards one side of the slot structure through the mortise lock piece, that is, the elastic buckle plate is limited and locked by the mortise lock piece, so that the stability of matched plugging of the connector seat end and the connector wire end is ensured; the plug-in connection of the socket end and the wire end is secondarily locked through the mortise lock piece, so that the risk that the wire end of the connector is mistakenly touched and pulled out in the use process is prevented, and the use safety of the product is ensured.

Owner:温州鑫荣电子有限公司

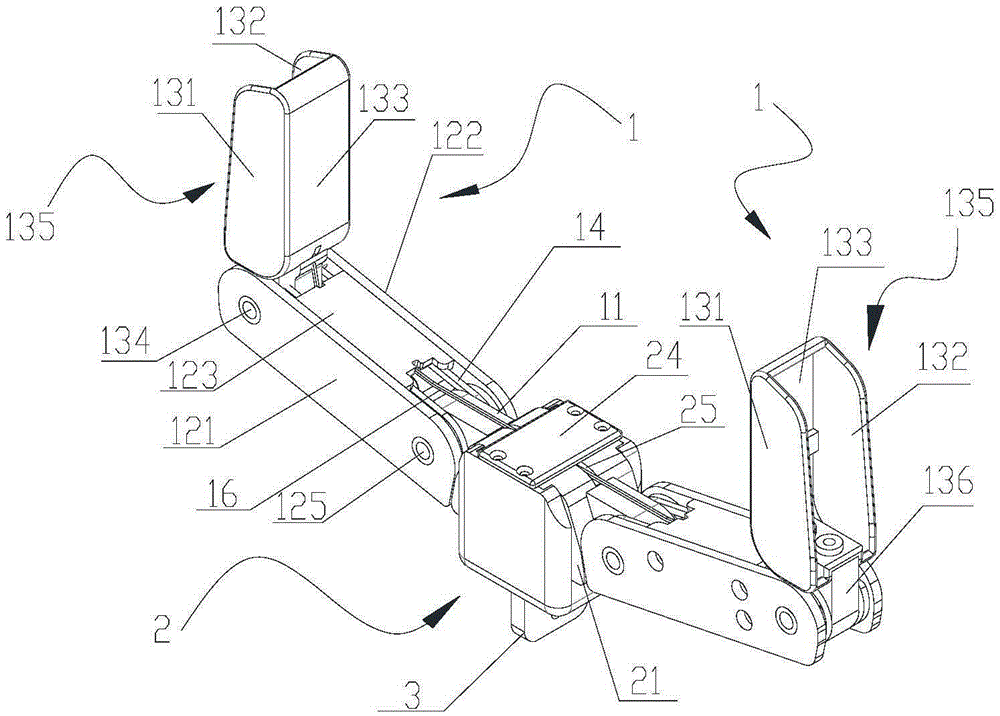

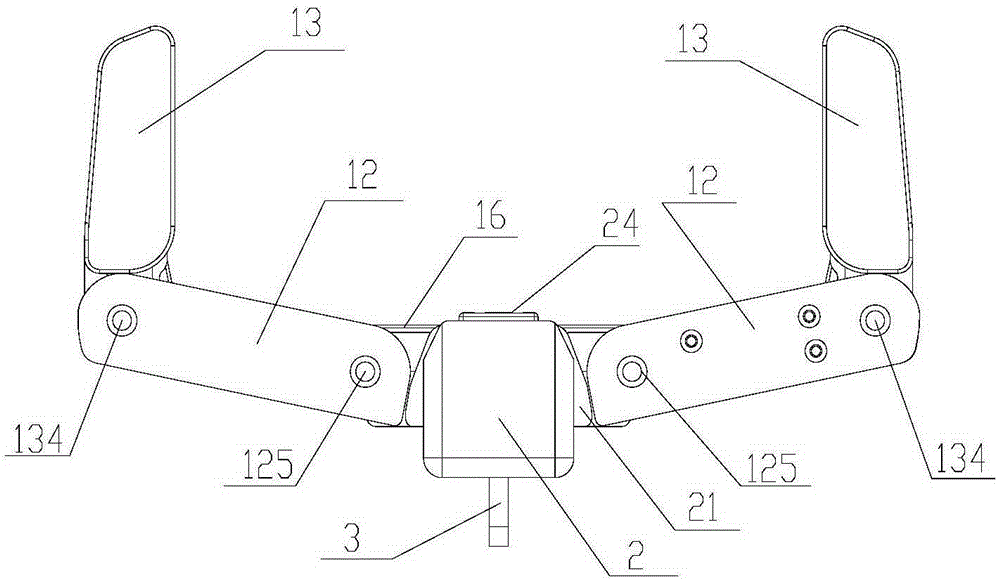

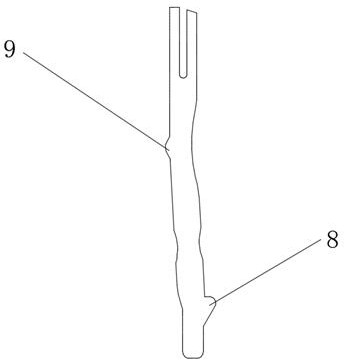

A kind of mechanical finger and mechanical hand

InactiveCN103612264BAchieving Elastic ContactAvoid deformationJointsGripping headsRobot handMechanical engineering

The invention discloses a mechanical finger and a mechanical arm. The mechanical finger comprises a first connecting piece, a first finger section, a second finger section, a first elastic piece, a second elastic piece and a pull line, wherein the first connecting part is used for fixing the mechanical finger to a fixed device, the first finger section is hinged to the first connecting piece through a first articulated shaft, and the second finger section is hinged to the first finger section through a second articulated shaft. The first elastic piece is connected with the first articulated shaft and the second articulated shaft, and the first finger section and the second finger section keep static relatively through the pretightening force of the first elastic piece. One end of the second elastic piece is connected with the first finger section, the other end of the second elastic piece is used for being connected with the fixed device, and the first finger section and the fixed device keep static relatively through the pretightening force of the second elastic piece. One end of the pull line extends along the first finger section from the end, close to the fixed device, of the first finger section and extends along the second finger section after winding around a certain portion on the first finger section, the end of the pull line and the second finger section are fixed, and the other end of the pull line is used for being connected with a driving device used for driving the finger to act. The mechanical finger and the mechanical arm make elastic contact with an article.

