Round glass polisher

A grinding machine and glass technology, which is applied to machine tools, grinders, grinding workpiece supports and other directions suitable for grinding the edges of workpieces, can solve problems such as unstable fixing of glass, and achieve the effect of inhibiting lateral movement of glass and fixing glass firmly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings and specific embodiments, the present invention is further elaborated:

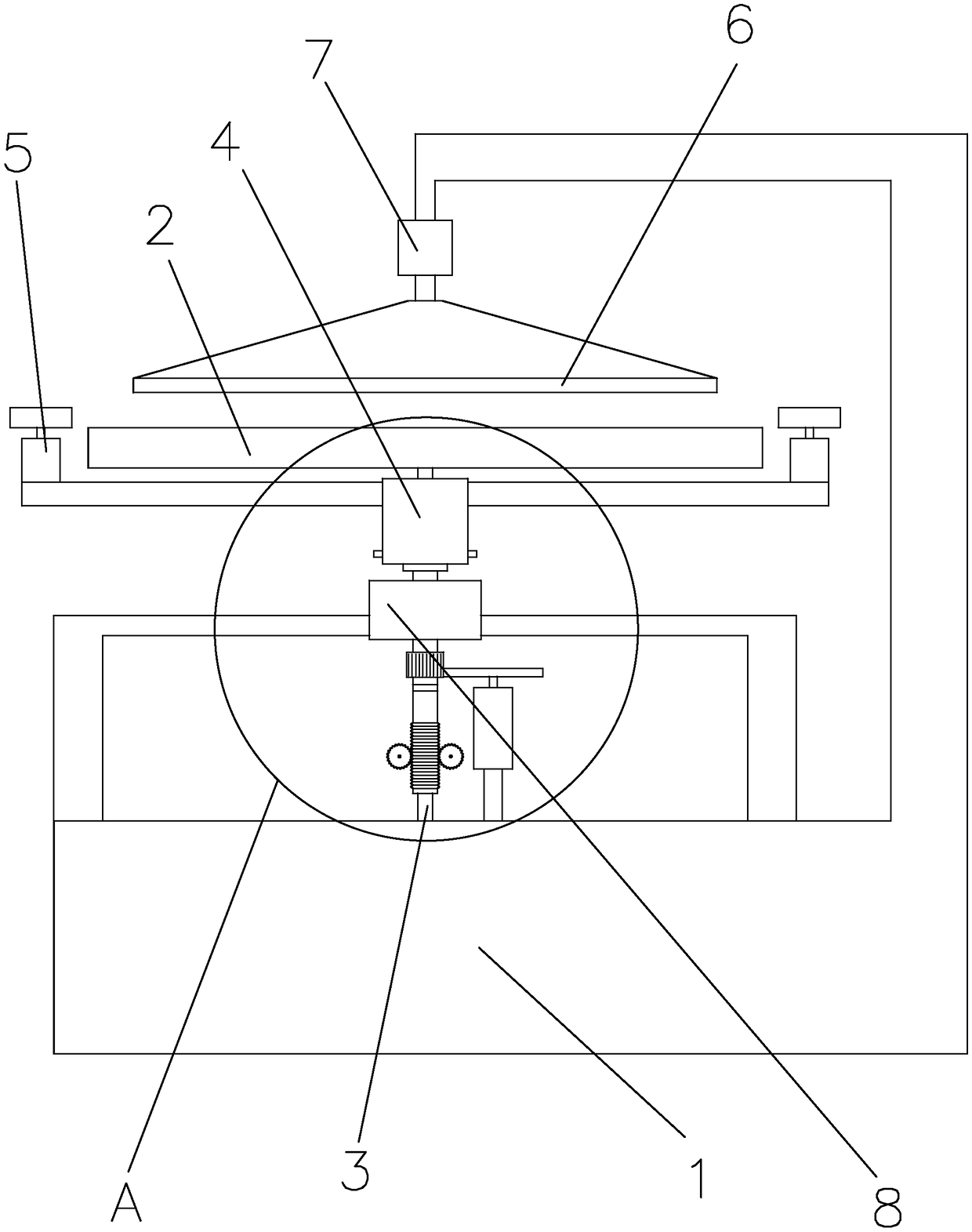

