A reliability allocation method for NC machine tools based on maximum entropy ordered weighted average

A CNC machine tool, weighted average technology, applied in data processing applications, instruments, resources, etc., to reduce machine tool maintenance costs, improve reliability, and control reasonable support costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

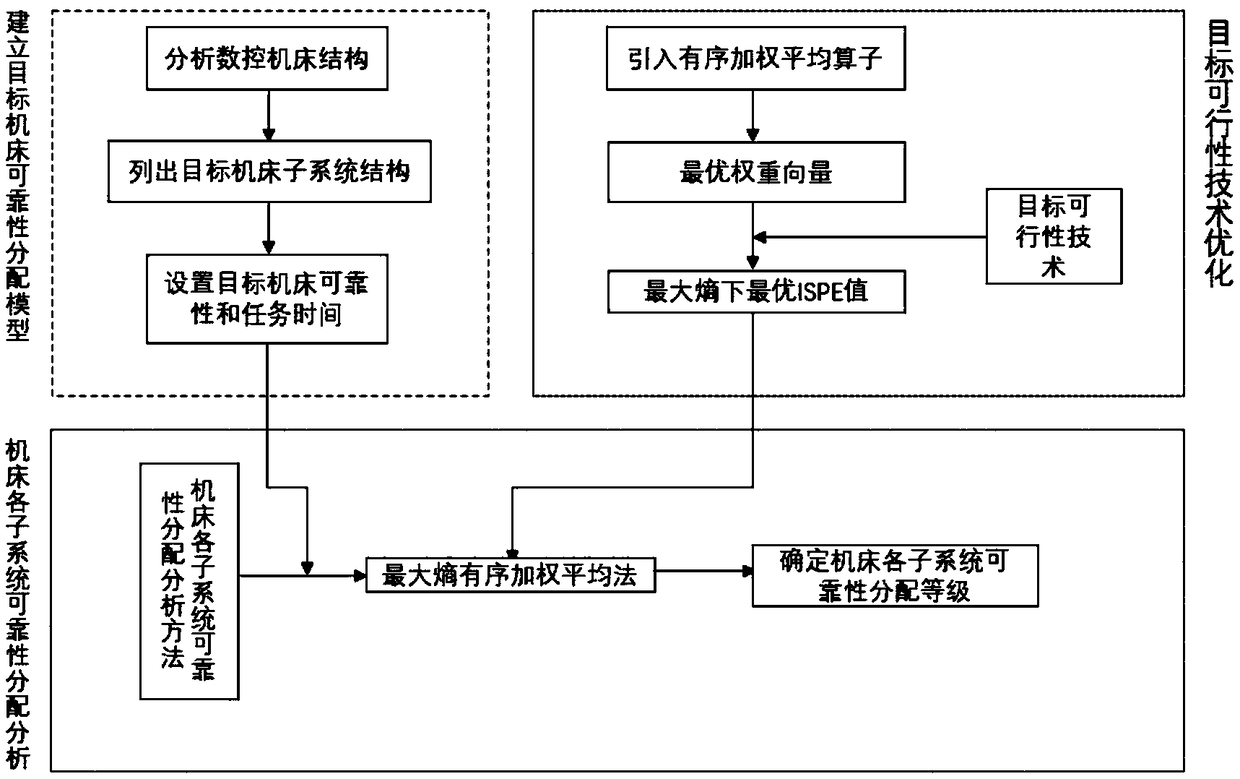

[0028] The present invention takes a numerical control machine tool as an example to verify whether the invention can achieve optimal distribution.

[0029] Specifically include the following steps:

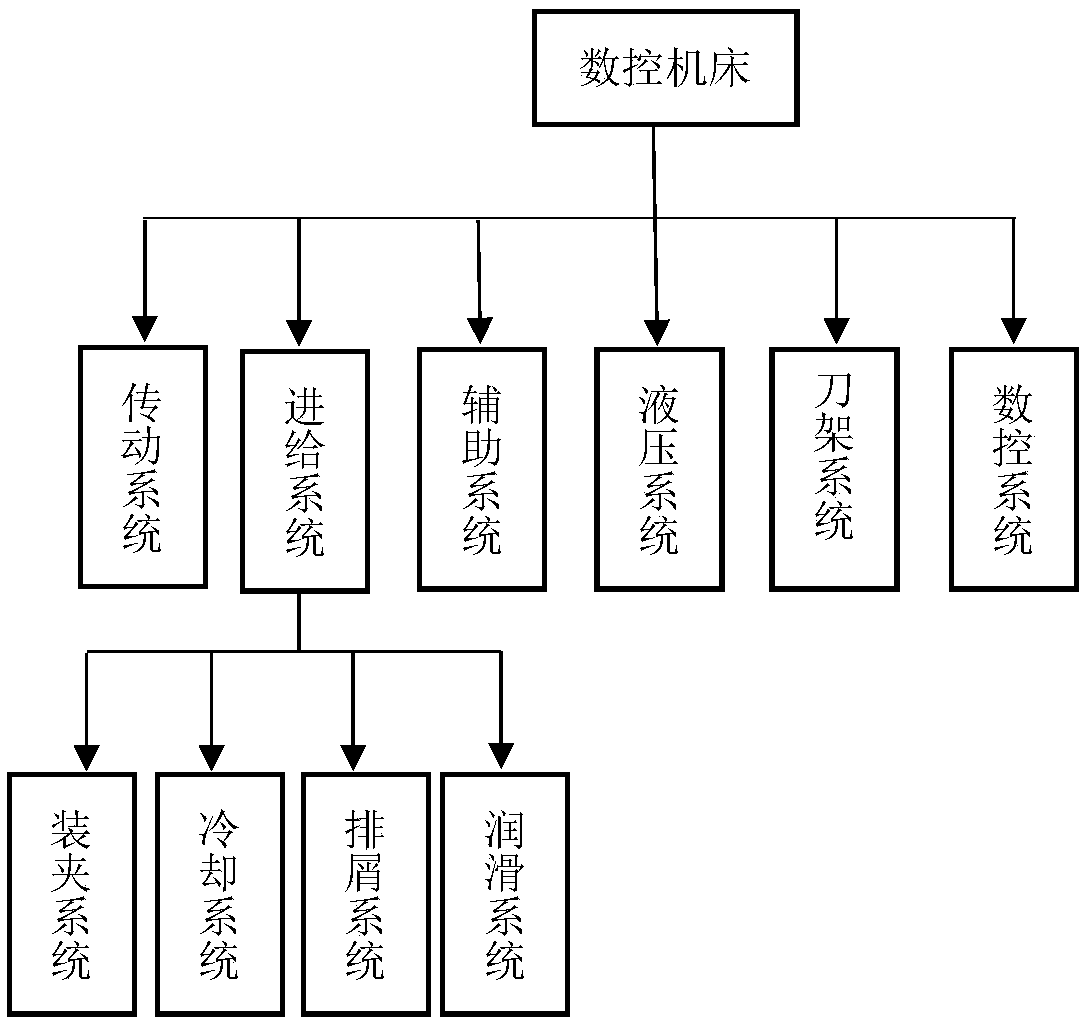

[0030] Step 1: List the structure of the CNC machine tool system and its subsystems, such as figure 1 shown

[0031] Step 2: Based on the design requirements and system operating environment, the system reliability of the CNC machine tool system is set to 0.995214, and the task time is set to 1000 hours. The failure rate of the CNC machine tool system can be calculated by formula (1), namely

[0032] lambda S =-ln(R) / T=0.0000047975=47.975×10 -7

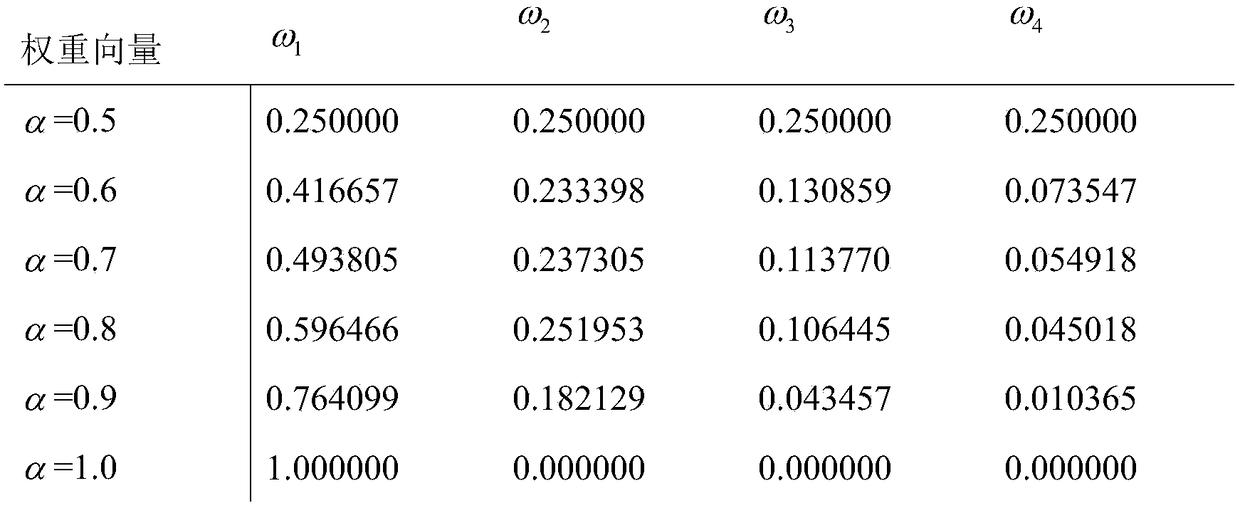

[0033] Step 3: Determine the scales of I, S, P, and E for each subsystem of the CNC machine tool (ISPE value is a number within 1 to 10), and then use the method of expert judgment to determine the ISPE of each subsystem of the CNC machine tool value, as shown in Table 2

[0034] Table 2: ISPE values of CNC machine tool subsystem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com