Owner:北京智能佳科技有限公司

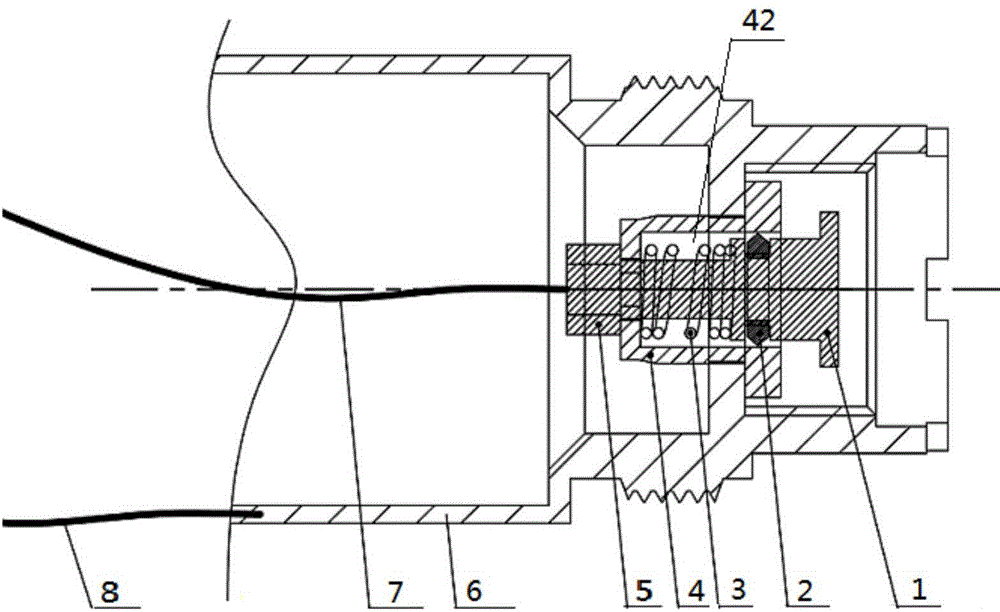

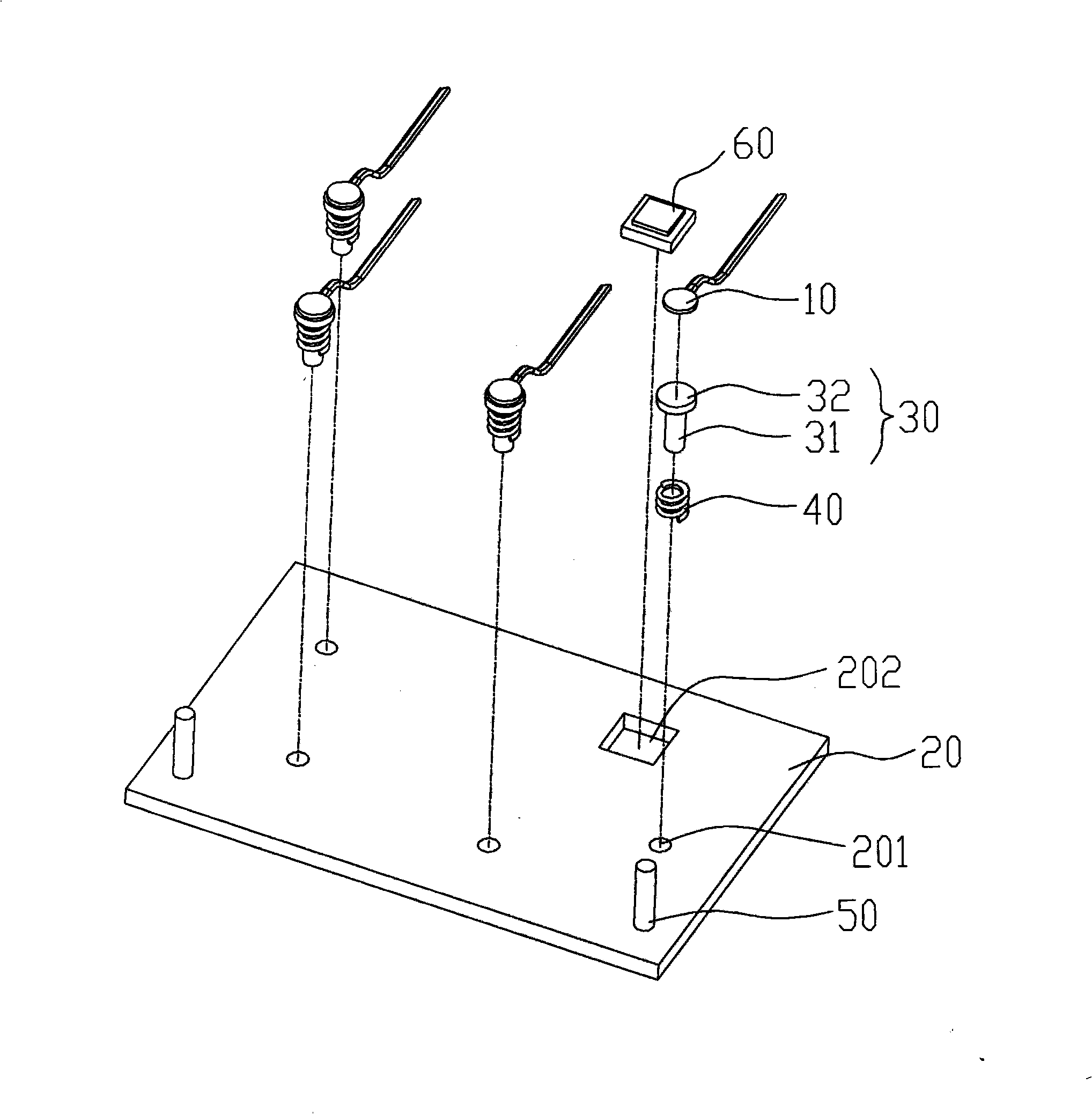

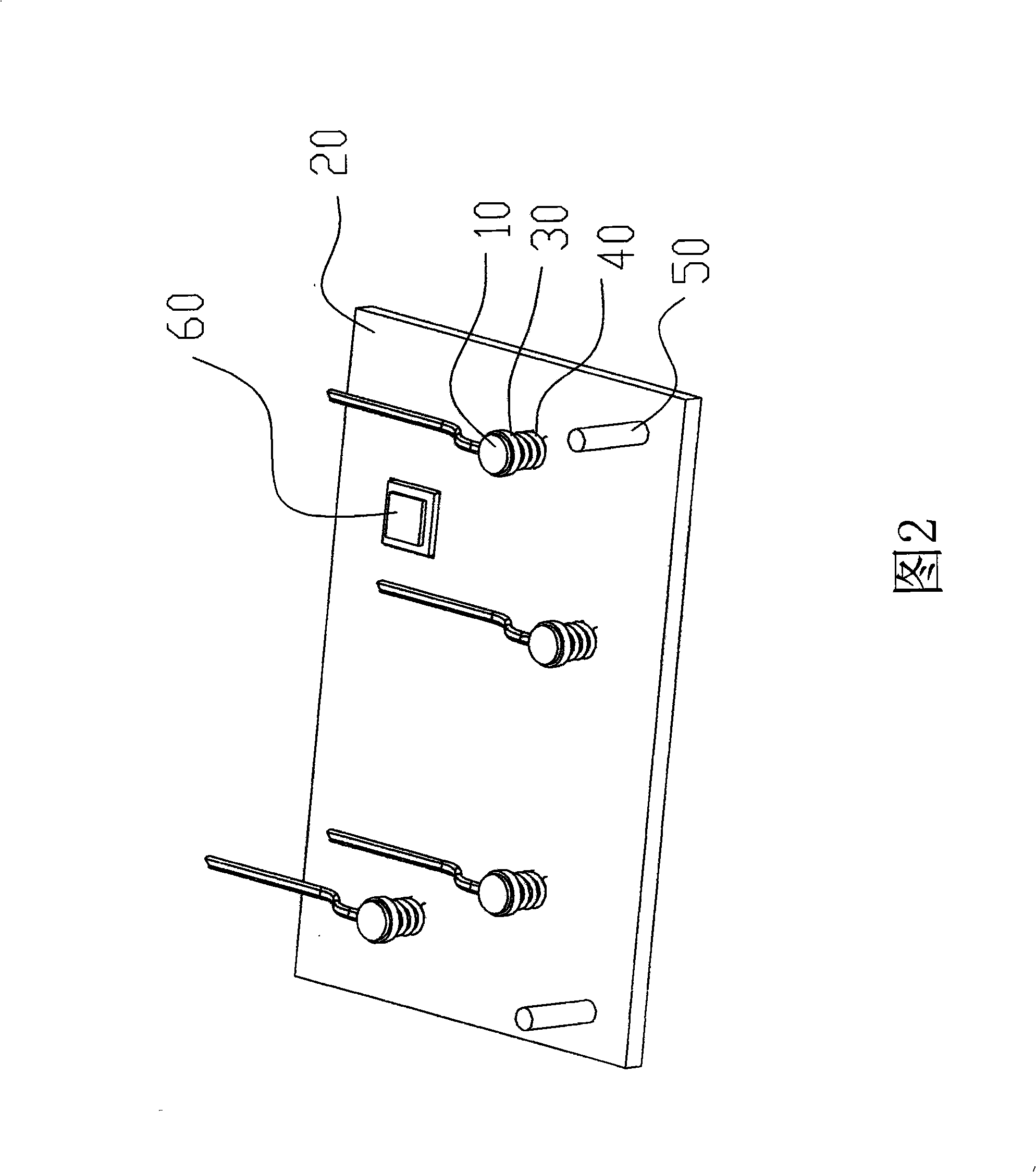

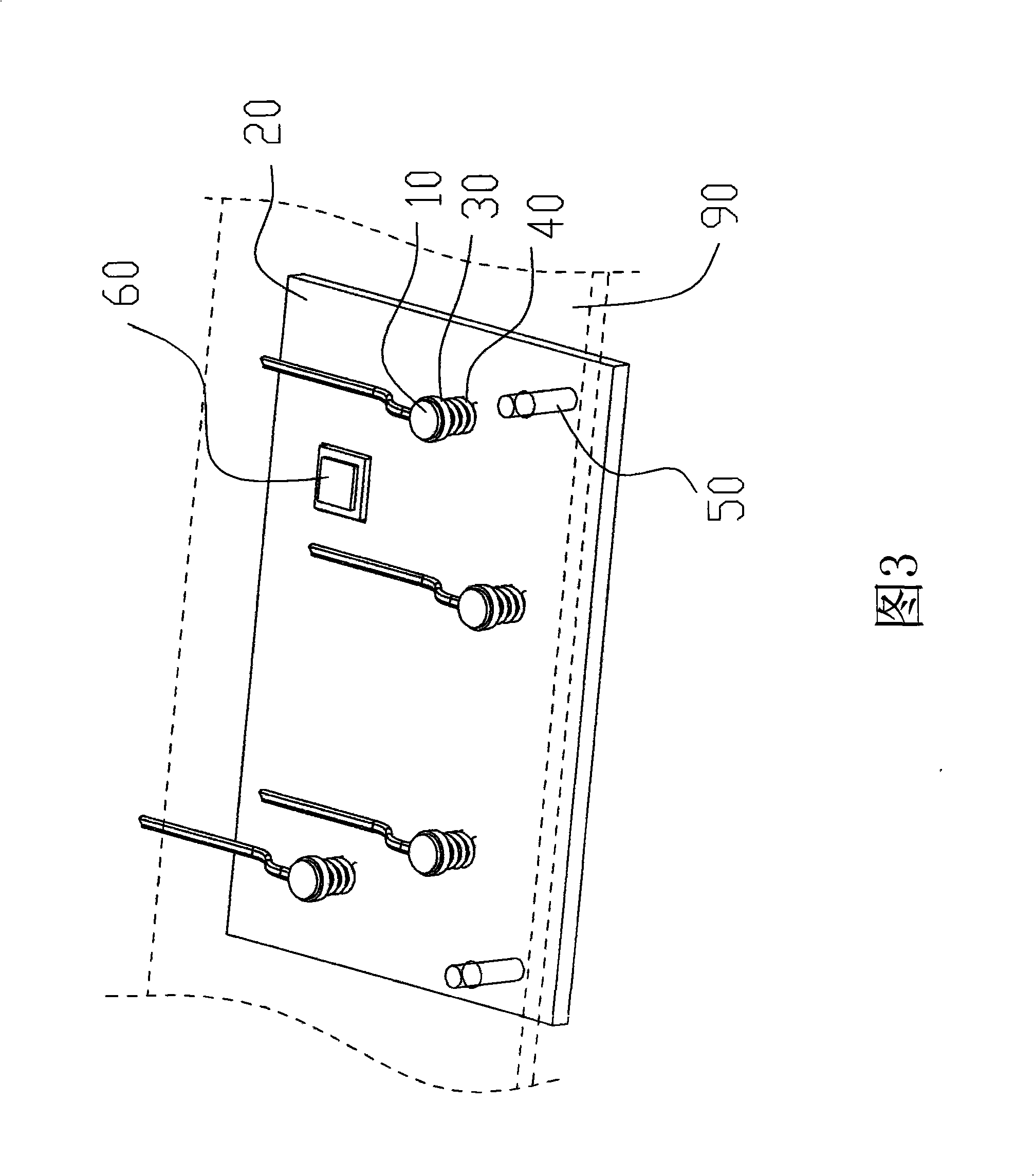

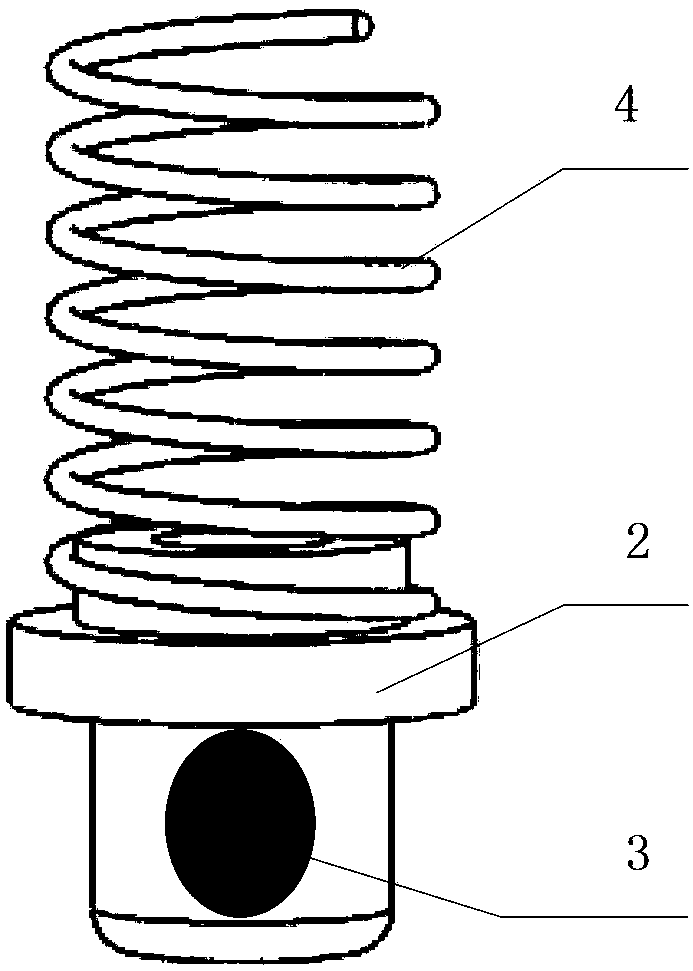

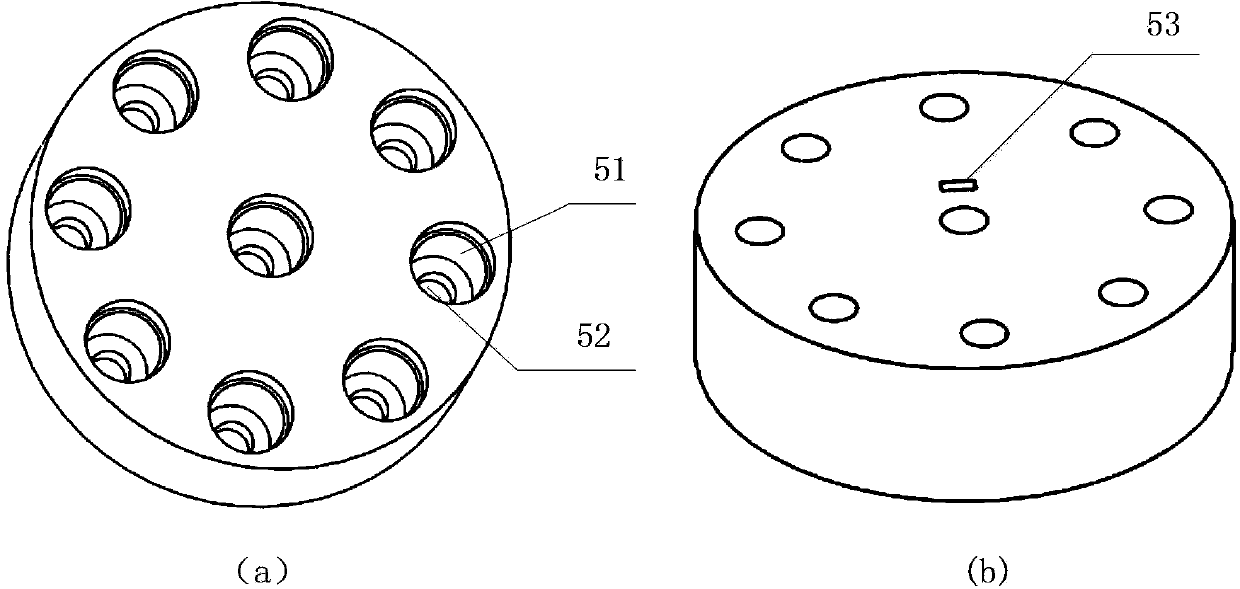

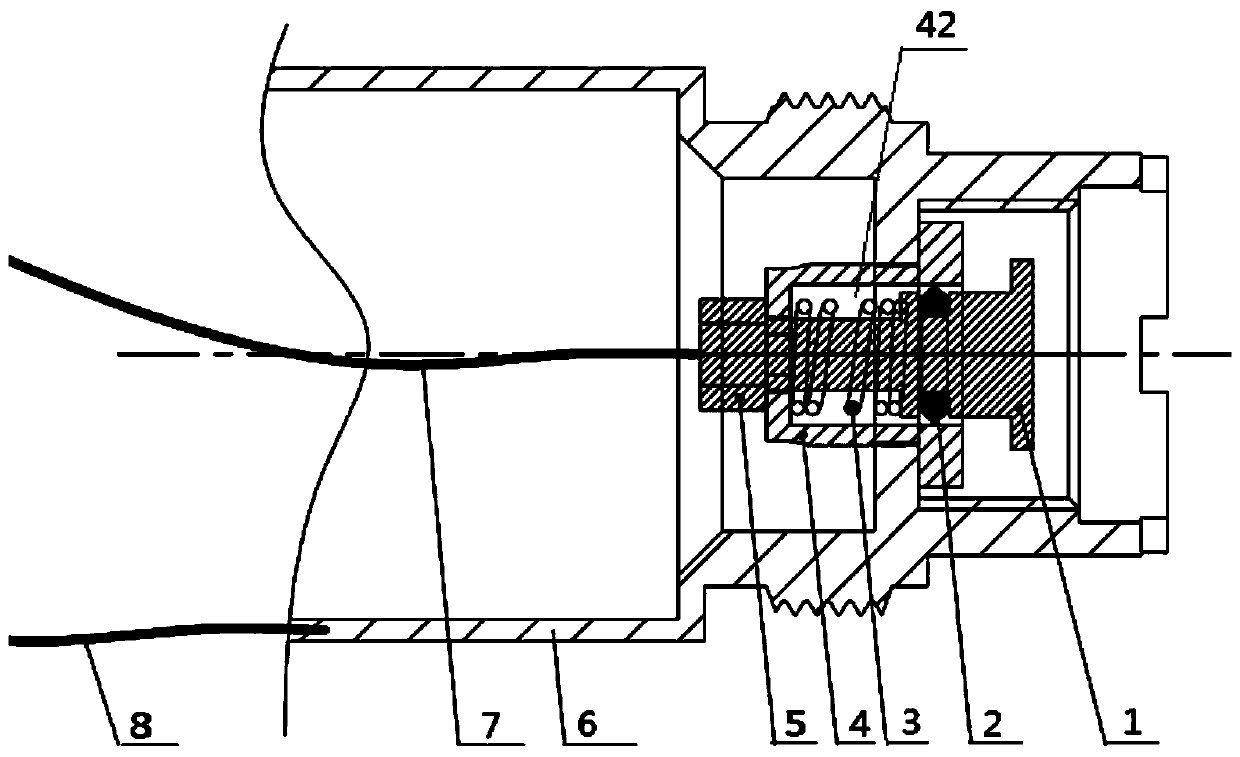

Temperature test fixture

InactiveCN101349594AAvoid pollutionAchieving Elastic ContactThermometer detailsThermometers using electric/magnetic elementsTest objectTemperature testing

The invention provides a temperature test jig, which is applied to fix a plurality of probes for testing temperature on tested points of a tested object. The temperature test jig comprises a base plate, wherein a plurality of punch holes are arranged on the base plate, a plurality of supports are respectively threaded through the punch holes, the support respectively comprises a shaft sleeve, the end portions of the shaft sleeves are respectively provided with a limiting portion, a probe is respectively fixed on the top portion of the limiting portion, and an elastic element is respectively sleeved outside the shaft sleeve, and one end of the elastic element is respectively pressed inside the liming portion, and the other end of the elastic element is respectively pressed on the surface of the base plate. The temperature test jig can fix the probes through the supports, and the tested object is pressed on the upper portion of the temperature test jig under the effect of gravity or down force when in test, and the probes are respectively corresponding to the positions of each tested point, thereby realizing the elastic contact between the probes and the tested points, in order to save the procedure of adhering the probes with hands, and increase the test efficiency.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

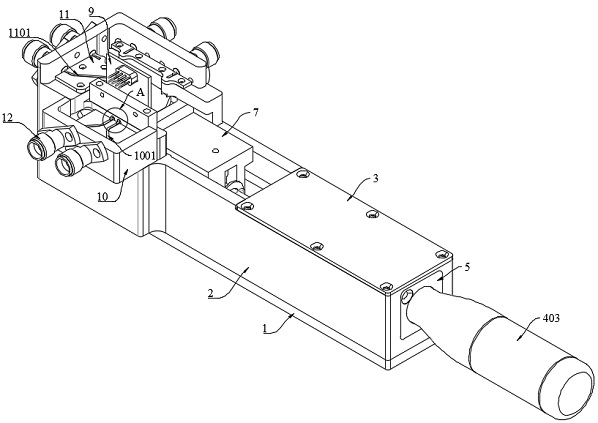

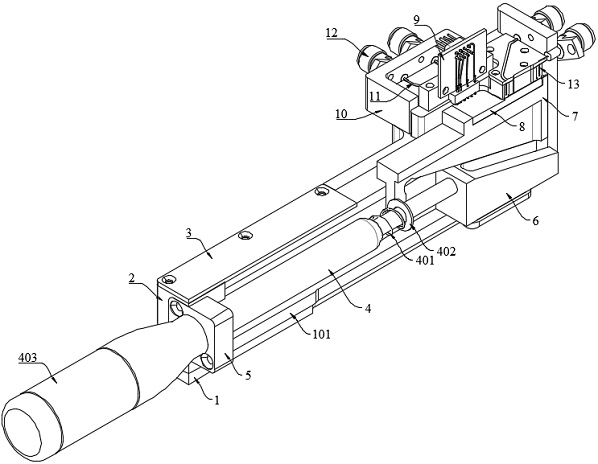

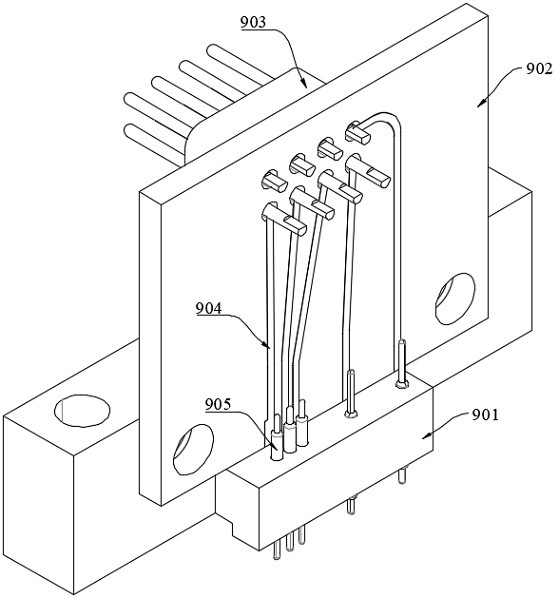

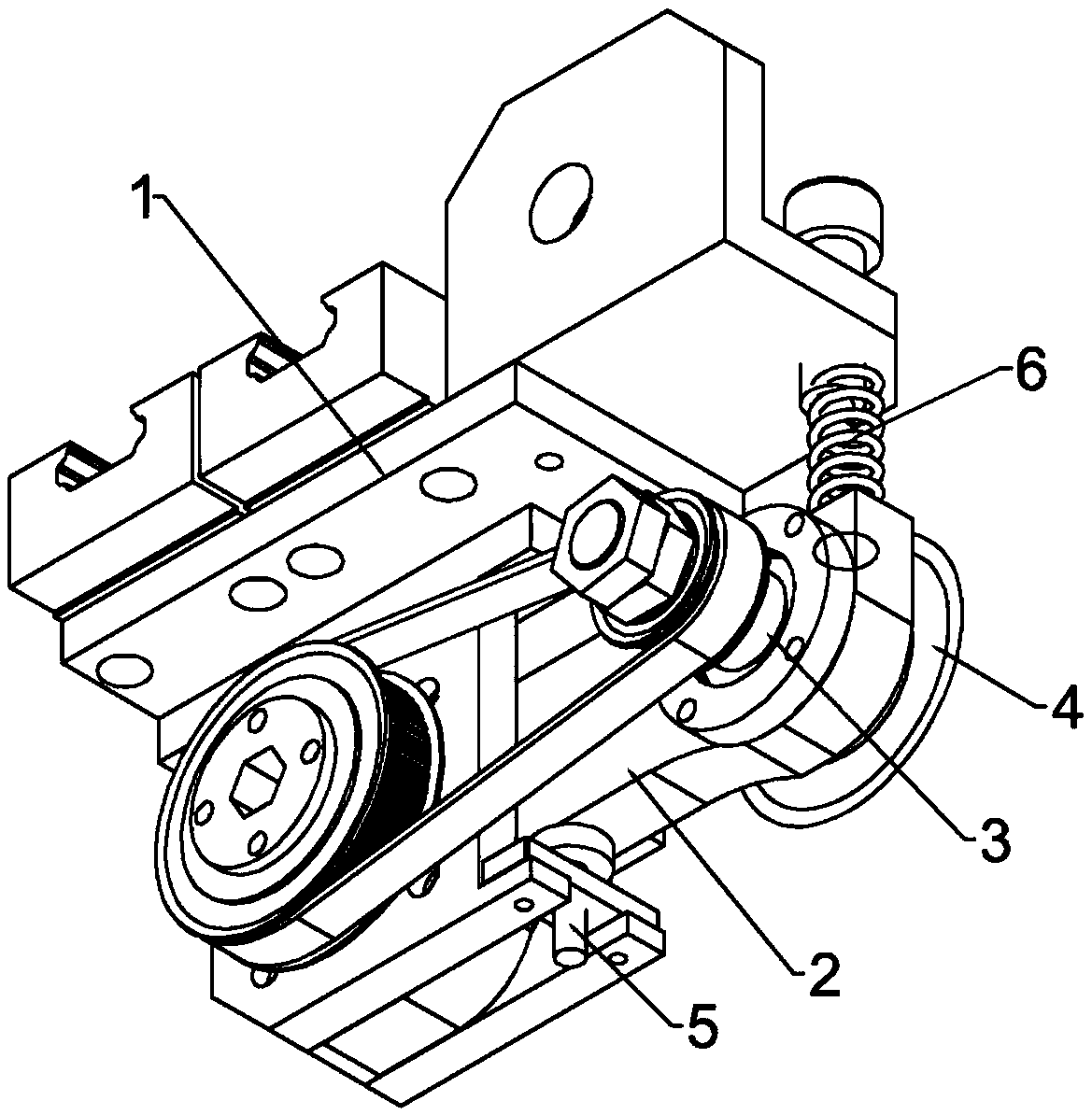

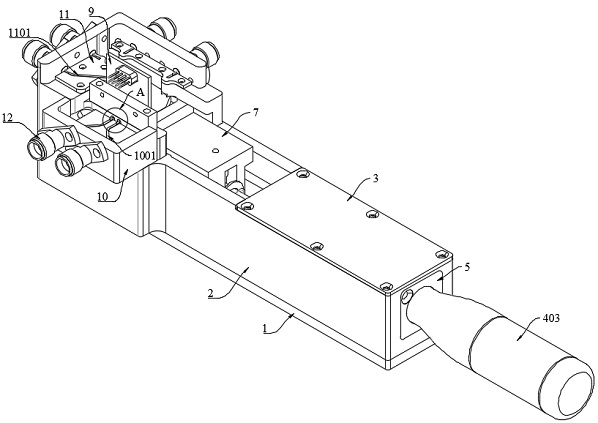

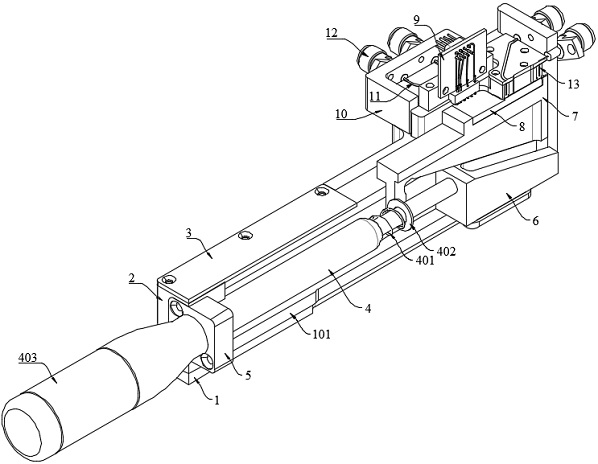

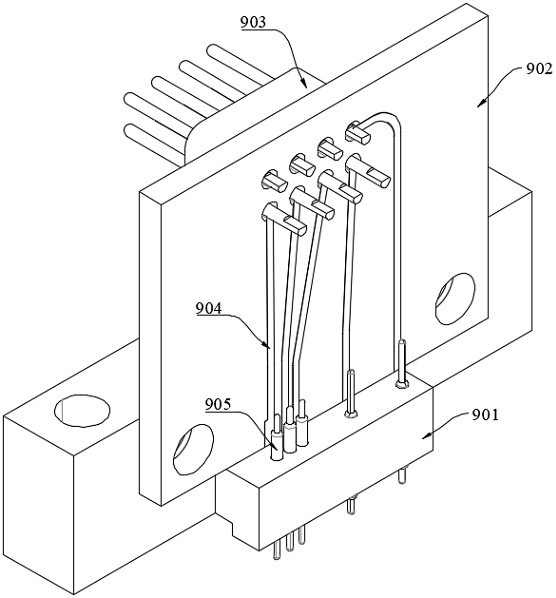

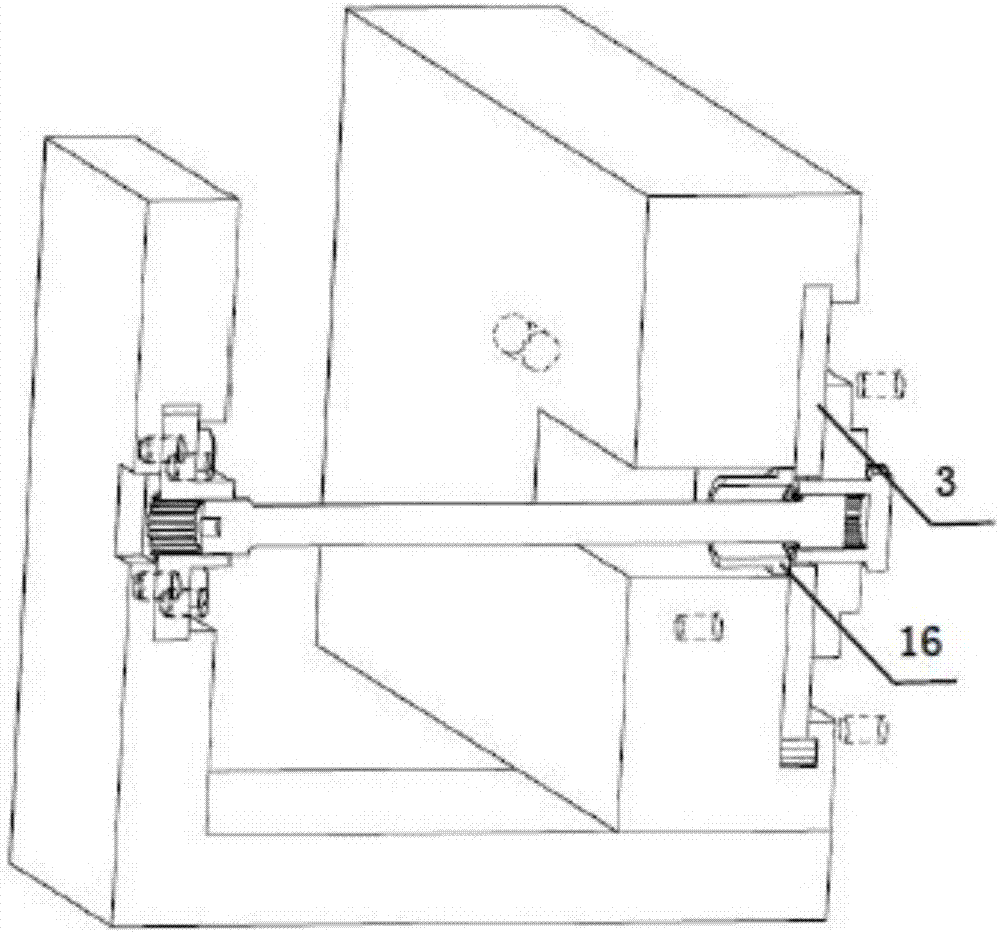

Carrier plate type bare chip power amplifier module testing device

ActiveCN112180244AQuick clampingEasy to testRadiofrequency circuit testingMeasurement instrument housingEngineeringElectrical performance

The invention provides a carrier plate type bare chip power amplifier module testing device which comprises a sliding rail supporting block, the top face of the sliding rail supporting block is connected with a base body block, the end of the base body block is connected with a locking nut, the locking nut is in threaded connection with a pull rod, the end of the pull rod is rotationally connectedwith a wedge-shaped sliding block, and the wedge-shaped sliding block is matched with a supporting block. A low-frequency probe board comprises a probe base, the probe base is connected with a low-frequency control board, a multi-core connector is inserted into the low-frequency control board, a low-frequency patch cord is welded to the multi-core connector, and the other end of the low-frequencypatch cord is connected with an elastic probe; the surface of a first radio frequency circuit board is provided with a first radio frequency transmission line, and the surface of a second radio frequency circuit board is provided with a second radio frequency transmission line. The radio frequency elastic probe assembly is matched with the second radio frequency circuit board; a radio frequency coaxial assembly is horizontally arranged on the base block in a penetrating mode. According to the invention, rapid clamping of the power amplifier module is realized by adopting a novel structural design, and the electrical performance index test problem of the power amplifier module is solved.

