Detergent mixing device and washing equipment

A mixing device and detergent technology, which is applied to washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of insufficient mixing of detergents and poor cleaning and decontamination effects, and achieve the best cleaning and decontamination effects without effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

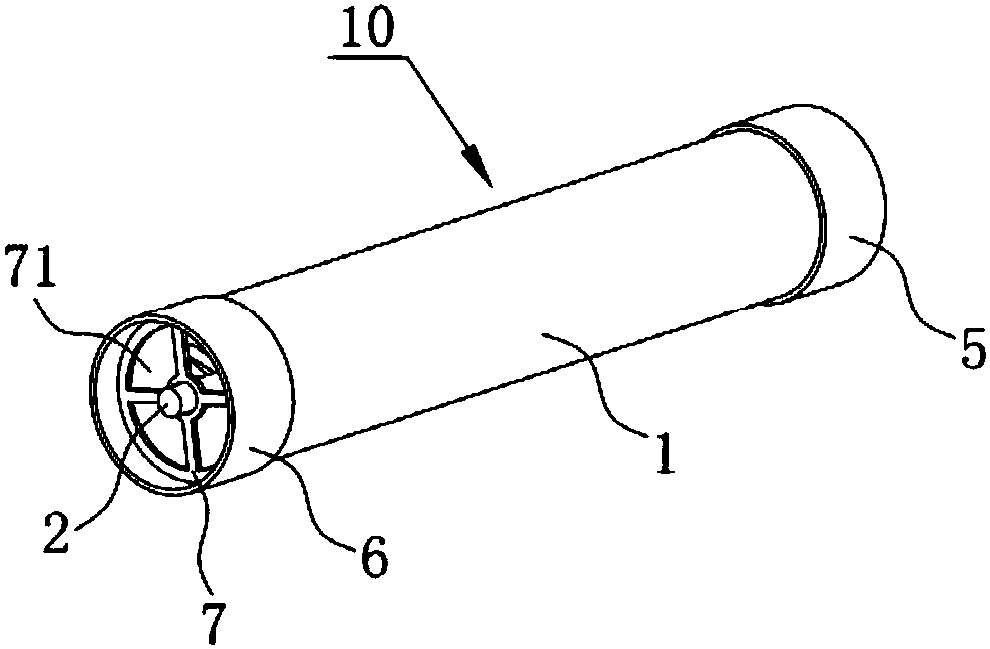

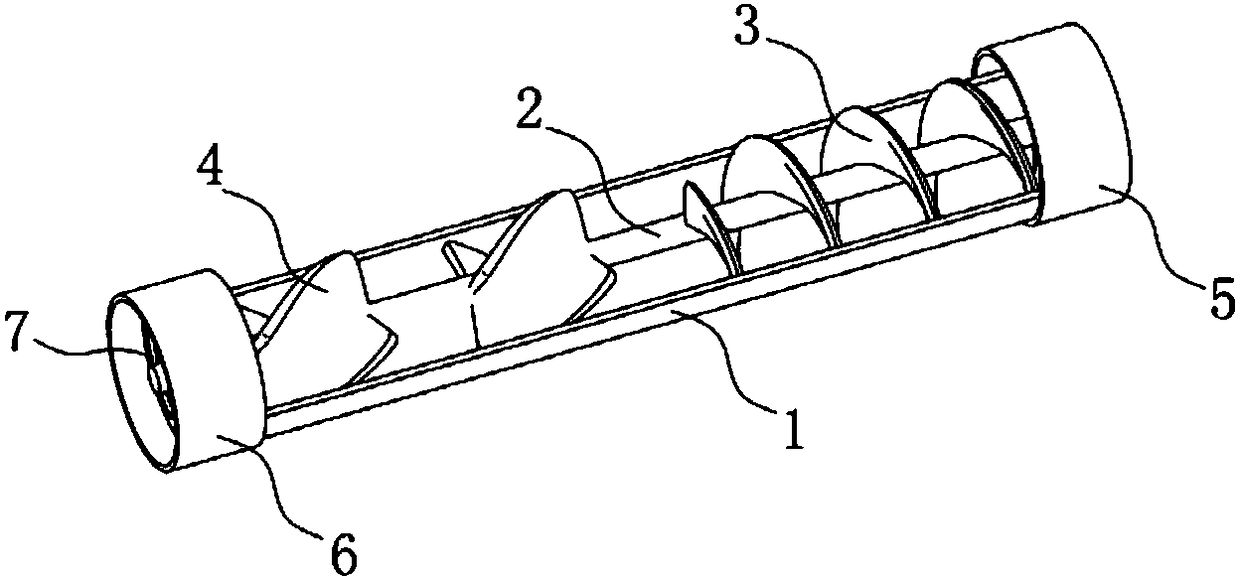

[0026] This embodiment provides a detergent mixing device 10, such as Figure 1-3 As shown, the detergent mixing device 10 includes a housing 1, water inlet joints 5 and water outlet joints 6 and a rotating shaft 2 respectively arranged at both ends of the housing 1, wherein:

[0027] The above-mentioned housing 1 adopts a cylindrical structure, which may be specifically a cylindrical structure, or a cylindrical structure of other shapes. The above-mentioned water inlet joint 5 is arranged at one end of the cylindrical structure, and is used to connect to the water outlet of the detergent box 20. It is used for detergent and tap water to enter, and the water outlet joint 6 is connected to the water inlet of the washing part 30 of the washing equipment, and is used to flush the mixed detergent into the washing part 30 of the washing equipment for use.

