Turbine inlet pipe structure for a rocket engine

A rocket engine and inlet pipe technology, which is applied to the air inlet of the turbine/propulsion device, engine components, charging system, etc., can solve the problem of the large axial size of the engine turbine pump, improve the working reliability, improve the turbine Intake conditions, effect of reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The following embodiments are used to illustrate the present invention , but not to limit the scope of the present invention.

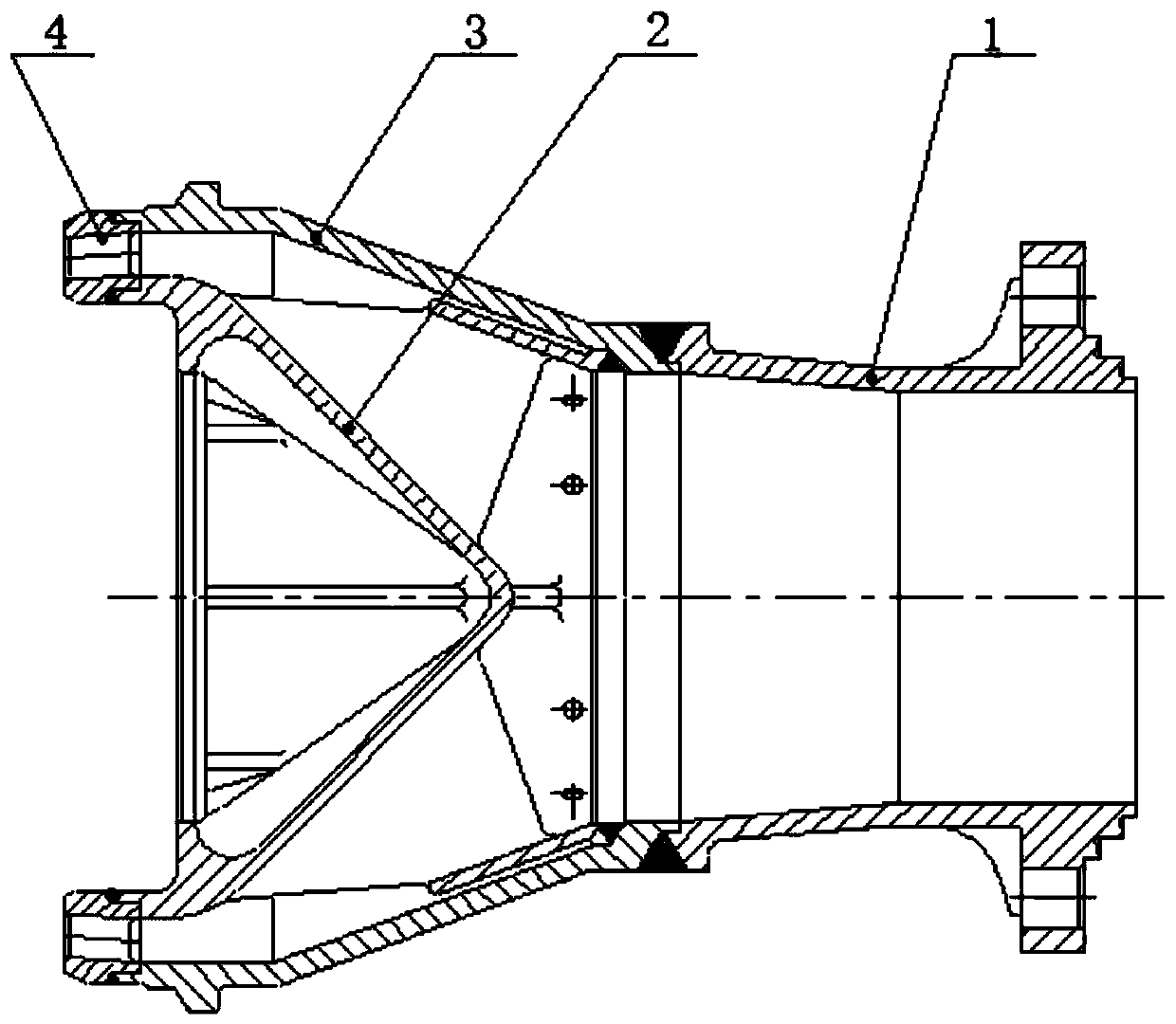