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

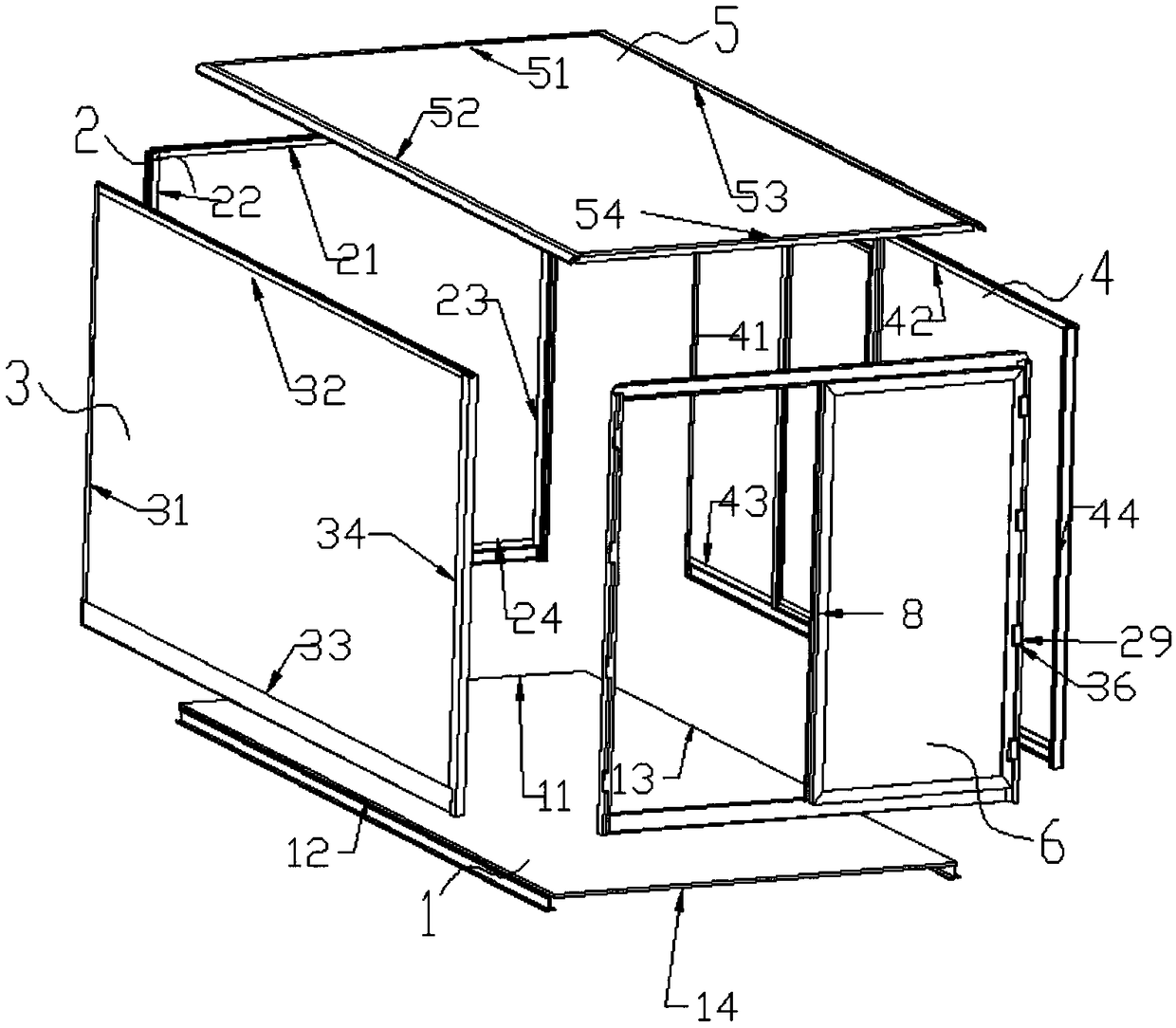

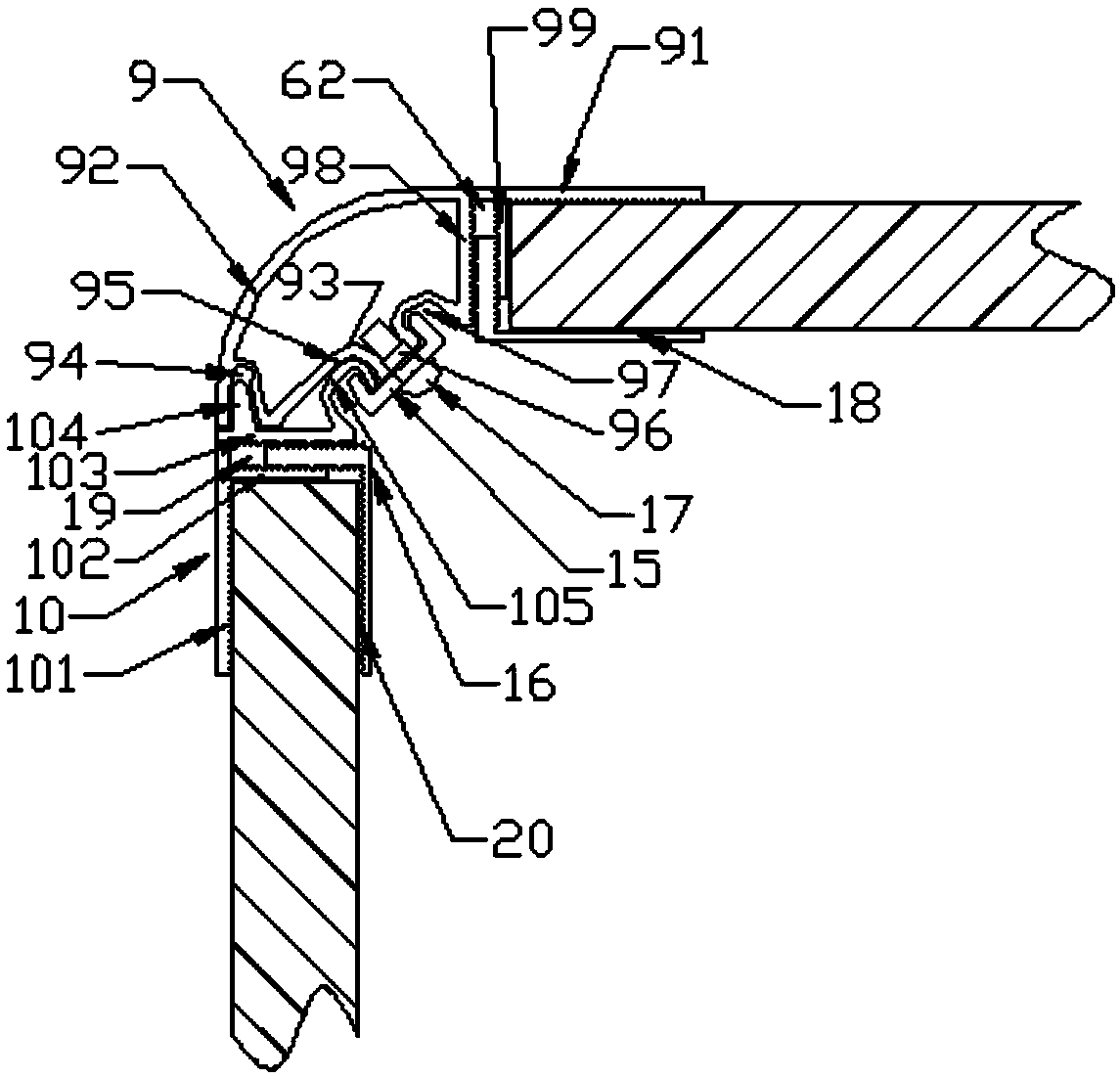

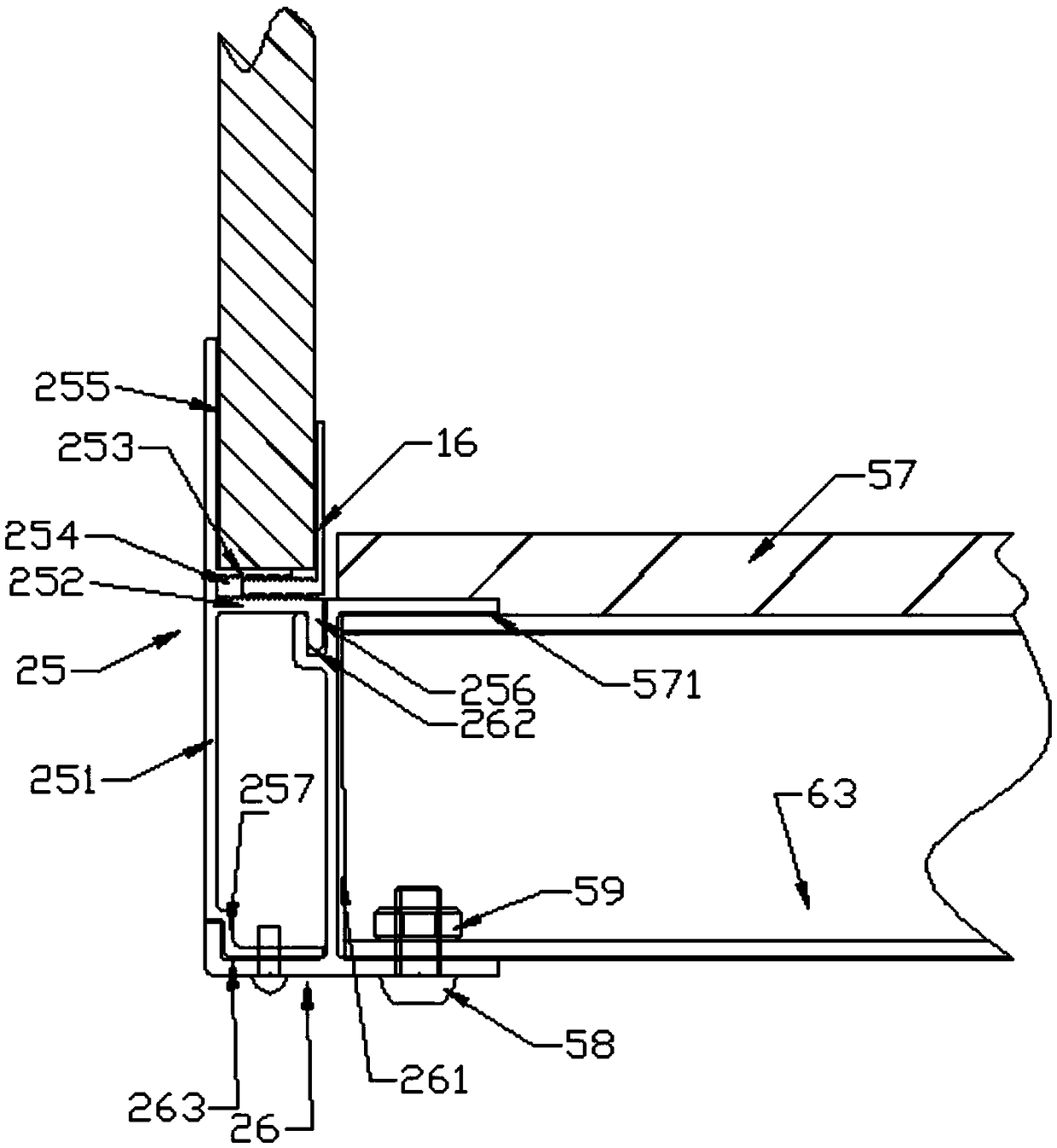

Vehicle compartment body capable of being assembled rapidly

PendingCN109334786AReduce your weightReduce fuel consumptionLoading-carrying vehicle superstructuresWater leakageBody compartment

The invention discloses a vehicle compartment body capable of being assembled rapidly. A finished compartment body product is simply formed by connecting several large plates and door plates of the compartment body through integrating connection structures of several profiles, and through the classification of the profiles, the simplicity of structure of the profiles, the same use of the profile structures and the adopting of aluminum alloy materials, the weight of the compartment body is reduced, the oil consumption of a vehicle is reduced, the utilization coefficient of the vehicle is improved and the cost of the vehicle is reduced. At the same time, the combination of six flour of the compartment body can be realized, and each flour can be dismounted and replaced; the phenomenon that alarge number of bolts are used for fixing a traditional compartment body is avoided, and water leakage is avoided; and finally, the standardization of parts is realized, the replacement efficiency ofdamaged parts is improved, and the after-sales maintenance cost is reduced.

Owner:南通航盛光电有限公司

A flexible neural electrode with a three-dimensional buckling structure and its preparation process

ActiveCN110367978BReliable recordAchieving Elastic ContactDiagnostic recording/measuringSensorsImideElastic substrate

Owner:SHANGHAI JIAOTONG UNIV

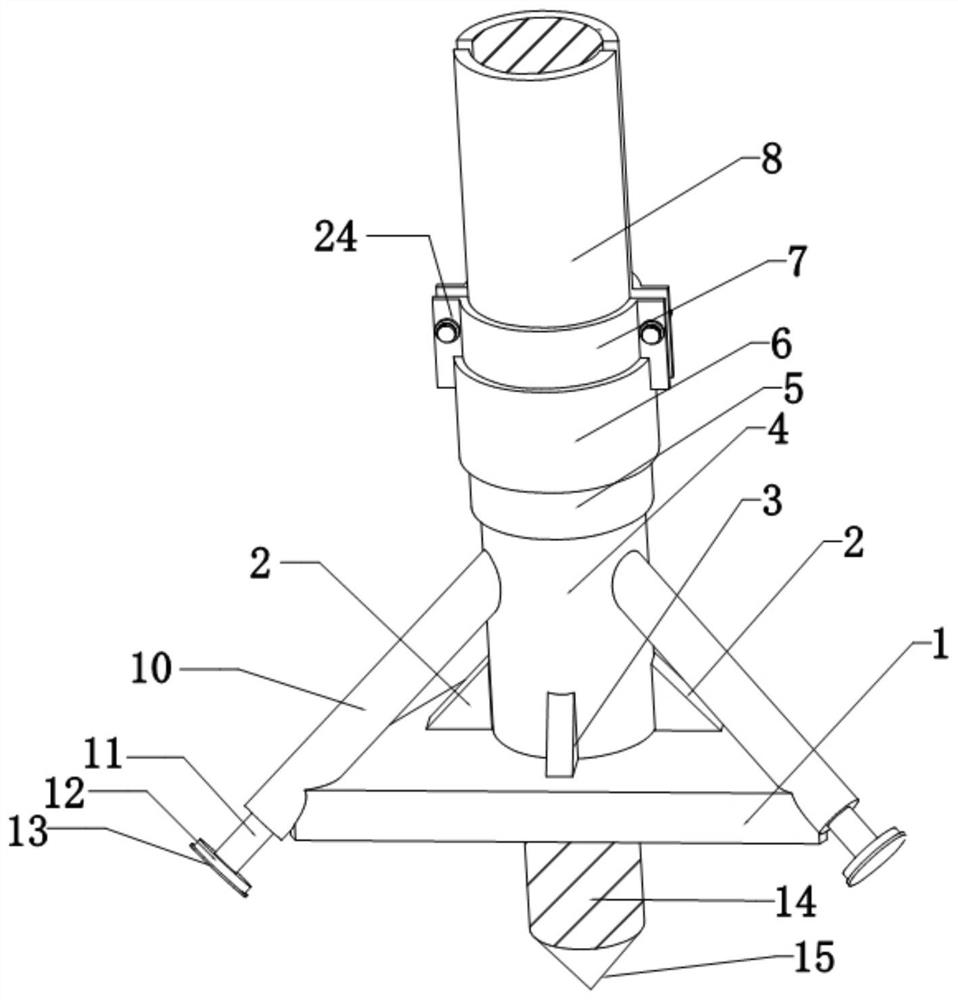

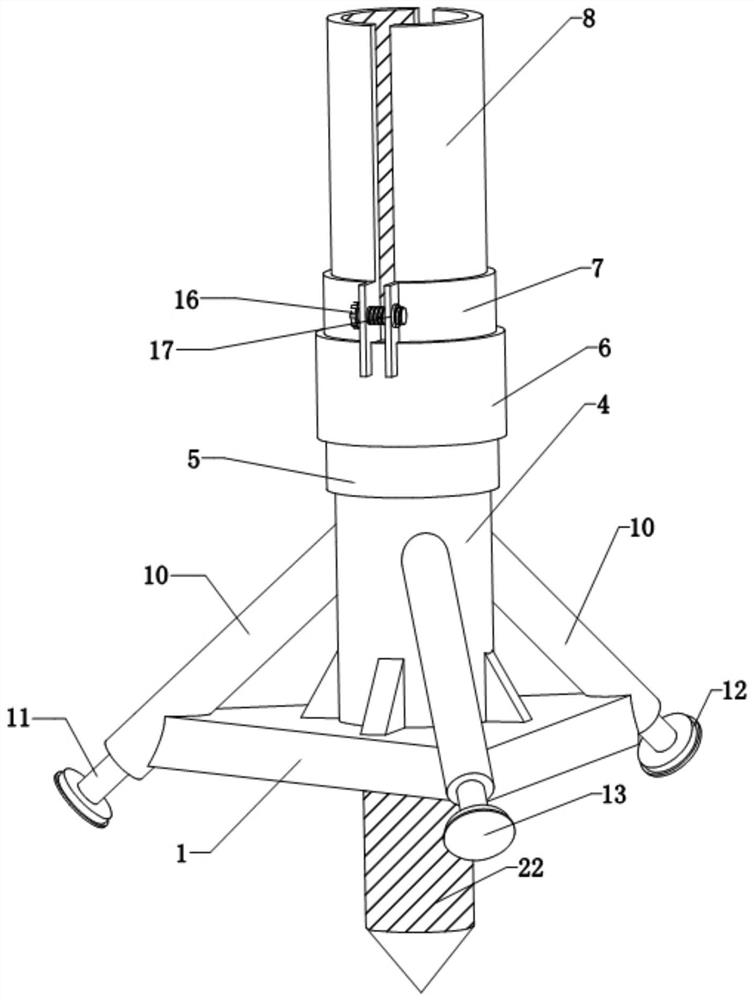

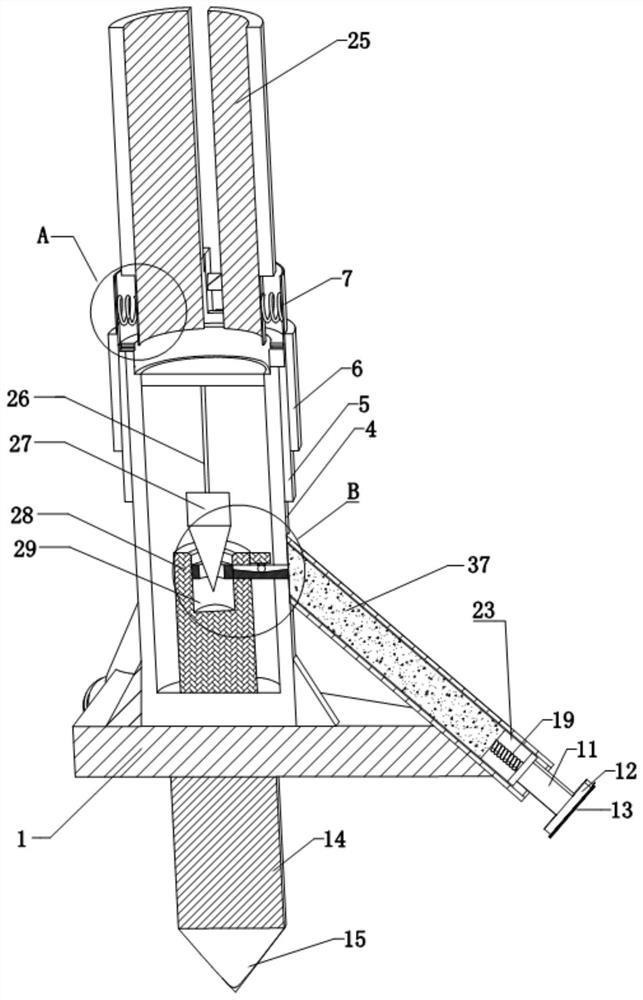

Scaffold bottom supporting device

ActiveCN112878662AImprove adaptabilityGood anti-skid supportScaffold accessoriesSteel tubeSelf adaptive

