Elastic contact structure of socket contact piece

An elastic contact and contact piece technology, applied in the direction of contact parts, etc., can solve the problems of small contact pressure between the moving contact piece and the static contact piece, limited movement stroke of the moving contact piece of the rotating block, and easy occurrence of electric sparks, etc., to achieve increased swing The effect of increasing the range, increasing the elastic activity margin, and improving the operating feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

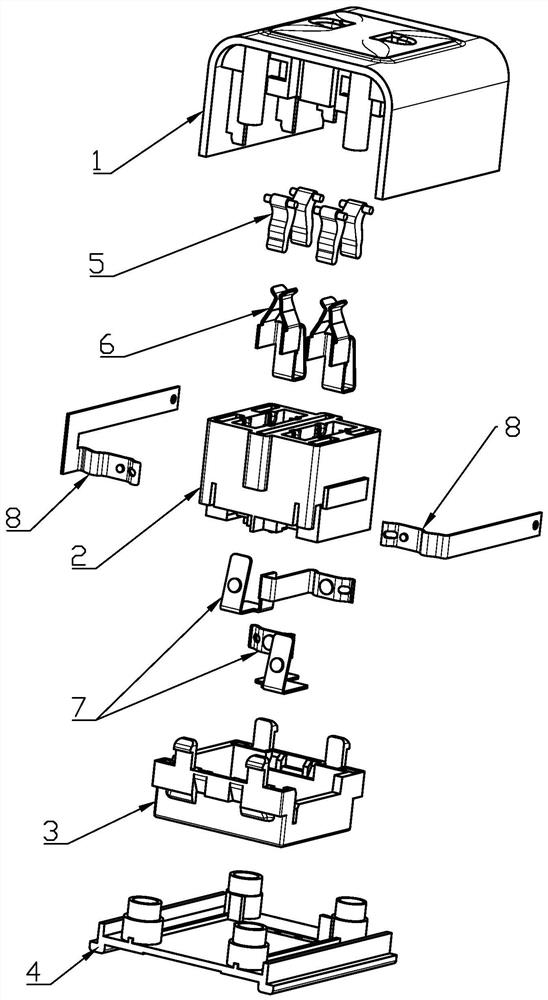

[0020] Such as figure 1 As shown, it is a kind of anti-electric shock safety socket, which includes an upper cover 1, a middle frame 2, a rear cover 3 and a lower cover 4. The upper cover 1 is provided with jacks for inserting the blades of the plug, and each jack is two Each side is pivotally connected with a rotary block 5, the middle frame 2 is fixed with an insertion grip 6, a movable contact piece 7 and a static contact piece 8 are fixed between the rear cover 3 and the middle frame 2, and the lower cover 4 and the The upper cover 1 is correspondingly closed.

