Industrial adsorption agent equipment

An adsorbent and equipment technology, applied in the field of industrial adsorbent equipment, can solve the problems of low work efficiency, waste of discharge time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

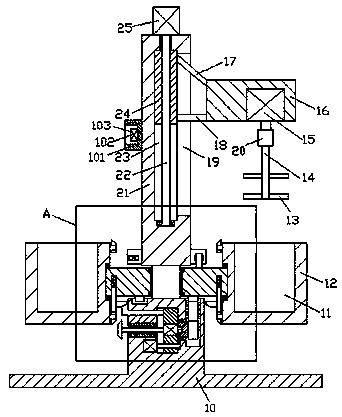

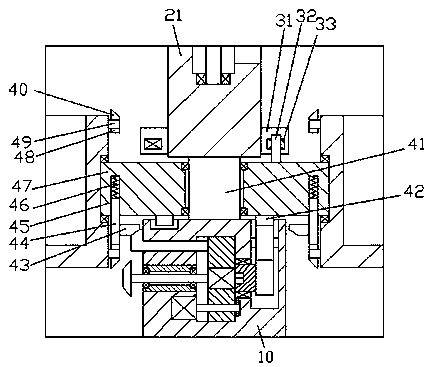

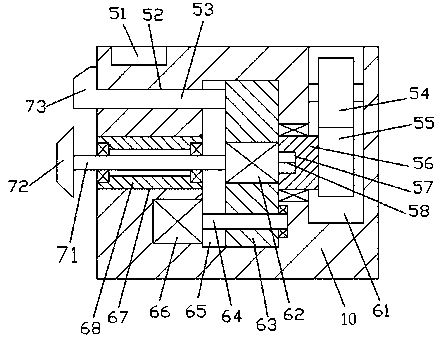

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] refer to Figure 1-4 , an industrial adsorbent device according to an embodiment of the present invention, comprising a chassis 10, a first steering shaft 41 is fixed at the center of the upper end of the chassis 10, and a bracket 21 is fixed at the upper end of the first steering shaft 41 , a mixing unit is installed on the support 21 for lifting adjustment, the outer circumference of the first steering shaft 41 is rotated and installed with a fixing plate 47, and the left and right sides of the fixing plate 47 are symmetrically fixed with storage barrels 12, The top end surface of the storage barrel 12 is provided with a storage cavity 11, and the opposite end surfaces of the storage barrel 12 on the left and right sides are fixed with a circular ring 49, and the outer circumference of the circular ring 49 is fixed with a cone. Ring gear 40, the inner ring of the circular ring 49 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com