Purification method of indigo

A purification method, the technology of indigo, applied in chemical/physical/physicochemical nozzle reactors, organic dyes, etc., can solve the problems of difficult removal of reaction precipitates and difficult transportation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

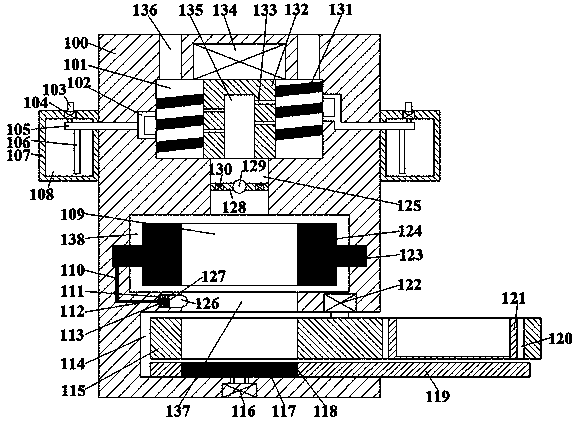

[0015] like figure 1 As shown, the purification method of indigo of the present invention uses an evaporation purification device, including a fuselage 100 and an evaporation chamber 138 arranged in the fuselage 100, and the inner wall of the evaporation chamber 138 top communicates with a discharge channel 125, the top of the discharge channel 125 communicates with the reaction chamber 101, the bottom of the evaporation chamber 138 communicates with a transition channel 137, and the bottom of the transition channel 137 communicates with a feeding chamber 114 with an opening to the right. The evaporation chamber 138 is provided with a heating cylinder 124, the heating cylinder 124 is provided with a heating chamber 109, the left and right inner walls of the evaporation chamber 138 are embedded with electrical connection support blocks 123, and the inner wall of the left end of the transition channel 137 is provided for connecting with the The automatic docking mechanism of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com