Cleaning device for tempered glass deep processing

A cleaning device and tempered glass technology, which is applied to the cleaning method using tools, the cleaning method using liquid, the cleaning method using gas flow, etc., which can solve the problems of low cleaning efficiency, dead ends in cleaning, and poor drainage of waste liquid Recycling and other issues, to achieve the effect of comprehensive cleaning, good clamping effect and excellent transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

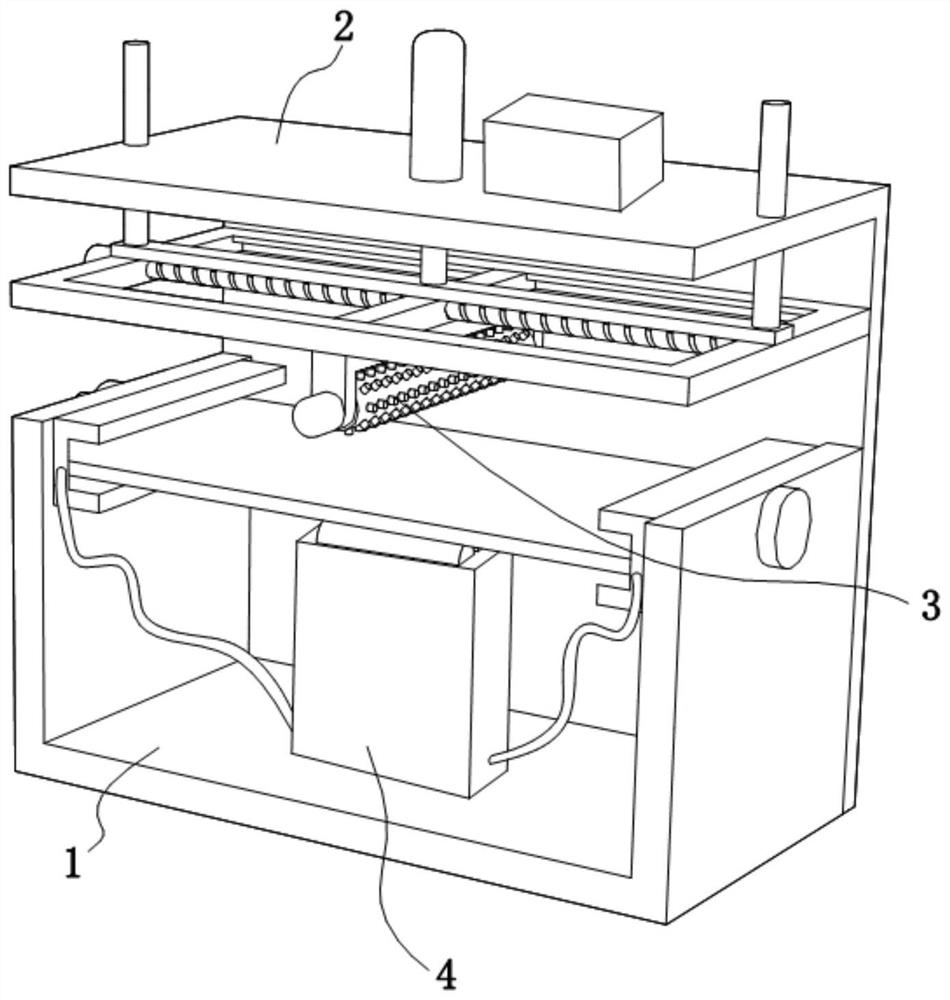

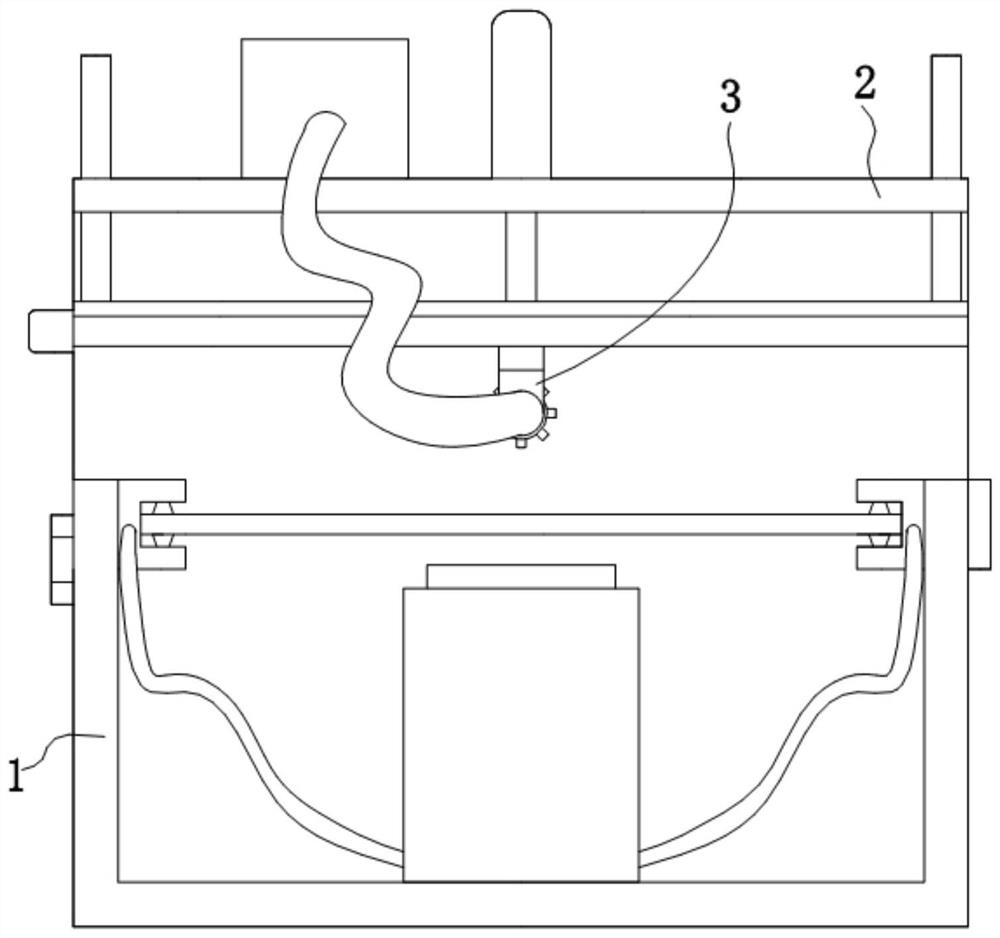

[0036] Such as Figure 1-8 As shown, the present invention provides a cleaning device for deep processing of tempered glass, comprising a bottom mechanism 1, the inner bottom of the bottom mechanism 1 is provided with a transmission mechanism 4, the transmission mechanism 4 is mainly connected with the transmission frame before the device, so that the tempered glass 113 to be ground Directly enter the device along the transmission mechanism 4 after the side, which improves the work efficiency. The top of the bottom mechanism 1 is provided with a sliding mechanism 2, and the bottom end of the sliding mechanism 2 is provided with a cleaning mechanism 3.

