Suspension arm for vehicle wheel suspension unit

A technology of wheel suspension and suspension arm, applied in the field of suspension arm, can solve the problems of increasing production cost and installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the various figures, parts of the same function are always provided with the same reference numerals, so that they are usually only described once.

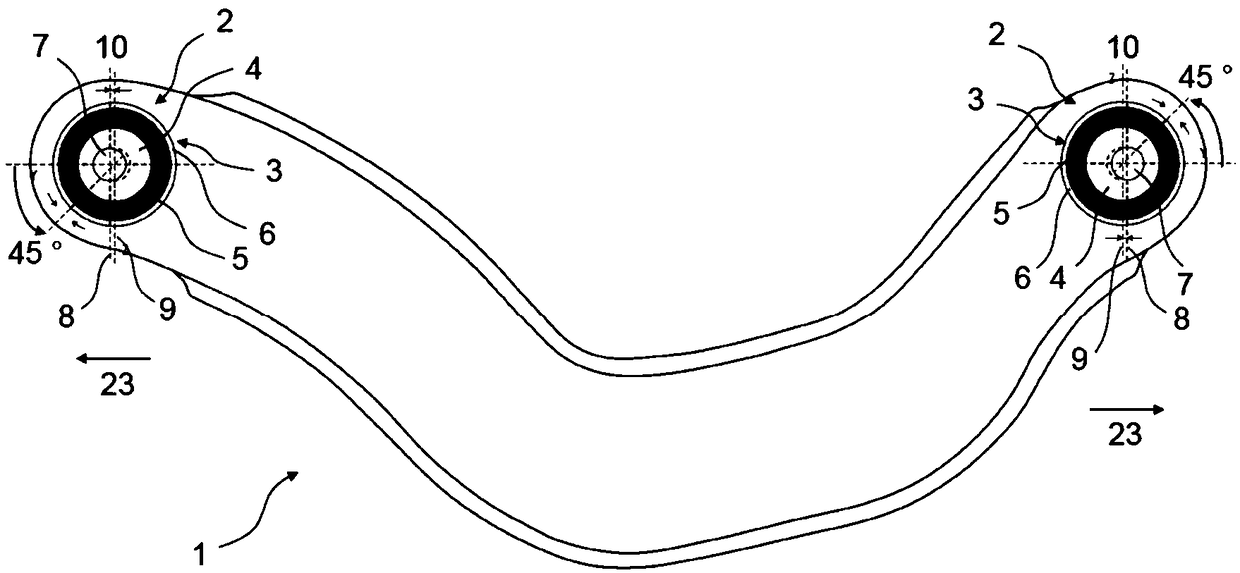

[0028] figure 1 A side view of an exemplary embodiment of a suspension arm 1 according to the invention is shown. figure 1The control arm 1 shown in is an arcuate arm of a wheel suspension unit of a motor vehicle (not shown), also not shown in detail. The arcuate arms are used in a manner known per se to fix the camber of the wheel attached to the wheel suspension unit. from figure 1 As can be seen in FIG. 1 , the control arm 1 has a substantially rod-shaped design, and bearing receptacles 2 for receiving rubber bearings 3 are respectively arranged on two opposite ends of the control arm 1 .

