A device for removing rust on the surface of an iron drum

An iron barrel and bottom surface technology, which is applied to grinding drive devices, grinding/polishing safety devices, manufacturing tools, etc., can solve problems such as poor processing effect, surface rust, performance impact, etc., and achieve high work efficiency and processing speed. Fast, smooth running results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

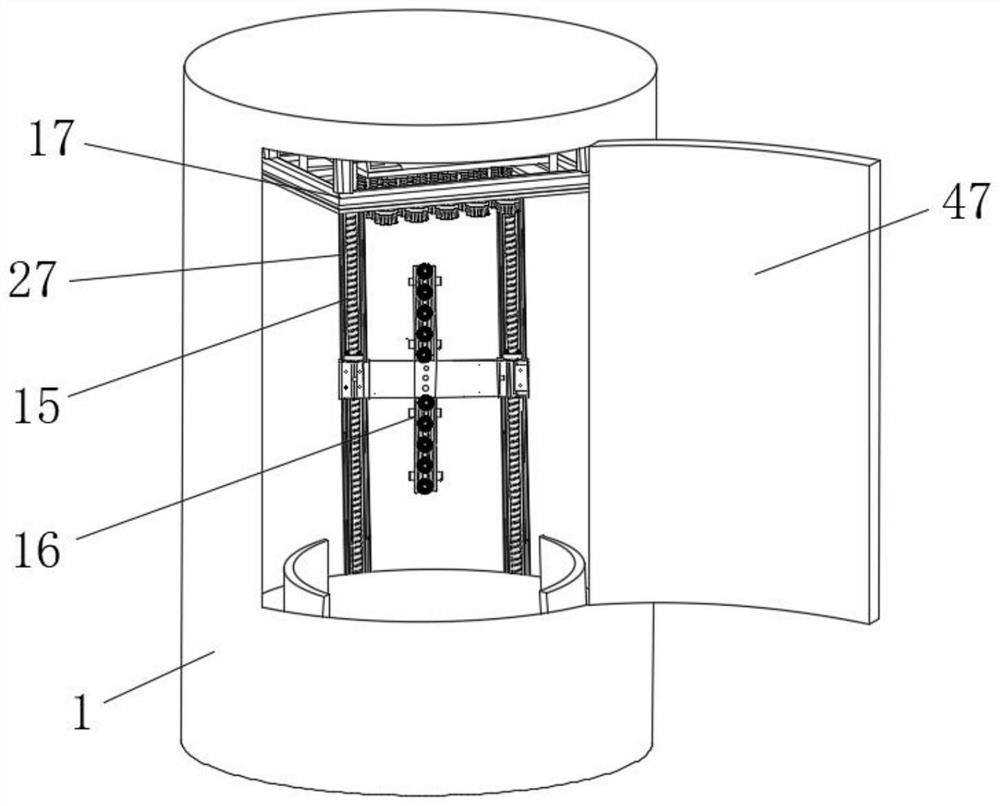

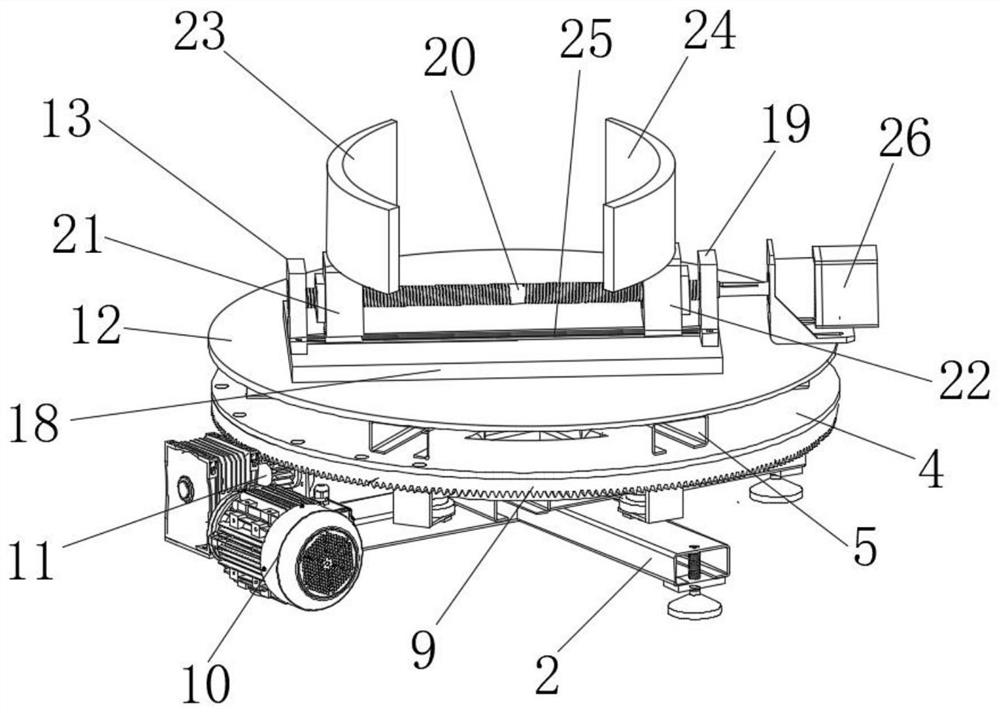

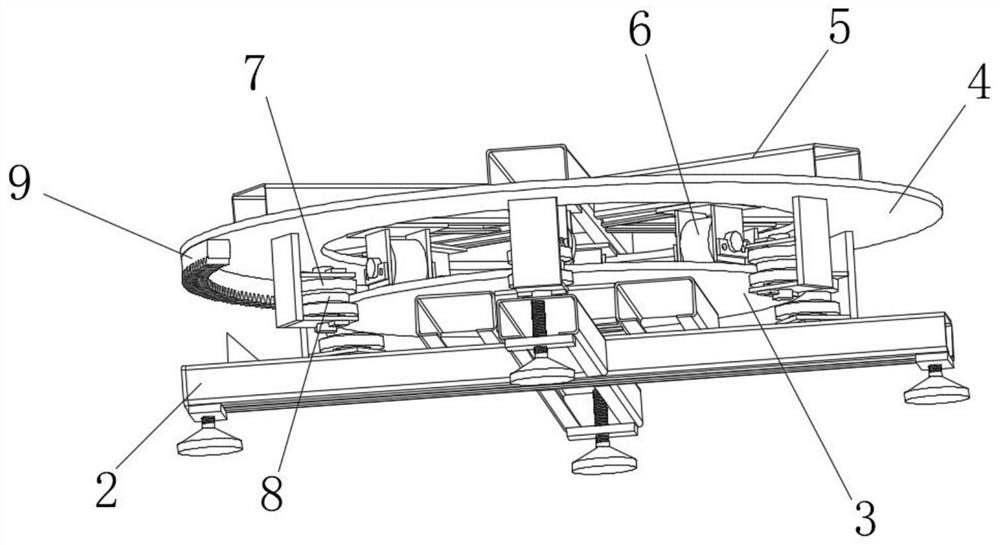

[0027] Embodiment: a kind of iron drum surface derusting device, as Figure 1-3 Shown, comprise derusting room 1, the bottom surface of derusting room 1 is provided with cross-shaped foot support, and circular orbit disc 3 is fixed on the foot support 2, and the top of orbit disc 3 is provided with rotating ring 4; The middle part of the ring 4 is fixed with a carriage 5, and the lower end surface of the carriage is provided with a plurality of annularly distributed first rollers 6, and the first rollers 6 are placed on the upper surface of the track disc 3; the lower end surface of the rotating ring 4 is provided with A plurality of annularly distributed second rollers 7, the middle part of the second rollers 7 is provided with a rolling groove 8, and the rolling groove 8 is clamped on the side end surface of the track disk 3; the outer side of the lower end surface of the rotating ring 4 is provided with an annular rack 9; It should be noted that, image 3 In order to show ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com