Uniformity degree controllable stirrer used in laboratory

A uniformity, mixer technology, applied in mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of inability to achieve mixing and inability to meet real-time control of the material to be mixed, and achieve good use effect and uniformity. degree of controllable effect

Inactive Publication Date: 2018-12-28

自贡莱德曼科技有限公司

View PDF1 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned laboratory mixer cannot satisfy the real-time control of the material to be stirred inside the mixer during use, and cannot realize the materials in the mixer to be stirred out in different situations. Materials with different degrees of uniformity required in different situations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

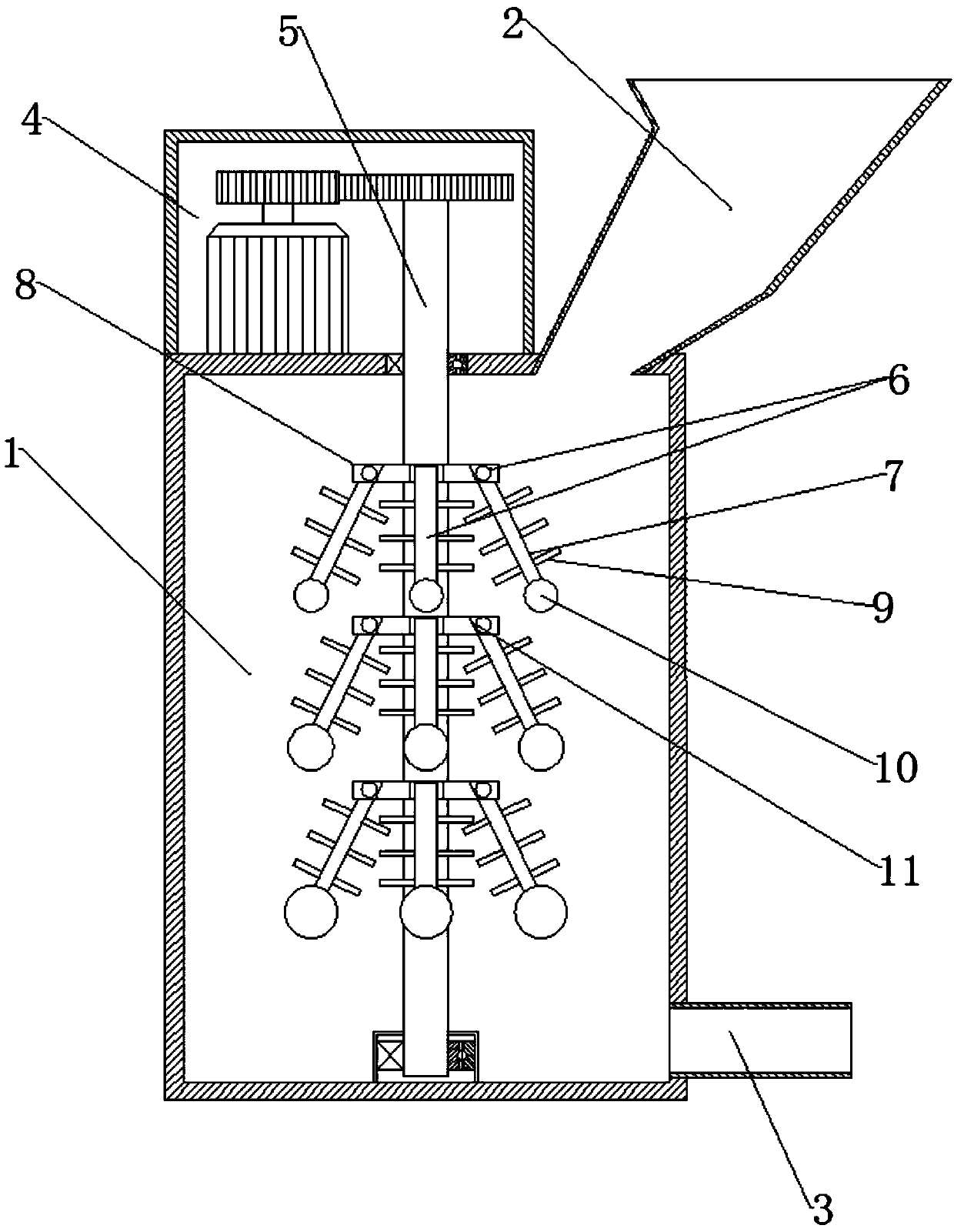

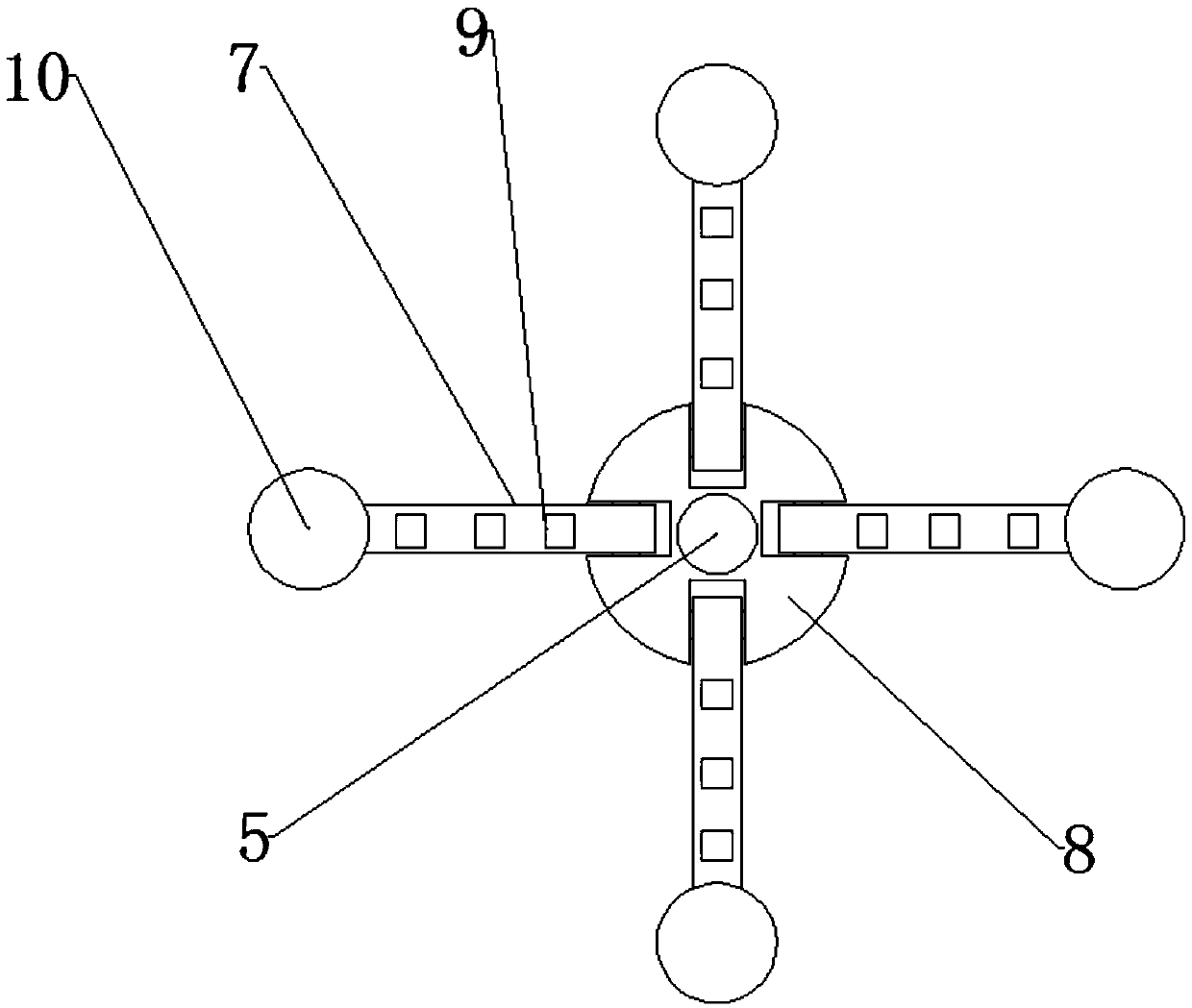

The invention discloses a uniformity degree controllable stirrer used in a laboratory, belongs to the technical field of laboratory equipment, and aims to provide a stirrer capable of stirring materials of different uniformity degrees. According to the technical scheme, the stirrer comprises a stirring tank body, a feeding hopper and a discharge tube, wherein the feeding hopper is arranged at theupper end of the stirring tank body, the feeding copper communicates with the interior of the tank body, the discharge tube is arranged at the lower end of the stirring tank body, and the discharge tube communicates with the interior of the stirring tank body; a power box is fixedly arranged at the upper end of the tank body; a stirring main shaft is arranged on the stirring tank body; the upper end of the stirring main shaft penetrates through the upper end of the