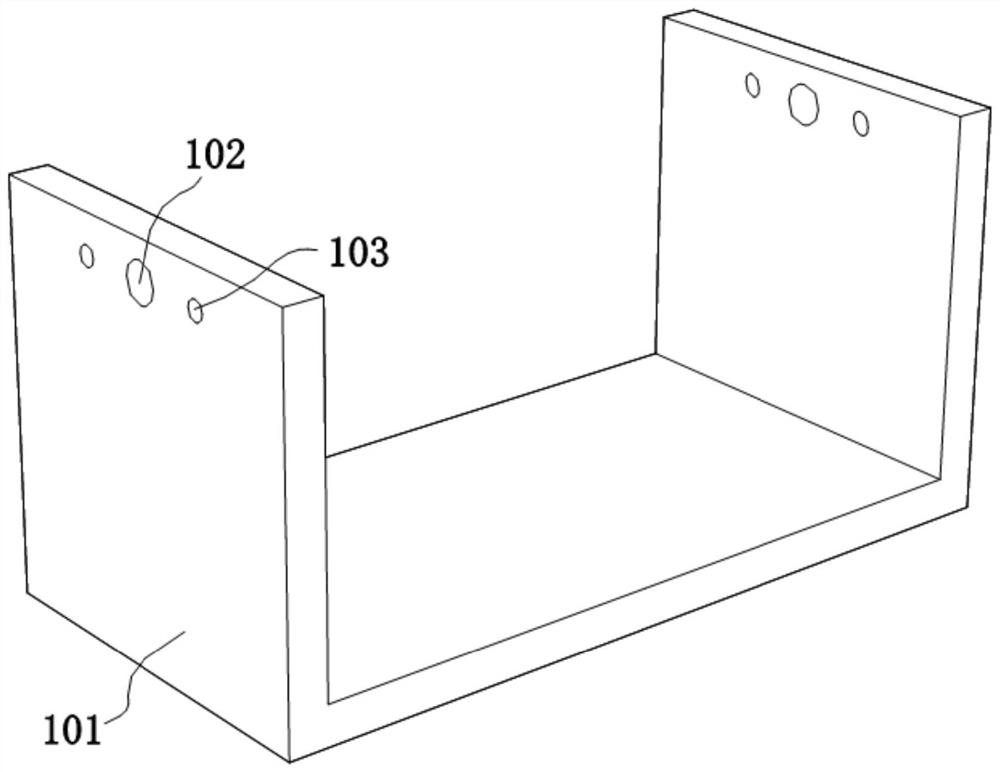

[0037] The bottom mechanism 1 includes a support frame 101. A shaft hole 102 is provided on the opposite inner wall of the support frame 101. Positioning holes 103 are provided on both sides of the shaft hole 102. The shaft holes 102 are symmetrically distributed and located at the symmetrical plane of the support frame 101. , ...

no. 2 example

[0043] Based on the cleaning device for deep processing of tempered glass provided in the first embodiment, only one side of the tempered glass 113 to be cleaned can be cleaned by one clamping during use. Clean and clean, the cleaning efficiency is low, and the toughened glass 113 has not been tempered, and the compressive capacity is poor. When the clamping plate 112 clamps it, it is easy to crack or break inside, which will affect the quality of the subsequent tempering process. After the plate 112 clamps the tempered glass 113 to be tempered, it is still necessary to manually fix the pin 117 in the positioning hole 103, the clamping efficiency is low, and the steps are cumbersome. In order to solve this problem, a combination of Figure 9-10 The cleaning device for deep processing of tempered glass also includes; the end of the rotating shaft 106 away from the support frame 101 is fixedly connected to the output end of the rotating motor 107, and the rotating motor 107 can d...

no. 3 example

[0047] Based on the cleaning device for deep processing of tempered glass provided in the second embodiment, if only the brush group 304 on the outer surface of the cleaning roller 302 is used to clean the top surface of the tempered glass 113 to be cleaned, the cleaning effect is poor and cannot be effectively used. The cleaning of the edged glass residue will affect the subsequent tempering process. Therefore, in order to solve this problem and improve the cleaning effect of the device, combined with Figure 11 The cleaning device for deep processing of tempered glass also includes a water tank 5 arranged on the top of the sliding mechanism 2, and a water pipe 6 is connected to one end of the water tank 5. The function of the water tank 5 is mainly to provide clean water for cleaning, and to assist the brush group 304 to efficiently treat the tempered glass. The top surface of the glass 113 is cleaned, the inside of the cleaning roller 302 is a cavity, and the central axis at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com