A fiberglass tank cultivation device for shellfish seedling cultivation

A cultivation device, glass fiber reinforced plastic technology, applied in application, climate change adaptation, fish farming, etc., can solve the problems of low cultivation efficiency, occupying more space, adverse effects on the growth of lower shellfish, etc. Cultivation efficiency, the effect of improving the cultivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

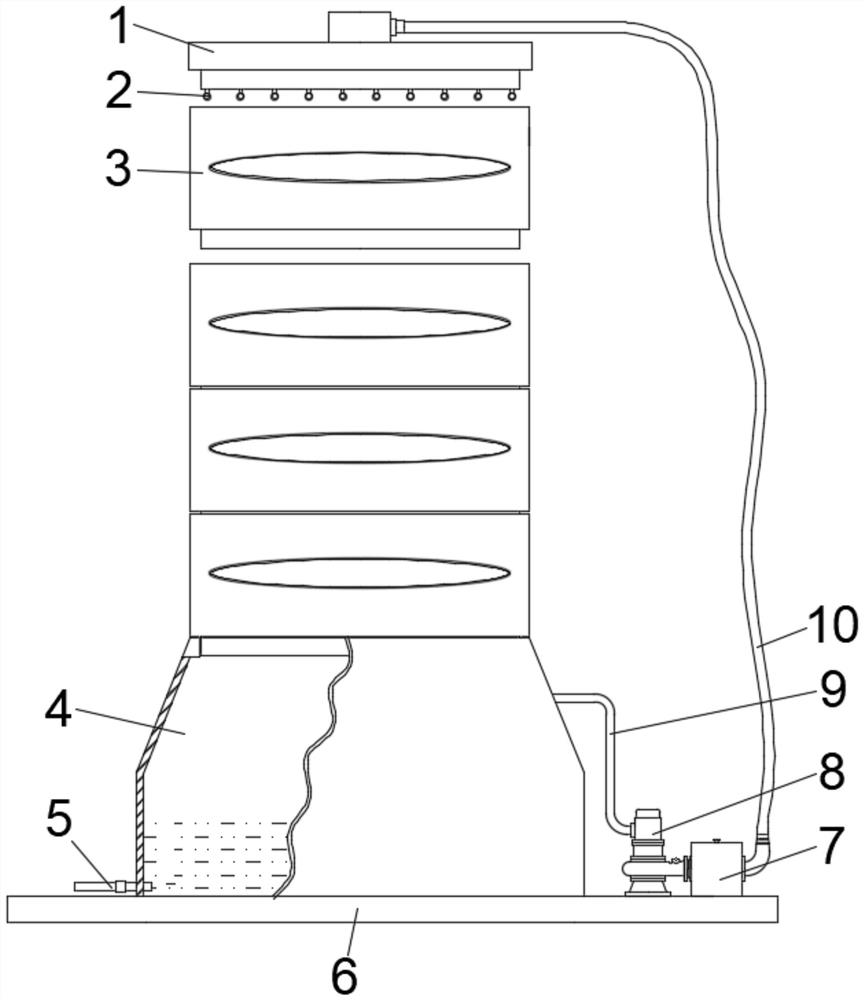

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The invention provides a fiberglass water tank cultivation device for shellfish seedling cultivation, comprising a top cover 1, a nozzle 2, a cultivation barrel body 3, a circulating water tank 4, a drainage pipe 5, a base 6, a filter box 7, a water pump 8, a water suction pipe 9, a spray Water pipeline 10, activated carbon filter plate 11, water guide plate 12, cultivation plate 13 and leaking pipe 14;

