Load wheel test device with elastic damping element and induction tooth arc base

A technology of elastic damping and testing equipment, which is applied in the field of vehicles, can solve the problems of unsuitable road wheels, large volume of driving drums of test benches, and no adjustment device for tires and drums, so as to reduce vibration and facilitate installation and adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

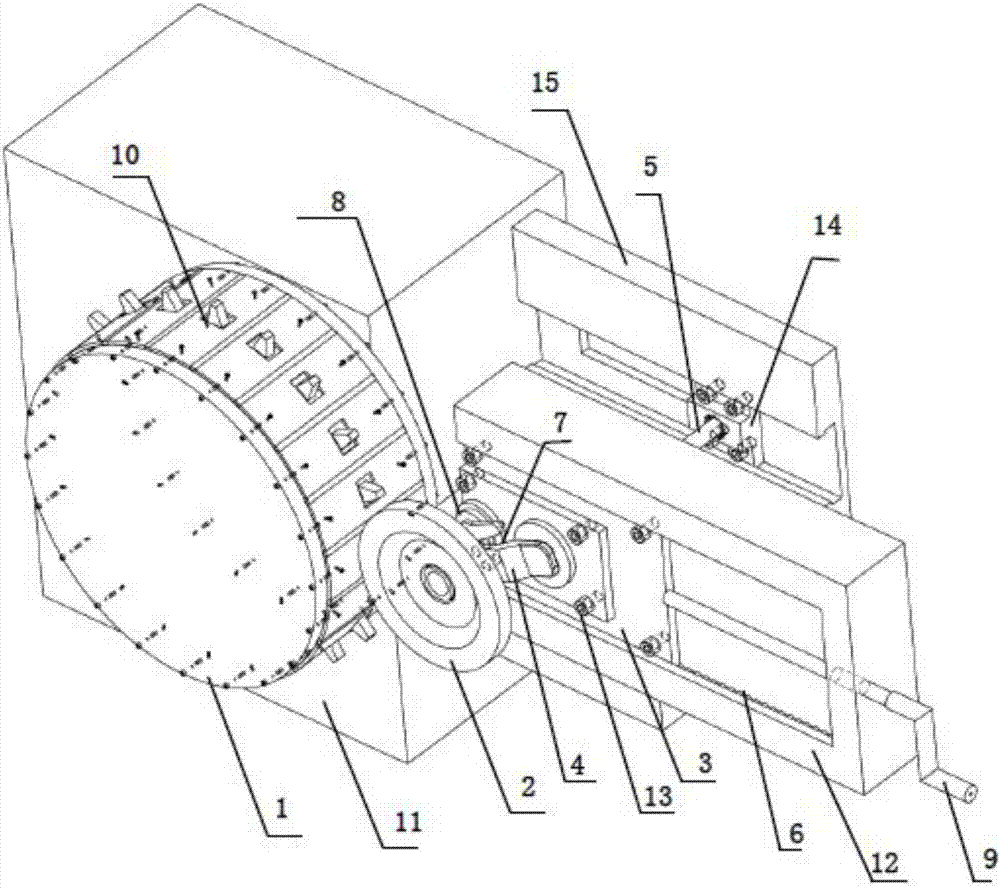

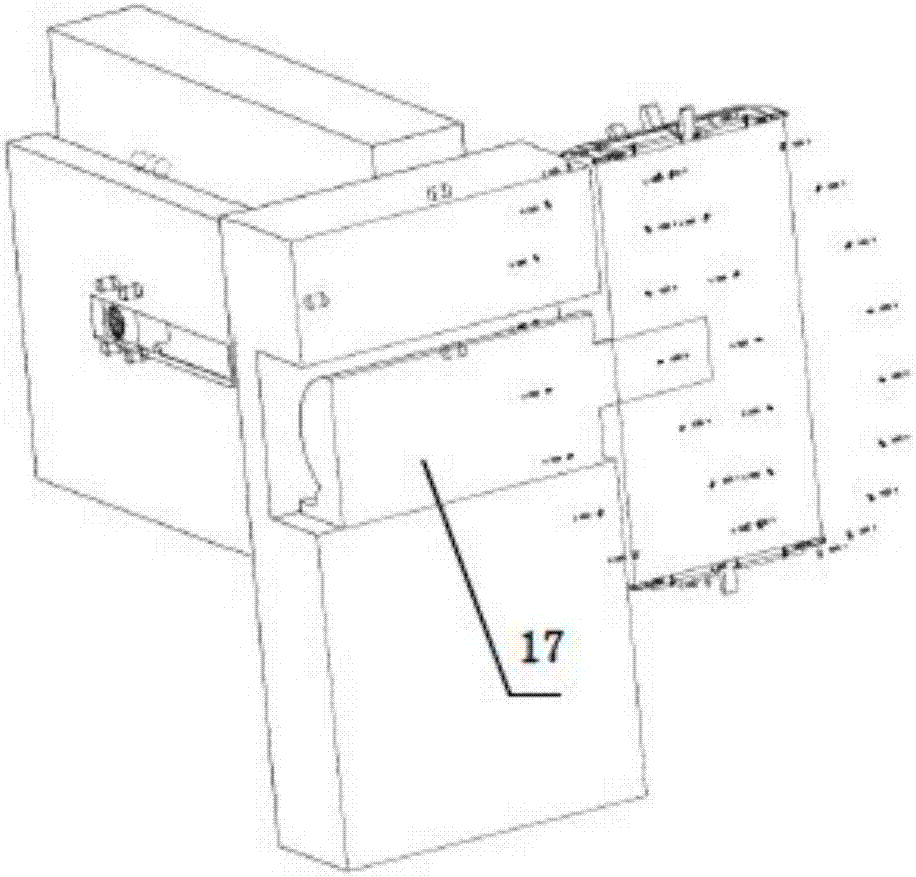

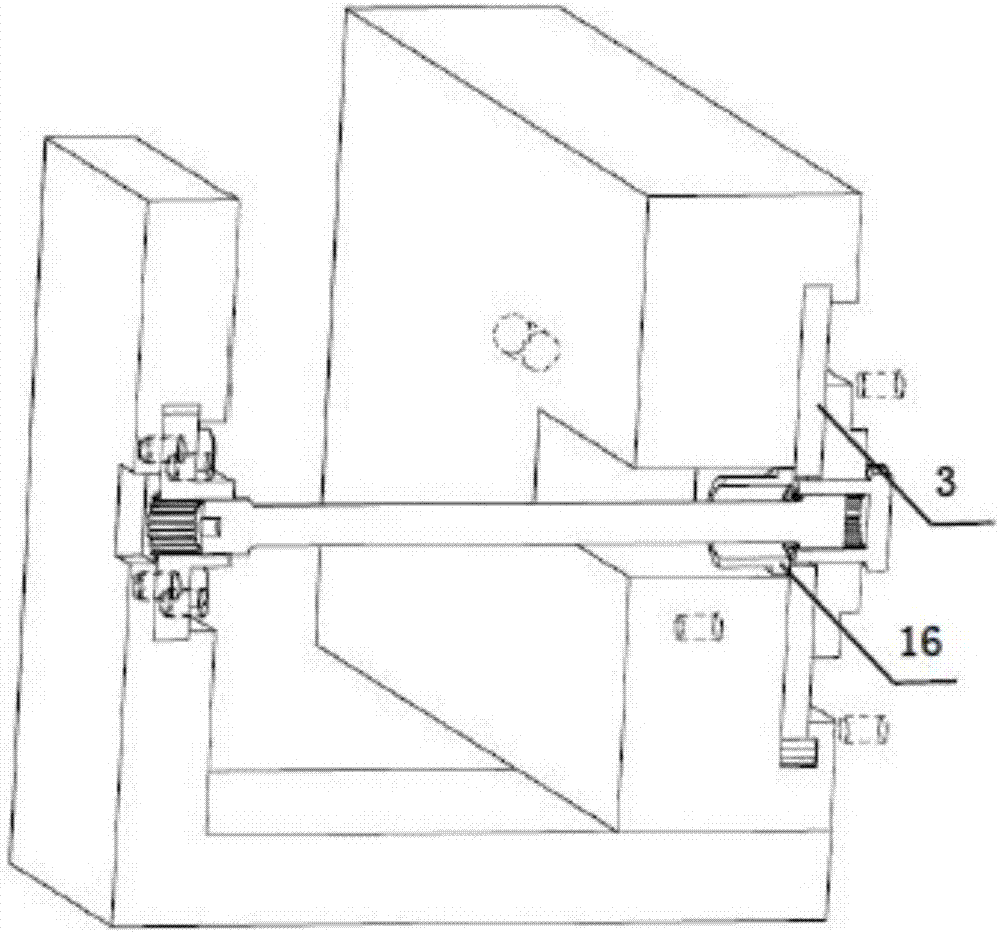

[0050] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a load wheel test device with an elastic damping element and an arc-shaped base of induced teeth, including a driving drum 1, an arc-shaped base 10 with induced teeth, a rubber gasket 18, a fixed frame 11, a base 12, and a slide plate 3 , needle roller 6, lead screw propulsion mechanism 9, load wheel tested object 2, balance elbow 4, balance elbow seat 13, torsion bar spring 5, torsion bar spring seat 14, L-shaped base 15, rotary shock absorber 8. Connecting arm 7, angle sensor 16, motor 17, outer nut 23, inner nut 24, inner adjusting ring 25, outer adjusting ring 26, intermediate ring 27, bearing 28, etc.

[0051] Wherein, the motor 17 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com