The invention belongs to the technical field of supporting, and discloses a scaffold bottom supporting device. The scaffold bottom supporting device comprises a bottom plate, wherein a fixing barrel is arranged at the center of the top of the bottom plate, a lantern ring is arranged on the outer surface of the end, away from the bottom plate, of the fixing barrel, a fixing ring is arranged at the top of the outer surface of the lantern ring, a plurality of first sliding grooves are formed in the top of the fixing barrel in a circumferential array mode, first sliding blocks are slidably connected into the first sliding grooves, a fixing clamp is arranged at the top of the first sliding blocks, a plurality of first springs are evenly arranged on the inner side face of the fixing clamp in a circumferential array mode, a semicircular ring is arranged at the end, away from the fixing clamp, of each first spring, the bottom plate is polygonal, a plurality of supporting columns are arranged on the outer surface of the fixing barrel in a circumferential array mode, the other sides of the supporting columns are fixedly connected with the vertex of the bottom plate, and second sliding grooves are formed in inner cavities of the supporting columns. The scaffold bottom supporting device is more stable, steel pipes of different sizes can be installed, the service life is long, the inclination degree is accurately controlled, and inclination can be adjusted in a self-adaptive mode.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO GUANGRAO POWER SUPPLY CO

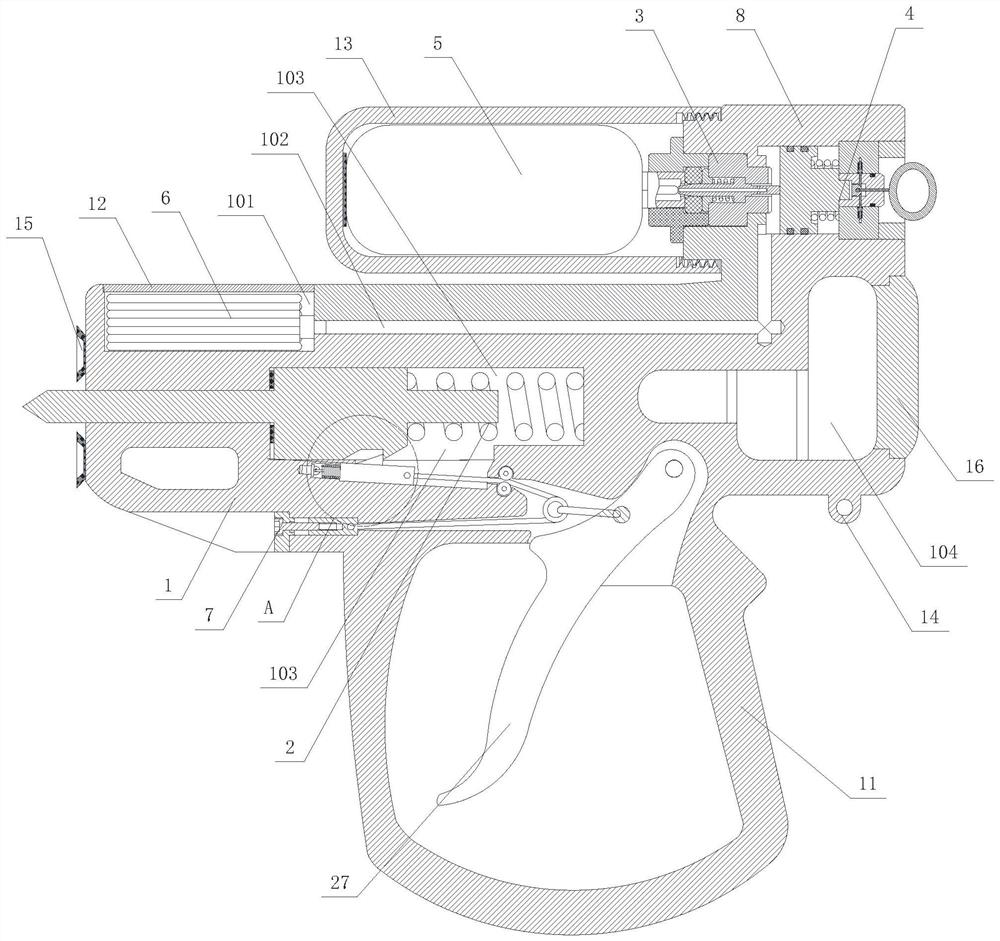

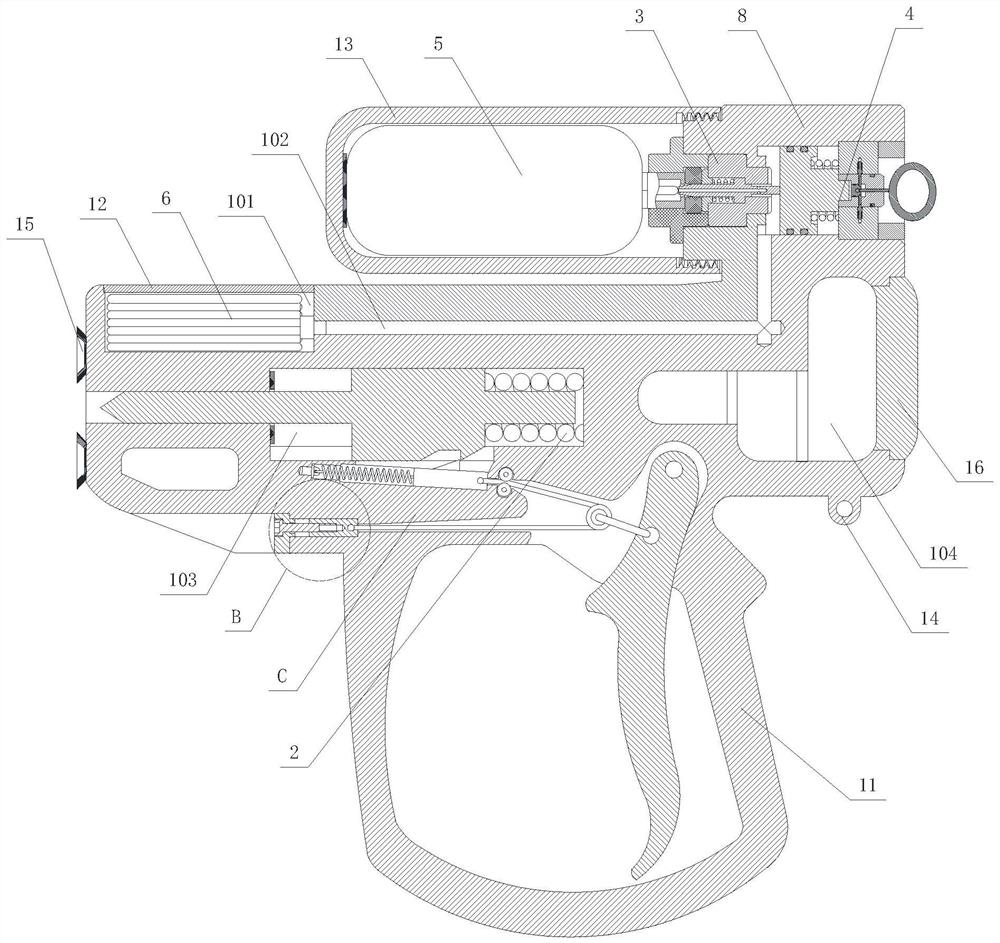

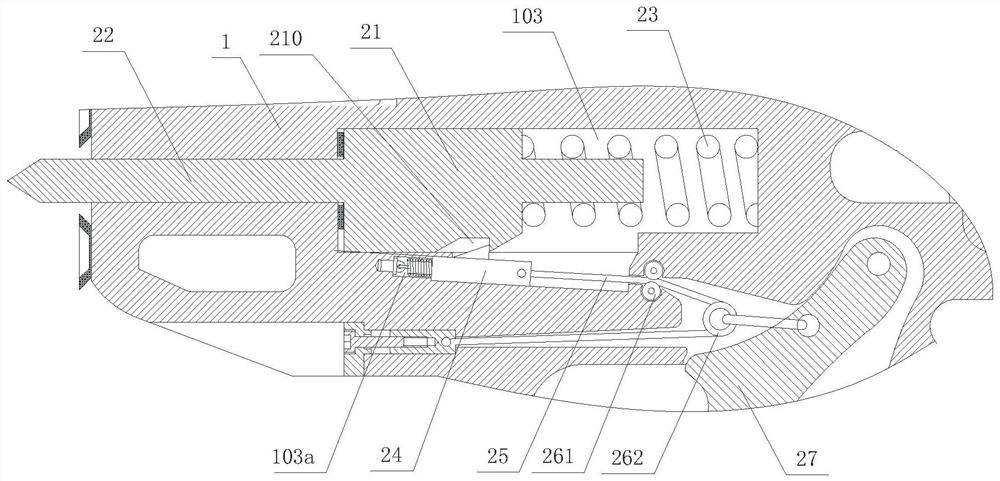

Escape device for vehicle falling into water

PendingCN114312649ATo achieve the same direction of motionFast same direction movementPedestrian/occupant safety arrangementBuilding rescueMarine engineeringMechanical engineering

The invention provides an escape device for a vehicle falling into water, which is used for self-rescue of the vehicle falling into water and comprises a main body, a window breaking mechanism and a floating mechanism, the window breaking mechanism is used for breaking vehicle window glass; the floating mechanism is used for providing buoyancy in water and comprises an air tank and an air bag connected with the air tank through a valve assembly, and the valve assembly is provided with a triggering mechanism used for rapidly opening and communicating the air bag and the air tank to achieve air inflation of the air bag. And the handheld part is used for being held by a hand when the window is broken or floats upwards. The escape device for the vehicle falling into water is easy and labor-saving to operate, suitable for common window breaking and escape from the vehicle falling into water, and high in personnel escape rate.

Owner:陈凯璐

Flexible cutting system mechanism

The invention discloses a flexible cutting system mechanism, and belongs to cutting equipment. The flexible cutting system mechanism comprises a rack body. A swing arm is rotationally connected to thelower portion of the rack body. A cutting blade is fixedly connected to the outer end of the swing arm through a rotationally connected positioning shaft. The lower portion of the rack body is in threaded connection with a limiting screw for limiting the swing angle of the swing arm. An elastic piece for pressing the swing arm to move downwards is fixedly connected between the rack body and the outer end of the swing arm. Compared with the prior art, the flexible cutting system mechanism has the beneficial effects that the cutting blade at the traditional fixing position is mounted at the outer end of the swing arm, elastic contact of the blade can be achieved through elastic limiting to the swing arm when the flexible cutting system mechanism conducts cutting, the blade is protected to the maximum extent, and various different cutting needs can be met.

Owner:义乌市安倩科技有限公司

A test device for a carrier-type bare-chip power amplifier module

ActiveCN112180244BQuick clampingEasy to testRadiofrequency circuit testingMeasurement instrument housingElectrical performanceMechanical engineering

A carrier-type bare chip power amplifier module testing device, comprising a slide rail support block, the top surface of the slide rail support block is connected with a base block, the end of the base block is connected with a lock nut, the lock nut is threadedly connected with a pull rod, and the end of the pull rod rotates The wedge-shaped slider is connected, and the wedge-shaped slider is matched with a bracket; the low-frequency probe board includes a probe seat, which is connected to a low-frequency control board, and the low-frequency control board is inserted with a multi-core connector, and the multi-core connector is welded with a low-frequency The other end of the low-frequency transfer line is connected with an elastic probe; the surface of the first radio frequency circuit board is provided with a first radio frequency transmission line, and the surface of the second radio frequency circuit board is provided with a second radio frequency transmission line; the radio frequency elastic probe assembly and the second radio frequency circuit Board matching; RF coaxial components are horizontally installed on the base block. The invention adopts a novel structural design to realize fast clamping of the power amplifier module, and solves the problem of testing the electrical performance index of the power amplifier module.

