Aluminum shell battery shell decontamination and rust removing agent and preparation method and application thereof

A technology of aluminum shell battery and rust remover is applied in the field of preparation of decontamination and rust remover, can solve the problems of good cleaning and decontamination effect, low cost of materials, pollution, etc., and achieves good cleaning and decontamination effect and cost of materials Inexpensive and stable effect of finished product ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

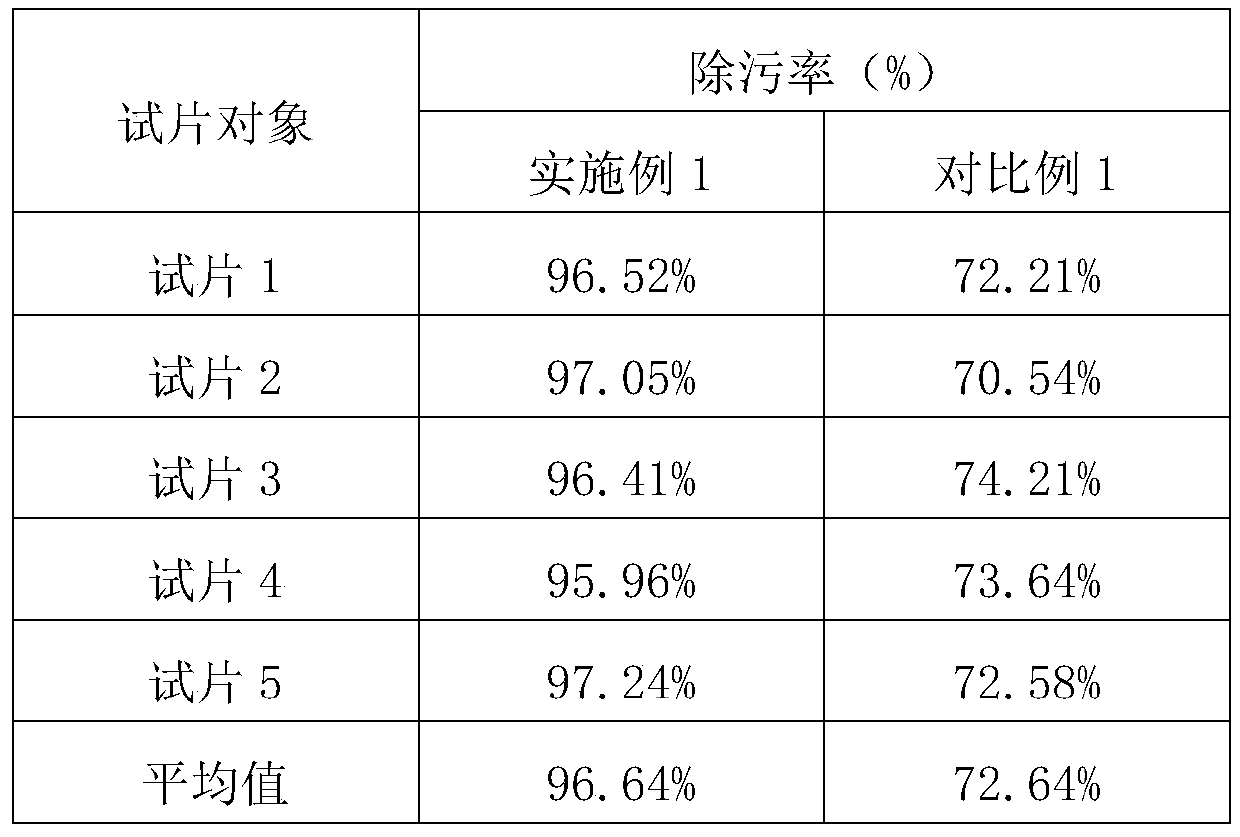

Examples

Embodiment 1

[0017] A preparation method of an aluminum case battery case decontamination and rust remover, specifically comprising the following steps:

[0018] (1) Preparation of aluminum material degreasing cleaning agent: calculate by mass 10% citric acid, 10% sodium chloride, 5% fatty alcohol, 10% polyoxyethylene powder, 5% trisodium phosphate, 10 % of penetrating agent, 10% of oil stain gripping agent, and the rest of water, mix and stir evenly, and then stand still for more than 30 minutes.

[0019] (2) Prepare 5% rosin water, 10% dimethyl carbonate, 20% sodium hydroxide, 15% water and 50% aluminum degreasing cleaning agent according to the following ratio; , pine water, dimethyl carbonate, and sodium hydroxide in the order according to the required amount of the formula, mix and stir evenly and let it stand for 30 minutes.

Embodiment 2

[0021] A preparation method of an aluminum case battery case decontamination and rust remover, specifically comprising the following steps:

[0022] (1) Preparation of aluminum material degreasing cleaning agent: calculate by mass 10% citric acid, 10% sodium chloride, 5% fatty alcohol, 10% polyoxyethylene powder, 5% trisodium phosphate, 10 % of penetrating agent, 10% of oil stain gripping agent, and the rest of water, mix and stir evenly, and then stand still for more than 30 minutes.

[0023] (2) Prepare 10% rosin water, 5% dimethyl carbonate, 15% sodium hydroxide, 15% water and 55% aluminum degreasing cleaning agent according to the following ratio; , pine water, dimethyl carbonate, and sodium hydroxide in the order according to the required amount of the formula, mix and stir evenly and let it stand for 60 minutes to get it.

Embodiment 3

[0025] A preparation method of an aluminum case battery case decontamination and rust remover, specifically comprising the following steps:

[0026] (1) Preparation of aluminum material degreasing cleaning agent: calculate by mass 10% citric acid, 10% sodium chloride, 5% fatty alcohol, 10% polyoxyethylene powder, 5% trisodium phosphate, 10 % of penetrating agent, 10% of oil stain gripping agent, and the rest of water, mix and stir evenly, and then stand still for more than 30 minutes.

[0027] (2) Prepare 8% rosin water, 8% dimethyl carbonate, 8% sodium hydroxide, 10% water and 66% aluminum degreasing cleaning agent according to the following proportions; , pine water, dimethyl carbonate, and sodium hydroxide are mixed according to the required amount of the formula, stirred evenly and left to stand for 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com