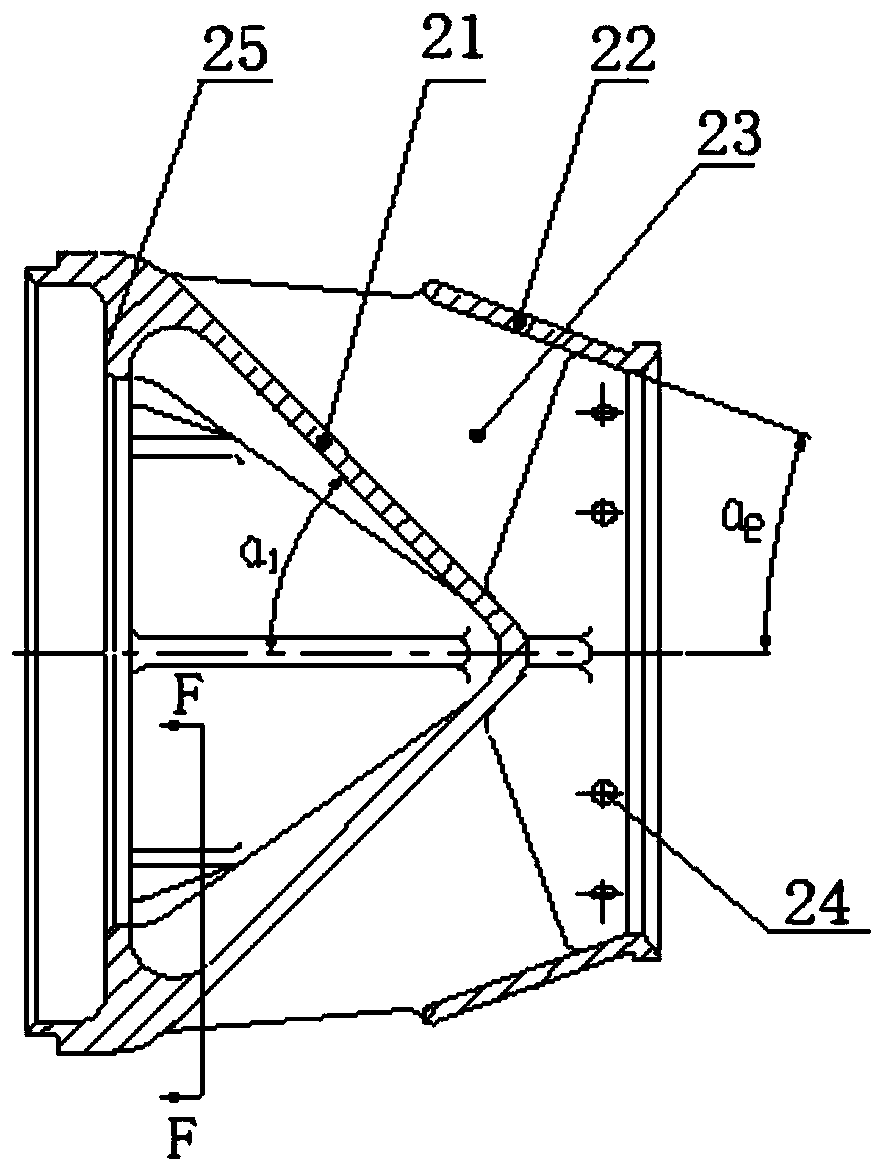

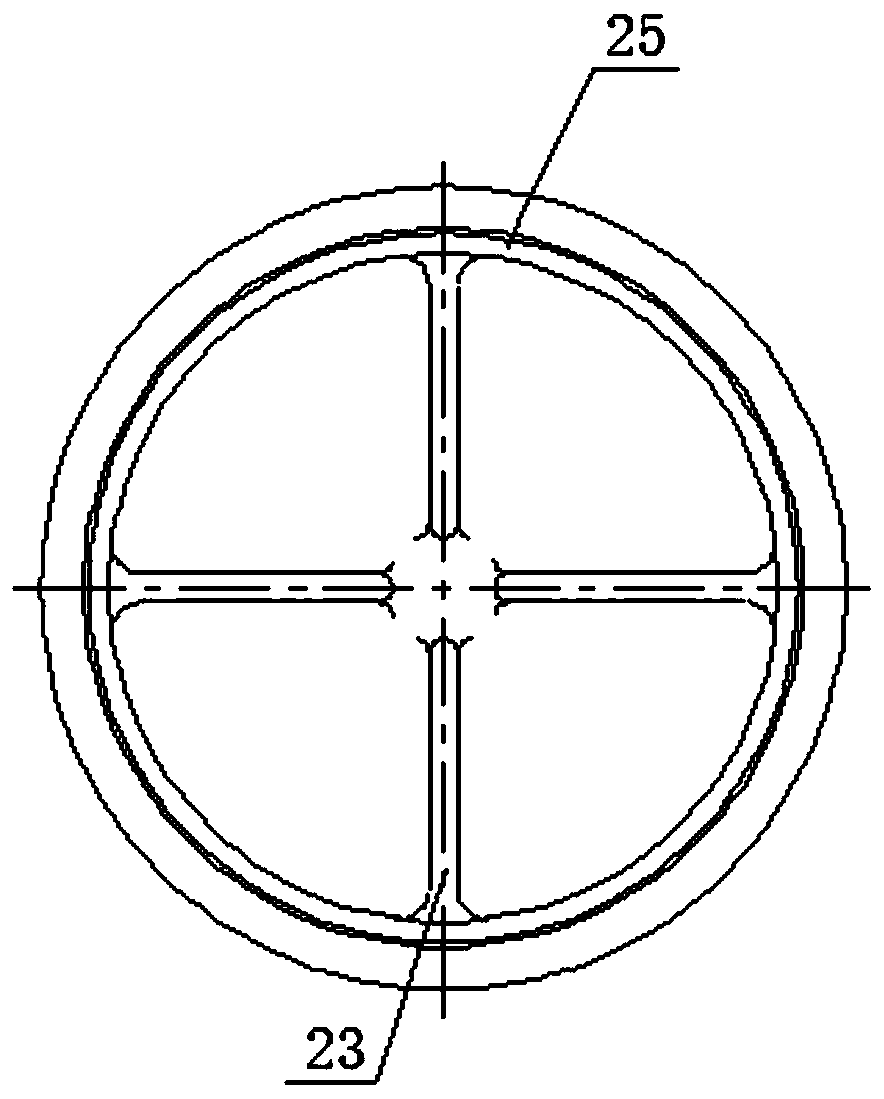

[0033] see Figure 1 to Figure 6 , a turbine inlet pipe structure for a rocket engine, the front section of the inlet pipe 1, the guide body 2, the inlet pipe shell 3 and the turbine stator 4.

[0034] The guide body 2 is a key part in the turbine inlet pipe, mainly composed of four parts, namely the inner shell 21, the outer shell 22, the support plate 23 and the rib 26, and the whole is processed by casting, the inner shell 21 is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com