Puncture riveting machine with waste material winder

A retractor and riveting machine technology, applied in the field of riveting machines, can solve the problems of time and manpower waste on-site 5S management, and achieve the effects of simple structure, improved production efficiency, and reduced loss cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

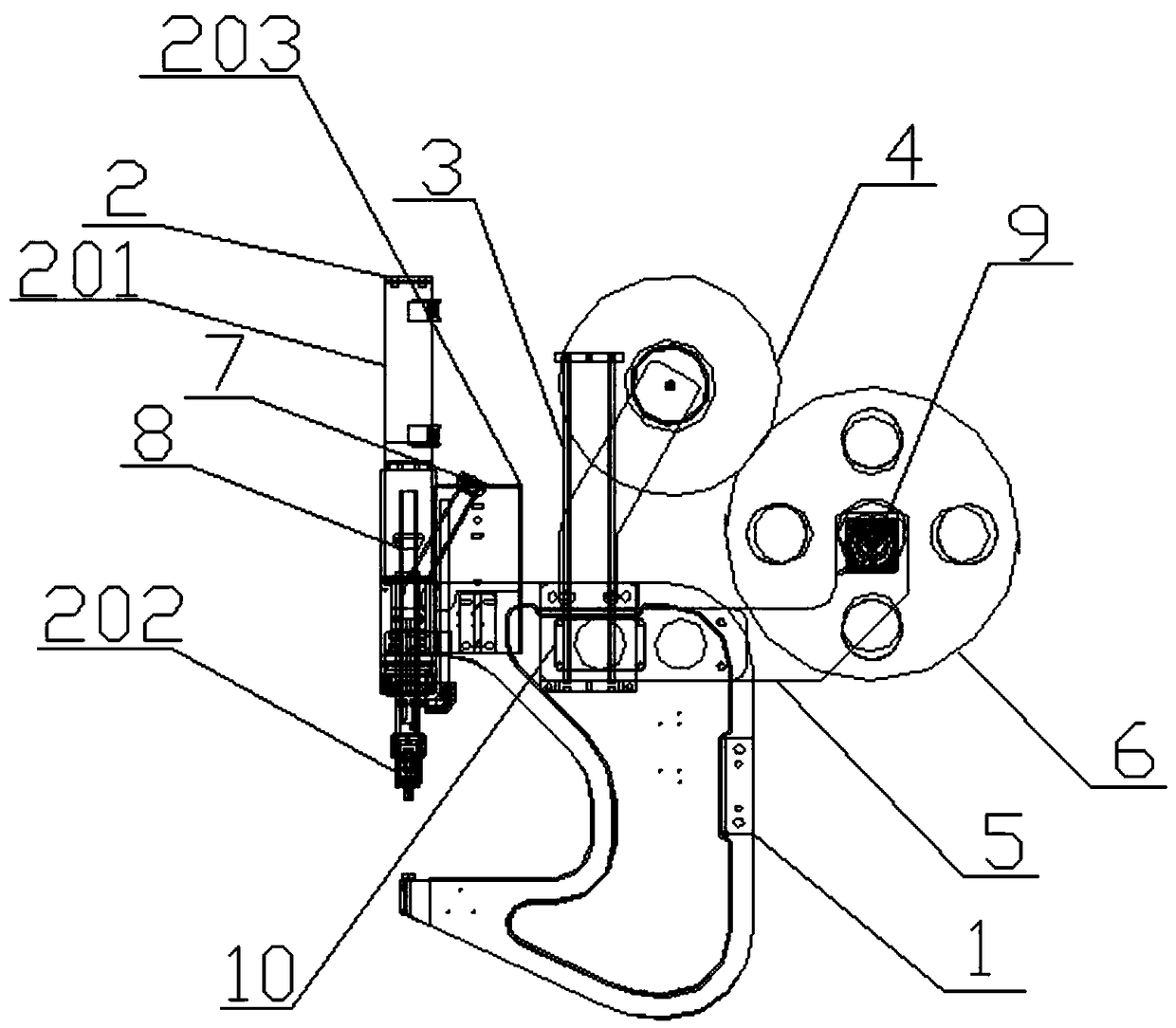

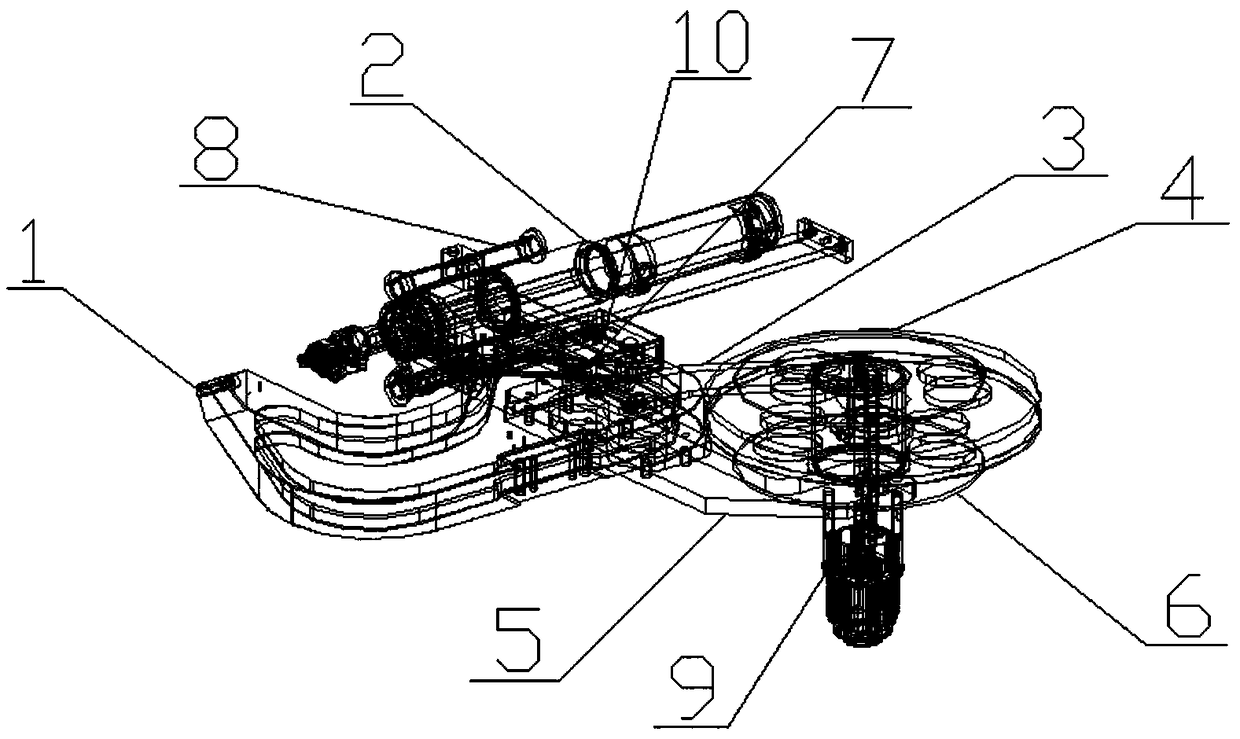

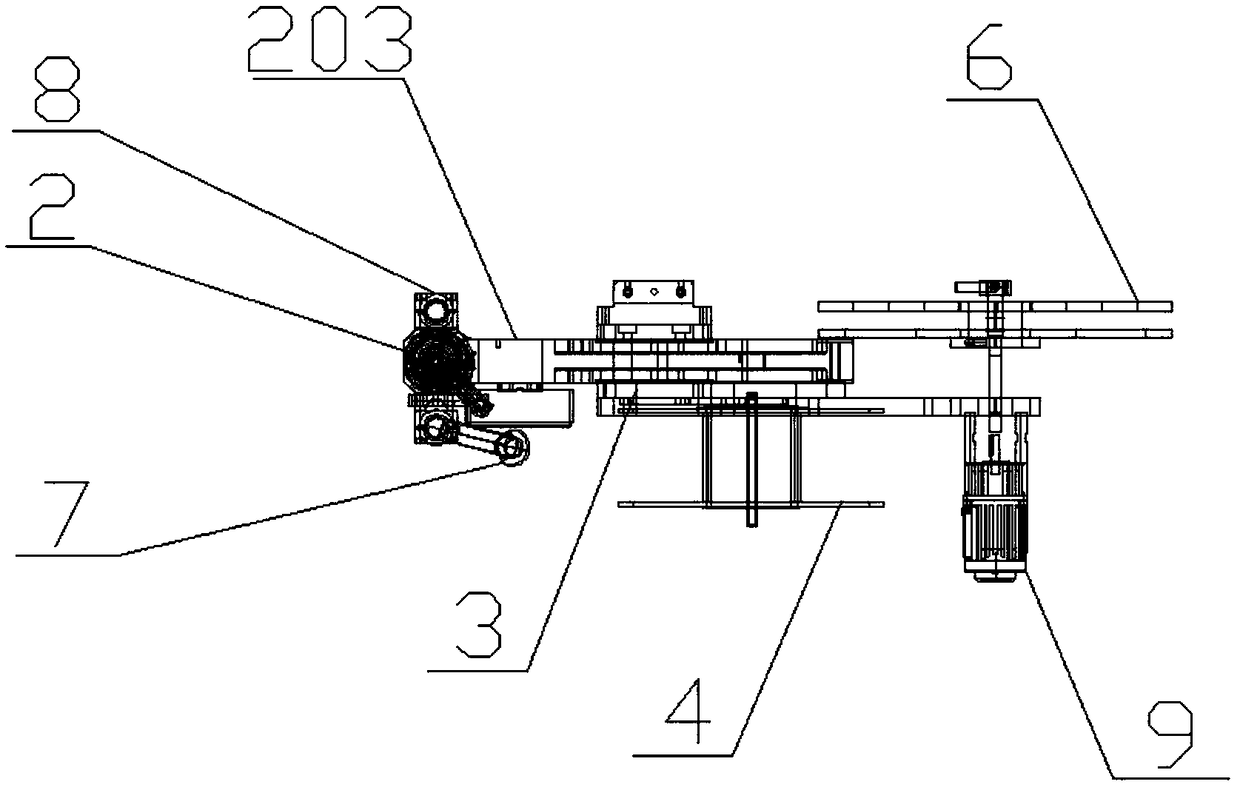

[0024] Such as figure 1 As shown, it includes a U-shaped bracket 1 and a riveting structure 2 arranged on the U-shaped bracket 1, a side end of the U-shaped bracket 1 is provided with a longitudinal bracket 3, and a feeding tray 4 is arranged above the U-shaped bracket 1, and the feeding tray 4 Connect with the U-shaped support 1 through the longitudinal support 3; the other side end surface of the U-shaped support 1 is provided with a transverse support 5, and the right side of the U-shaped support 1 is provided with a waste tray 6, and the waste tray 6 is connected to the U-shaped support through the transverse support 5 1 connection; one side end surface of the riveted structure 2 is provided with a feed pipe 7, and the other side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com