Structure-optimized switch cabinet

A switchgear and cabinet technology, applied in the field of switchgear, can solve the problems affecting the conductive contact of the common knife 6', the deformation of the common knife 6', and the lack of a limit structure, so as to avoid serious deformation of the knife and copper bars. bad contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

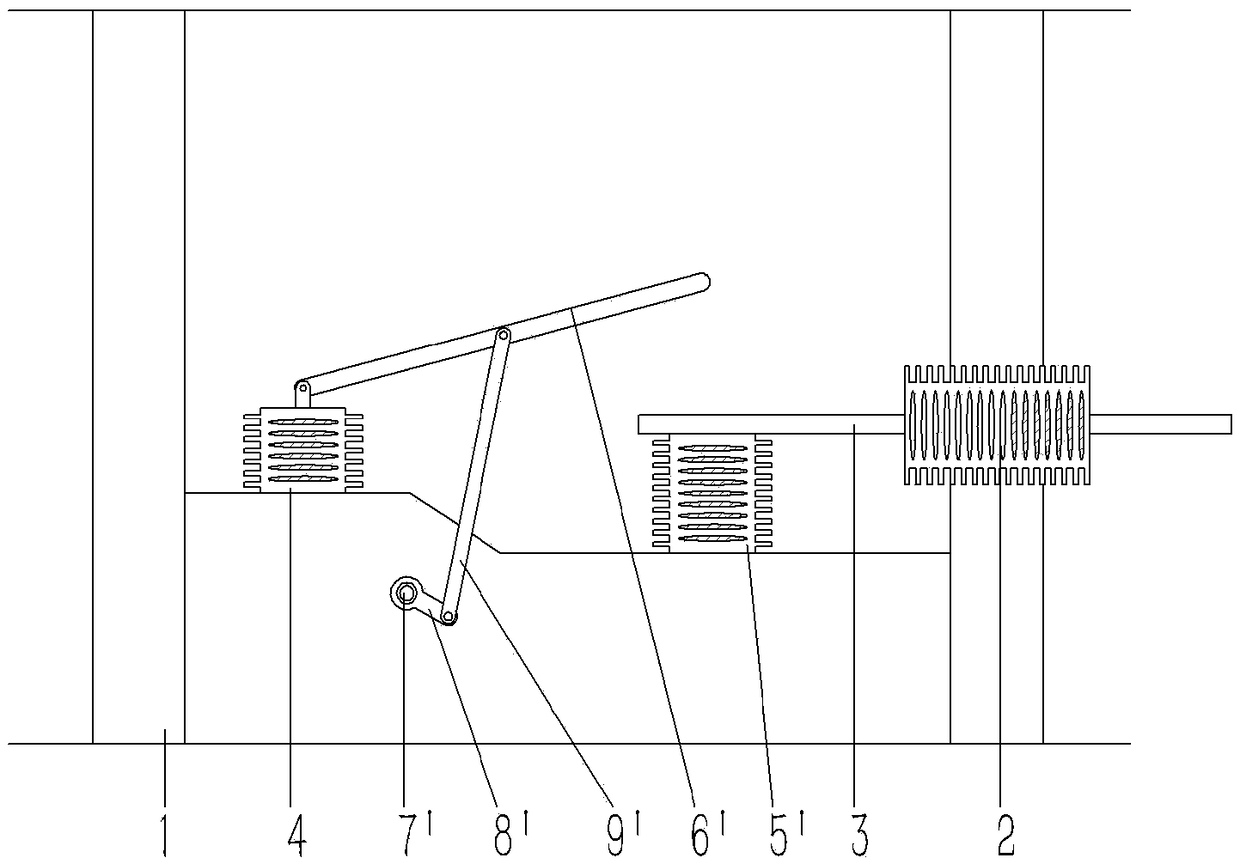

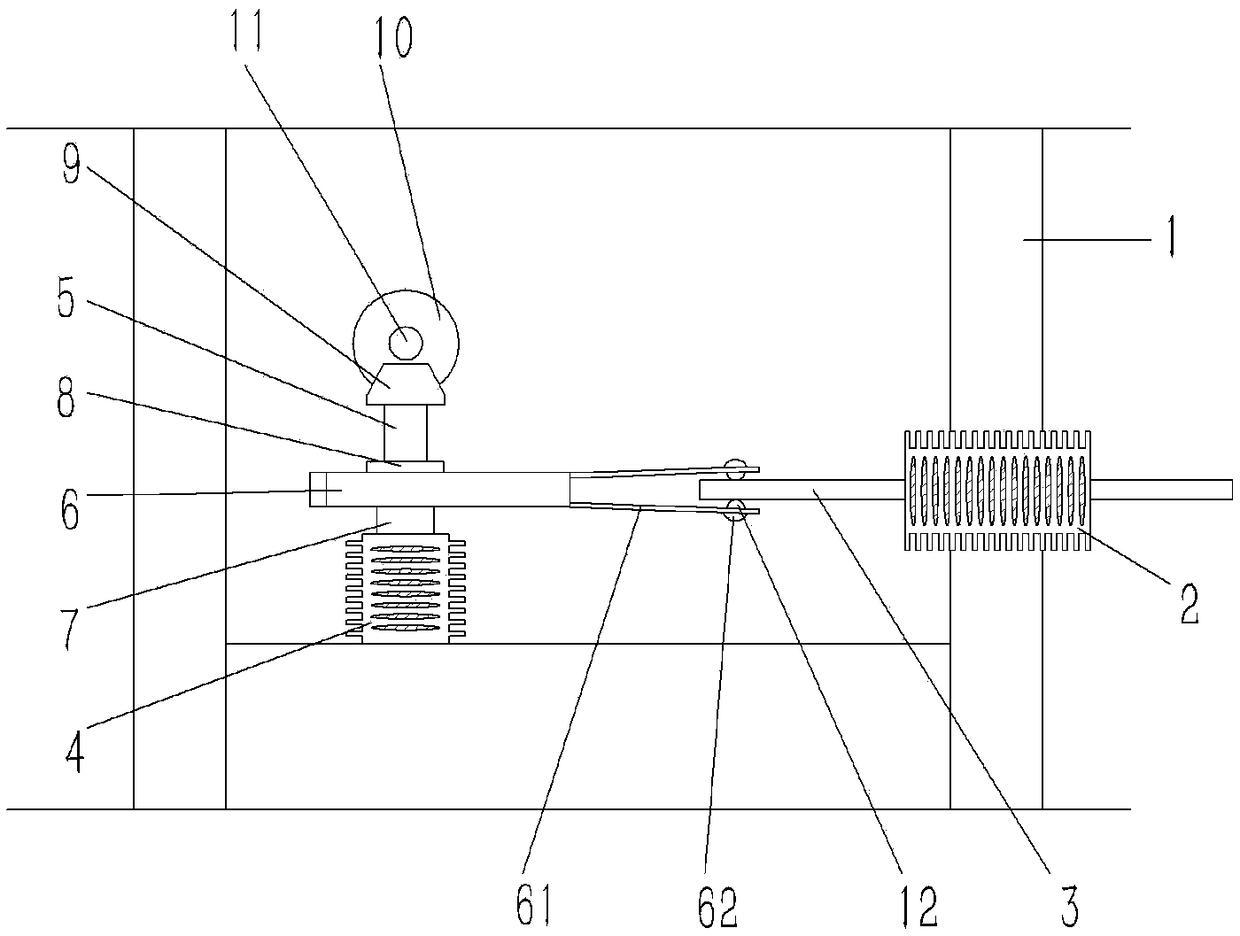

[0015] Example: see figure 2 As shown, a switch cabinet with an optimized structure includes a cabinet body 1 of the switch cabinet. Several groups of switch knife assemblies are arranged in the cabinet body 1. The switch knife components are composed of copper bars 3 and special-shaped switch knives 6. The cabinet body 1 A horizontal insulating sleeve 2 is plugged and fixed on one side of the side wall, and a horizontal copper bar 3 is inserted in the insulating sleeve 2. One end of the copper bar 3 is inserted in the cabinet body 1, and the other end is exposed outside the cabinet body 1. The cabinet body A special-shaped gate knife 6 opposite to the copper bar 3 is inserted in the body 1. The end of the special-shaped gate knife 6 close to the copper bar 3 is formed with two elastic contact pieces 61, and the two ends of the elastic contact piece 61 are elastically against the On the upper and lower end faces of the copper bar 3, the other end of the special-shaped switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com