Owner:SICHUAN SIAIPU ELECTRONICS TECH CO LTD

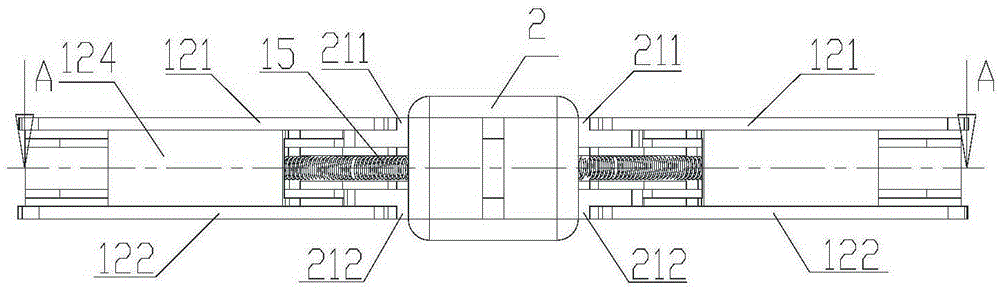

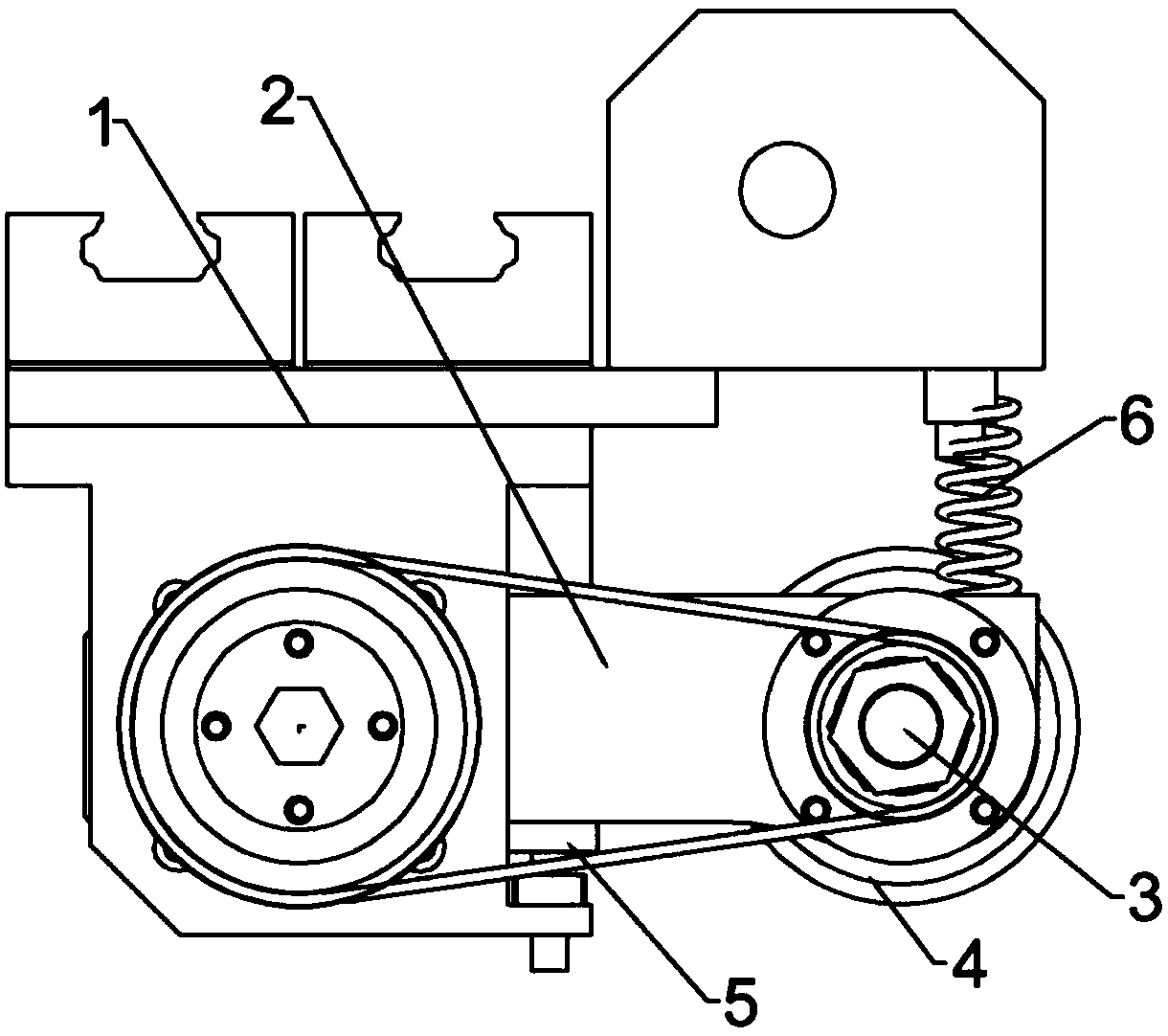

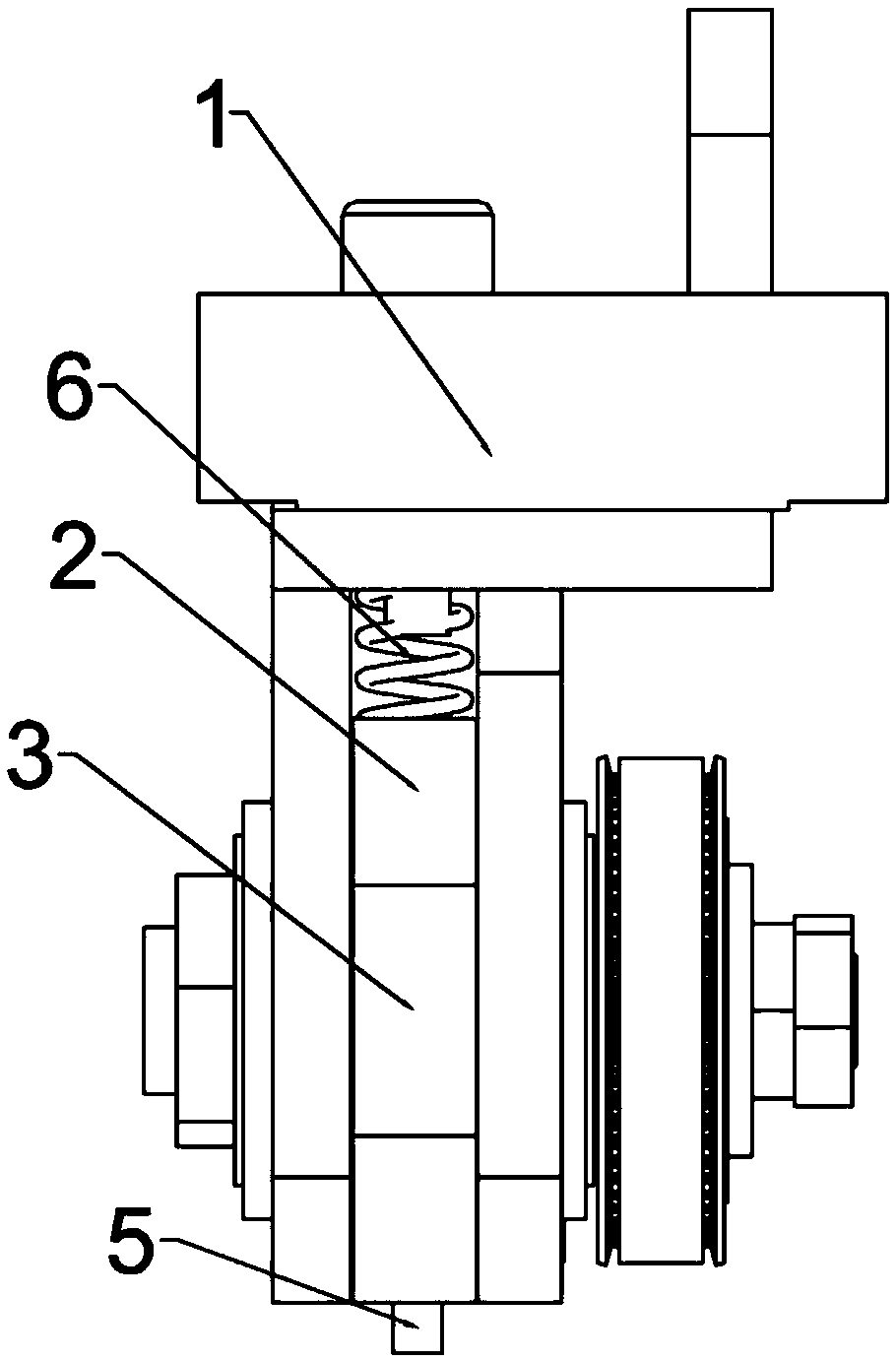

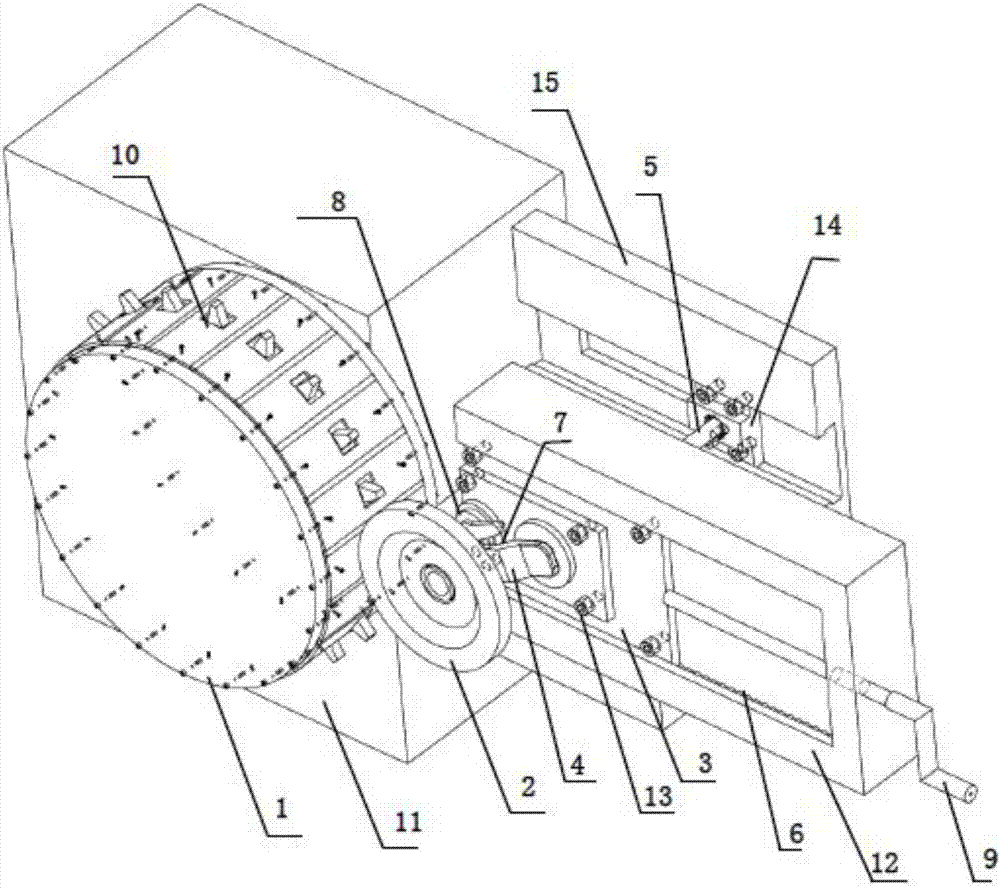

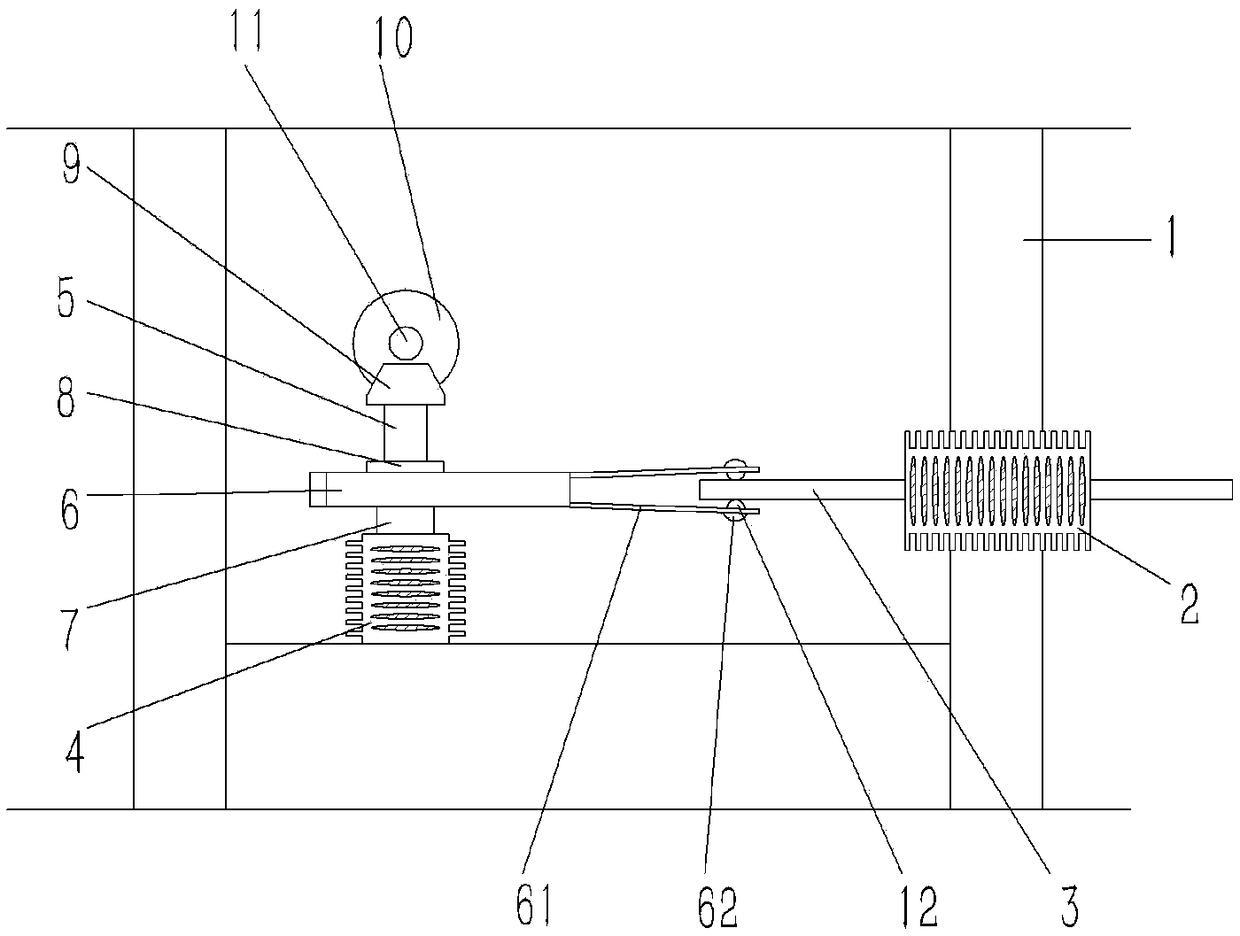

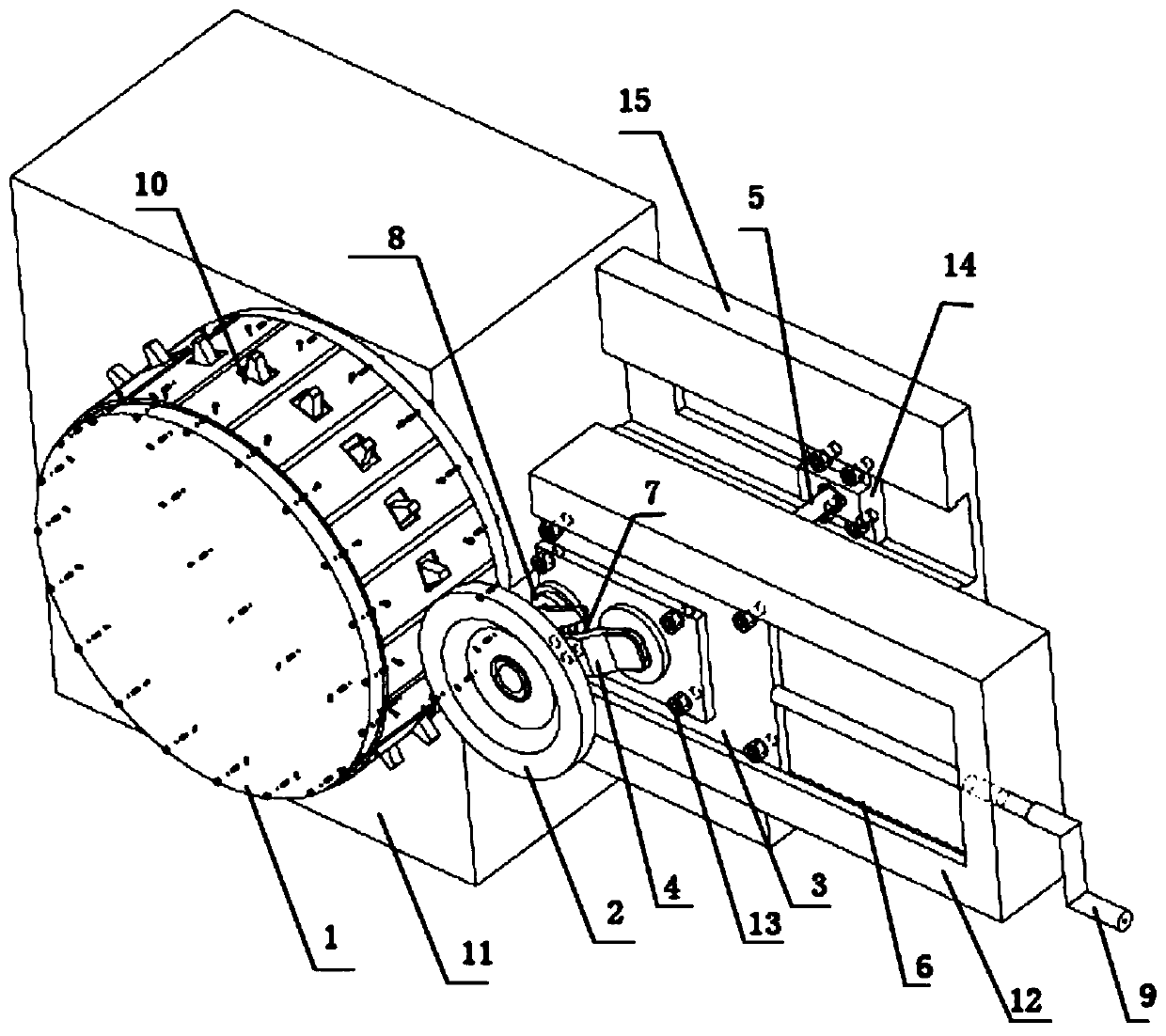

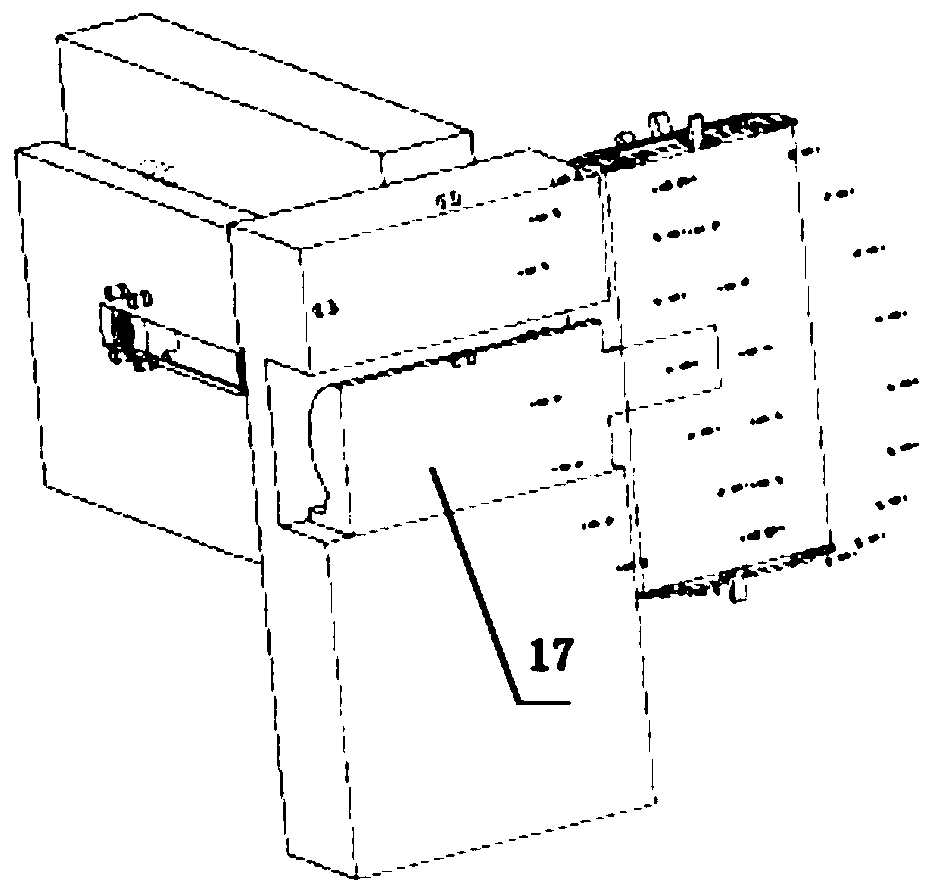

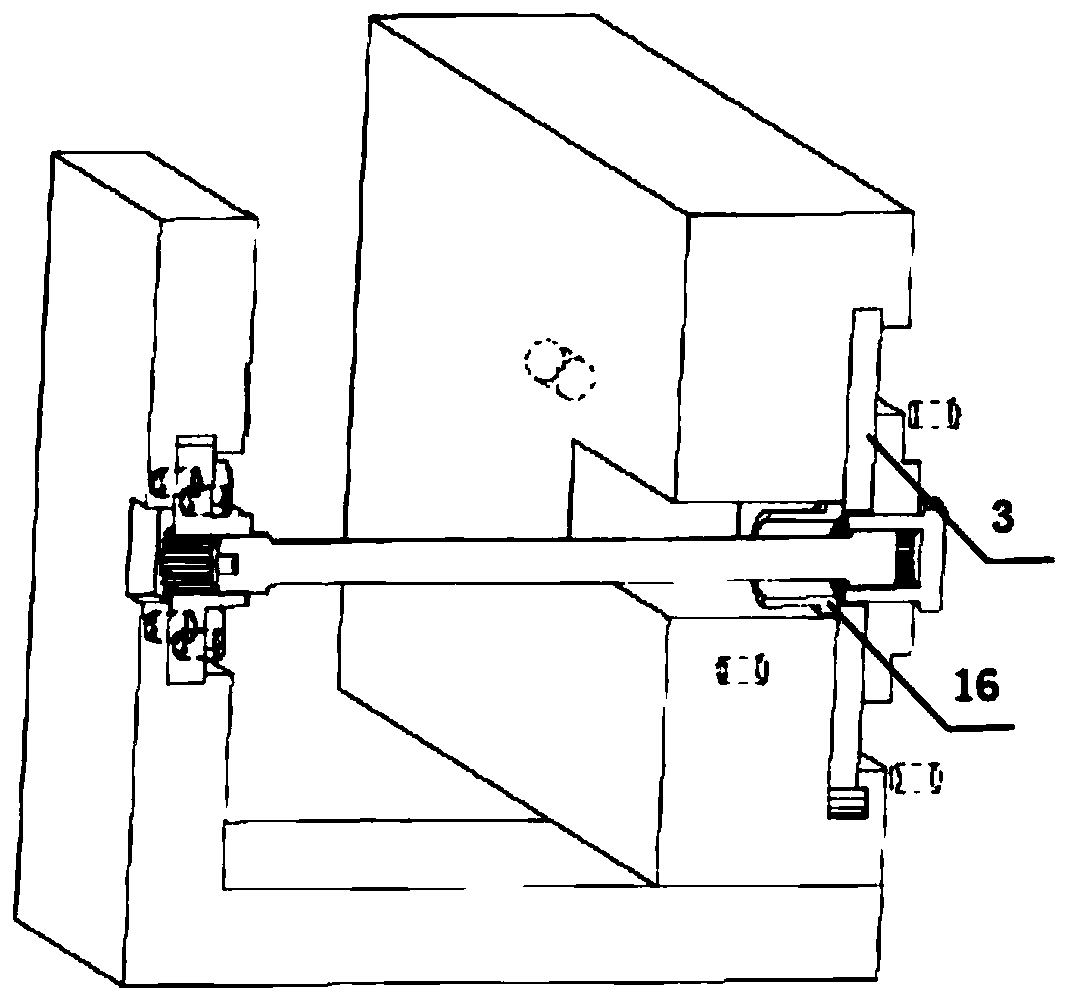

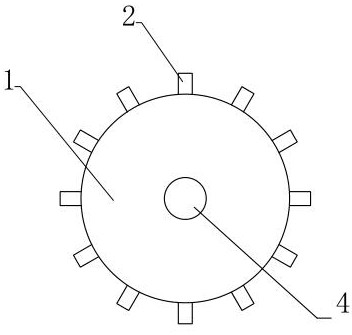

Load wheel test device with elastic damping element and induction tooth arc base

The invention discloses a load wheel test device with an elastic damping element and an induction tooth arc base. The device comprises a fixed frame (11) and a load wheel component. A motor (17) is mounted on the fixed frame (11). The output shaft of the motor (17) is connected with a drive wheel hub (1). The motor (17) drives the drive wheel hub (1) to rotate. The drive wheel hub (1) is near one side of the fixed frame (11), and protrudes from the edge of the side. An arc base (10) with induction teeth is arranged on the circumferential surface of the drive wheel hub (1). The load wheel component includes a load wheel (2) mounted on one side of the surface of the drive wheel hub (1). With the device adopted, the characteristic, durability and other performances of the load wheel under a simulated actual condition can be tested. Rotary shock absorbers with different damping forces can be selected and used together with a torsion bar spring to simulate the dynamic force applied to a load wheel on an actual vehicle and to reduce the vibration during test.

Owner:CHINA NORTH VEHICLE RES INST

Elastic contact structure of socket contact piece

PendingCN112864669AIncrease distanceIncrease flexibilityCoupling contact membersEngineeringMechanical engineering

The invention provides an elastic contact structure of a socket contact piece. The elastic contact structure is characterized in that a rotating block is arranged on the outer side of a ridge part of an insertion piece; a movable contact piece is arranged on the outer side of the rotating block; a static contact piece is arranged on the outer side of the movable contact piece; the upper end of the rotating block is pivoted and fixed; a convex stress part is arranged on one the portion, located at one side close to the ridge part and between an upper end and a lower end, of the rotating block; the lower end of the rotating block extends out towards a direction far away from the ridge part; the movable contact piece is a metal piece body and is provided with an elastic arm which is formed by bending and extending a horizontal bottom upwards; the top end of the elastic arm abuts against one side, far away from the ridge part, of the lower end of the rotating block; a movable contact is arranged between the upper end and the lower end of the elastic arm; and the static contact piece is a metal piece body and is provided with two supporting legs which are arranged in a separated mode, a suspension part is arranged between the two supporting legs, and a static contact is arranged on the suspension part. According to the invention, elastic contact between the contact pieces can be realized, so rigid impact is avoided, the operation hand feeling of insertion of the insertion piece can be improved, and the service life of the socket is prolonged.

