Kitchen waste treating device

A technology for processing equipment and kitchen waste, which is applied in water supply equipment, indoor sanitary pipeline installations, buildings, etc., can solve problems such as shortening the service life of equipment, sewer blockage, and difficulty in crushing, so as to improve cutting efficiency and cutting performance and ensure use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

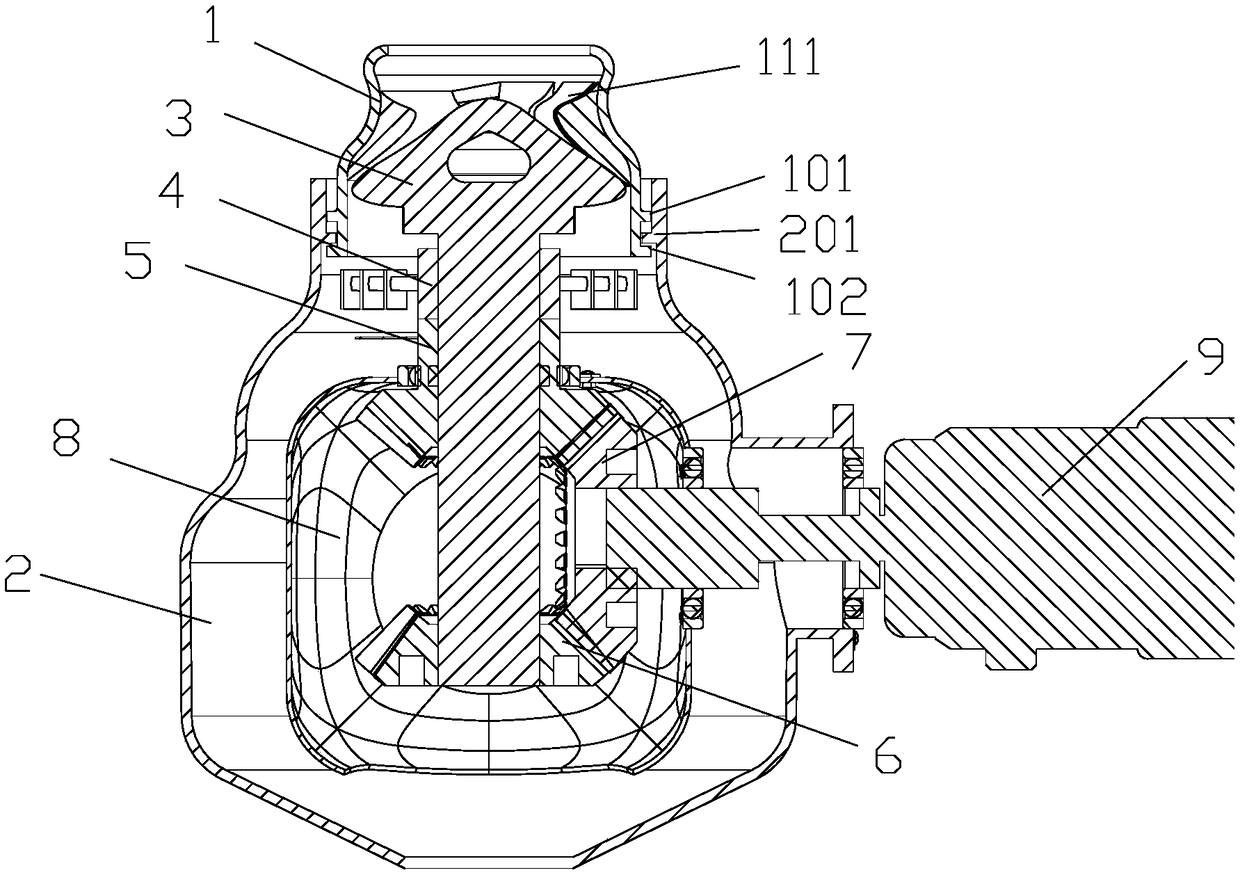

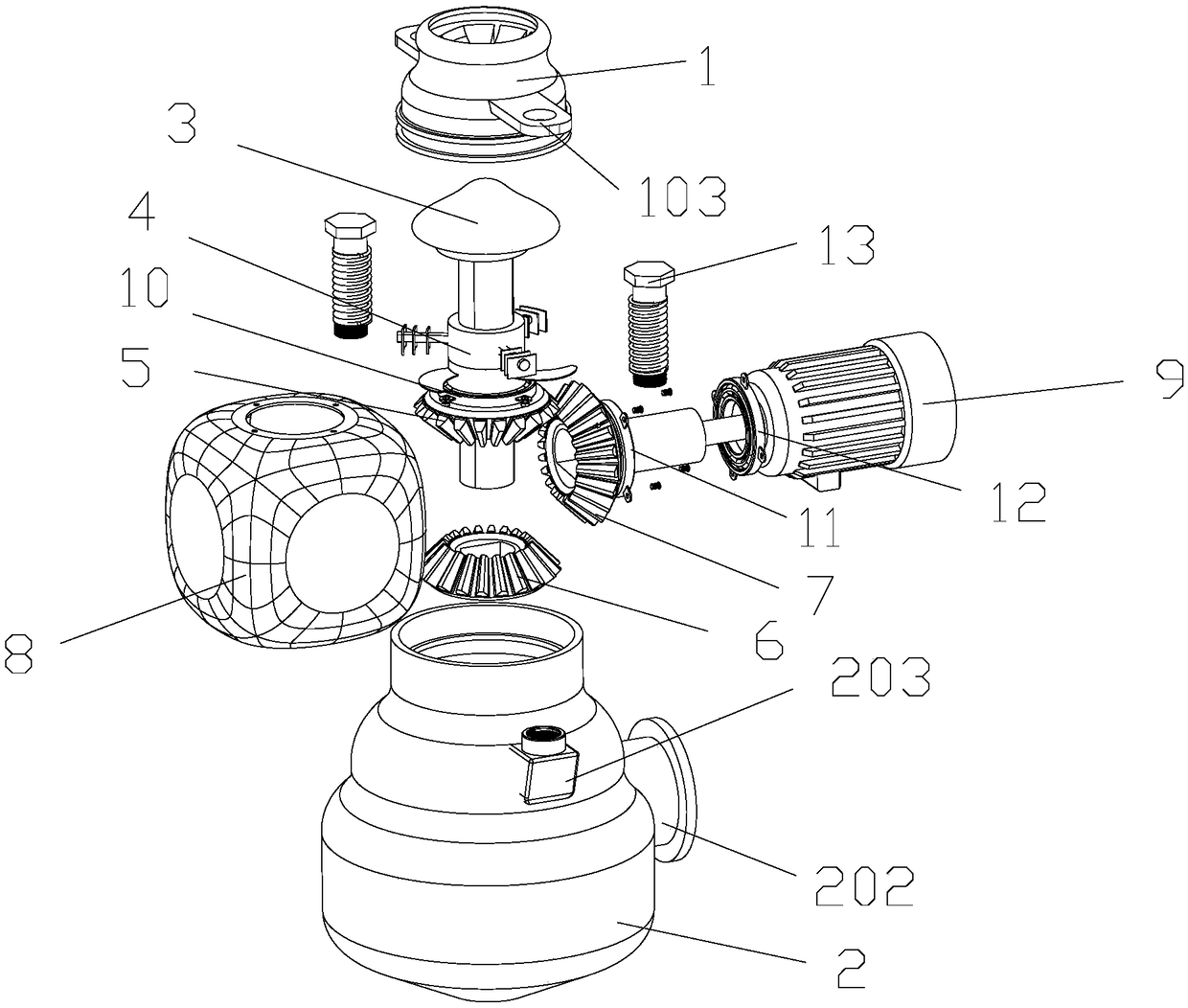

[0025] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

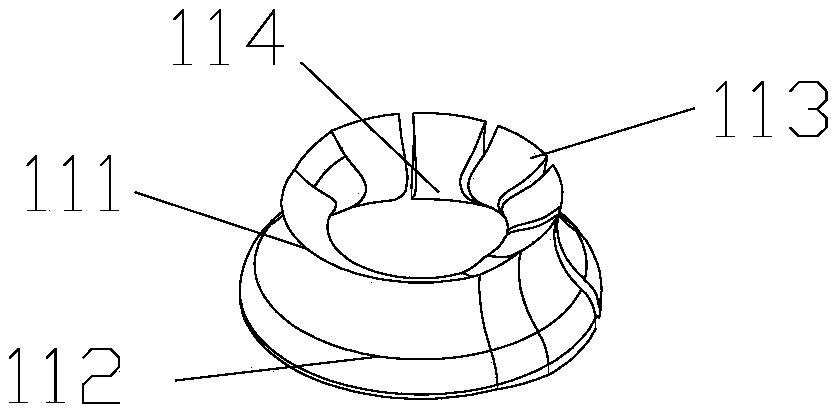

[0026] Such as figure 1 , figure 2 and image 3 As shown, the kitchen waste treatment device includes a feed casing 1 , an outer casing 2 , a feed rod 3 , a breaking mechanism 4 , a cutting mechanism 5 , a diversion protective cover 8 and a motor 9 .

[0027] Such as Figure 1 to Figure 3 As shown, the lower part of the feeding housing 1 is connected to the upper part of the outer housing 2, the outer wall of the feeding housing 1 is provided with a connecting arm 103 for installing the screw 13, and the bottom of the feeding housing 1 is provided with a first protruding ring 101 and a second flange. Two protruding rings 102, a third protruding ring 201 is arranged on the inner wall of the outer casing 2 top, the upper part of the outer casing 2 is sleeved on the bottom of the feed housing 1, and the third pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com