Lithium battery pole piece rolling mill

A lithium battery and pole piece technology, which is applied in the direction of metal rolling, metal rolling, and workpiece surface treatment equipment, can solve the problems of reduced performance, inconvenient pole piece transportation, and bending, so as to improve performance and work Efficiency and usability, and the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

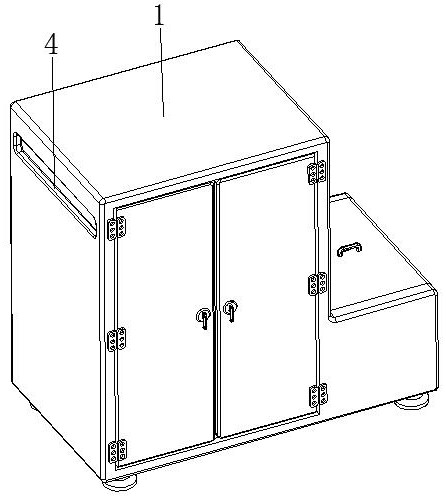

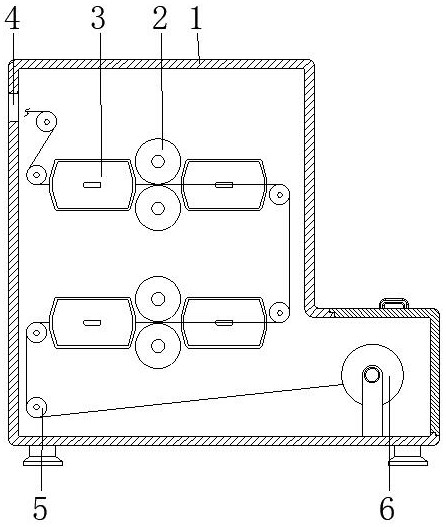

[0031] see Figure 1-8 , the present invention provides a technical solution: a lithium battery pole piece rolling mill, including a machine body 1, a pressure roller 2, and a hot rolling device 3, the pressure roller 2 is arranged inside the machine body 1 and is located at a central position, and the hot rolling device 3 is arranged in Inside the body 1 and located on both sides of the pressure roller 2;

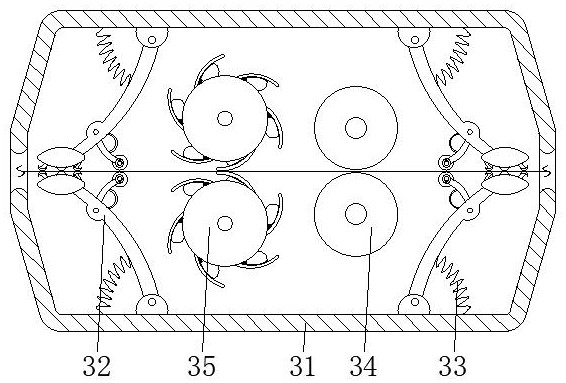

[0032] The hot rolling device 3 is provided with a casing 31, a tensioning device 32, an arc spring 33, a hot pressing roller 34, and a preheating device 35. The surface of the casing 31 is fixedly connected with the body 1, and the tensioning device 32 is arranged on the casing. Inside the body 31 and close to the end position, the arc spring 33 is arranged between the two sides corresponding to the surface of the tensioning device 32 and the inner wall of the box body 31, and the hot pressing roller 34 is arranged inside the box body 31 and close to the central position,...

Embodiment example 2

[0035] The tensioning device 32 is provided with a support member 321, a flattening device 322, and a pressing device 323. One end of the support member 321 is hinged with the inner wall of the box body 31, and the flattening device 322 is arranged on an end of the support member 321 away from the inner wall of the box body 31, and presses The device 323 is disposed on the surface of the support member 321 and close to the leveling device 322 .

[0036] The flattening device 322 is provided with an arc surface substrate 3221, a curved surface flattening part 3222, and an arc surface flattening part 3223. At the center of the top of the surface base 3221, the arcuate flattening piece 3223 is fixed on the top of the arcuate surface 3221 and on both sides of the curved surface flattening piece 3222, and the tensioning device 32 is set on the corresponding two sides inside the box body 31 at the same time. And under the elastic force of the arc spring 33, the supporting member 321...

Embodiment example 3

[0039] The preheating device 35 is provided with a driving roller 351, a hot air chamber 352, a pressing plate device 353, a rubber elastic part 354, and an elastic capsule body 355. The end of the driving roller 351 is rotationally connected with the box body 31, and the hot air chamber 352 is opened on the driving roller. 351 inside the central position, the platen device 353 is arranged on the surface of the driving roller 351, the rubber elastic member 354 is fixed between the surface of the platen device 353 and the surface of the driving roller 351 corresponding to the two sides, and the elastic capsule 355 is arranged on the surface of the platen device 353 Between the two sides corresponding to the surface of the driving roller 351 and close to the position of the rubber elastic member 354 , the air inlet end of the elastic bag 355 communicates with the hot air cavity 352 .

[0040] The pressing plate device 353 is provided with a pressing plate main body 3531 and an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com