Owner:JIANGSU GENERAL PROTECHT

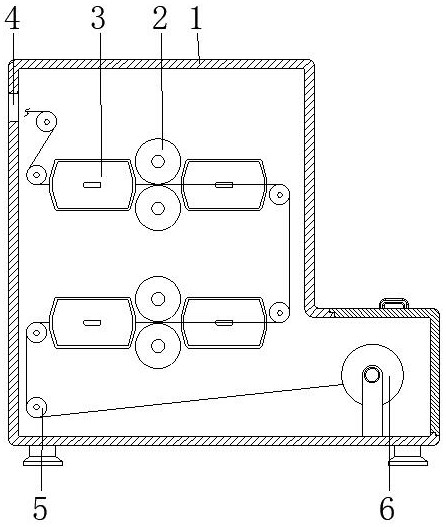

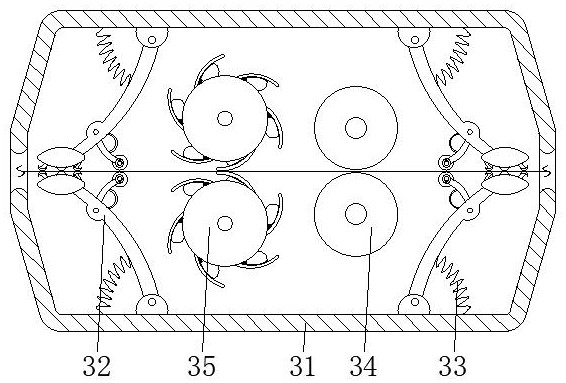

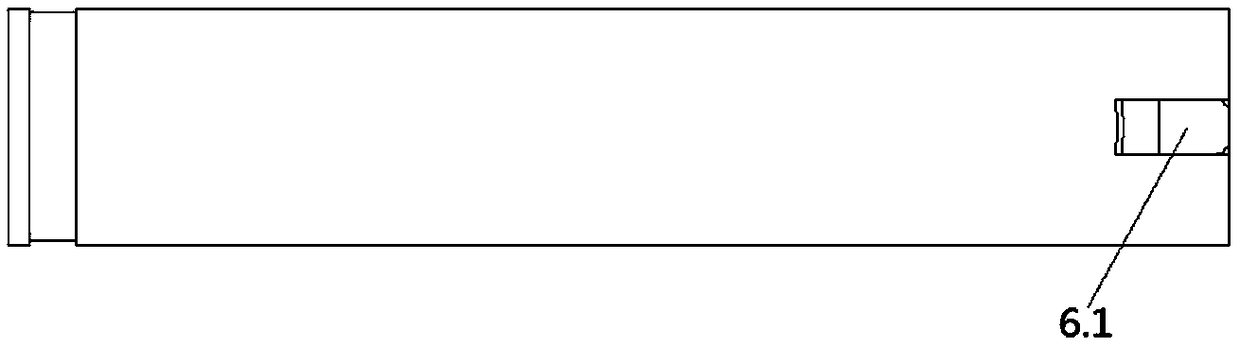

Lithium battery pole piece rolling mill

PendingCN114309063ALess susceptible to excessive tensionNot susceptible to too small an impactGuiding/positioning/aligning arrangementsWork treatment devicesPole pieceMachine

The lithium battery pole piece rolling mill comprises a machine body, a pressing roller and hot rolling devices, the pressing roller is arranged in the machine body and located in the center, the hot rolling devices are arranged in the machine body and located on the two sides of the pressing roller, a tensioning device is arranged in a box body and close to the end, and the hot pressing roller is arranged in the box body and close to the center. And the preheating device is arranged in the box body and close to the hot pressing roller, the bulldozing device is arranged at the end, away from the inner wall of the box body, of the supporting piece, and the pressing device is arranged on the surface of the supporting piece and close to the bulldozing device. According to the lithium battery pole piece rolling mill, the elastic tensioning effect is achieved, bi-directional and elastic tensioning can be conducted on a pole piece, the situation that the pole piece is affected by too large or too small tensioning force is not prone to occurring, and the situations of bending, loosening and wrinkling are not prone to occurring, so that subsequent hot rolling and rolling are facilitated, and the use performance is improved.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

Sliding temperature tactile sensor

InactiveCN102998023BIncrease contactImprove reliabilityMaterial heat developmentThermometers using electric/magnetic elementsInsulation layerEngineering

Owner:SOUTHEAST UNIV

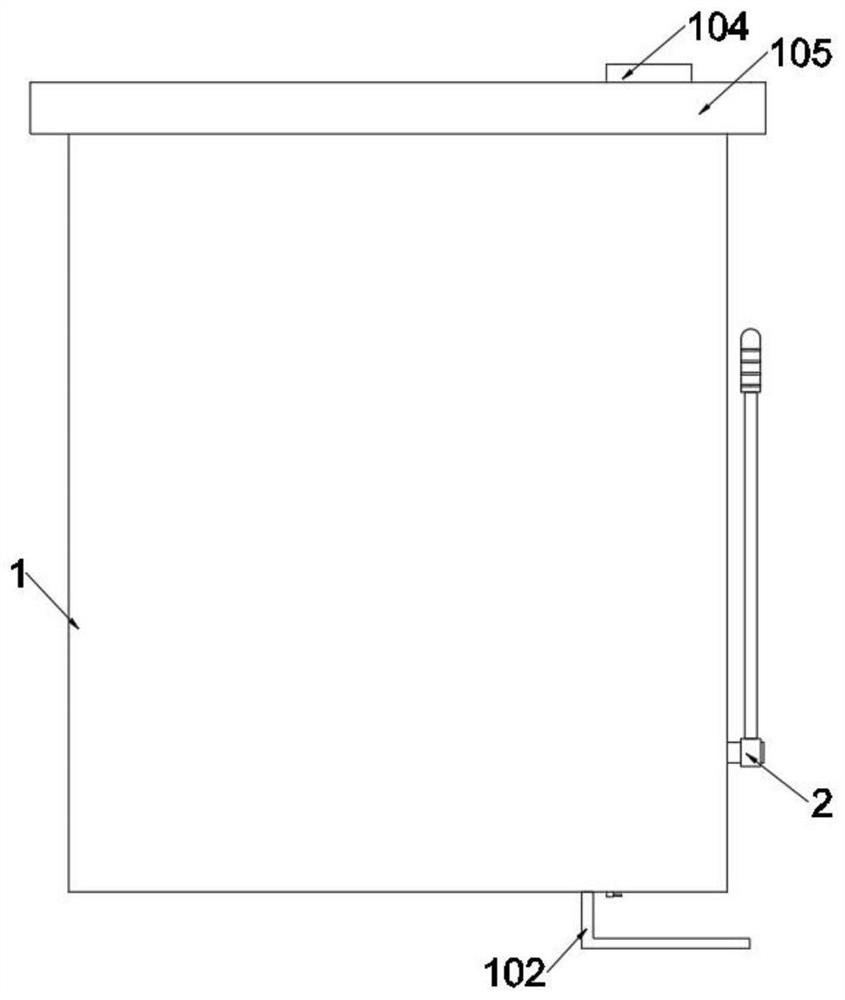

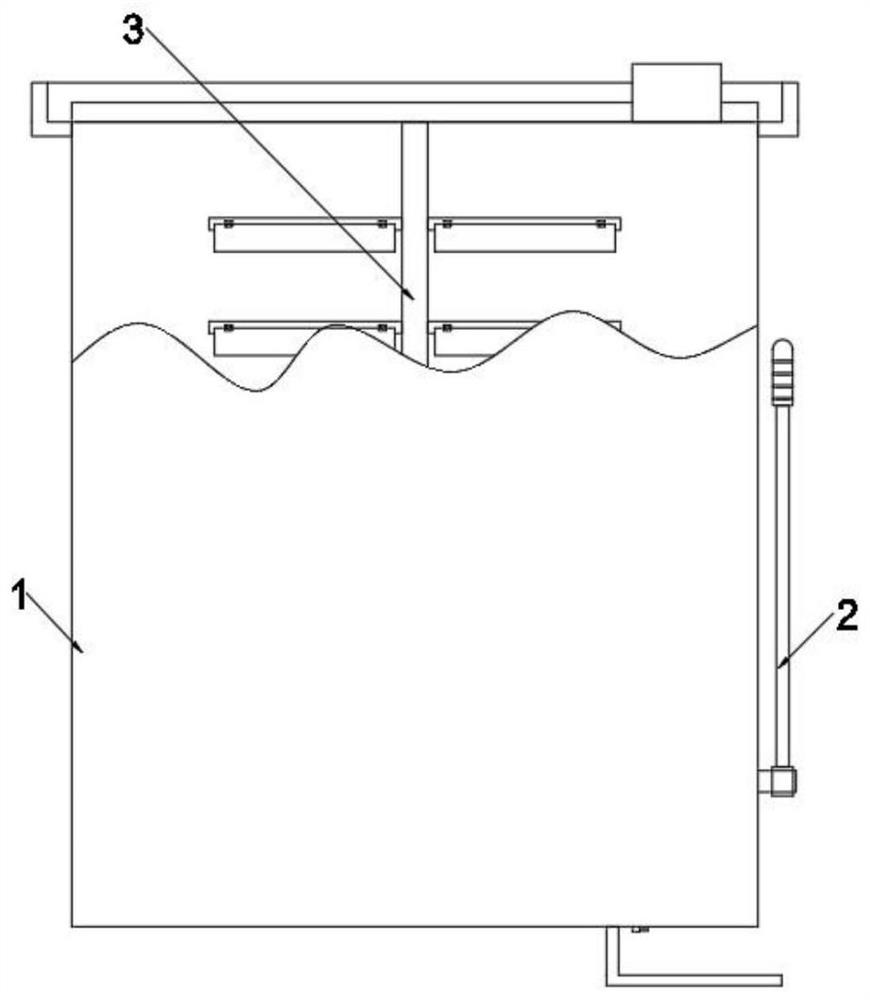

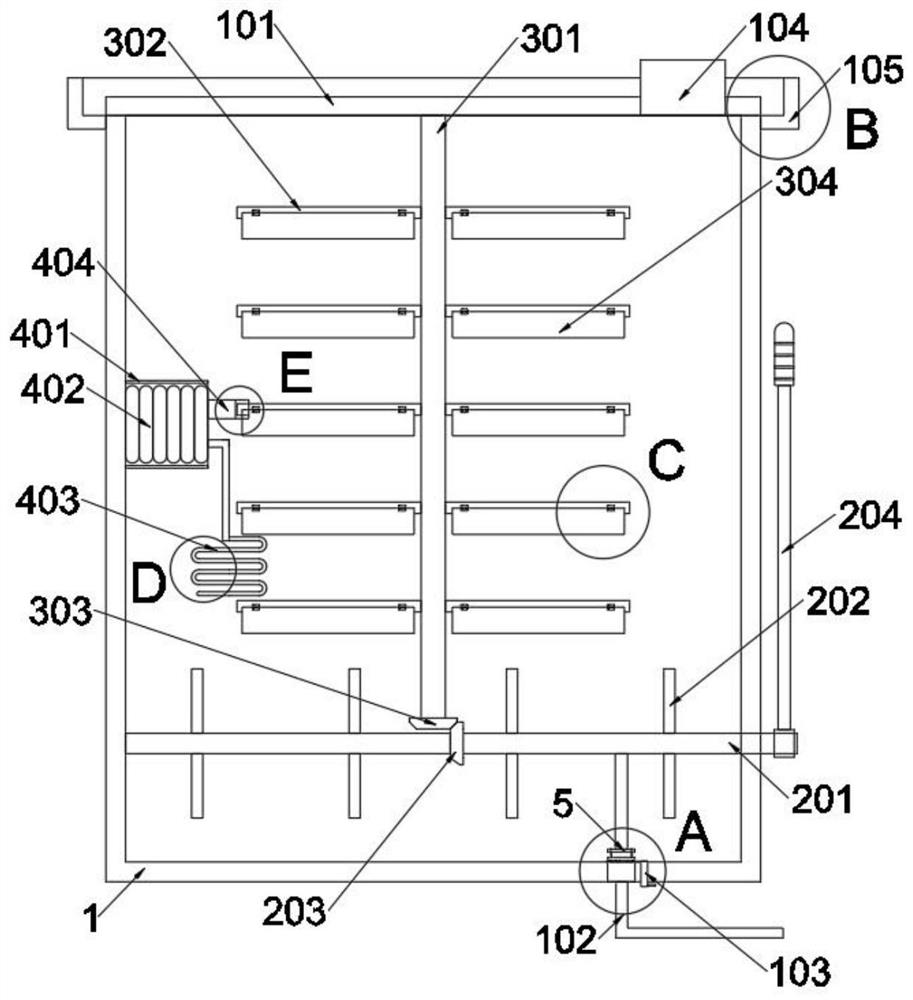

Liquid medicine mixing device for soil treatment

PendingCN112642320AReduce resistanceImproved Hybrid StructureFlow mixersTransportation and packagingSoil scienceEngineering

The invention provides a liquid medicine mixing device for soil treatment, relates to the technical field of medicine mixing devices, and solves the problem that: mutual linkage work of multiple mixing structures cannot be realized through structural improvement so as to improve the mixing efficiency; a filter screen cannot be automatically cleaned while rotating and mixing, and manual cleaning is troublesome and labor-consuming; and stirring blades are single in structure, so that the resistance to the liquid medicine is greatly influenced after the blades stop rotating. The liquid medicine mixing device for soil treatment comprises a mixing box body, a rotating shaft A and stirring teeth B, and a first stirring structure is mounted in the mixing box body, and a second mixing structure is further mounted in the mixing box body. Each stirring tooth B is rotationally connected with a rectangular plate through a hinge, and the rectangular plates rotationally connected to the stirring teeth B form a resistance eliminating structure of a second mixing structure, so that after the rotating shaft A stops rotating, the liquid medicine can push the rectangular plates to rotate and lift, and the resistance to the rotation of the liquid medicine is reduced.

