Drying temperature automatic adjusting device for rice drying

A drying temperature and automatic adjustment technology, which is applied in drying, drying machines, grain drying, etc., can solve the problems of difficult control of drying temperature and the impact of rice yield rate on rice safety storage, etc., and achieves compact structure and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

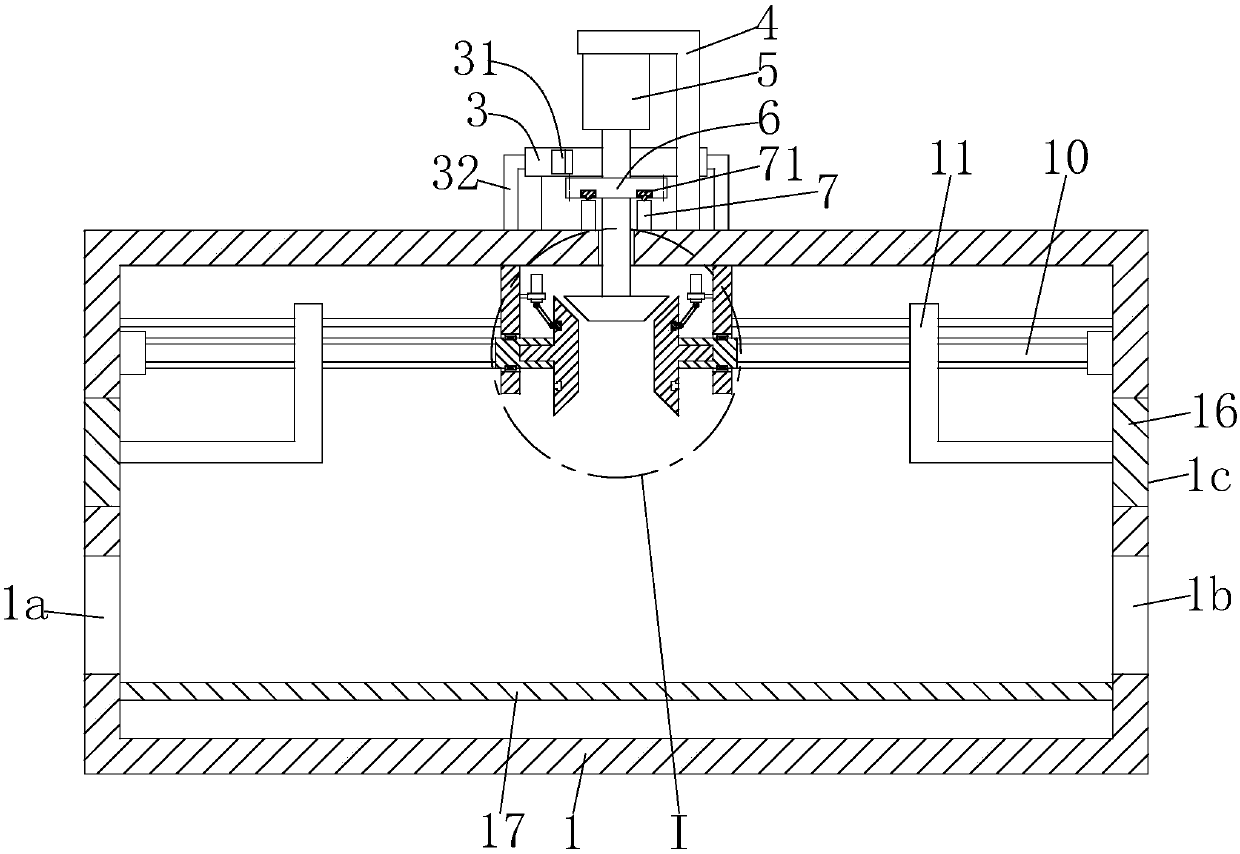