power box; the upper end of the stirring main shaft is placed in the power box; a centrifugal stirring component is arranged at apart, placed inside the stirring tank body, of the stirring main shaft; a centrifugal moveable stirring rod is arranged in the centrifugal stirring component; and the centrifugal moveable stirring rodis hinged with the stirring main shaft. The invention provides the uniformity degree controllable stirrer, and materials of different uniformity degrees can be stirred.

Description

technical field The invention belongs to the technical field of laboratory equipment, and in particular relates to a mixer with controllable uniformity used in laboratories. Background technique The stirrer is a kind of equipment commonly used in the laboratory. The stirrer generally includes a vertical container body and a stirring device; the stirring device includes a stirring shaft and a stirring paddle. The stirring paddle is installed on the stirring shaft, and the stirring shaft is mainly driven by a motor to stir the solution. Make it evenly distributed. Application number CN201721038368.2 discloses a laboratory mixer. The mixer includes a shell and a stirring shaft installed in the shell, the stirring shaft is driven by a driving device, the shell is provided with a shell cover above the shell, a circular guide rail is arranged on the shell cover, and the stirring The shaft is installed in the guide rail, and driven by the second driving device to move on the gui...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F7/16B01F15/00

CPCB01F27/0542B01F27/0722B01F27/0723B01F27/111B01F27/192B01F27/80B01F35/221422B01F2101/23

Inventor 何翠英

Owner 自贡莱德曼科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com