A method for recycling calcium carbide

A calcium carbide and relay technology is applied in the field of recycling and reusing calcium carbide, which can solve the problems of resource waste, potential safety hazards, and the inability of calcium carbide dust to achieve safe and economic comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

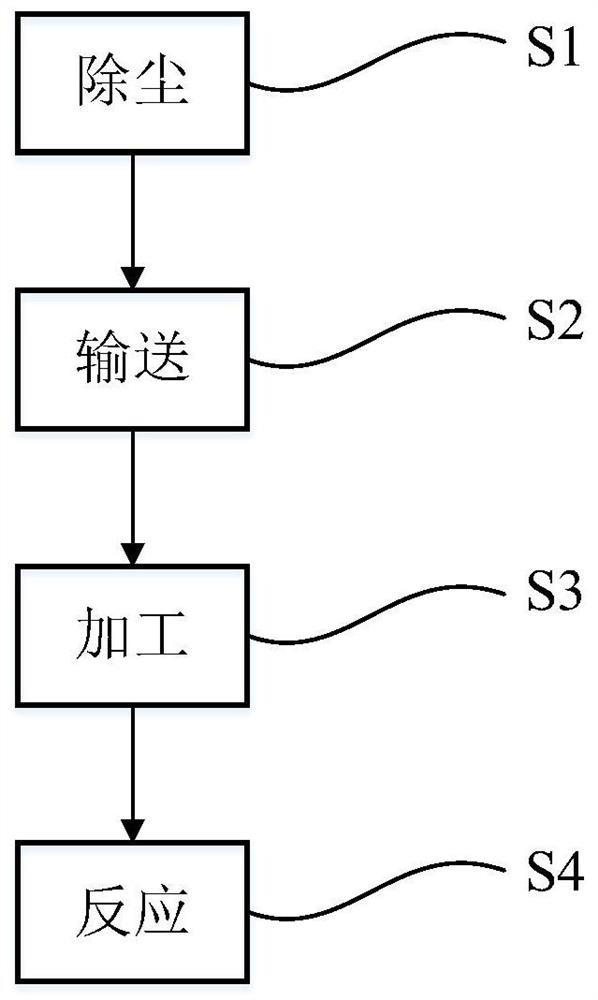

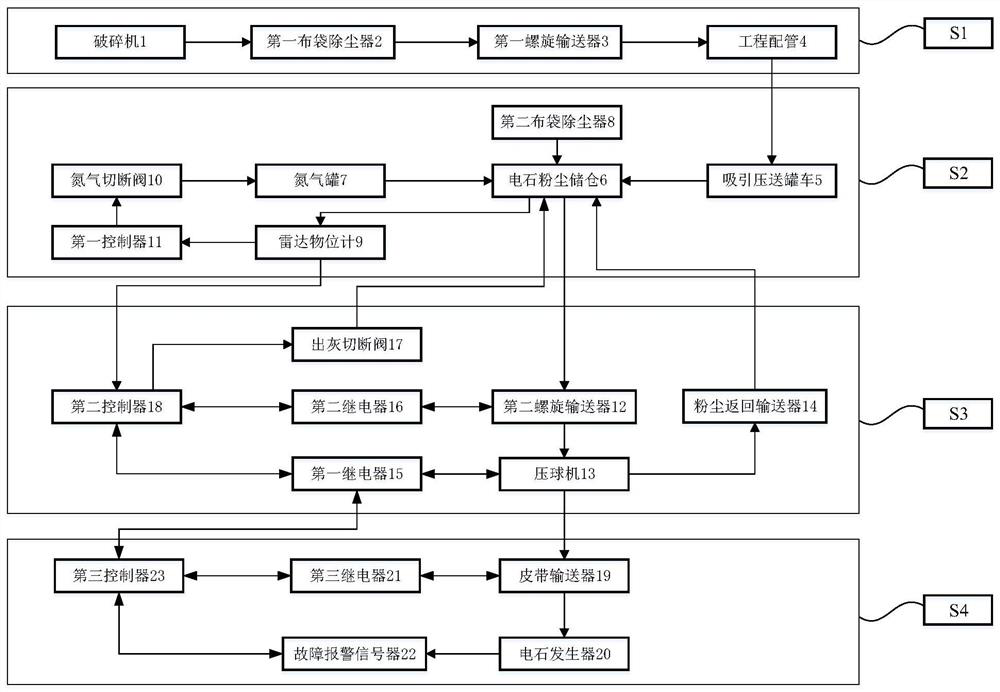

[0060] figure 1 It is a flowchart of a method for recycling calcium carbide according to the present invention.

[0061] Such as figure 1 As shown, the described method for recycling calcium carbide may further comprise the steps:

[0062] Dust removal step S1:

[0063] The calcium carbide is crushed to obtain calcium carbide dust;

[0064] The calcium carbide dust is collected by the first bag filter 2;

[0065] Delivery step S2:

[0066] The calcium carbide dust is transported to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com