Noise reduction diversion grid

A technology of guide grille and noise reduction, applied in the field of noise reduction guide grille, can solve the problems of unsatisfactory noise reduction function of guide grille

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

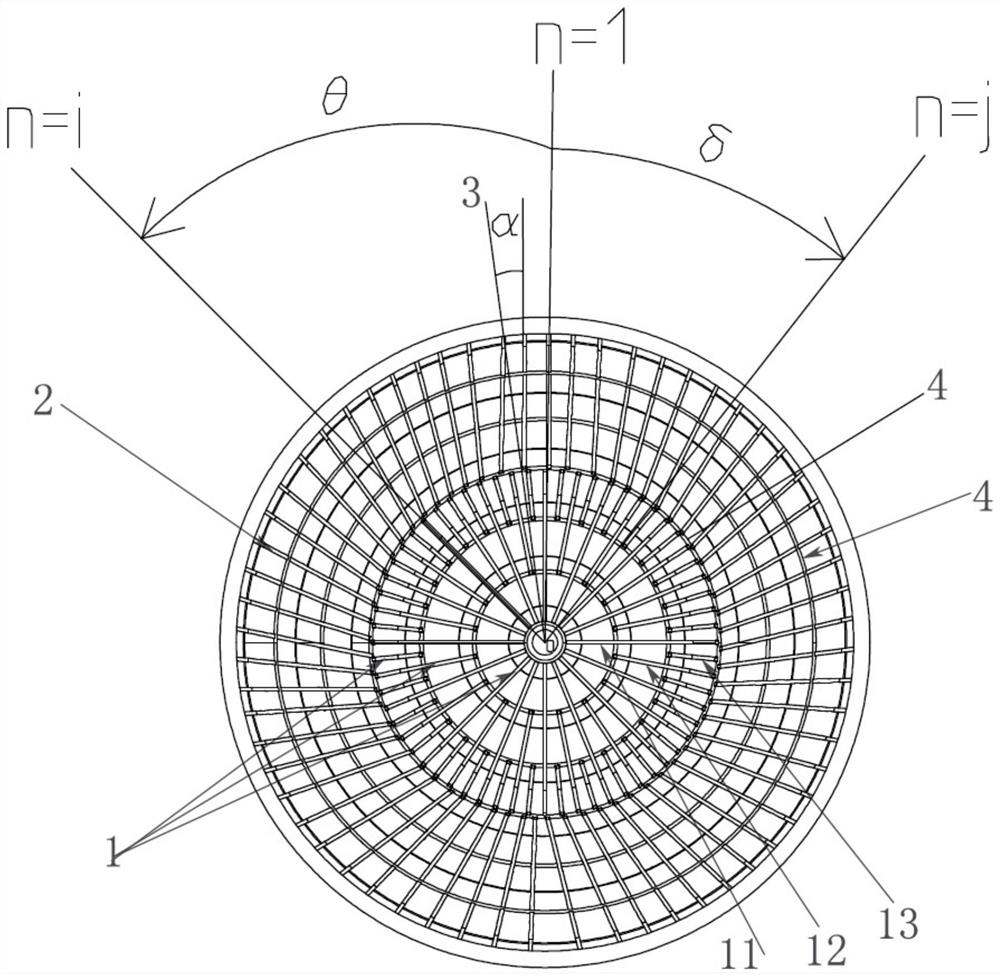

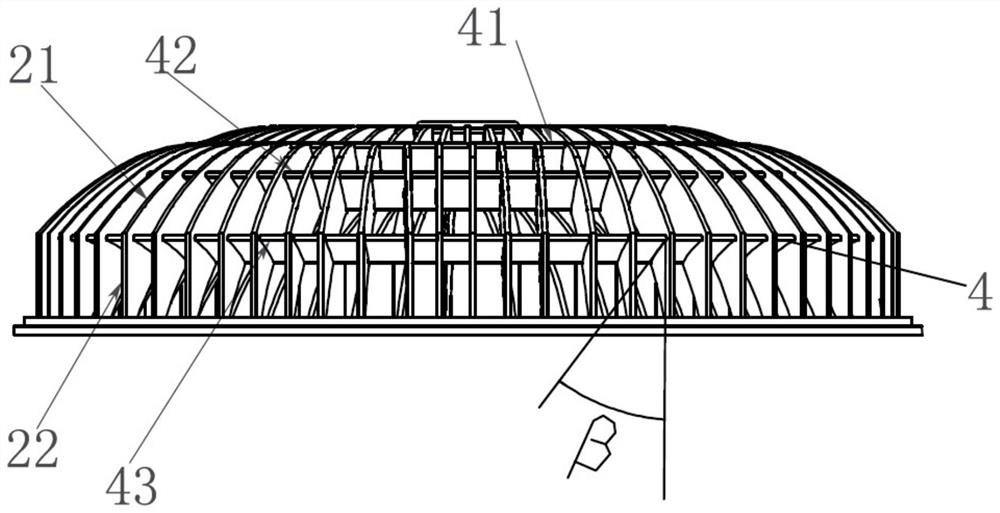

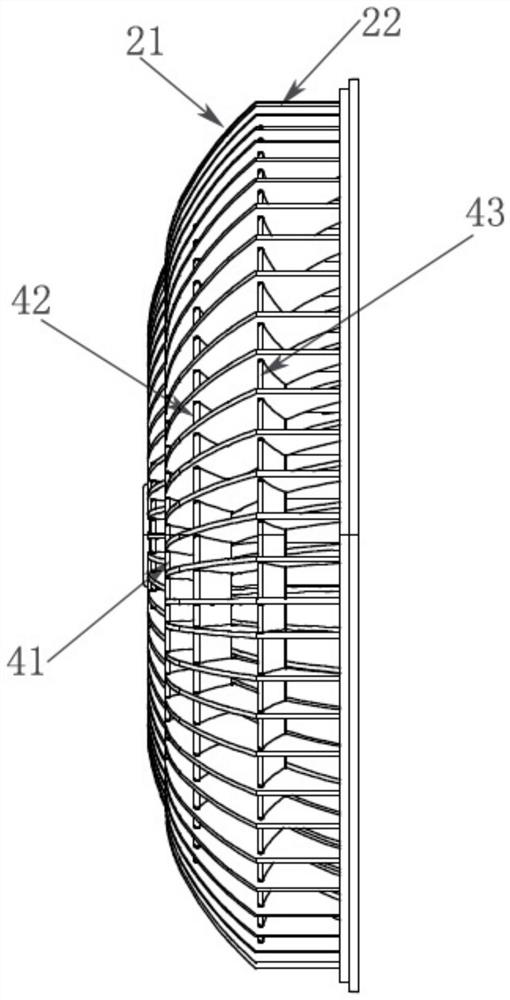

[0056] Such as Figure 1~3 As shown, a noise reduction diversion grid, the diversion grid has a grid structure, the grid structure includes:

[0057] Radial grids and circumferential grids 4, the radial grid extends radially along the diversion grid, and several radial grids are distributed along the circumference of the diversion grid at intervals. A number of coaxial circumferential gratings 4 are distributed at radial intervals with the axis of the diversion grid as the center, and the circumferential gratings 4 are ring structures; radially, the radial gratings include at least A set of concentric radial grille groups 1 whose extensions pass through the axis of the diversion grid and at least one set of eccentric radial grilles whose extensions deviate from the axis of the diversion grid; The extended section of the grate close to the axis does not pass through the axis. The radial grids are intersected with the circumferential grids 4, and the circumferential grids 4 pr...

Embodiment 2

[0072] This embodiment only describes the differences from the above-mentioned embodiments. In this embodiment, the distance between the head end of the concentric radial grille group 1 of the same group and the axis of the diversion grid is in the form of an arithmetic sequence increase in turn.

Embodiment 3

[0074] This embodiment only describes the differences from the above-mentioned embodiments. In this embodiment, the eccentric radial grille in this embodiment includes a horizontal section, a curved section and a vertical section 22, and the horizontal section is adjacent to the concentric section. The radial grate set 1 is arranged, and the curved section is located between the horizontal section and the vertical section 22 . Preferably, at least one circumferential grille 4 is provided on the curved section, a circumferential grille 4 is provided at the junction of the horizontal section and the curved section, and a circumferential grille 4 is provided at the junction of the curved section and the vertical section 22. As for the grating 4, such setting can provide flow diversion for the curved transition of the radial grating, and at the same time strengthen the strength of the eccentric radial grating at the curved transition.

[0075] In this embodiment, preferably, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com