Novel micro lift rotation paddle pump performance test device

A test device, the technology of wiper pump, applied in pump control, non-variable capacity pump, machine/engine, etc., can solve the problems of low operation efficiency, energy waste, lack of performance testing, etc., to improve pump performance, solve the problem of operation inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

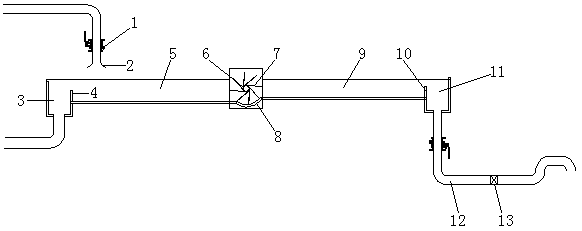

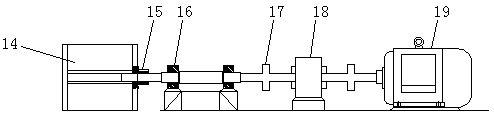

[0021] Such as Figure 1-2 As shown, a new micro-lift rotary scraper pump performance test device is provided with a motor 19 on the frame, and a torque meter 18 is connected to the output shaft of the motor 19. The torque meter 18 is connected to the rolling bearing 16 through the coupling 17 The shafts are connected, and the shaft end of the shaft is provided with an impeller 14 composed of a hub 6, blades 7 and a wheel rim 8. The left side of the impeller 14 is connected with a water inlet tank 5, and the left end of the water inlet tank 5 is provided with an inlet overflow chamber. 3. The connection between the water inlet overflow chamber 3 and the water inlet tank 5 is provided with a water inlet overflow plate 4, and the top of the water inlet tank 5 is provided with a water supply pipe 2, and the water supply pipe 2 is provided with a water supply valve 1, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com