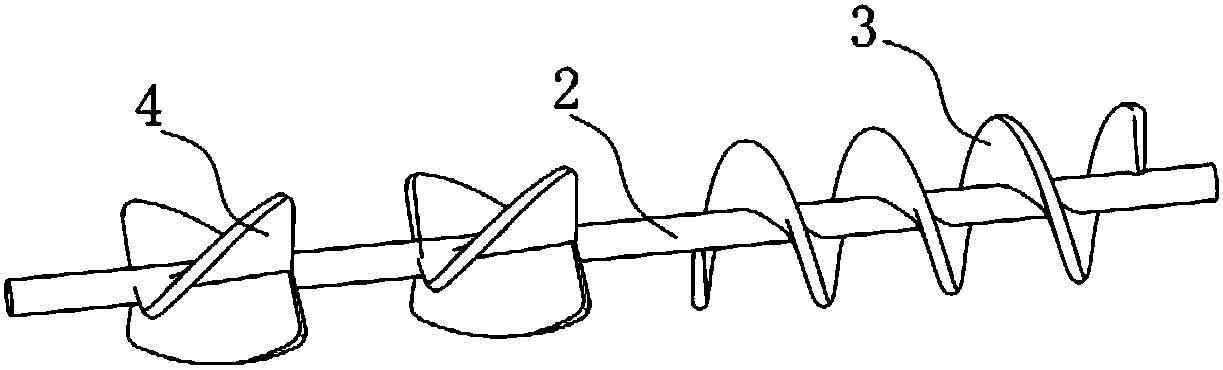

[0028] The rotating shaft 2 is rotatably arranged in the casing 1 , specifically, a rotating shaft bracket 7 may be provided i...

Embodiment 2

[0037] The difference between the present embodiment and the first embodiment is only that the structure of the stirring blade 4 of the detergent mixing device 10 of the present embodiment is different from that of the stirring blade 4 of the first embodiment, which can be referred to Figure 5 Each set of stirring blades 4 in this embodiment includes at least one rectangular blade arranged radially along the rotating shaft 2 , and when there are multiple rectangular blades, the plurality of rectangular blades are evenly distributed on the rotating shaft 2 in the circumferential direction. By means of the aforementioned rectangular blades, repeated and homogeneous mixing of detergent and water is possible.

[0038] The rest of the structure is the same as that of the first embodiment, so it will not be repeated here.

[0039] This embodiment also provides a washing device, including the detergent mixing device 10 described in this embodiment. Specifically, the washing equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com