Mode switch control method of hot water system of heat pump

A heat pump hot water and mode switching technology, applied in fluid heaters, lighting and heating equipment, mechanical equipment, etc., can solve the problems of slow heating speed and insufficient hot water supply, and achieve improved comfort and hot water supply. ability to solve the effect of poor user comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

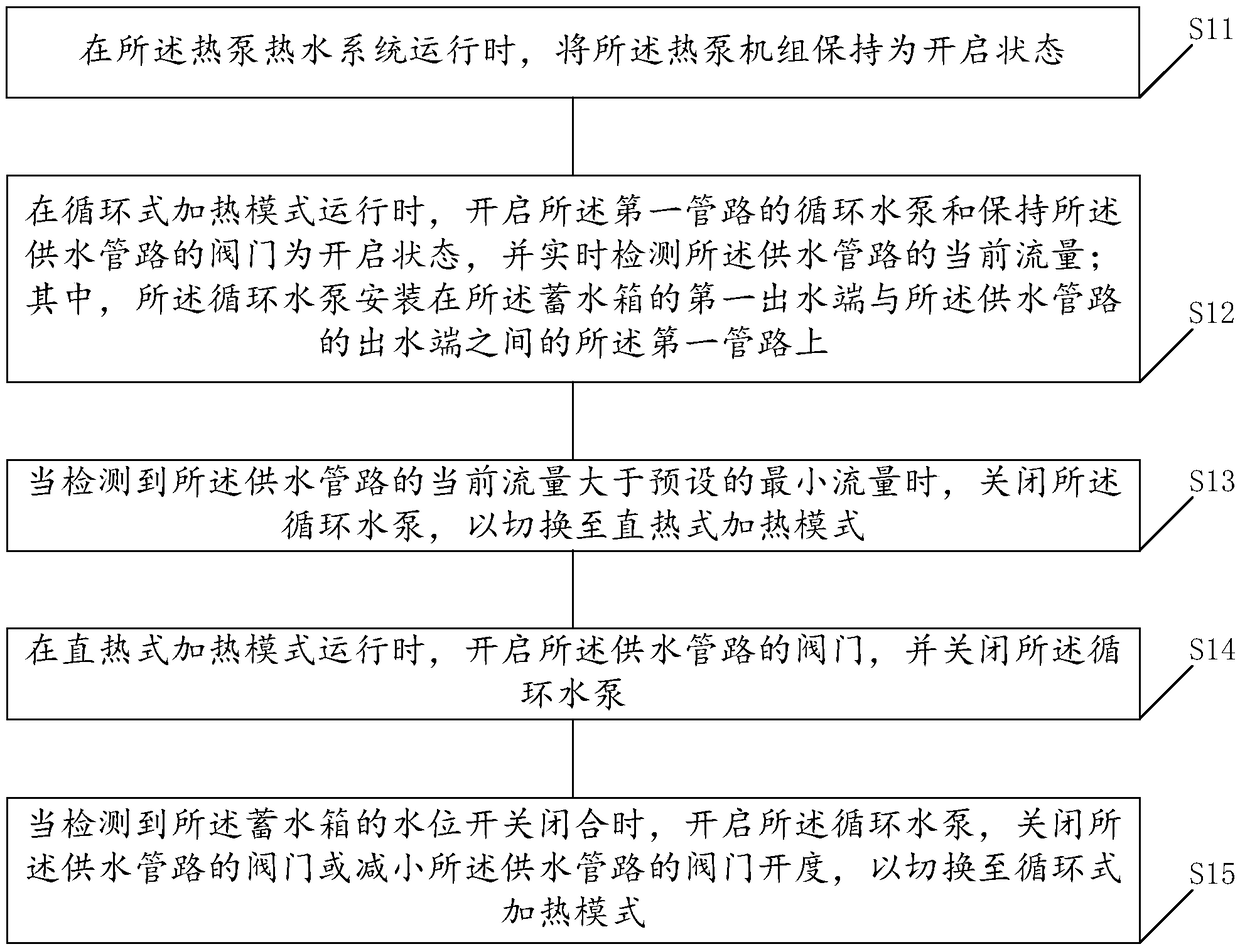

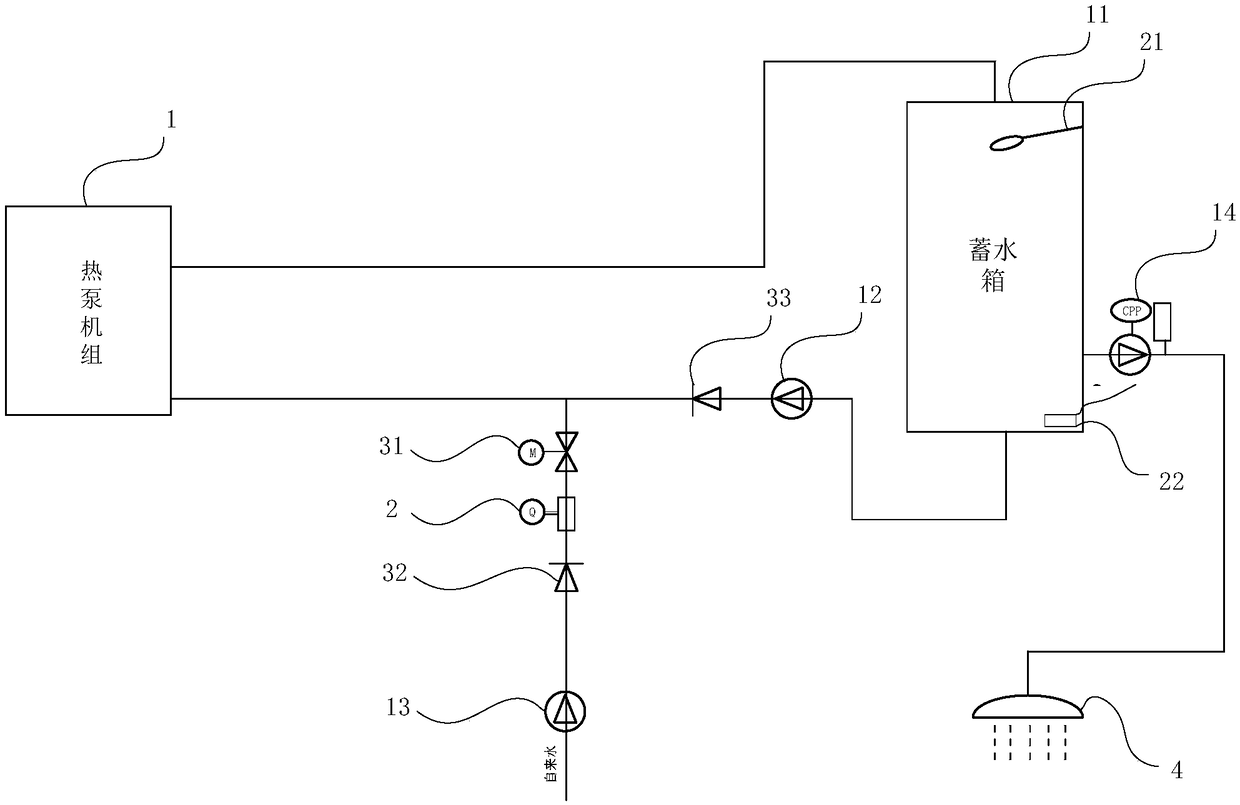

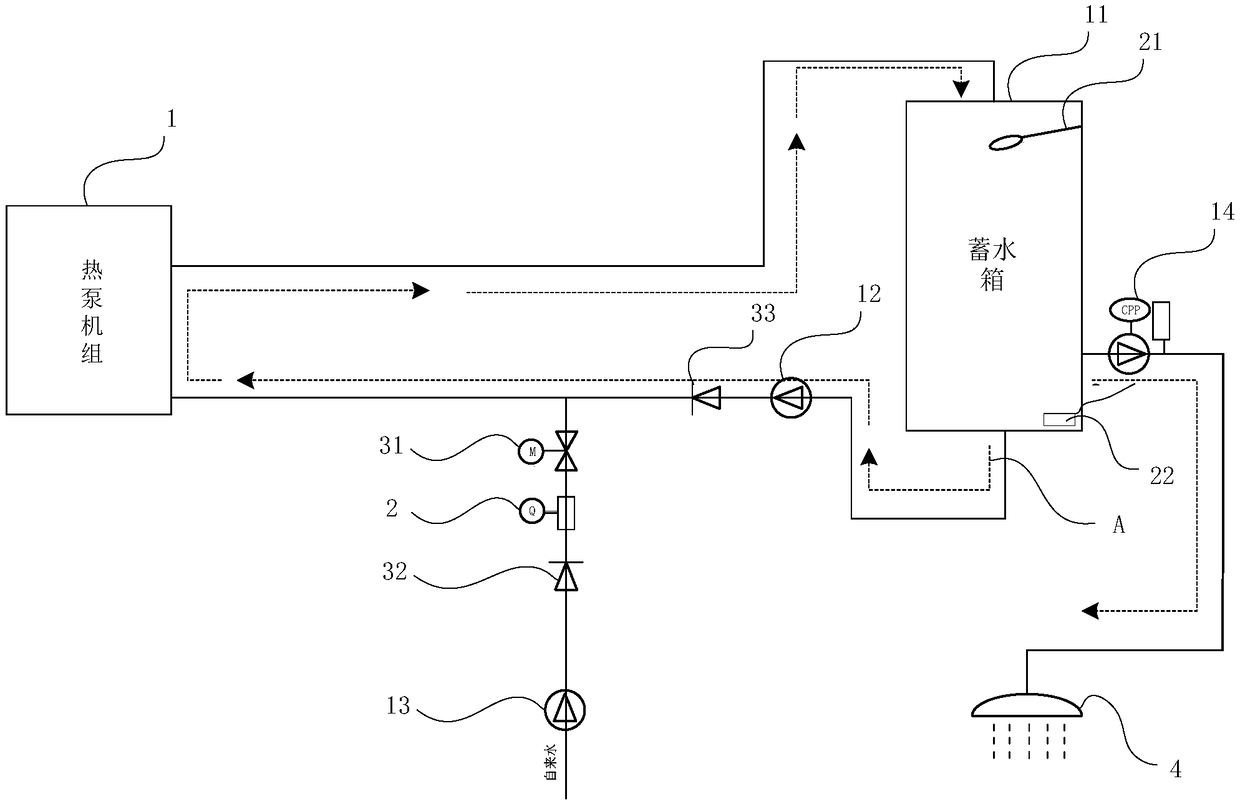

[0069] See Figure 1 to Figure 4 , the first embodiment of the present invention provides a mode switching control method for a heat pump hot water system, which is suitable for the heat pump hot water system, and the heat pump hot water system includes a heat pump unit 1, a water storage tank 11, and a water supply pipeline;

[0070] Wherein, the first water outlet end of the water storage tank 11 communicates with the water inlet end of the heat pump unit 1 to form a first pipeline, and the water inlet end of the water storage tank 11 and the water outlet end of the heat pump unit 1 communicate with and form a second pipeline, and the water outlet end of the water supply pipeline is connected to the first pipeline;