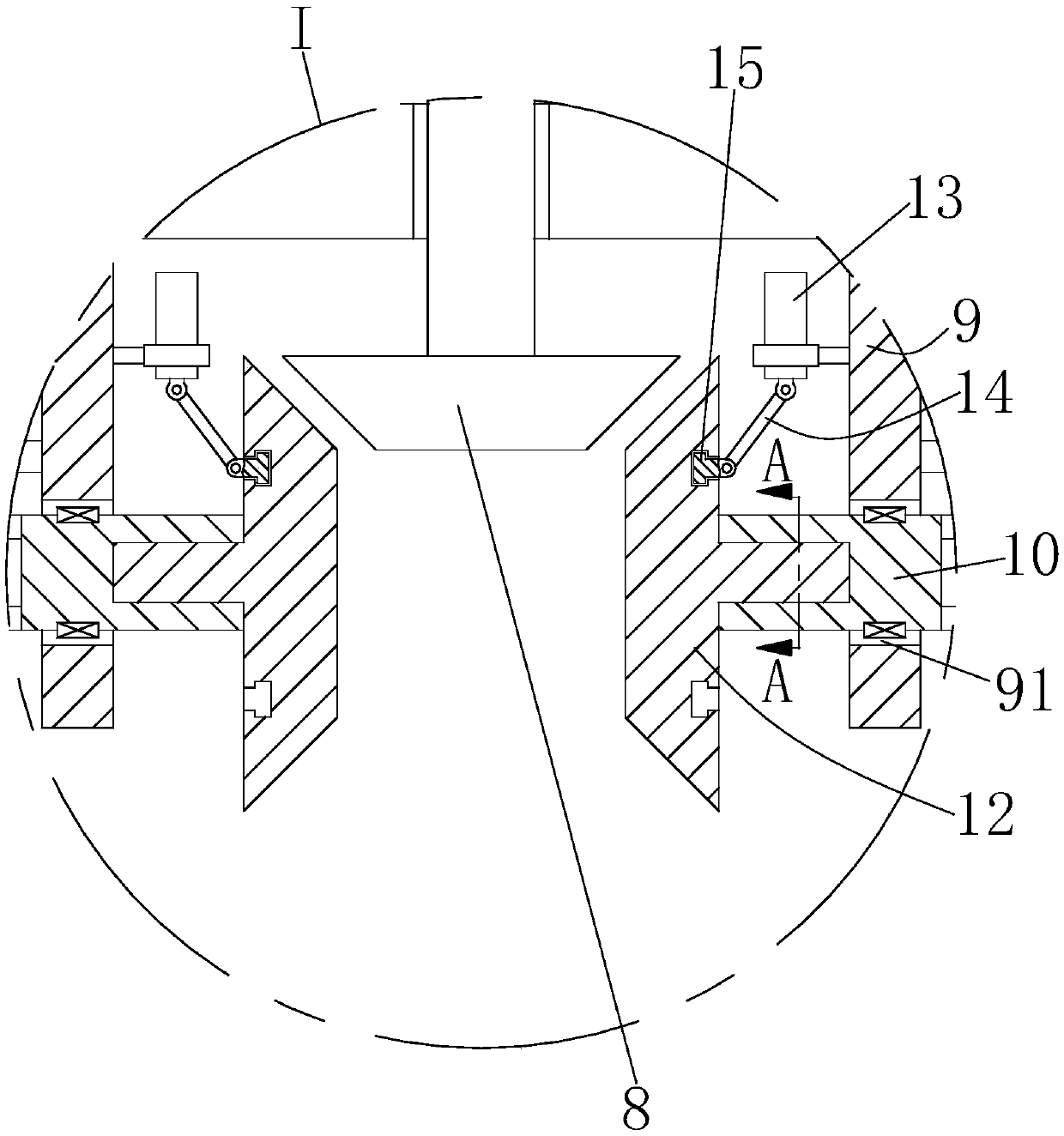

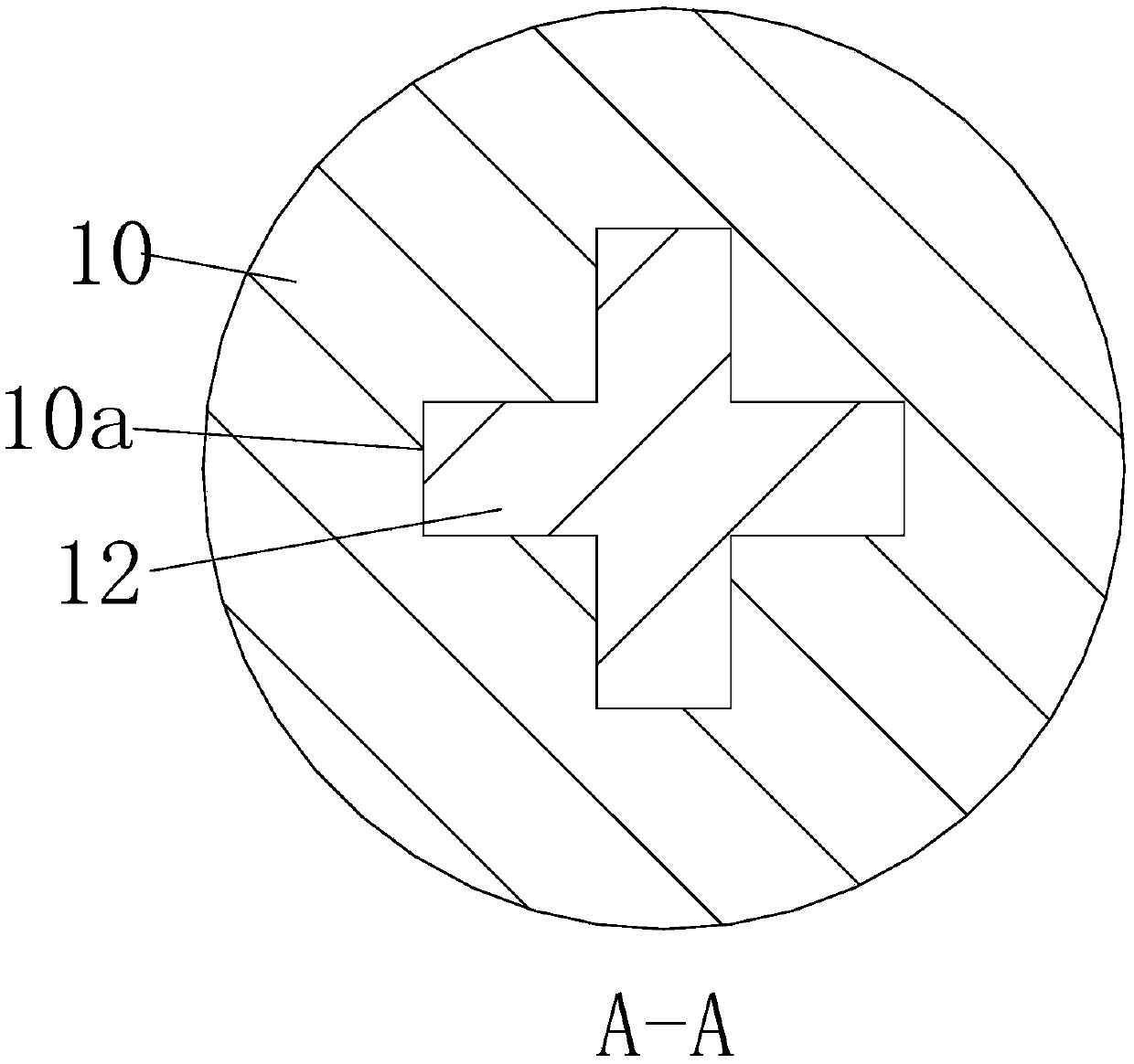

[0023] like Figure 1 to Figure 5 As shown, a drying temperature automatic adjustment device for rice drying includes a drying box 1, a feed port 1a and a discharge port 1b that are correspondingly arranged on the left and right sides of the drying box 1, and the bottom of the drying box 1 drying station 17;

[0024] The left and right sides of the drying box 1 are provided with regulating tuyeres 1c, the top of the drying box 1 is provided with a hot air inlet 2, and the hot air inlet 2 is connected with the first adjusting mechanism slidingly arranged on the top of the drying box 1 In cooperation, the first adjustment mechanism is connected with a drive mechanism arranged on the drying box 1, the drive mechanism is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com