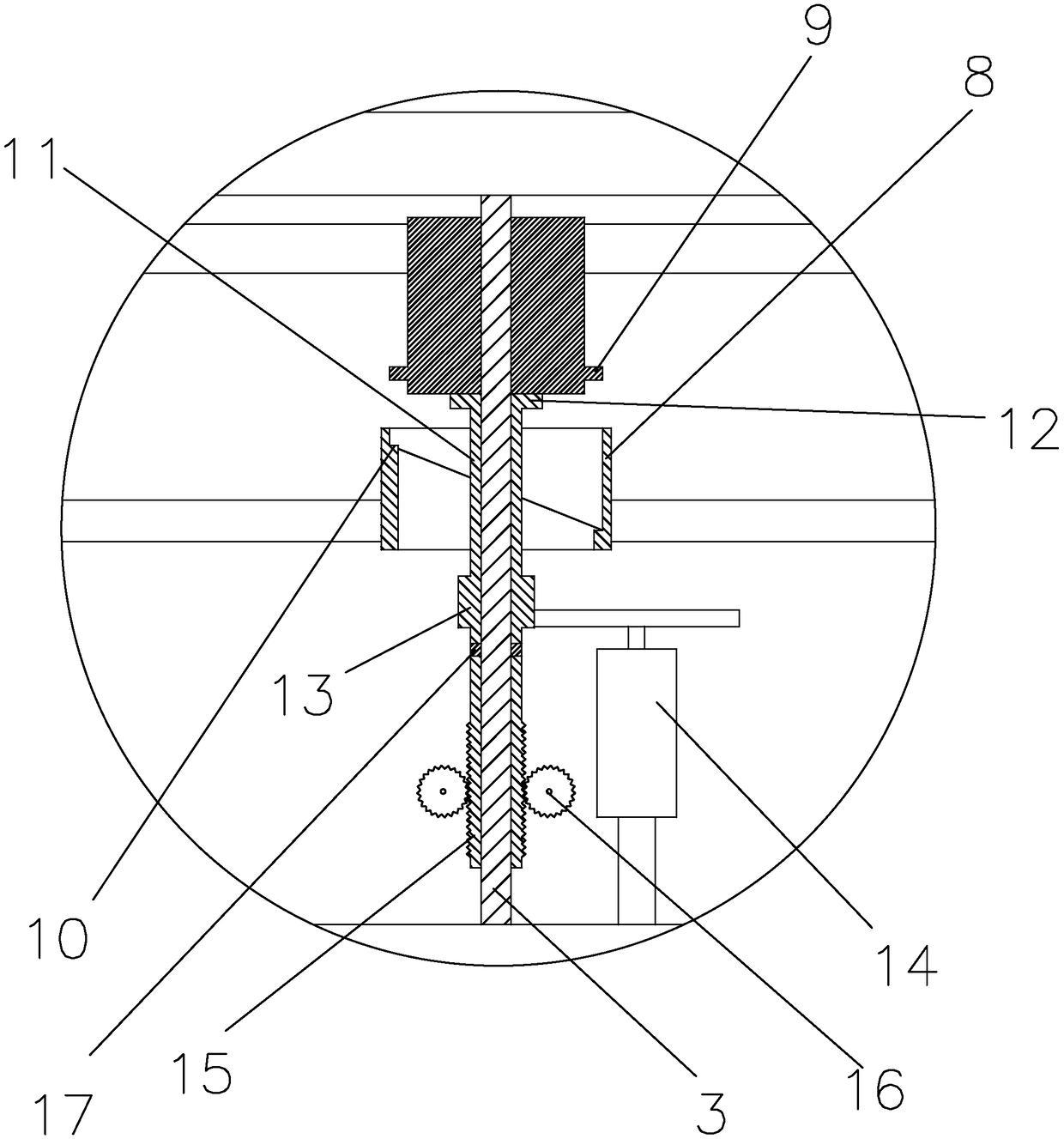

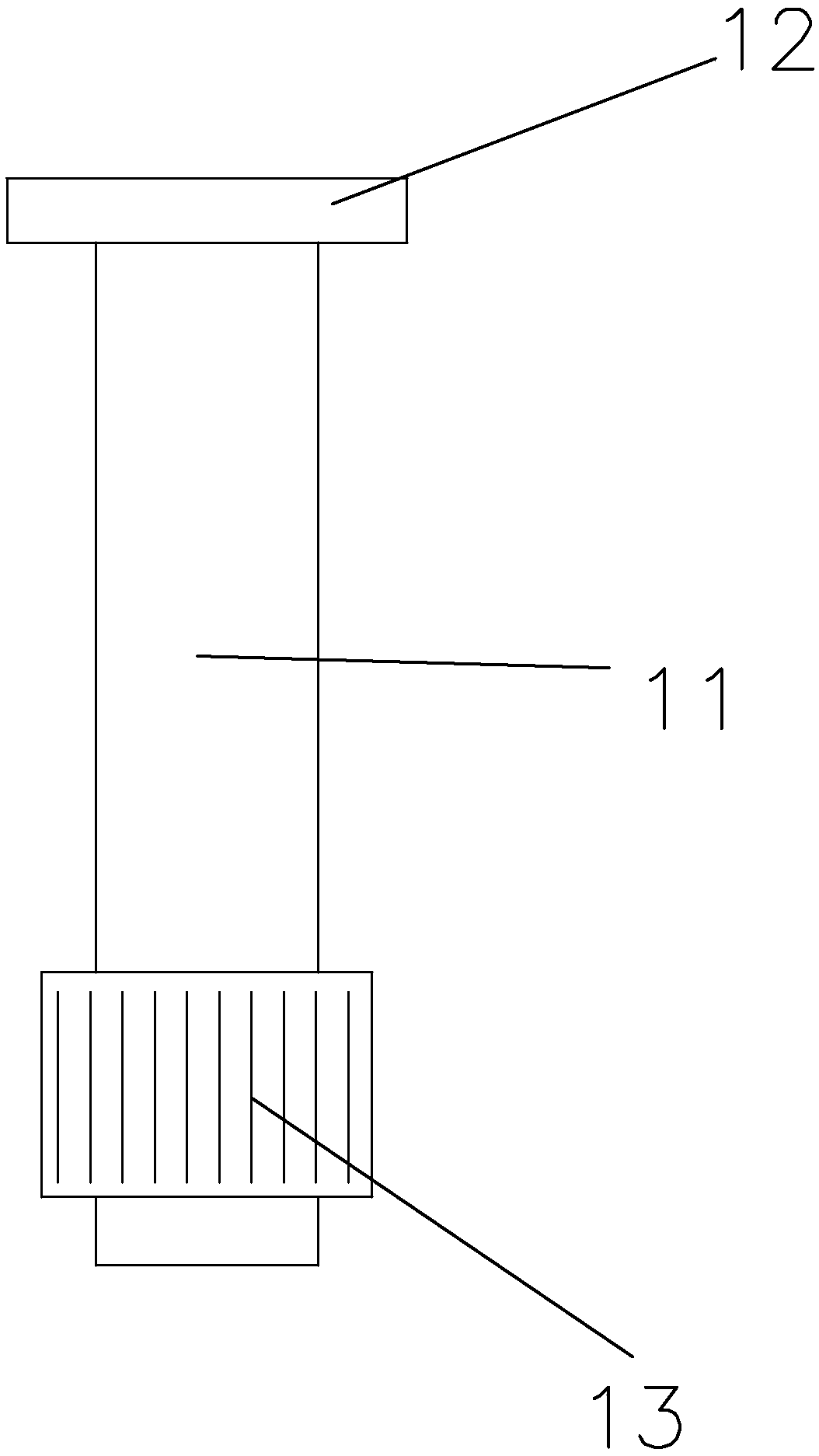

[0024] figure 1 and Figure 7 It is a circular glass grinding machine, comprising a base 1, a glass fixing table 2 is arranged above the base 1, and a vertical support rod 3 is arranged between the base 1 and the glass fixing table 2, and the support The top of the rod 3 is affixed to the glass fixing table 2, the bottom end of the pole 3 is affixed to the base 1, the pole 3 is connected with a rotating sleeve 4, and the two sides of the rotating sleeve 4 are respectively provided with a Grinding motor 5, the grinding motor 5 is symmetrically arranged with the axis of the pole 3, the grinding motor 5 is fixedly connected to the rotating sleeve 4, the glass fixing table 2 is located between the two grinding motors 5, the A pressing plate 6 for fixing the glass is arranged above the glass fixing table 2 , the pressing plate 6 is a ring structure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com