Use and installation method of kitchen range energy gathering and heat insulation ring

An installation method and heat insulation ring technology, applied in the direction of furnace/stove furnace top, etc., can solve problems such as the inability to adjust the diameter of the energy-saving ring, excessive carbon monoxide emissions, and insufficient combustion of gas, so as to facilitate large-scale popularization and reduce carbon monoxide Emissions and energy-saving effects are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

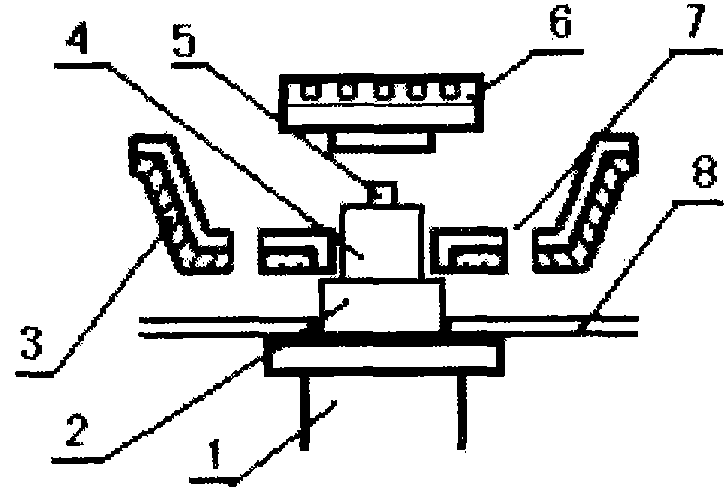

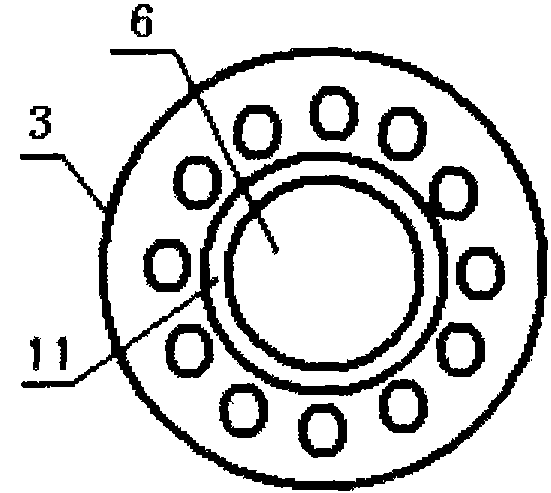

[0096] see figure 1 and Picture 1-1 , as shown in the figure, the energy-gathering insulation ring 3 passes through its lower central hole 10 (see image 3 ) is installed on the burner step 2 above the burner 1, the center hole 10 of the lower part of the energy-gathering heat insulation ring 3 is located outside the gas outlet 4 of the burner outer ring at the same time, and the burner 6 is installed on the burner outer ring gas outlet 4 and the center On the air outlet 5, since the energy-gathering heat-insulation ring 3 is installed on the burner step 2, the distance between the energy-gathering heat-insulation ring and the water tray 8 or the stove top is increased, and the air inlet hole at the bottom of the energy-gathering heat-insulation ring is increased. 7 air intake, so as to ensure the oxygen supply required for the combustion of the burner above the burner, while gathering energy and heat insulation, it can ensure the full combustion of the gas, improve the comb...

Embodiment 2

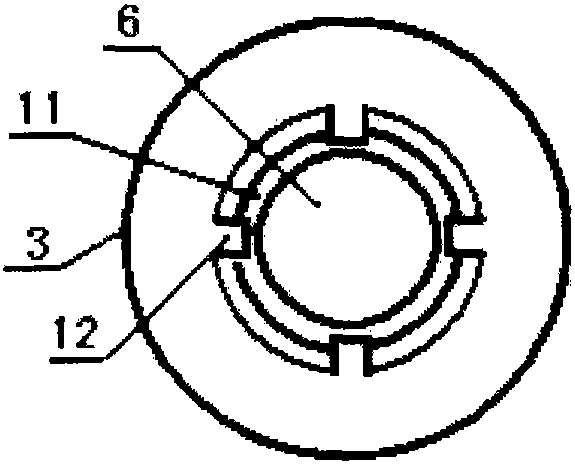

[0105] see Figure 4, as shown in the figure, an annular step is provided on the outer side of the burner base 11 above the burner head 1, and the energy-gathering heat-insulating ring 3 is installed on the annular step through its central hole, increasing the distance between the energy-gathering heat-insulating ring and the lower water pan or cooker table top. Therefore, by increasing the oxygen supply to the burner of the burner at the bottom of the energy-gathering heat insulation ring, it can ensure the full combustion of the gas and improve the combustion efficiency while the energy-gathering and heat-insulating ring, and can be easily disassembled and assembled. clean. In application, the outer circumference of the burner base 11 can be inclined ( Pic 4-1 shown in ) or a circular arc surface ( Figure 4-2 shown in), the energy-gathering heat insulation ring is installed on the inclined surface or circular arc surface on the outside of the base through its central hol...

Embodiment 3

[0110] see Figure 5 , as shown in the figure, the mounting ring 14 is fixed around the base of the burner 6 through the head screw 13, and the energy-gathering heat insulation ring 3 is arranged above the mounting ring, so that the heat energy generated by the burner is gathered above the burner, preventing thermal energy Spread around the burner to reduce heat loss.

[0111] In application, steps or outward flanges can be provided above the mounting ring.

[0112] In applications, the mounting ring spring clip 15 can be used inside the mounting ring (see Image 6 ) Instead of the head screw 13, the installation ring is clamped around the burner base through the installation ring spring clip. In application, the installation ring 14 can also be clamped around the burner base through the lower spring clip 16 (see Figure 7 ).

[0113] In application, the mounting ring can also be installed directly on the annular step around the base of the burner, or on the inclined surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com