A Microcone-Based Electromagnetic Railgun Rail

An electromagnetic rail gun and rail technology, which is applied to electromagnetic launchers, weapon types, weapons without explosives, etc., can solve problems such as armature loss of contact, and achieve the effects of ensuring uniformity, good protection, and improving power utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

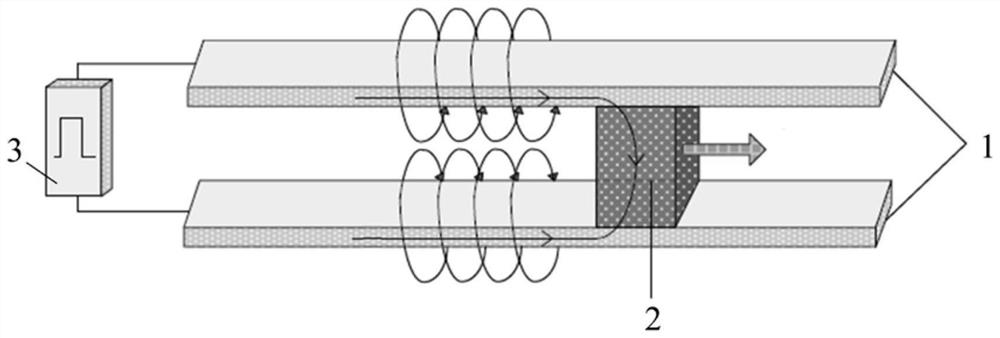

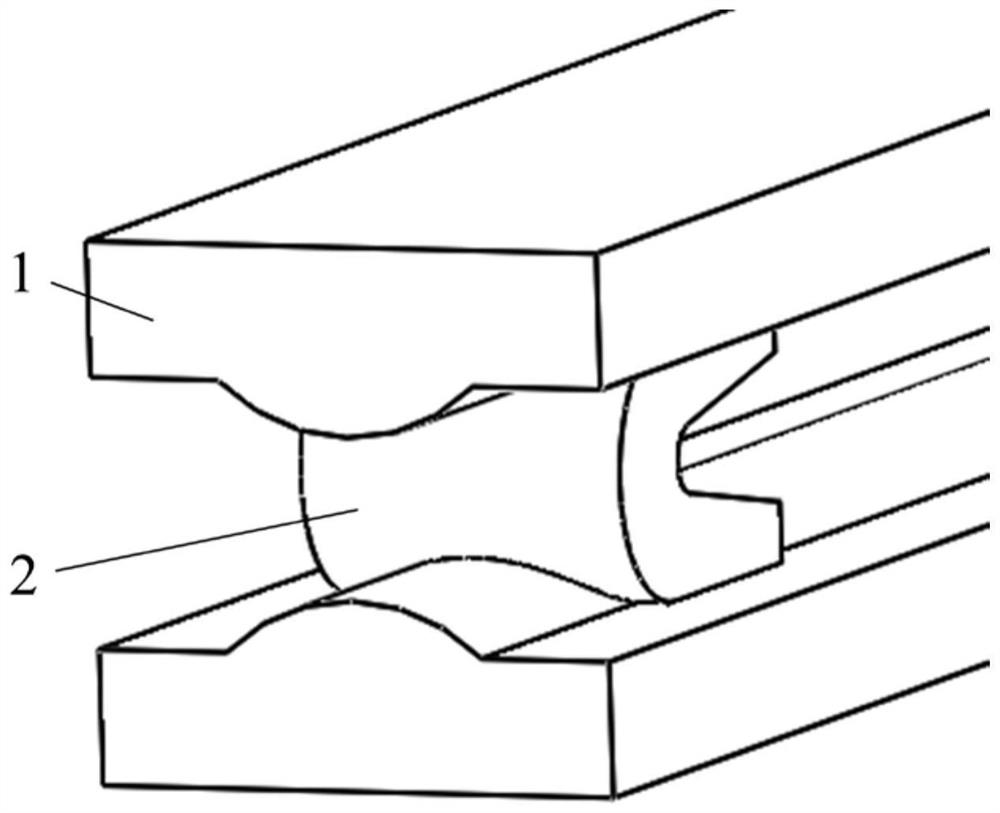

[0031] From the analysis of the basic principle of the electromagnetic railgun, it is equivalent to a single-turn current motor, which is a launcher that propels the armature 2 and accelerates the projectile by means of electromagnetic force. The working principle of the entire electromagnetic railgun system is as follows figure 1 shown.

[0032] The electromagnetic railgun consists of two parallel-connected high-current fixed rails and an armature 2 that maintains good electrical contact with the rails and can slide along the axis of the rails 1 . When the power supply is connected, the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com