Moving device for disabled limb 3D printer spraying head

A technology of 3D printers and mobile devices, applied in the direction of manufacturing auxiliary devices, processing heating elements, household components, etc., can solve the problems of limited printing area, limited rescue site space, and increased equipment complexity, so as to prevent vertical deviation and apply The effect of wide range and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

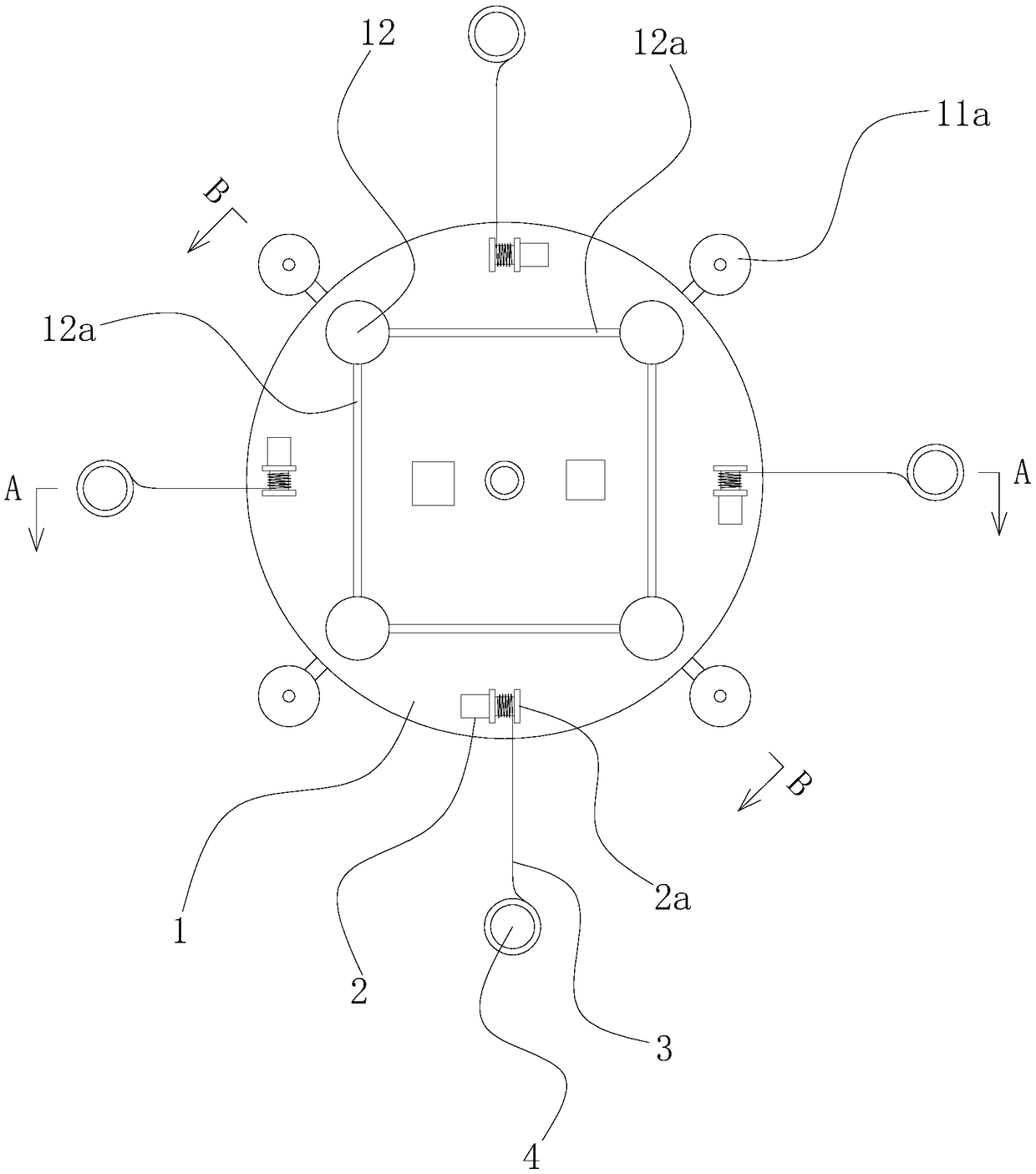

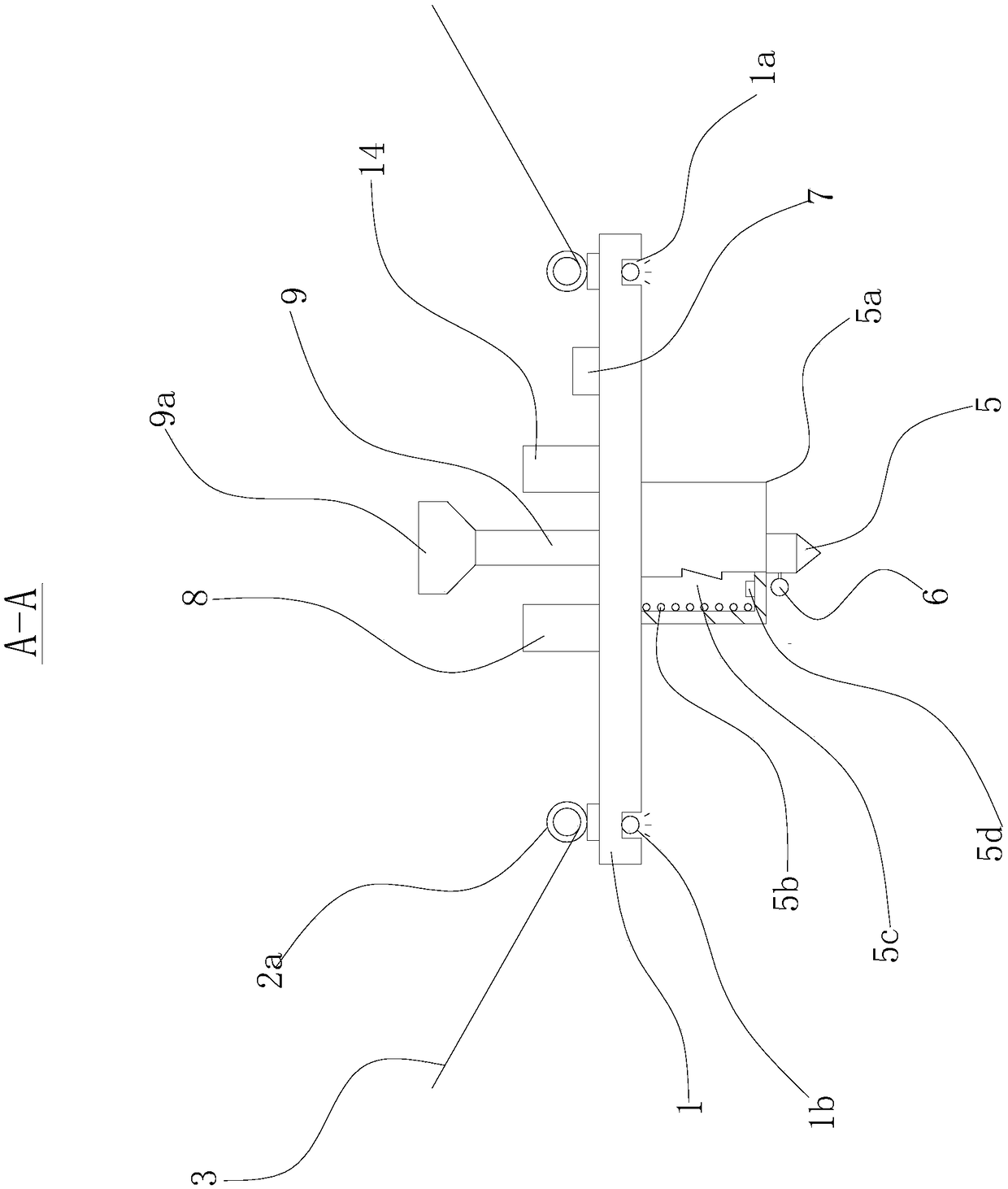

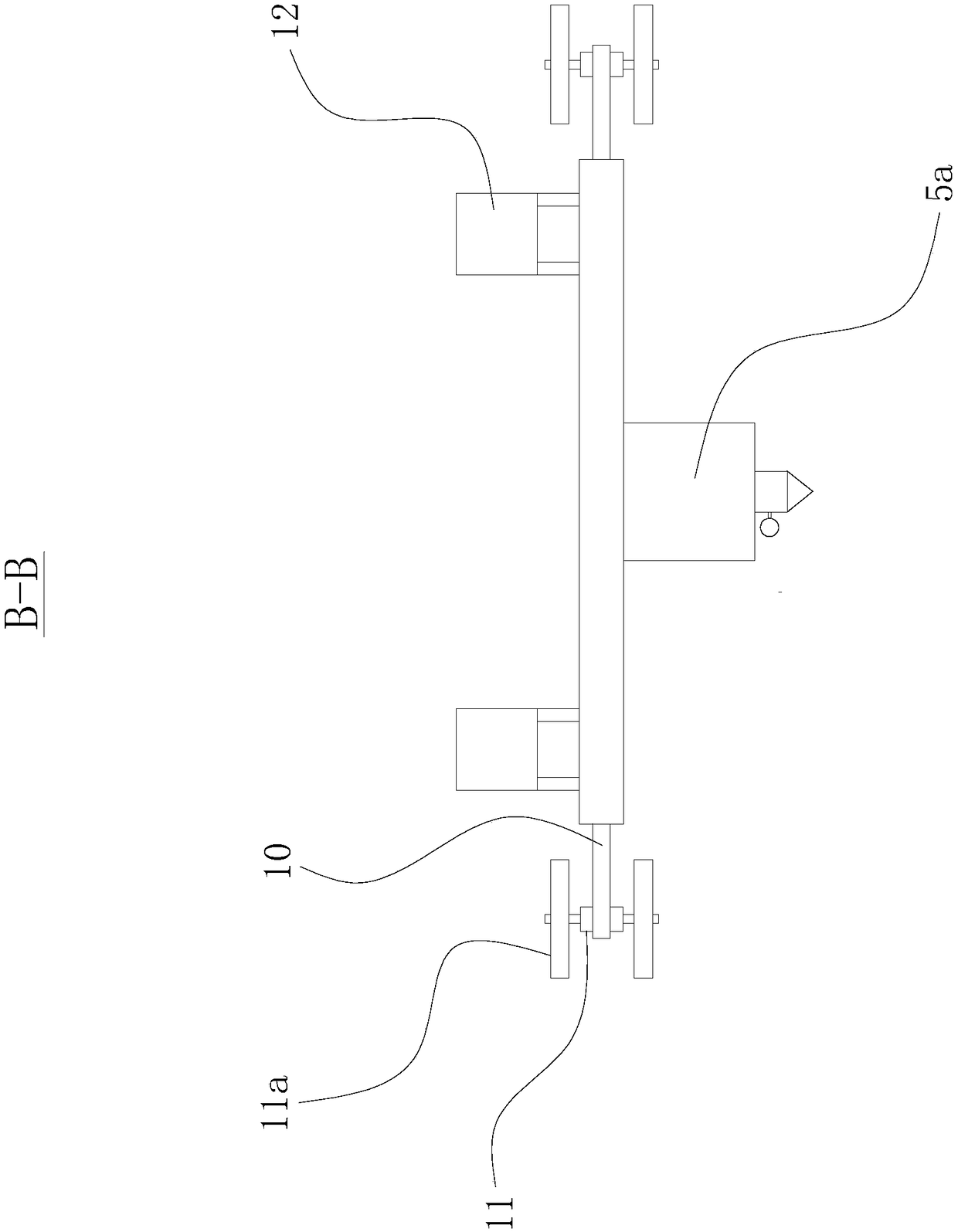

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0031] Such as Figures 1 to 4 As shown, a mobile device for the nozzle of a 3D printer for disabled limbs includes a fixed seat 1 and a nozzle 5, the nozzle 5 is arranged below the fixed seat 1, and the upper side of the fixed seat 1 is evenly provided with four Positioning mechanism, described positioning mechanism comprises motor one 2 and stay cord 3, the output shaft end of described motor one 2 is provided with reel 2a, and one end of described stay cord 3 is wound on the reel 2, and described stay cord The other end of 3 is detachably connected to the fixed column 3a, the upper side of the fixed seat 1 is provided with a battery 8 and the controller 7, the lower side of the fixed seat 1 is provided with a storage box 5a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com