Temperature test fixture

A technology for testing jigs and objects under test, applied in thermometers, thermometer parts, measuring devices, etc. The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

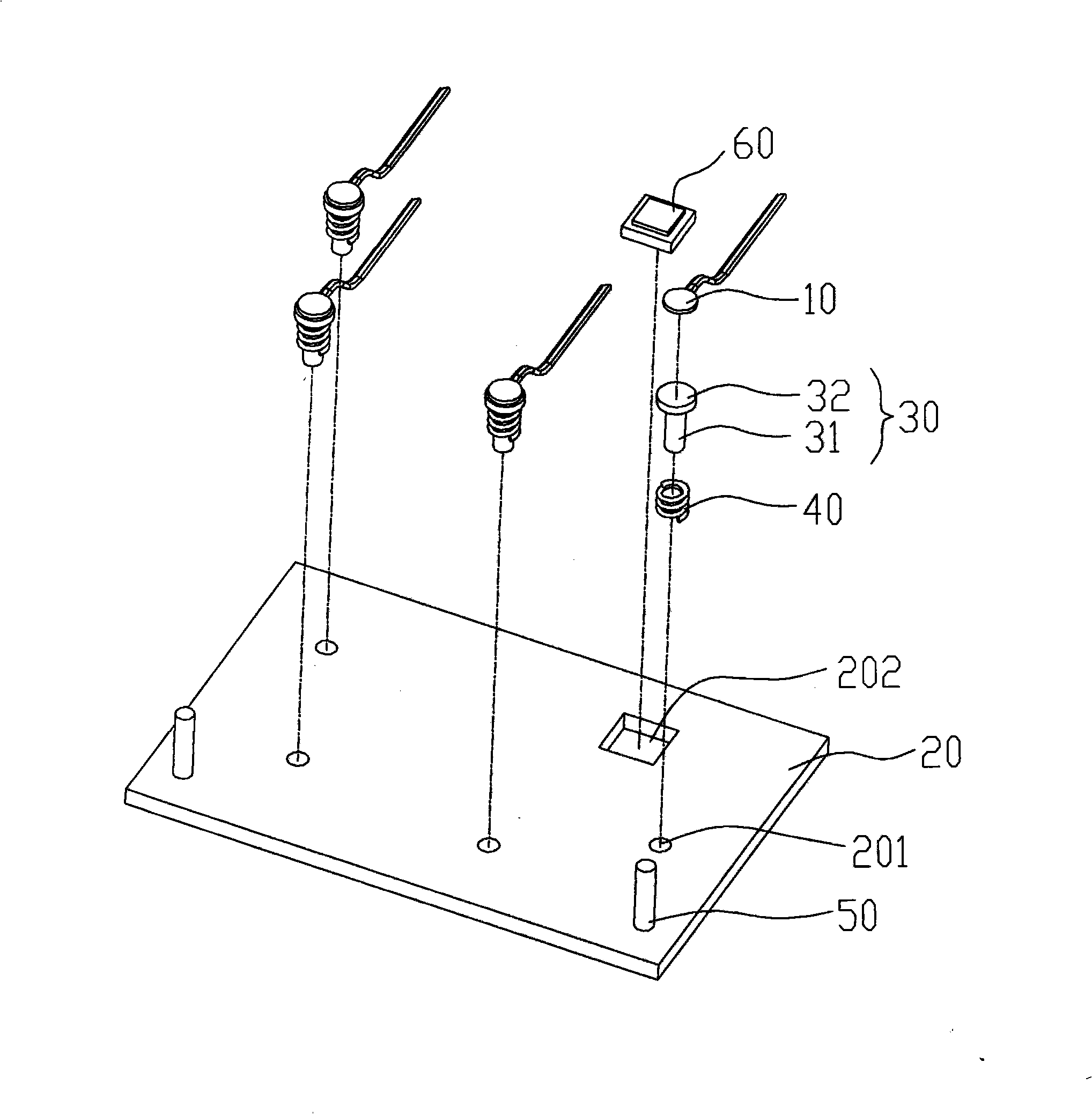

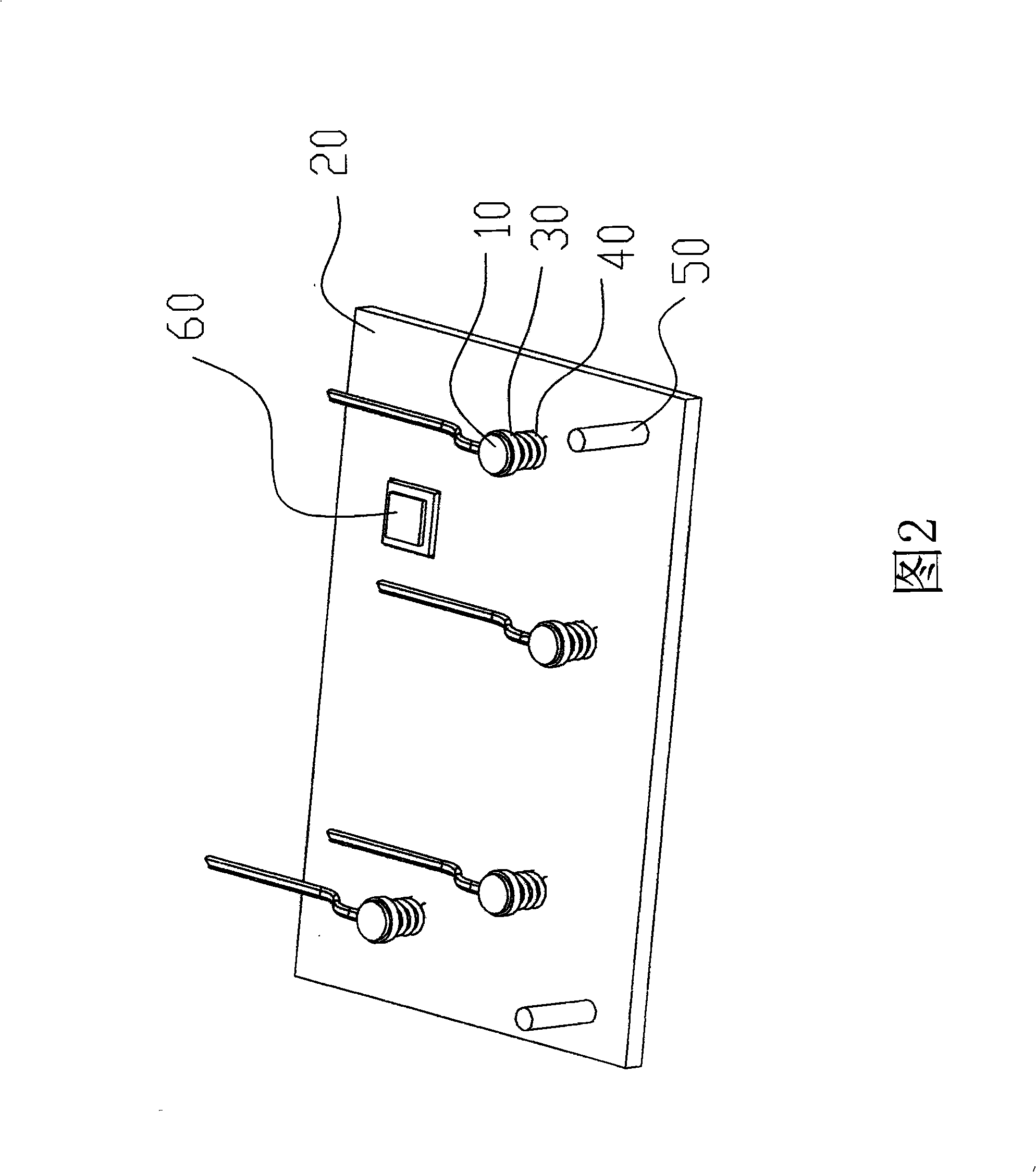

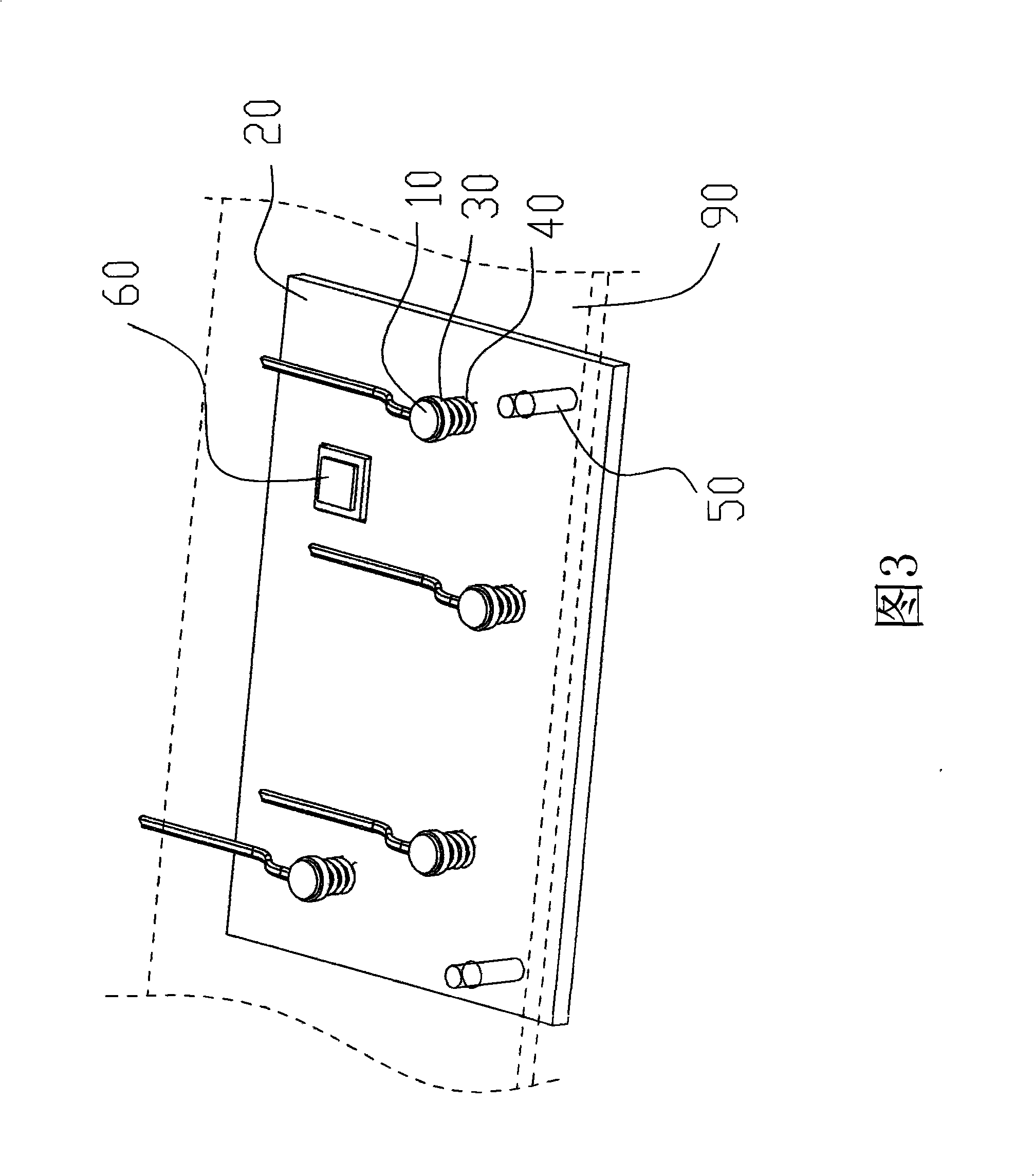

[0015] see figure 1 , shown in Fig. 2 and Fig. 3, the temperature test fixture of the present invention is suitable for fixing several probes 10, to test the temperature at some measured points on a measured object 90; This temperature test fixture comprises a substrate 20, and this substrate 20 is provided with a number of perforations 201, and the position of each perforation 201 corresponds to the position of the measured point. In this embodiment, the shape of the perforation 201 is circular; in addition, the substrate 20 can also be provided with several heating grooves 202 (The number of heating tanks 202 can be set according to actual needs, and the number of heating tanks 202 can be 0, 1, 2...). And in these through-holes 201, be respectively provided with a plurality of bearings 30, and these bearings 30 respectively comprise a set of shafts 31, these sleeve shafts 31 can move up and down in the perforation 201, and the ends of these sleeve shafts 31 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com