Vehicle compartment body capable of being assembled rapidly

A vehicle and van body technology, which is applied in vehicle parts, transportation and packaging, the superstructure of trucks, etc. problems, to achieve the effect of reducing after-sales maintenance costs, reducing costs, and achieving standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

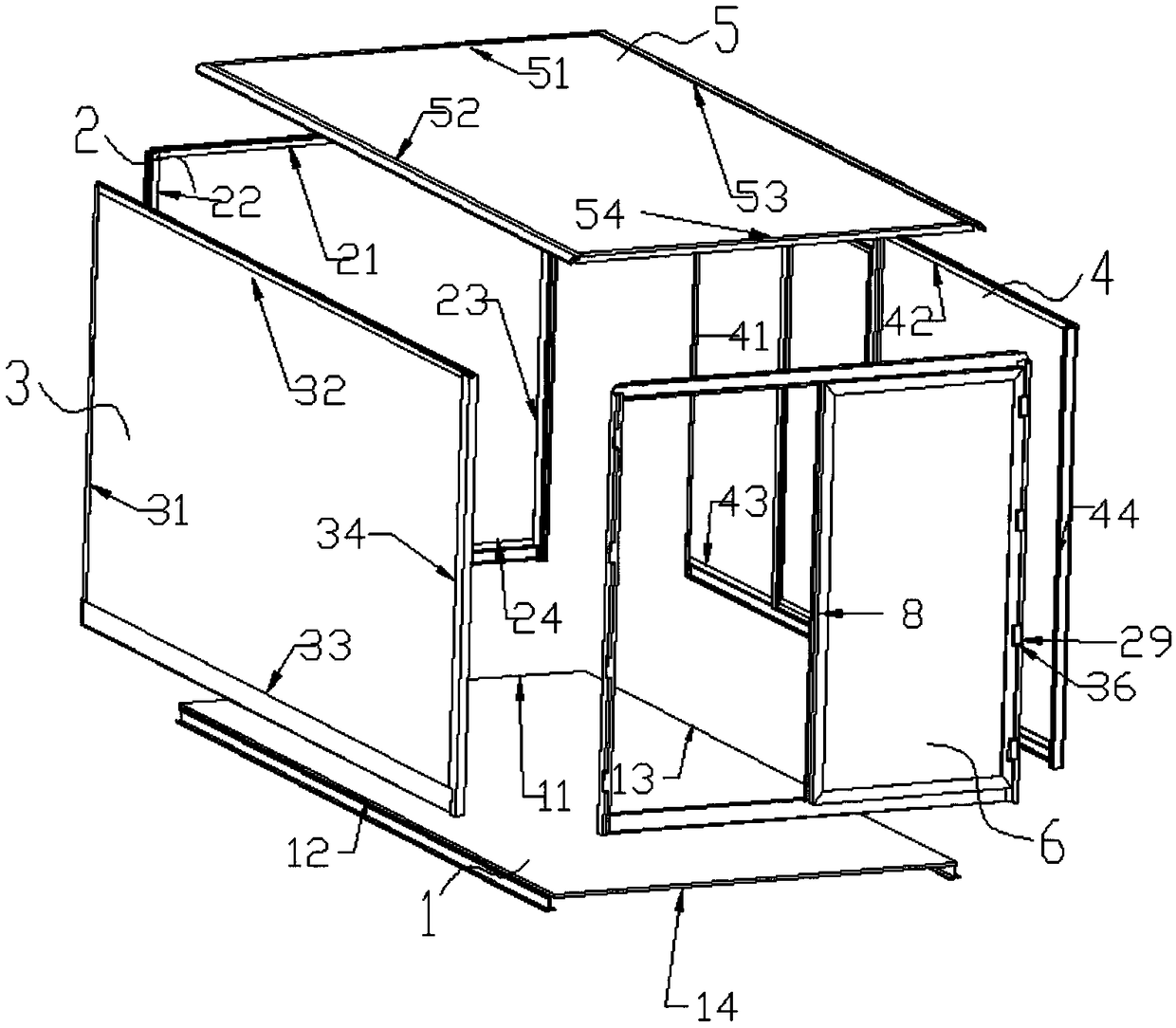

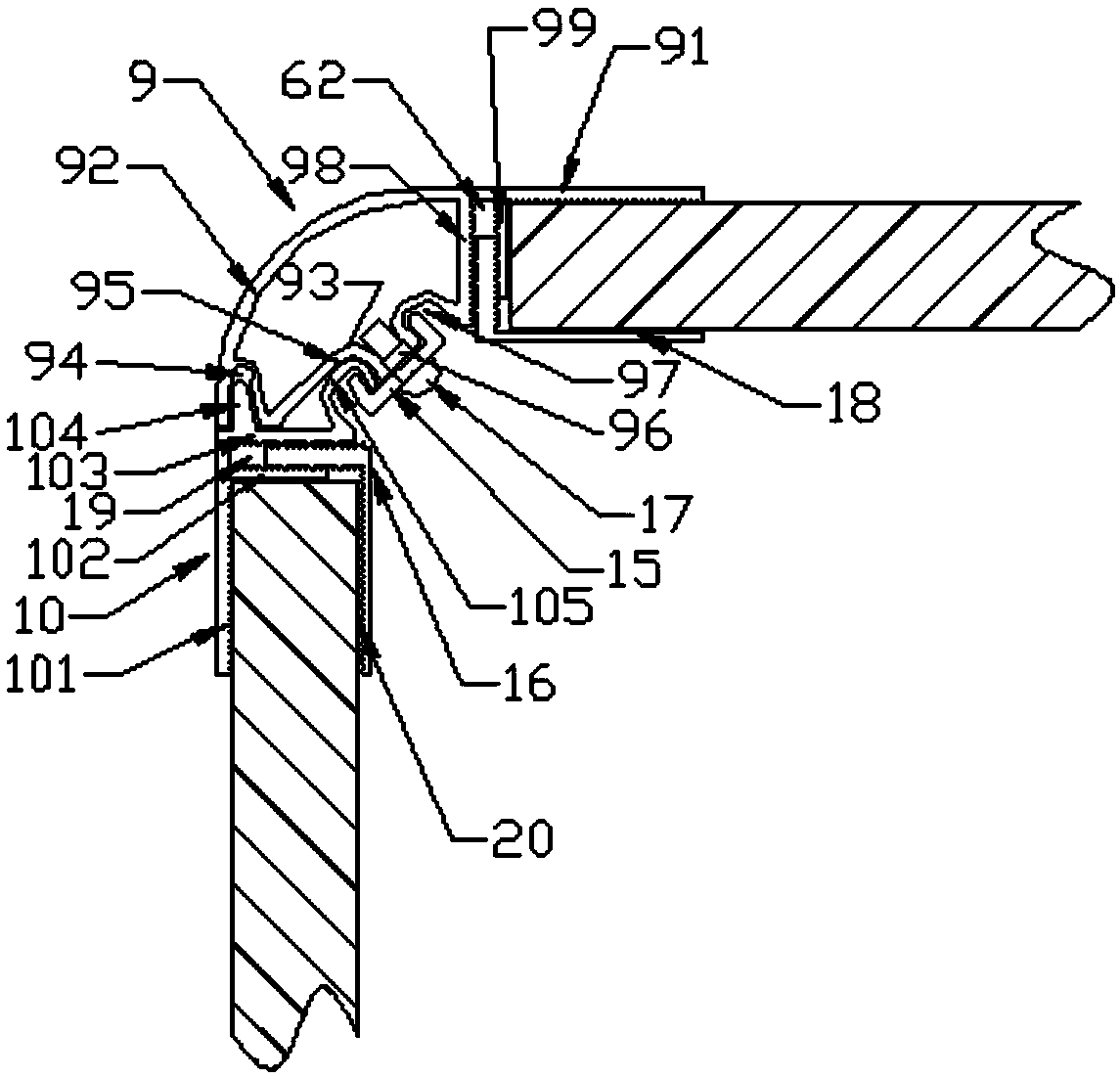

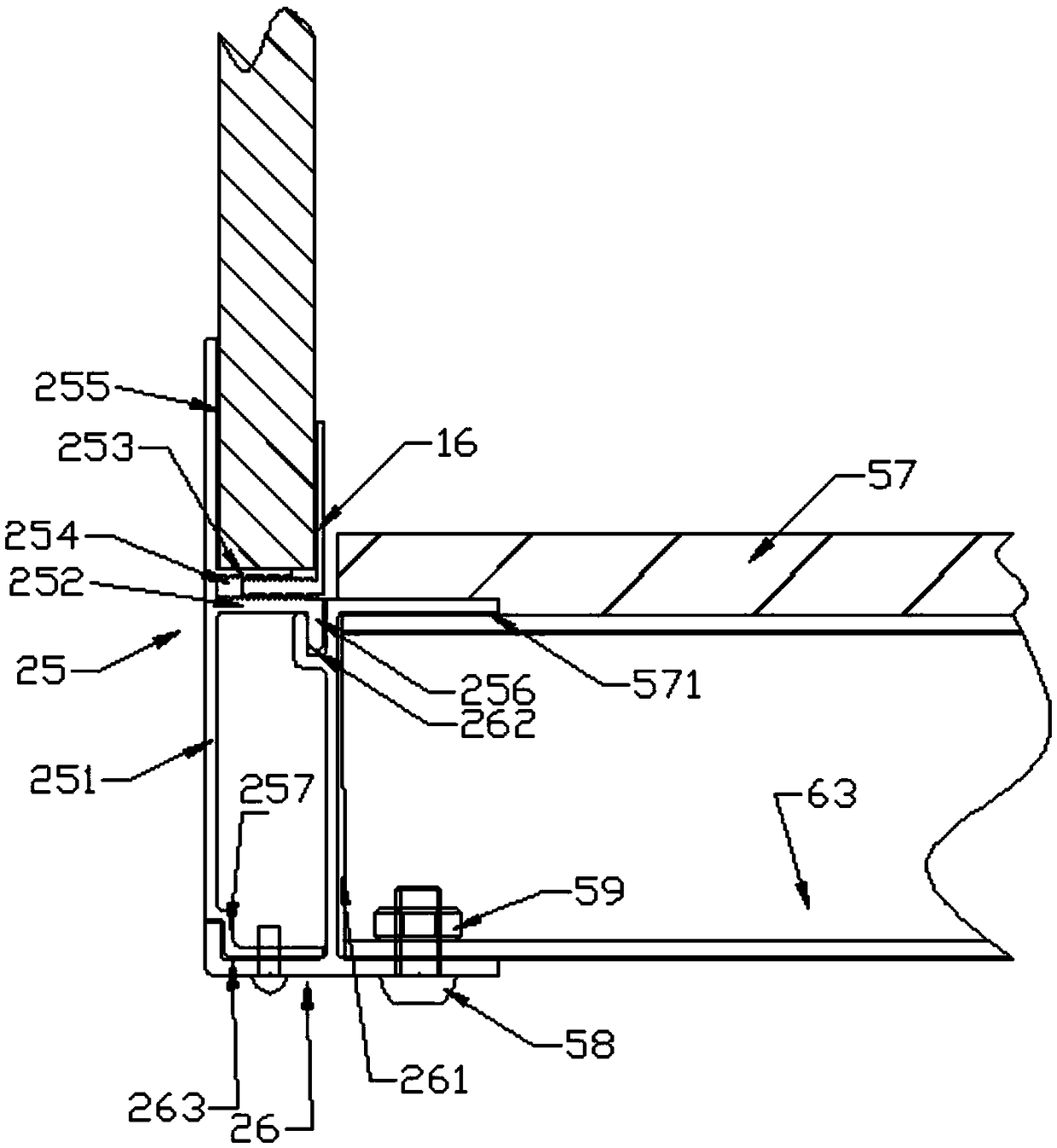

[0060] Such as Figure 1-13As shown, the present embodiment discloses a vehicle body that can be assembled quickly. The body is suitable for trucks. Of course, it can also be applied to other vehicle bodies according to its size. It includes: a front plate 2, a top plate 5, a bottom plate Assembly 1, left side panel 3, right side panel 4; between the front panel top edge 21 of the front panel 2 and the top panel front edge 51 of the top panel 5 and between the front panel left side 22 of the front panel 2 and the Between the left side panel front edge 31 of the left side panel 3 and between the front panel right side 23 of the front panel 2 and the right side panel front edge 41 of the right side panel 4 and between the top panel left side 52 of the top panel 5 and the Between the left side plate top edge 32 of the left side plate 3 and between the top plate right side 53 of the top plate 5 and the right side plate top edge 42 of the right side plate 4, respectively, are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com