Owner:李述斌

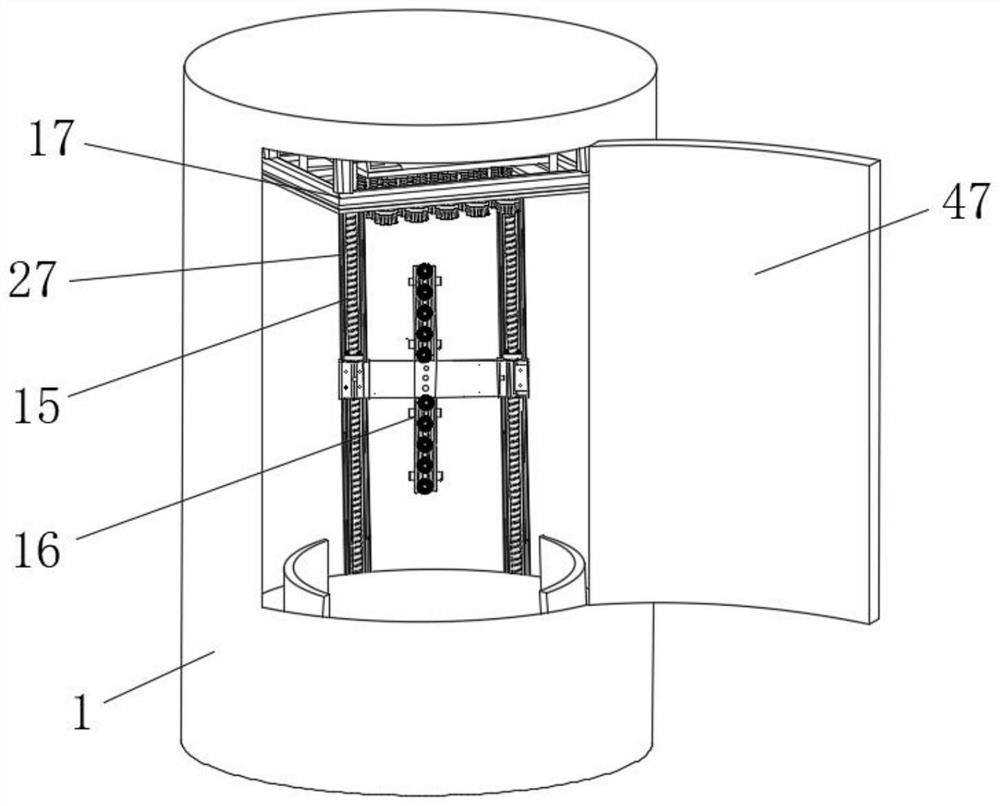

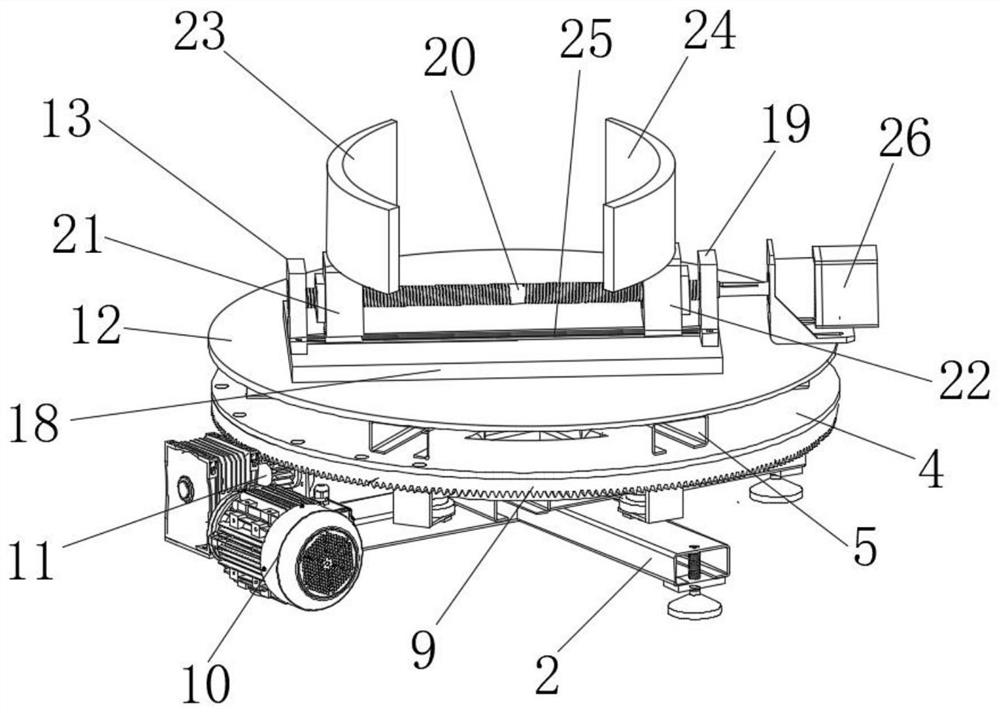

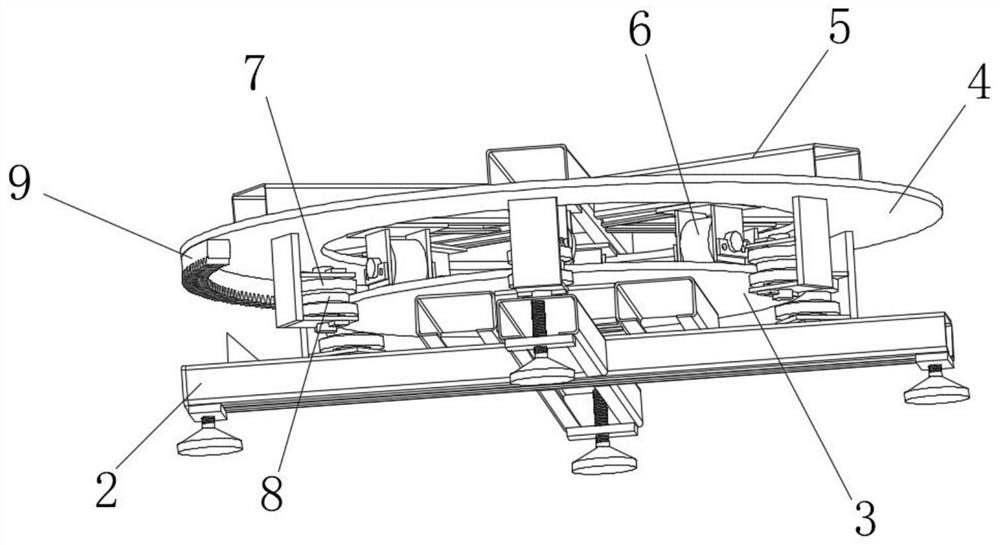

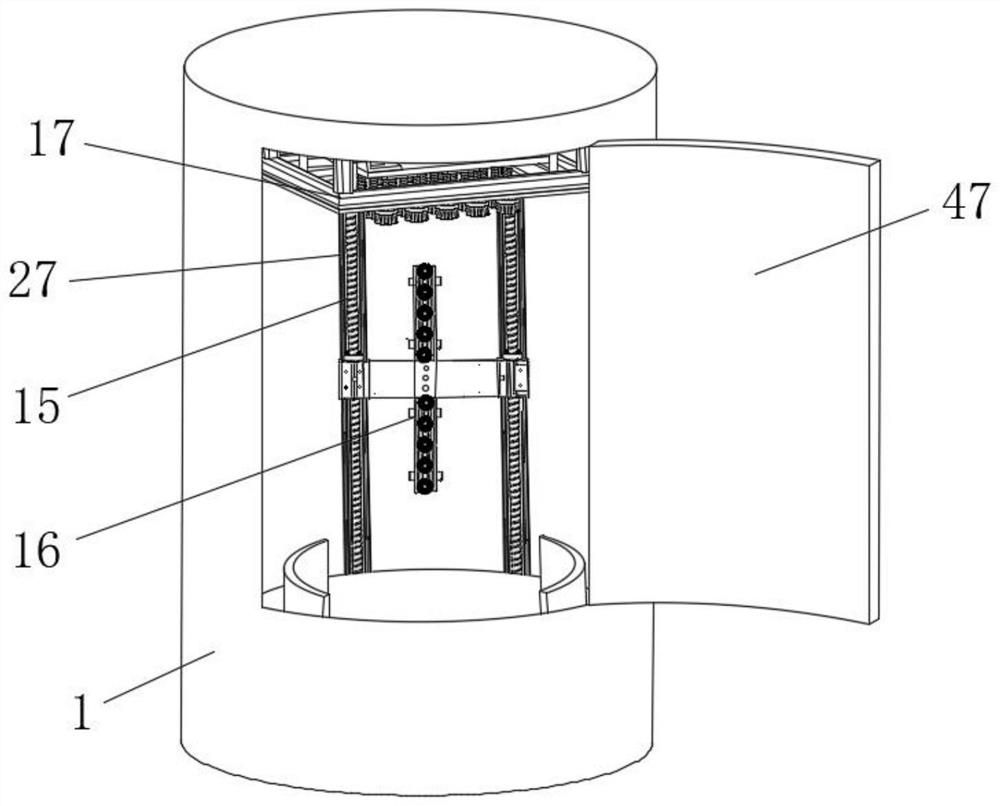

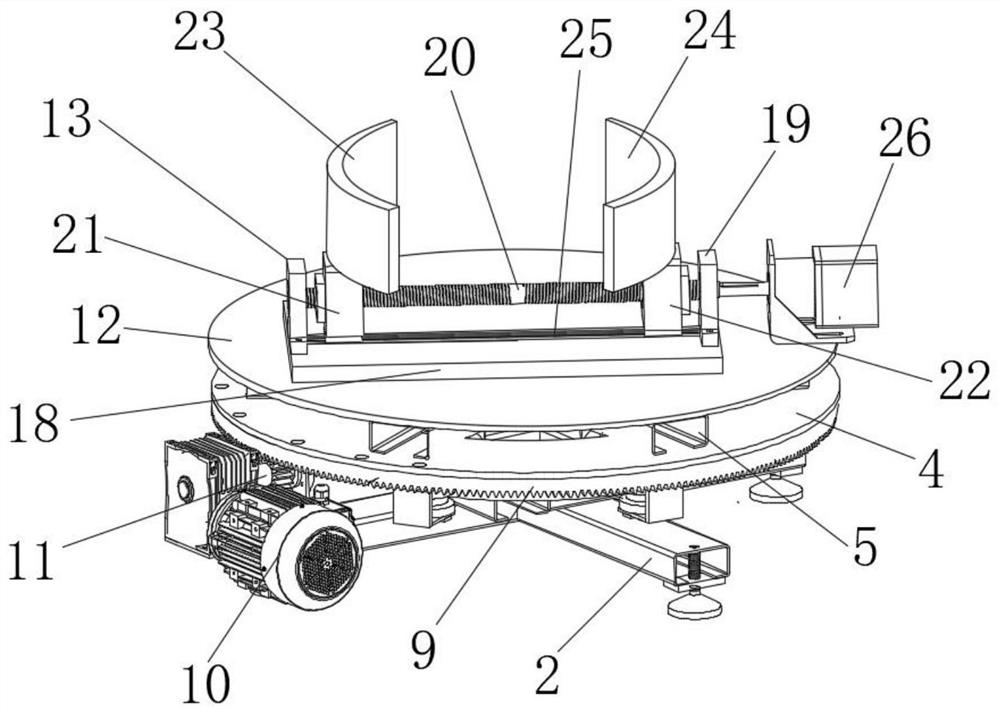

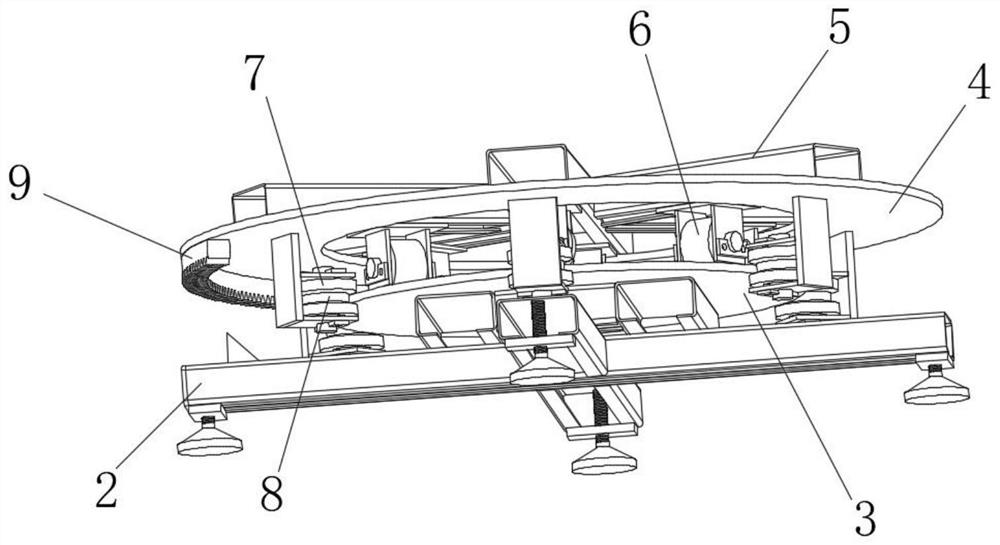

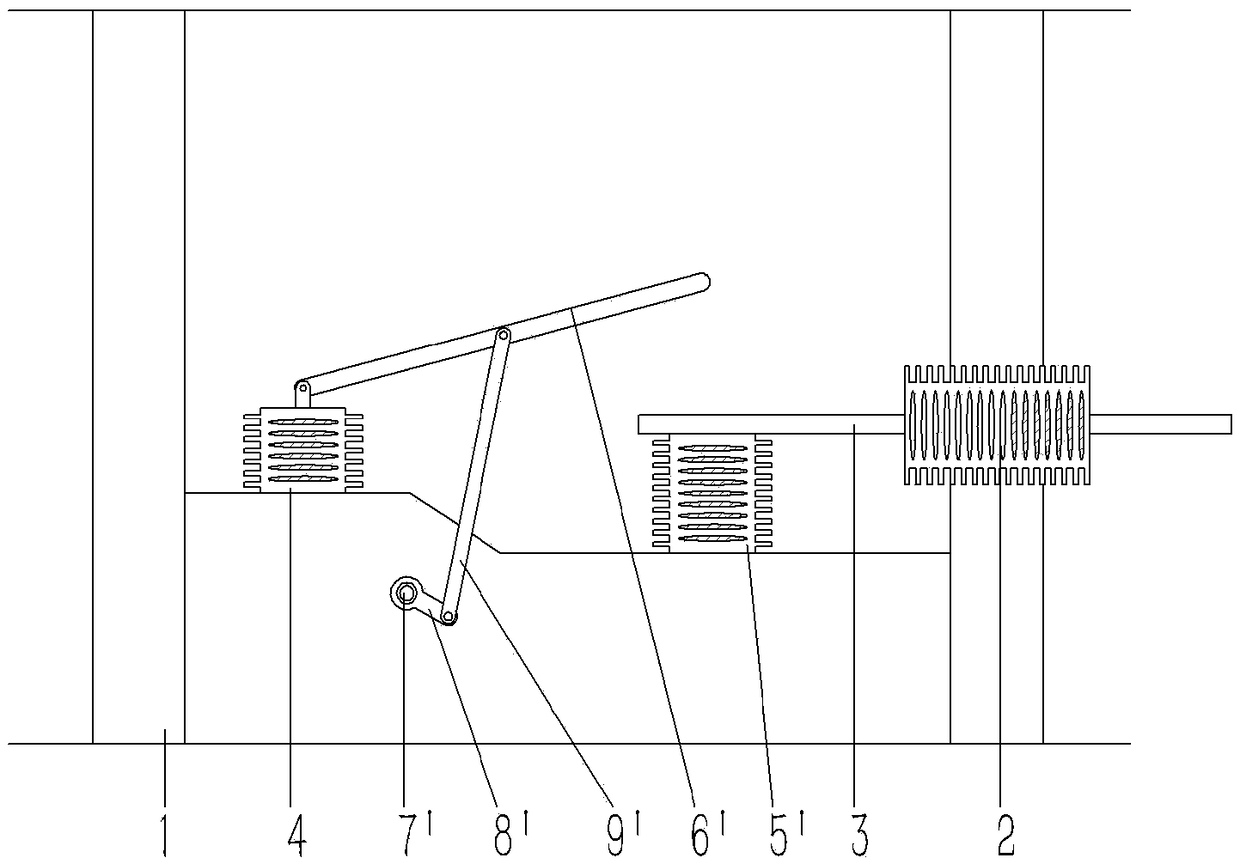

A device for removing rust on the surface of an iron drum

ActiveCN112405282BGuaranteed uptimeFast processingGrinding drivesGrinding machinesElectric machineGear wheel

The invention discloses a device for removing rust on the surface of an iron drum, which comprises a rust removal room, a foot support is provided on the bottom surface of the rust removal room, an orbital disc is fixed on the foot support, and a rotating ring is arranged above the orbital disc; The middle part is fixed with a carriage, and the lower end surface of the bracket is provided with a plurality of first rollers; the lower end surface of the rotating ring is provided with a plurality of second rollers, and the middle part of the second rollers is provided with a rolling groove, which is clamped on the track The side end surface of the disc; the outer side of the lower end surface of the rotating ring is provided with a rack; one side of the foot support is provided with a rotating motor, and the output end of the rotating motor is connected with a driving gear meshing with the rack; The upper end is provided with a fixed plate, and the fixed plate is provided with a clamping mechanism; one side of the derusting room is provided with a lifting mechanism, and the lifting mechanism is provided with a side wall derusting mechanism; the top surface of the derusting room is provided with a top Wall derusting device. The invention can efficiently and quickly derust the surface of the iron drum, and has the advantages of fast processing speed, convenient use and high work efficiency.

Owner:安徽安发机械有限公司

Electronic cigarette conductive contact column and elastic conductive contact body

The invention discloses a conductive contact pole of an electronic cigarette. The conductive contact pole comprises a columnar sliding body, which is made from a conductor material, and an insulating base, wherein a disc-shaped electric contact point is arranged at the top of the columnar sliding body; and a radial limiting column body is arranged at the lower part of the disc-shaped electric contact point. The base is a cavity barrel-shaped body which is provided with a bottom limiting hole; the limiting hole is matched with the radial limiting column body of the columnar sliding body, so that radial limiting is achieved; and the columnar sliding body, instead of radial rotation, is capable of doing axial sliding in the limiting hole of the base. A columnar connecting part is arranged at the other end of the columnar sliding body; a fastening ring is arranged on the columnar connecting part; and a seal ring and a reset elastic body are arranged between the columnar sliding body and the base.

Owner:INNOKIN TECH

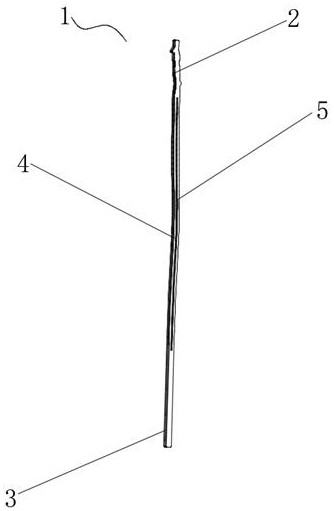

Wafer test micro probe based on micro electro mechanical system

PendingCN111929479ALittle elasticityReduce volumeElectrical measurement instrument detailsDecorative surface effectsMicro electrical mechanical systemsEngineering

The invention discloses a wafer test micro probe based on a micro electro mechanical system. The probe comprises a probe main body, the probe main body is of an approximately L-shaped structure, the probe main body comprises a first end part, a second end part and a connecting part located between the first end part and the second end part and used for connecting the first end part and the secondend part, a groove parallel to the connecting part is formed in the connecting part, and the groove penetrates through the connecting part front and back. The probe provided by the invention can be used for testing chips with small spacing.

Owner:SUZHOU TAOSHENG ELECTRONICS TECH CO LTD

Iron drum surface rust removal device

ActiveCN112405282AGuaranteed uptimeFast processingGrinding drivesGrinding machinesMetallurgyElectric machine

The invention discloses an iron drum surface rust removal device. The iron drum surface rust removal device comprises a rust removal chamber, a foot support is arranged on the bottom surface of the rust removal chamber, a rail disc is fixed to the foot support, and a rotating ring is arranged above the rail disc. A bracket is fixed in the middle of the rotating ring, and a plurality of first rollers are arranged on the lower end surface of the bracket; a plurality of second rollers are arranged on the lower end face of the rotating ring, and rolling grooves are formed in the middles of the second rollers and clamped in the side end faces of the rail disc; a rack is arranged on the outer side of the lower end surface of the rotating ring; a rotating motor is arranged on one side of the footsupport, and the output end of the rotating motor is connected with a driving gear meshing with the rack; a fixed disc is arranged at the upper end of the bracket, and a clamping mechanism is arranged on the fixed disc; a lifting mechanism is arranged on one side of the rust removal chamber, and a side wall rust removal mechanism is arranged on the lifting mechanism; and a top wall rust removal device is arranged on the top surface of the rust removal chamber. The iron drum surface rust removal device can remove rust on the surface of an iron drum efficiently and quickly, and has the advantages of being high in machining speed, convenient to use and high in working efficiency.

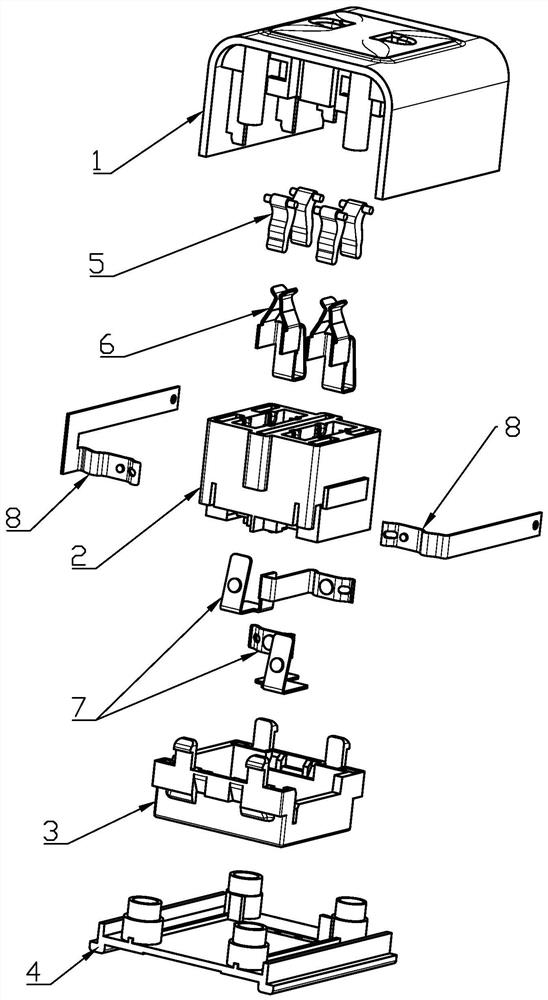

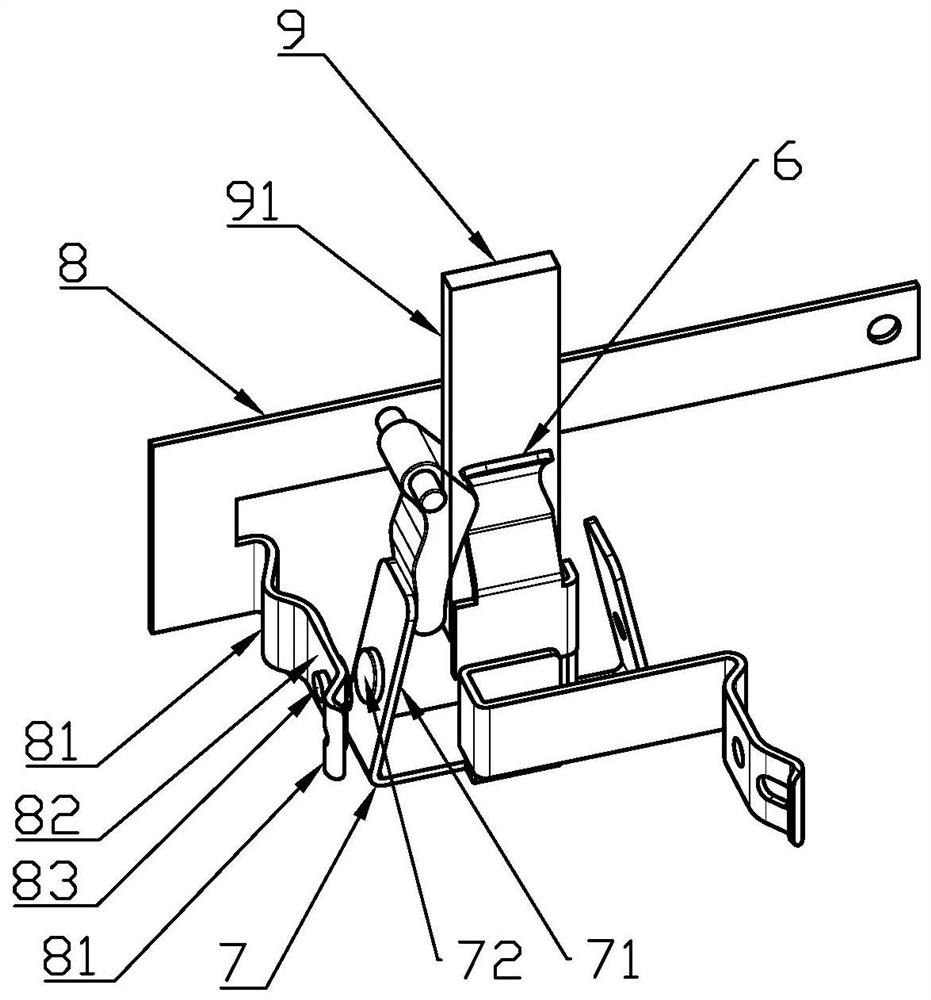

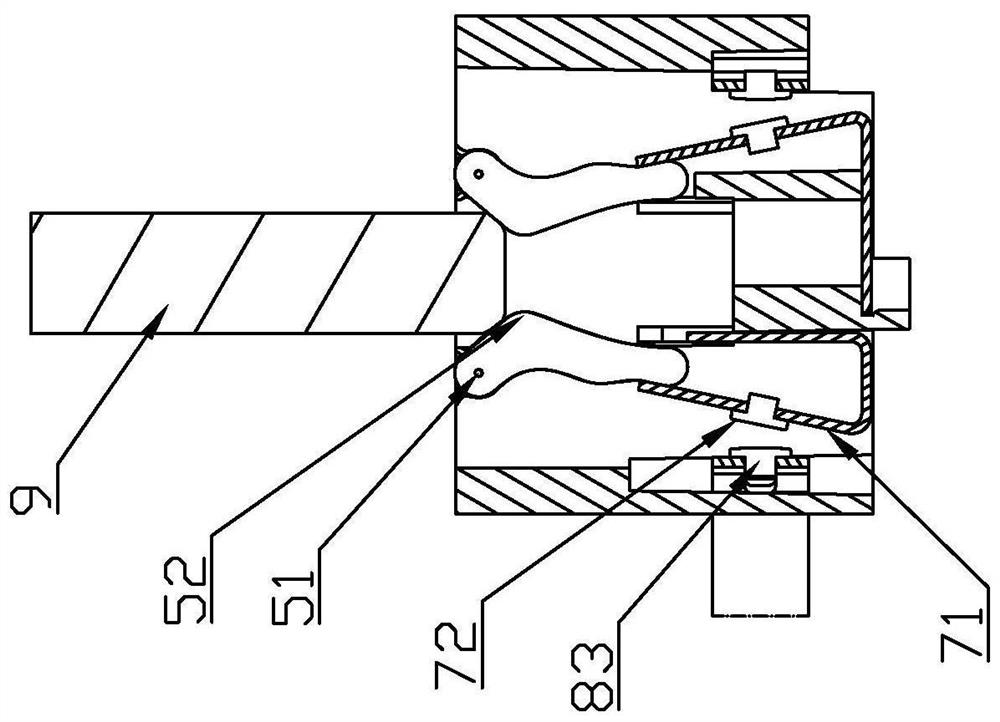

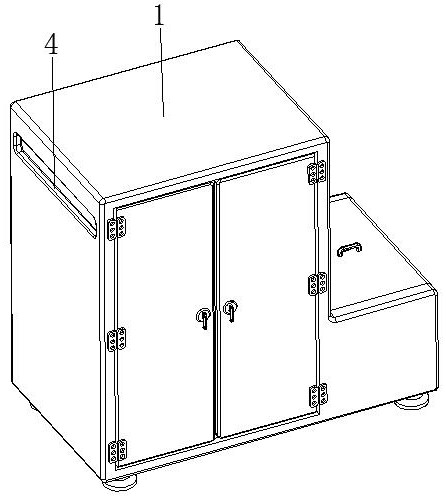

Structure-optimized switch cabinet

InactiveCN109449036AStructural improvementAvoid severe deformationSubstation/switching arrangement detailsDrive shaftEngineering

The invention discloses a structure-optimized switch cabinet. The structure-optimized switch cabinet comprises a cabinet body of the switch cabinet, wherein multiple groups of knife switch assembliesare arranged in the cabinet body, a horizontal insulation sleeve is fixedly inserted into a side wall of one side of the cabinet body, a horizontal copper bar is inserted into the insulation sleeve, one end of the copper bar is inserted into the cabinet body, the other end of the copper bar is exposed out of an outer side of the cabinet body, an irregularly-shaped knife switch is inserted into thecabinet body and is opposite to the copper bar, an upper elastic contact piece and a lower elastic contact piece are formed in one end, near to the copper bar, of the irregularly-shaped knife switch,two ends of the elastic contact pieces elastically prop against an upper end surface and a lower end surface of the copper bar, the other end of the irregularly-shaped knife switch is fixedly inserted to a vertical support shaft, a lower end of the support shaft is hinged with a first insulator, the first insulator is fixed in the cabinet, a driven bevel gear is fixedly inserted to an upper end surface, extending out of the irregularly-shaped knife switch, of an upper end of the support shaft, a driving bevel gear is engaged with the driven bevel gear, a driving shaft is fixedly inserted to the driving bevel gear, and two ends of the driving shaft are hinged with the cabinet body. By the structure-optimized switch cabinet, the situation that the knife switch is seriously deformed and is unfavorably contacted with the copper bar in the prior art is prevented.

