Excessive dyeing liquid extrusion discharging device for cloth

A redundant and fabric technology, applied in the direction of liquid/gas/steam removal with squeeze rollers, can solve problems affecting fabric quality, fabric fiber burning, and large floor space, saving process time and material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

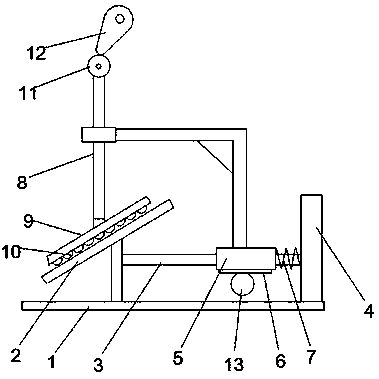

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, a device for displacing excess dye liquor from cloth according to the present invention includes a bottom plate 1, on which a connecting column and a vertical plate 4 are arranged, and an inclined plate 2 is arranged on the upper end of the connecting column, and the vertical plate 4 and the side of the connecting column is provided with a guide rod 3, the guide rod 3 is parallel to the bottom plate 1, the sleeve 5 is arranged on the guide rod 3, the outer surface of the sleeve 5 is provided with a rack 6 along the length direction, the teeth The bar 6 is provided with an incomplete gear 13, the toothed part of the incomplete gear 13 meshes with the rack 6, the incomplete gear 13 is driven by the motor to rotate, and a spring 7 is provided between the end of the sleeve 5 and the vertical plate 4, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com