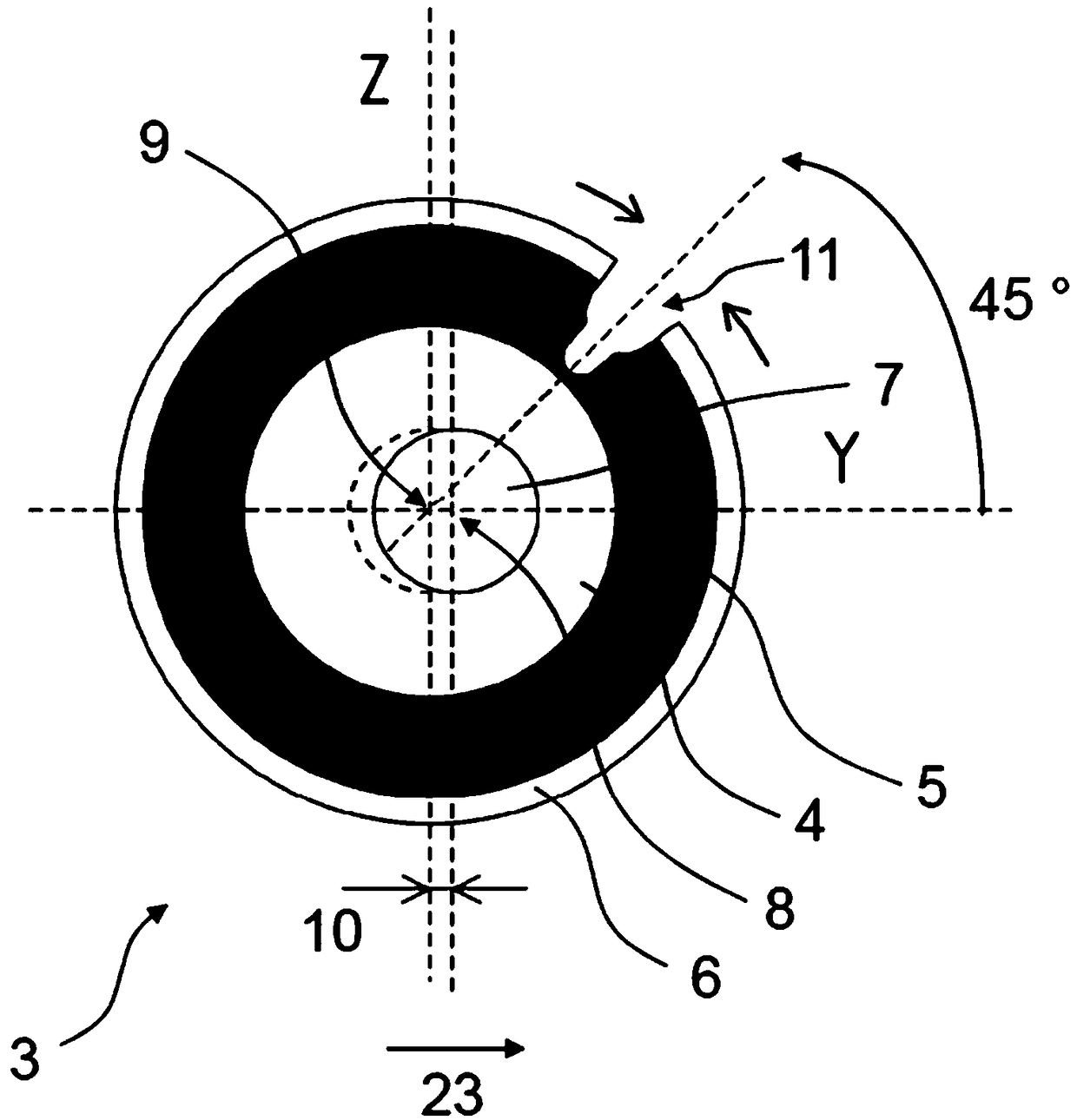

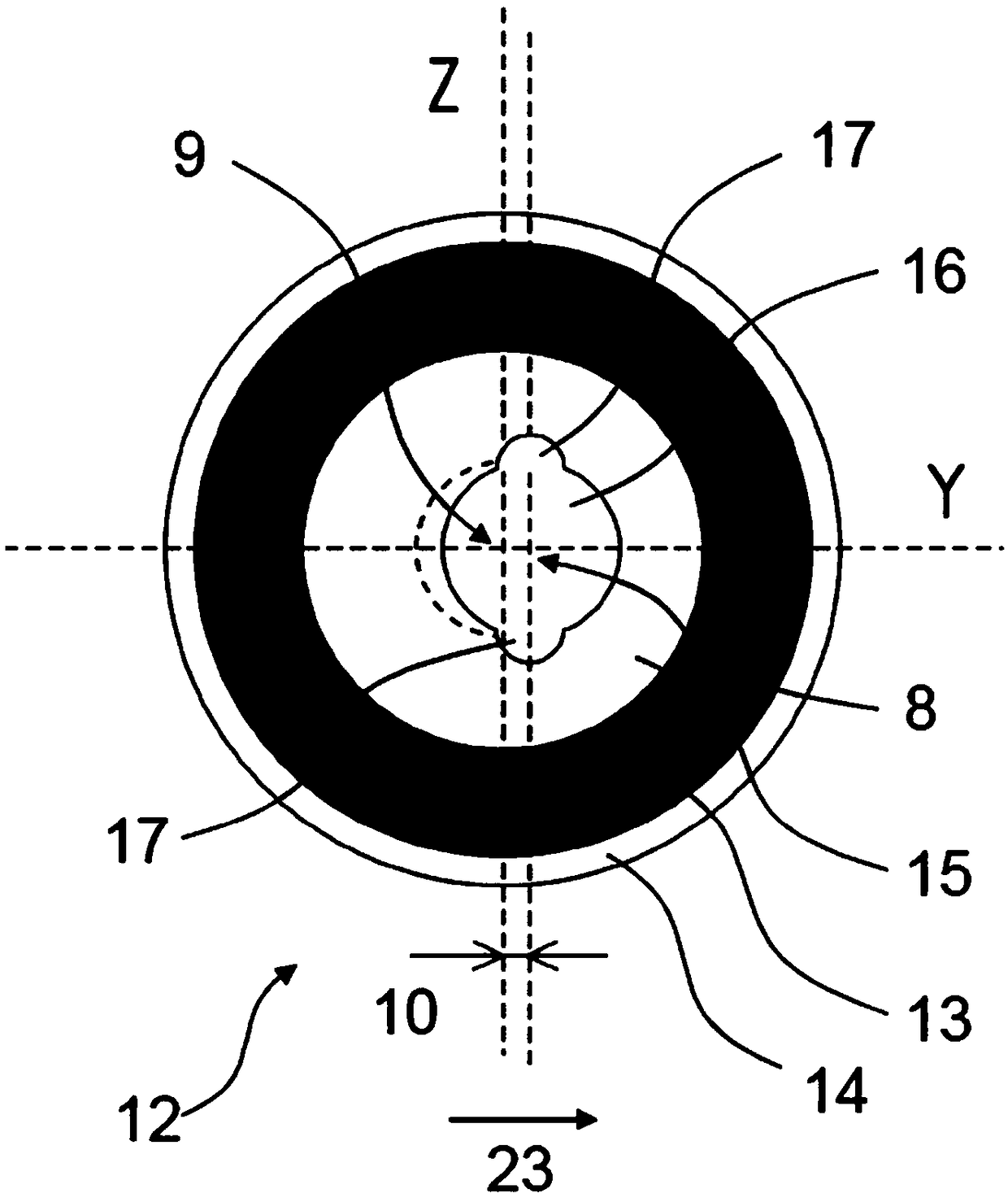

[0029] exist figure 2 , enlarged side view showing press-in figure 1 Rubber bearings 3 in the two bearing receptacles 2 of the control arm 1. especially, figure 2 The rubber bearing 3 in is shown in a state of being remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com