[0071] The water storage tank 11, the first pipeline, the heat pump unit 1 and the second pipeline are sequentially connected to form a circulating heating circuit;

[0072] The water supply pipeline, the first pipeline, the heat pump unit 1, and the water stor...

no. 2 example

[0115] See Figure 5 , on the basis of the first embodiment of the present invention, the heat pump hot water system further includes a first one-way valve 32 and a first electromagnetic two-way valve 3 electrically connected to the controller, the constant pressure water pump 14 and The first electromagnetic two-way valve 3, the first one-way valve 32, and the outlet end of the water supply pump 13 are sequentially connected to form a hot water recovery circuit C;

[0116] The method also includes:

[0117] After closing the constant pressure water pump 14, open the first electromagnetic two-way valve 3 and the water supply pump 13 to start the hot water recovery mode, and recover the hot water in the hot water recovery circuit C to the heat pump Unit 1 is heating.

[0118] In this embodiment, the heat pump hot water system is provided with a hot water recovery circuit C, which can recycle and heat the unused hot water of the user through the hot water recovery circuit C, a...

no. 3 example

[0120] On the basis of the first embodiment of the present invention, the heat pump hot water system further includes a temperature sensor 22 for detecting the water temperature of the water storage tank 11, and the temperature sensor 22 is electrically connected to the controller; the method Also includes:

[0121] When the heat pump hot water system is running, keep the heat pump unit 1 in the open state, detect the open / close state of the water level switch 21 and obtain the current temperature of the water storage tank 11 through the temperature sensor 22 Hot water temperature value;

[0122] When it is detected that the water level switch 21 is disconnected, it is determined that the water storage tank 11 is in a low water level state;

[0123] When the current hot water temperature value is less than the preset first target temperature value R02, switch to the circulating heating mode;

[0124] When the current hot water temperature value is greater than or equal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com