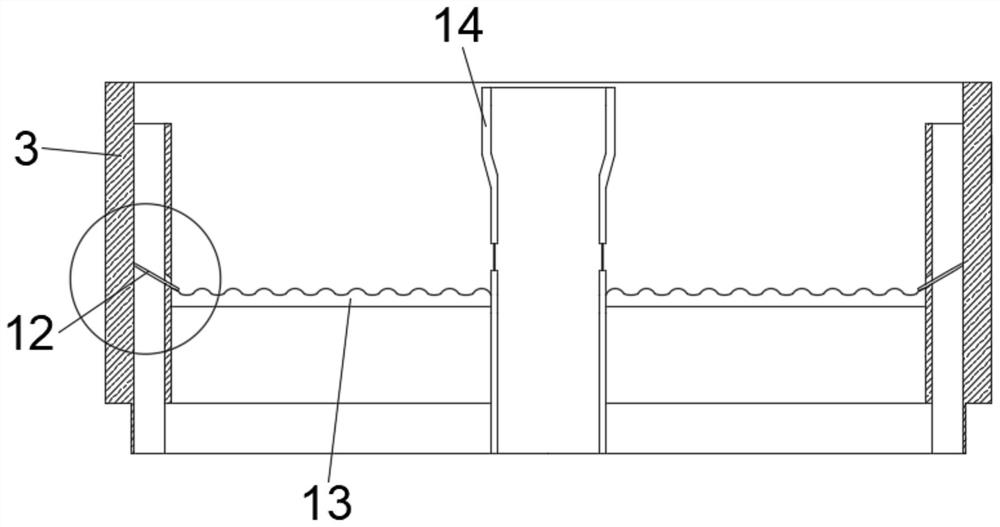

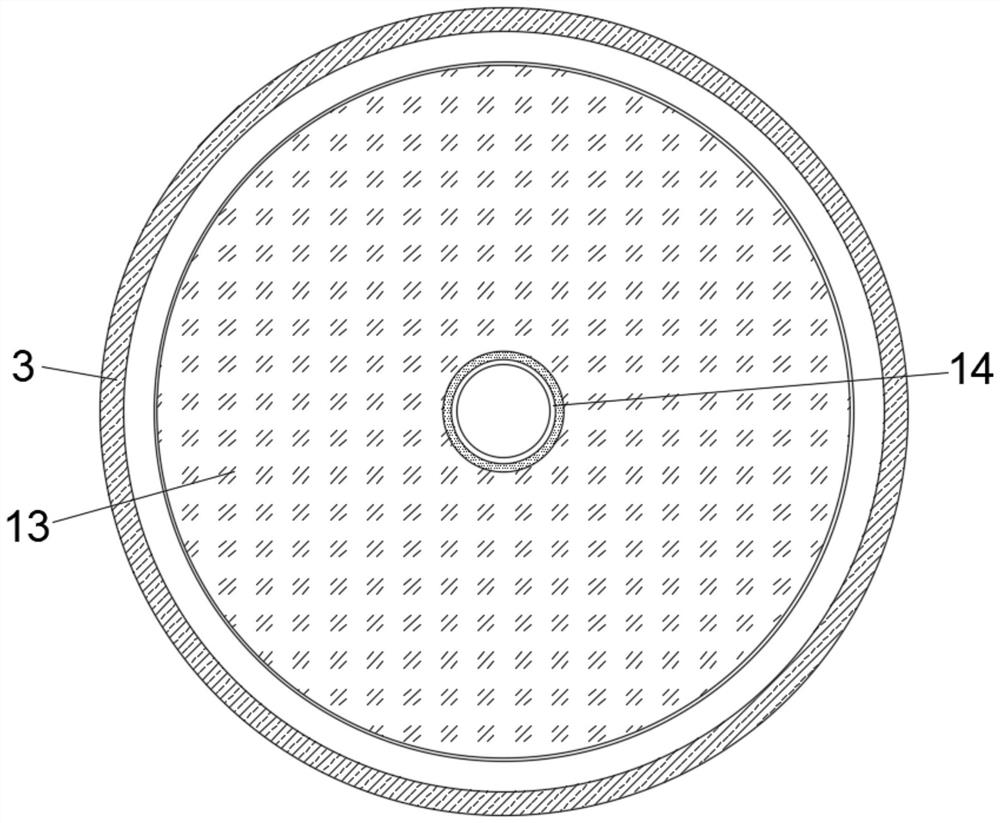

[0034] The top of the base 6 is fixedly provided with a circulating water tank 4 by welding; a drainage pipe 5 is embedded on one side of the bottom of the circulating water tank 4; A top cover 1 is movably installed on the top; a cultivation plate 13 is fixedly installed on the inner side of the cultivation barrel body 3;

[0035] The inner side of the cultivation plate 13 is fixedly embedded with a leaking pipe 14; the inner side of the barrel wall of the cultivation barrel body 3 is also embedded with a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com