Method for cleaning spotting head of chip spotting instrument

A technology of a spotting head and a spotting instrument, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc. The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

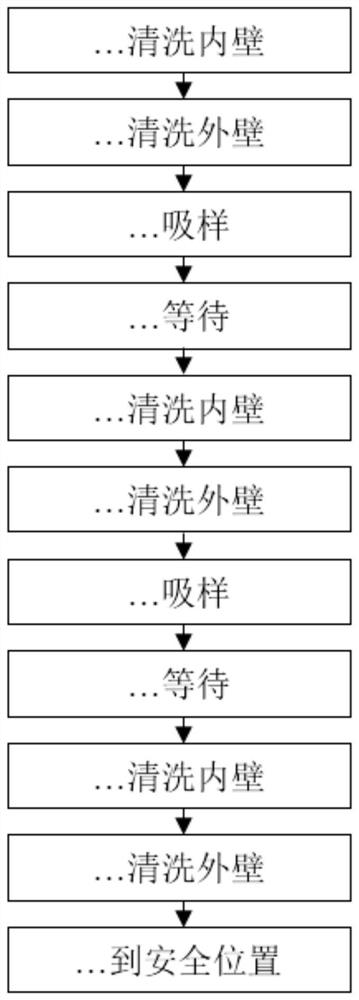

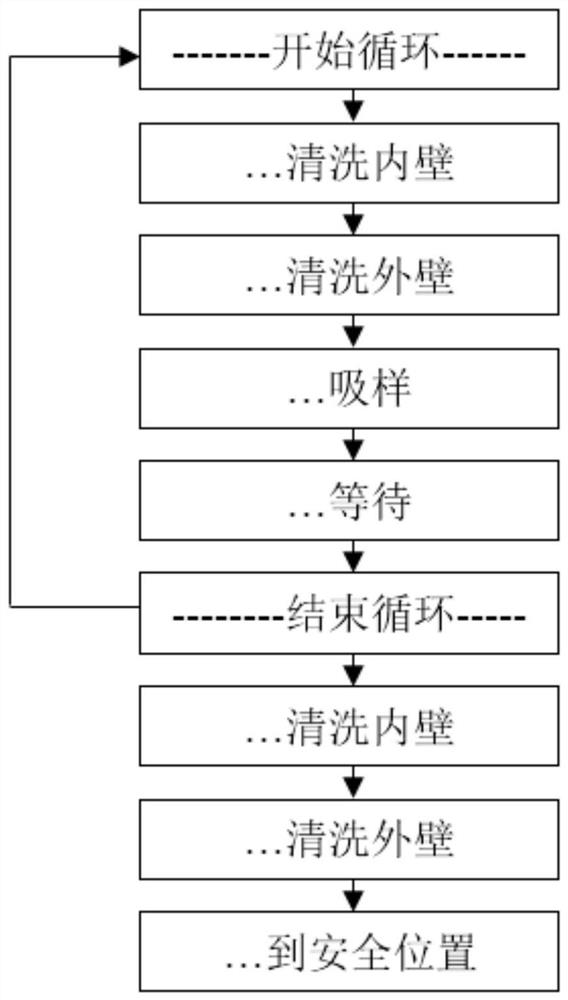

[0051] A method for cleaning the sampling head of a chip spotting instrument of the present invention is carried out according to the following steps:

[0052] (1) Prepare two reagents in advance:

[0053] A: 3% (V / V) Hellmanex III aqueous solution (a cleaning agent produced by HELLMA Analytics, Germany) and 5% (W / V) SDS aqueous solution,

[0054] B: 75% (V / V) isopropanol aqueous solution.

[0055] (2), add 300ul of A solution in the No. 1 hole and the No. 3 hole of the sample strip, and add 300ul of the B solution in the No. 2 hole and the No. 4 hole;

[0056] The cleaning process is:

[0057] (1) Wash the inner wall of the sampling head with purified water 10-15 times (250ul each time), and the outer wall 2 times (2 seconds each time),

[0058] (2) The sampling head absorbs 80ul of liquid A in the No. 1 hole of the sample loading strip, and soaks the sampling head in the remaining liquid A in the No. 1 hole for more than 10 minutes;

[0059](3) Wash the inner wall of the...

Embodiment 2

[0067] A method for cleaning the sampling head of a chip spotting instrument of the present invention is carried out according to the following steps:

[0068] (1) Prepare two reagents in advance:

[0069] A: 2% (V / V) Hellmanex III aqueous solution (a cleaning agent produced by HELLMA Analytics, Germany) and 10% (W / V) SDS aqueous solution,

[0070] B: 80% (V / V) isopropanol aqueous solution.

[0071] (2), add 300ul of A solution in the No. 1 hole and the No. 3 hole of the sample strip, and add 300ul of the B solution in the No. 2 hole and the No. 4 hole;

[0072] The cleaning process is:

[0073] (1) Wash the inner wall of the sampling head with purified water 10-15 times (250ul each time), and the outer wall 2 times (2 seconds each time),

[0074] (2) The sampling head absorbs 80ul of liquid A in the No. 1 hole of the sample loading strip, and soaks the sampling head in the remaining liquid A in the No. 1 hole for more than 10 minutes;

[0075] (3) Wash the inner wall of t...

Embodiment 3

[0083] A method for cleaning the sampling head of a chip spotting instrument of the present invention is carried out according to the following steps:

[0084] (1) Prepare two reagents in advance:

[0085] A: 4% (V / V) Hellmanex III aqueous solution (a cleaning agent produced by HELLMA Analytics, Germany) and 1% (W / V) SDS aqueous solution,

[0086] B: 70% (V / V) isopropanol aqueous solution.

[0087] (2), add 300ul of A solution in the No. 1 hole and the No. 3 hole of the sample strip, and add 300ul of the B solution in the No. 2 hole and the No. 4 hole;

[0088] The cleaning process is:

[0089] (1) Wash the inner wall of the sampling head with purified water 10-15 times (250ul each time), and the outer wall 2 times (2 seconds each time),

[0090] (2) The sampling head absorbs 80ul of liquid A in the No. 1 hole of the sample loading strip, and soaks the sampling head in the remaining liquid A in the No. 1 hole for more than 10 minutes;

[0091] (3) Wash the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com