Owner:王赛

Road Wheel Test Device with Elastic Damping Elements and Induced Tooth Curved Base

The invention discloses a load wheel test device with an elastic damping element and an induction tooth arc base. The device comprises a fixed frame (11) and a load wheel component. A motor (17) is mounted on the fixed frame (11). The output shaft of the motor (17) is connected with a drive wheel hub (1). The motor (17) drives the drive wheel hub (1) to rotate. The drive wheel hub (1) is near one side of the fixed frame (11), and protrudes from the edge of the side. An arc base (10) with induction teeth is arranged on the circumferential surface of the drive wheel hub (1). The load wheel component includes a load wheel (2) mounted on one side of the surface of the drive wheel hub (1). With the device adopted, the characteristic, durability and other performances of the load wheel under a simulated actual condition can be tested. Rotary shock absorbers with different damping forces can be selected and used together with a torsion bar spring to simulate the dynamic force applied to a load wheel on an actual vehicle and to reduce the vibration during test.

Owner:CHINA NORTH VEHICLE RES INST

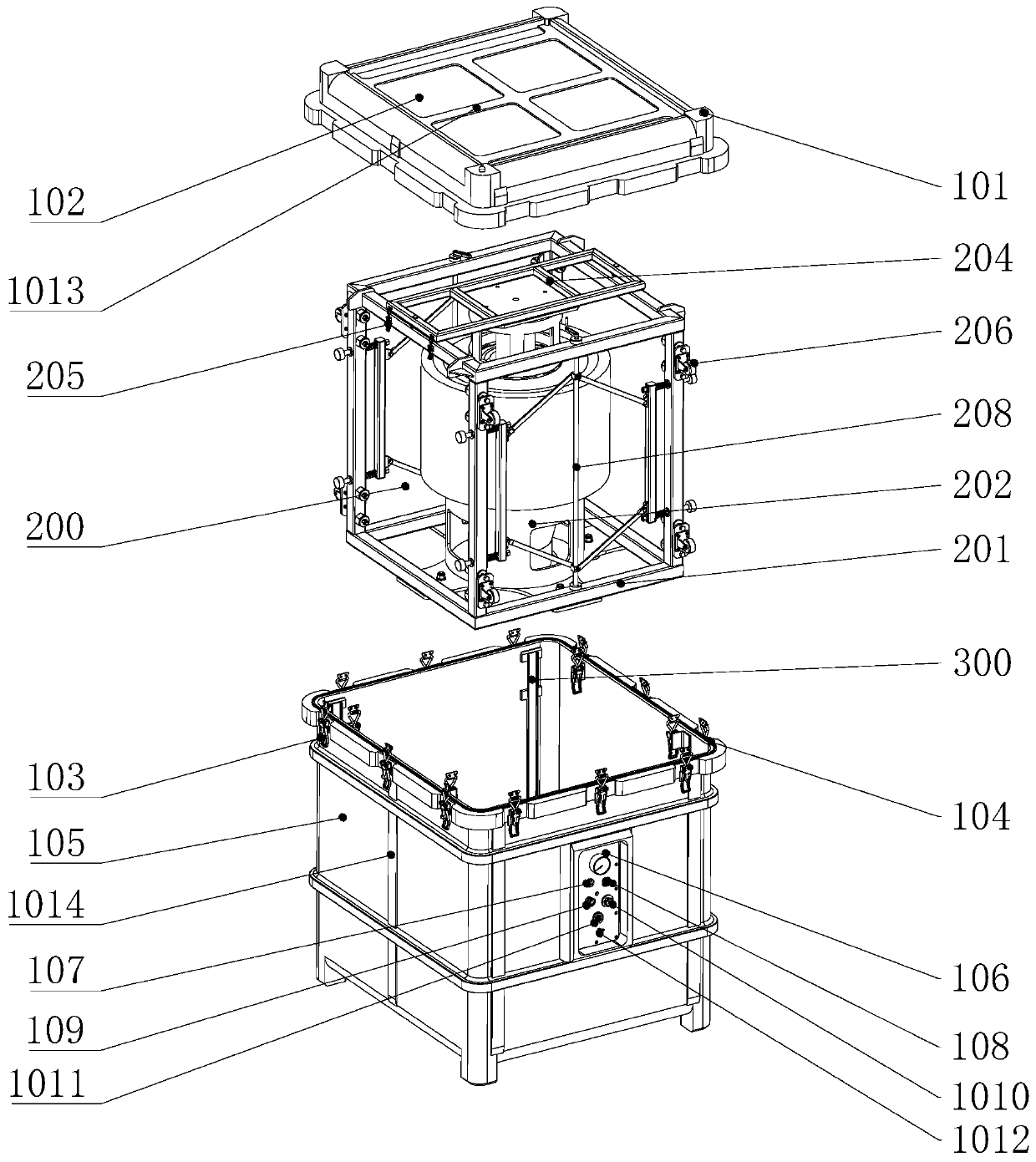

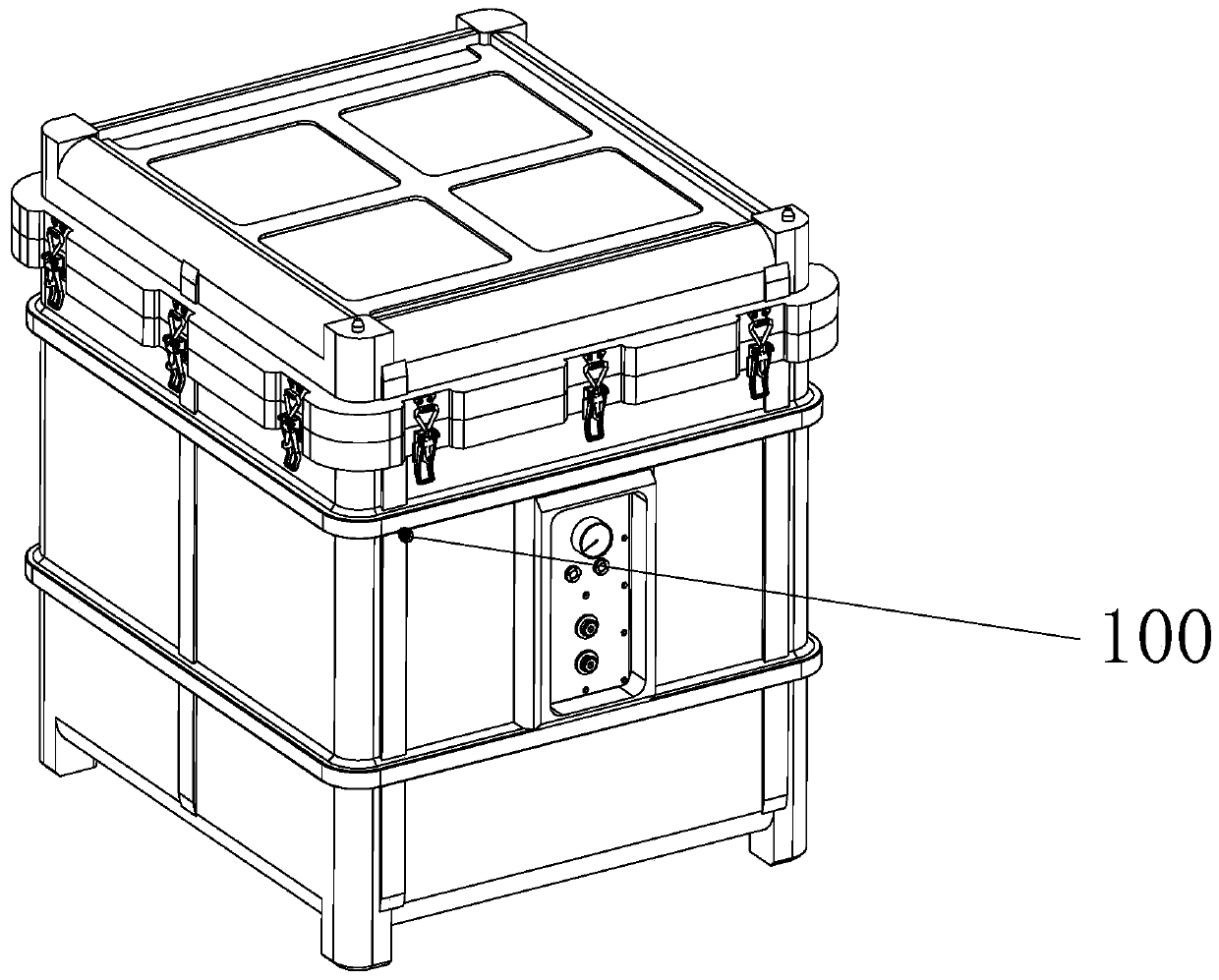

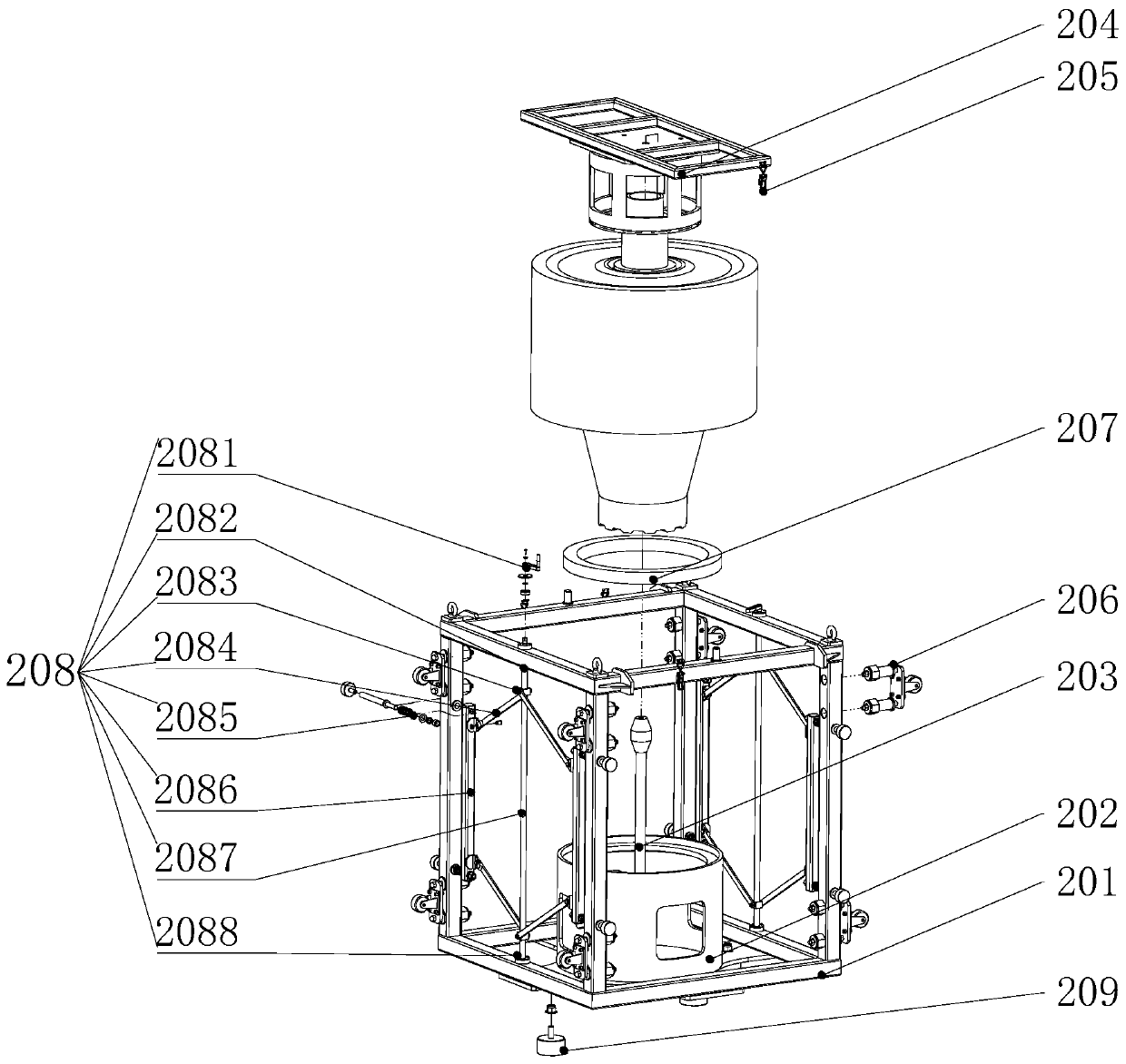

Heavy article storage and transportation box

PendingCN111301828AConvenient internal humidityConvenient and quick air tightnessRigid containersClamping mechanismMechanical engineeringIndustrial engineering

The invention relates to the technical field of storage and transportation boxes, in particular to a heavy article storage and transportation box. The heavy article storage and transportation box is provided with a storage and transportation box body and a retainer, the retainer is hoisted into the storage and transportation box body and makes elastic fixed contact with the storage and transportation box body; and four vertical guide rails are further arranged on the inner wall of the storage and transportation box body, and the retainer plays a role in guiding through the guide rails and is hoisted in place. According to the heavy article storage and transportation box, a sealed, safe and reliable storage environment can be effectively provided for products, and elastic contact between acontained object and the external environment can be realized, so that the products are better protected; and the heavy article storage and transportation box can be assembled with the contained object into a whole, so that the safety of the contained object in the storage and transportation process is ensured.

Owner:CHANGZHOU ZHONGHANG TAIKE SHIP EQUIP

Bump pressure roller device

Owner:LAIZHOU JINGCHENG RUBBER

Spiral jack

The invention provides a spiral jack and relates to the technical field of hoisting equipment. The spiral jack comprises a handle, a base, a supporting pipe, a shell connecting the base and the supporting pipe, a thrust bearing, a first bevel gear connected with the thrust bearing in a matched manner, a guiding pipe arranged inside the supporting pipe, a jacking rod, a large screw rod, a small screw rod, a jacking head component, a second bevel gear and a gear shaft, wherein the joint of the shell and the gear shaft is provided with a gear shaft sleeve arranged on the outer side of the gear shaft in a sleeving manner, the outer wall of the gear shaft sleeve is relatively fixed with the shell, the end portion, close to the second bevel gear, of the gear shaft sleeve is provided with an elastic structure connected with the end face of the second bevel gear in an abutted manner, the periphery of the elastic structure is arranged at the end portion of the gear shaft sleeve, and the elasticstructure is in a compression state all the time. According to the spiral jack, the outer sides of the jacking rod and the guiding pipe are provided with a first sliding block and a second sliding block which are molded in an integrated manner correspondingly, the sliding blocks are arranged on the outer side, the processing efficiency is improved, by means of the gear shaft sleeve with elastic pieces, jamming appearing in the gear transmission process is effectively solved, and the service life of the jack is prolonged.

Owner:NANTONG TONGRUN AUTO ACCESSORY

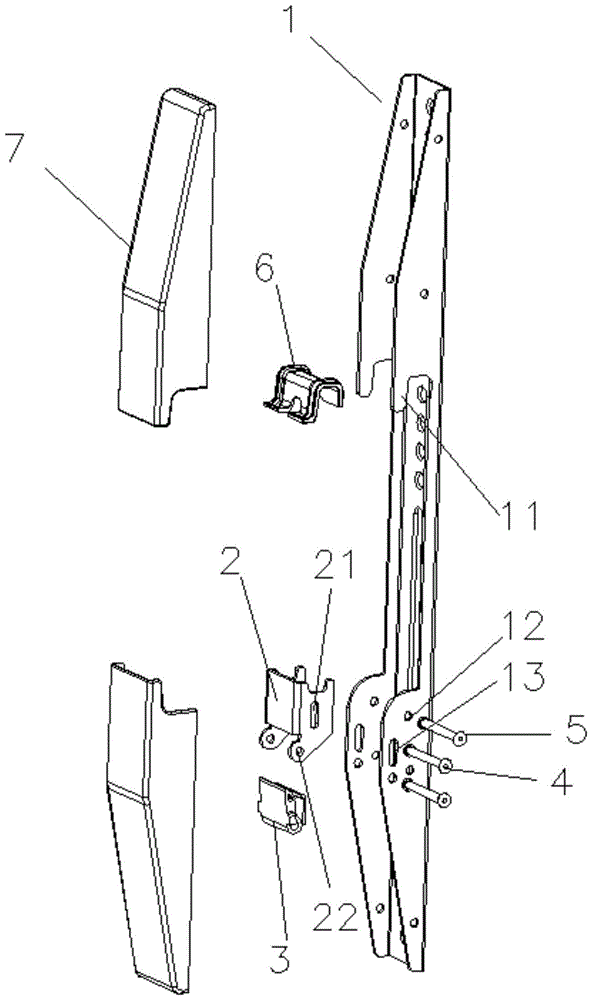

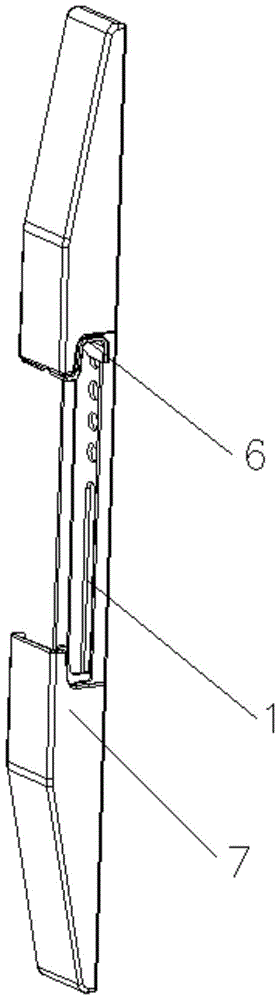

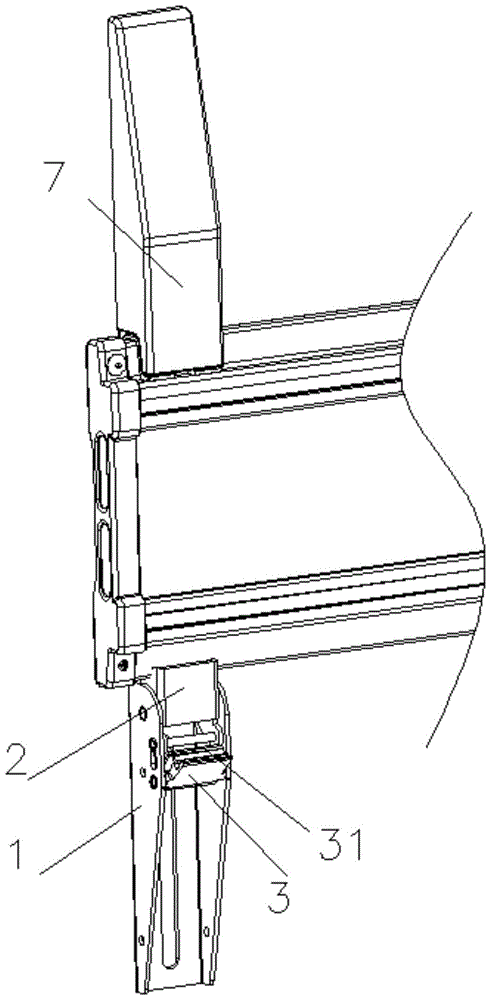

New hook fastening structure

ActiveCN104913169BAchieve releaseAchieving Elastic ContactMachine supportsEngineeringSurface structure

The invention discloses a novel hook fastening structure. The novel hook fastening structure comprises a hook body of a U-shaped structure, and coupler bodies are arranged at one end of the opening side of the U-shaped structure of the hook body; the opening direction of the coupler bodies faces the other end of the hook body, and the novel hook fastening structure is further provided with a locking hook and a driving component; the locking hook can slide in the length direction of the hook body to be located at the other end of the hook body, and opening clamping grooves opposite to the coupler bodies are formed in one side, facing the coupler bodies, of the locking hook; and the driving component can drive the locking hook to move to the designated position in a manner of facing the direction of the coupler bodies. According to the structure, the driving component drives the locking hook to vertically slide so as to achieve fastening and loosening of the hook and a hanging plate; an elastic body is adopted in the driving component, and an inclined surface structure is arranged on the elastic body to tightly jack the locking hook; the elastic body rotates so as to enable the elastic body to slide in a manner of jacking the locking hook, and the elastic contact between the locking hook and the hanging plate is achieved; and according to the structure, in the adjustment process, a user only needs to press the elastic body, operation is convenient, labor is saved, and the phenomenon that due to the hard contact between the locking hook and the hanging plate, the surface is scratched is avoided.

Owner:KUNSHAN HONGJIE ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com