Supporting device for fuel gas double-wall pipeline inner tube

A technology of supporting device and inner pipe, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of large differences in thermal expansion and cold contraction, deformation of support brackets, affecting pipeline gas supply, etc. Reliability, low manufacturing cost, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

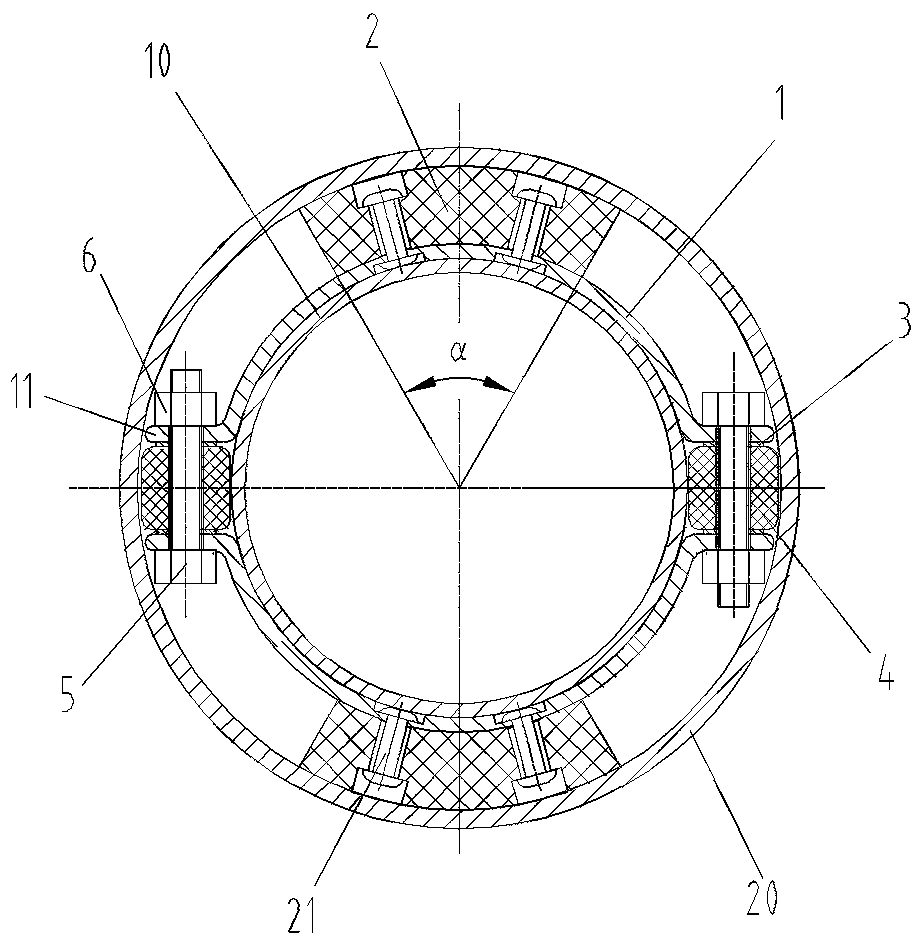

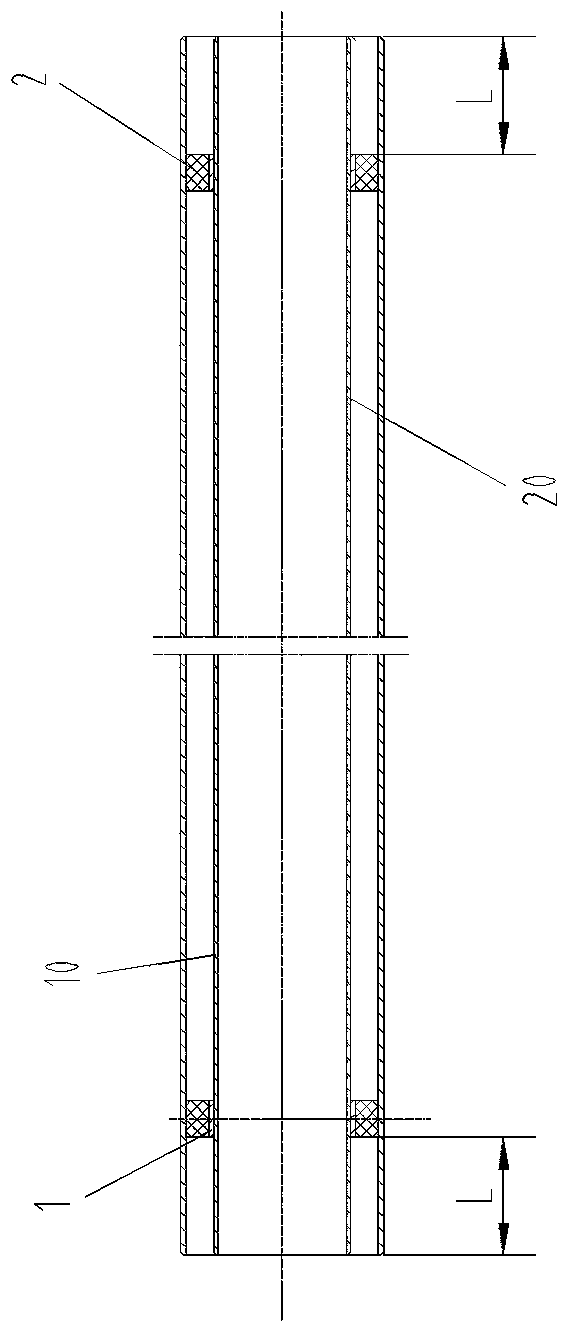

[0014] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the inner tube support device of the gas double-wall pipeline with the outer diameter of the outer tube of φ134mm and the outer diameter of the inner tube of φ89mm.

[0015] Such as figure 1 As shown, this embodiment includes a pair of saddle-shaped support pieces 1 and two elastic support blocks 2, the inner tube 10 is sleeved among the outer tube 20, and a pair of saddle-shaped support pieces 1 clamp the inner tube 10 up and down, the saddle-shaped The support piece 1 is in the shape of a hoop, and the middle part is bent into an arc shape. The arc-shaped inner surface of the saddle-shaped support piece 1 made of Q235 low-carbon steel matches the outer peripheral surface of the inner tube 10. The saddle-shaped support piece 1 is two Horizontal edges 11 are extended from the ends respectively, and nylon guide wheels 4 equipped with elastic gaskets 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com