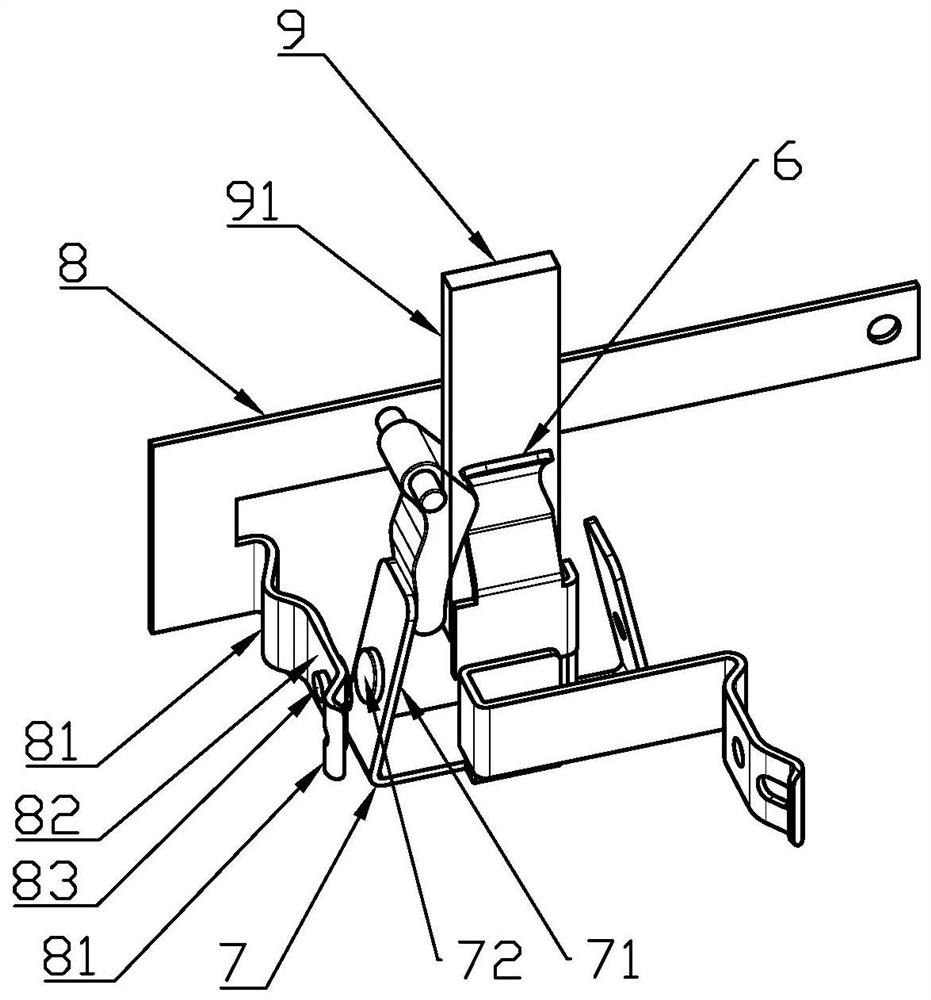

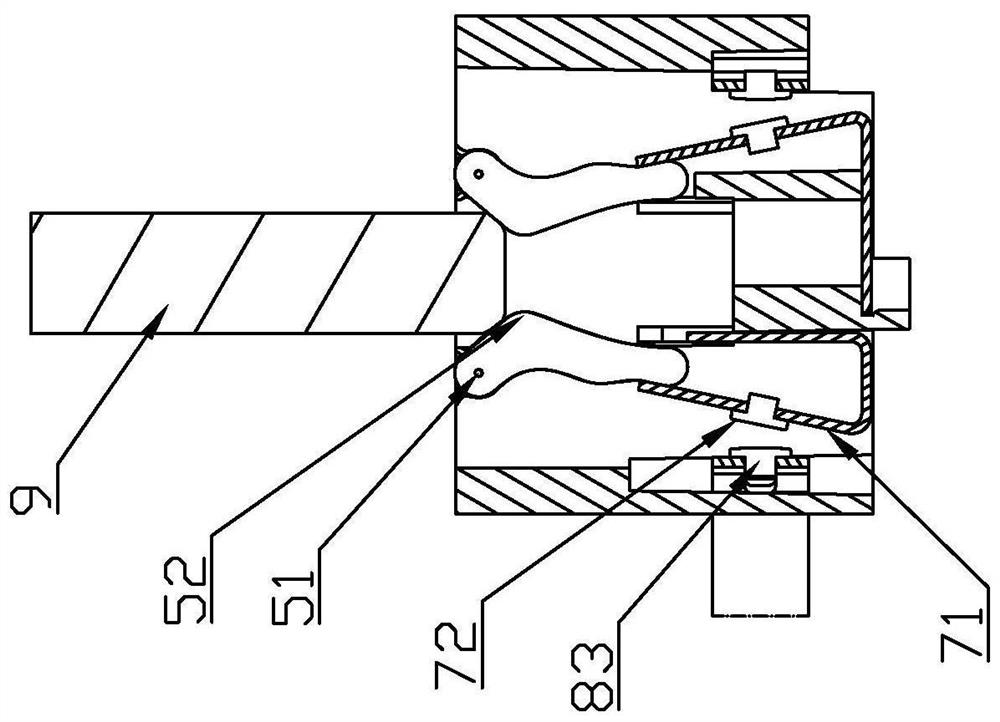

[0021] Such as Figure 2-Figure 4 As shown, the inserting piece 9 has two planar parts and two ridges 91 arranged oppositely, the inserting handle 6 can clamp the two planar parts of the inserting piece 9, and each of the inserting pieces 9 A said rotary block 5 is arranged on the outside of each ridge 91; the rotary block 5 is C-shaped as a whole, and its upper end is pivotally connected to the upper cover 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com