Iron drum surface rust removal device

An iron barrel and bottom surface technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of poor processing effect, low efficiency, performance impact, etc., and achieve high work efficiency and good clamping effect , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

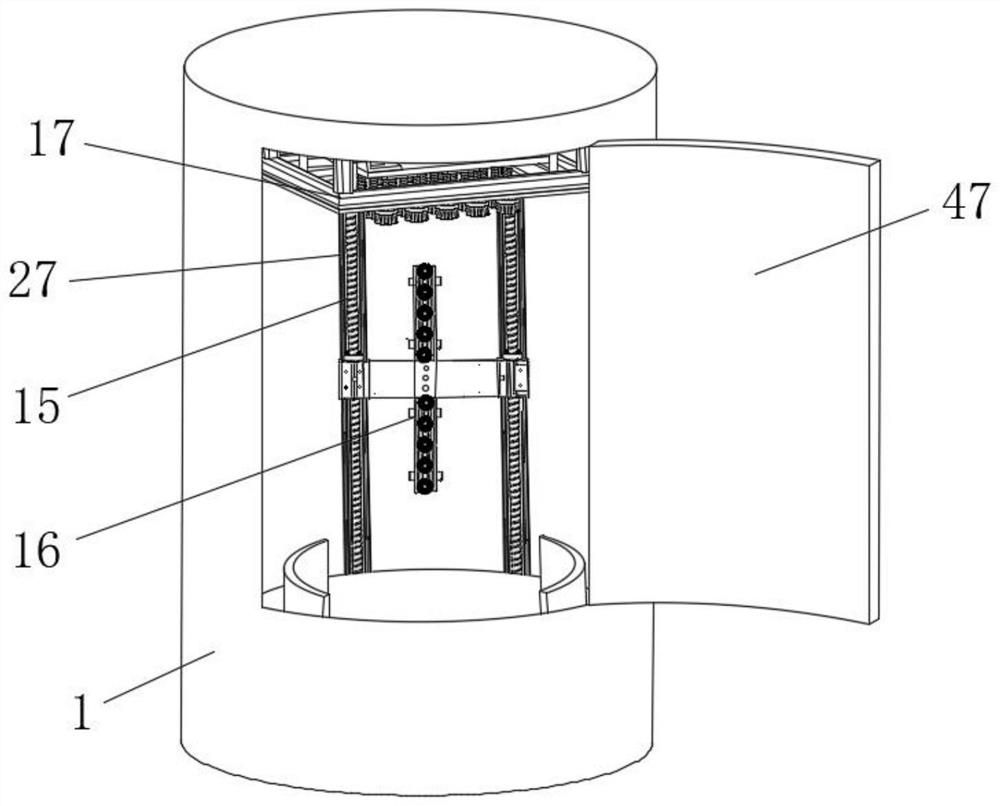

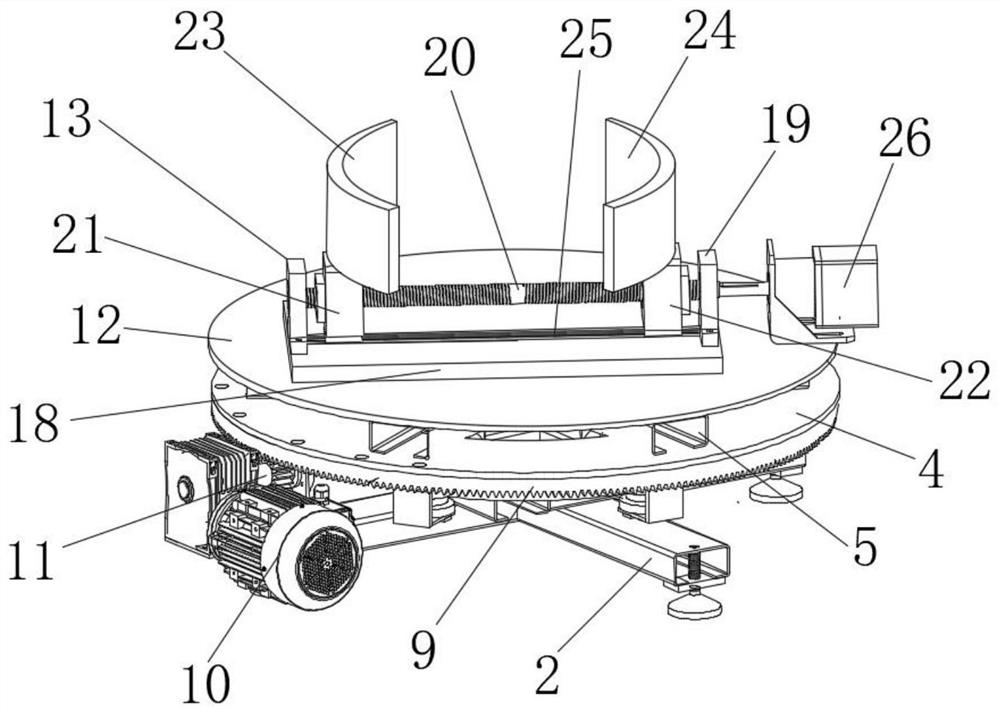

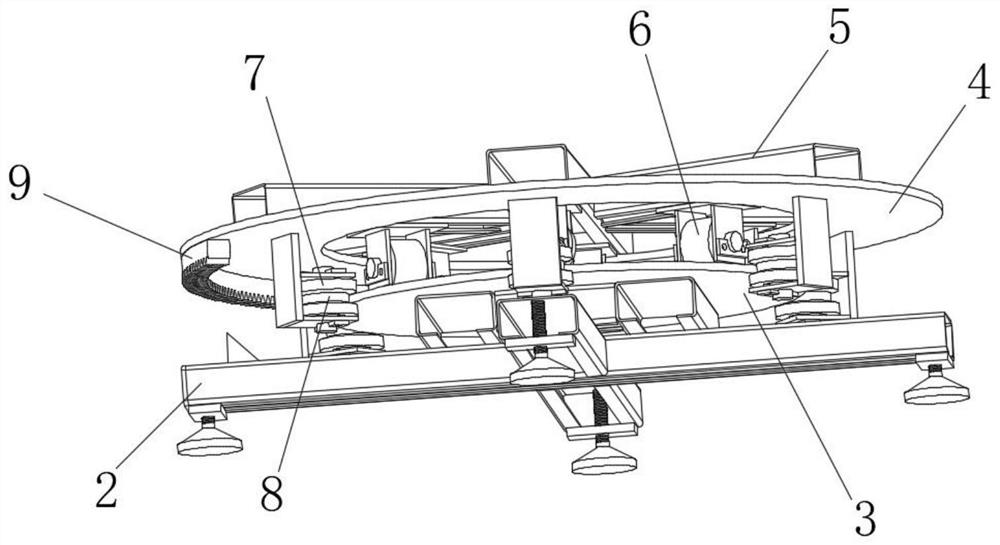

[0027] Embodiment: a kind of iron bucket surface derusting device, as Figure 1-3 As shown, the derusting chamber 1 is included, the bottom surface of the derusting chamber 1 is provided with a cross-shaped foot support, and a circular orbital disc 3 is fixed on the foot drag 2, and a rotating ring 4 is arranged above the orbital disc 3; The middle part of the ring 4 is fixed with a carriage 5, and the lower end surface of the carriage is provided with a plurality of annularly distributed first rollers 6, and the first rollers 6 are placed on the upper surface of the track disc 3; the lower end surface of the rotating ring 4 is provided with A plurality of annularly distributed second rollers 7, the middle part of the second rollers 7 is provided with a rolling groove 8, and the rolling groove 8 is clamped on the side end surface of the track disk 3; the outer side of the lower end surface of the rotating ring 4 is provided with an annular rack 9; It should be noted that, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com