FOUP and automated wafer transfer system

A wafer transfer box and wafer technology, applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of wafer pollution, wafer transfer box cannot be closed and opened automatically, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

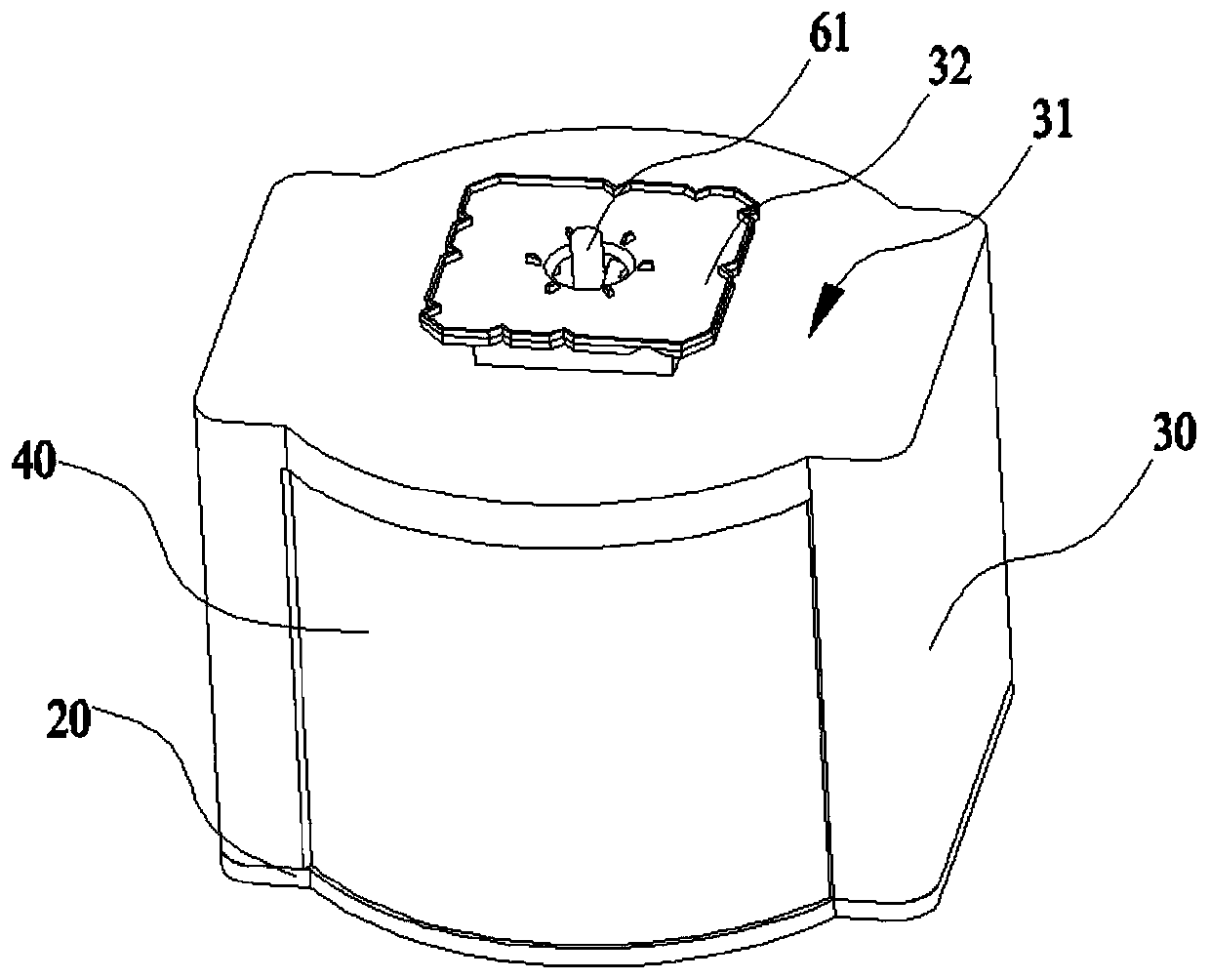

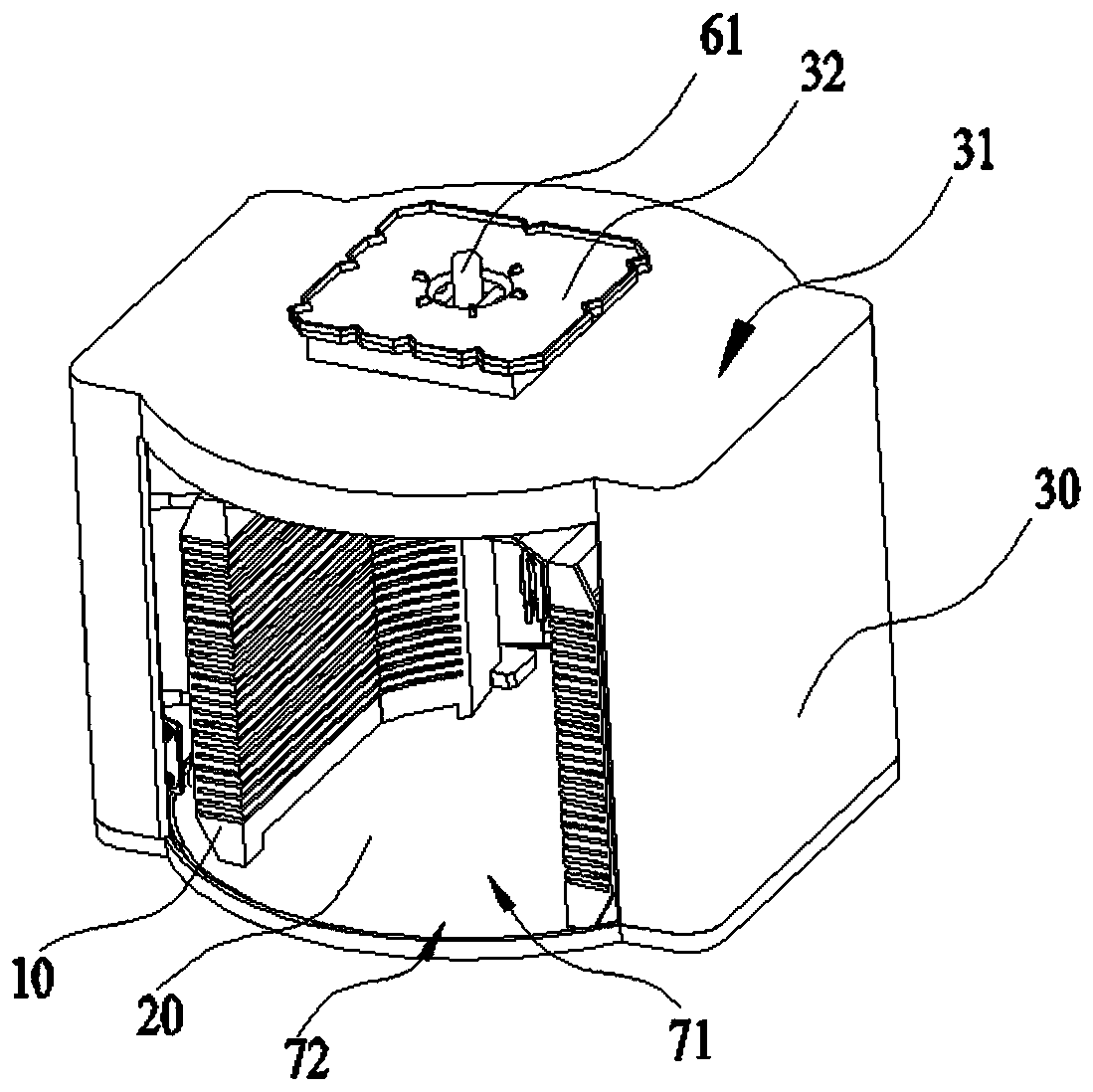

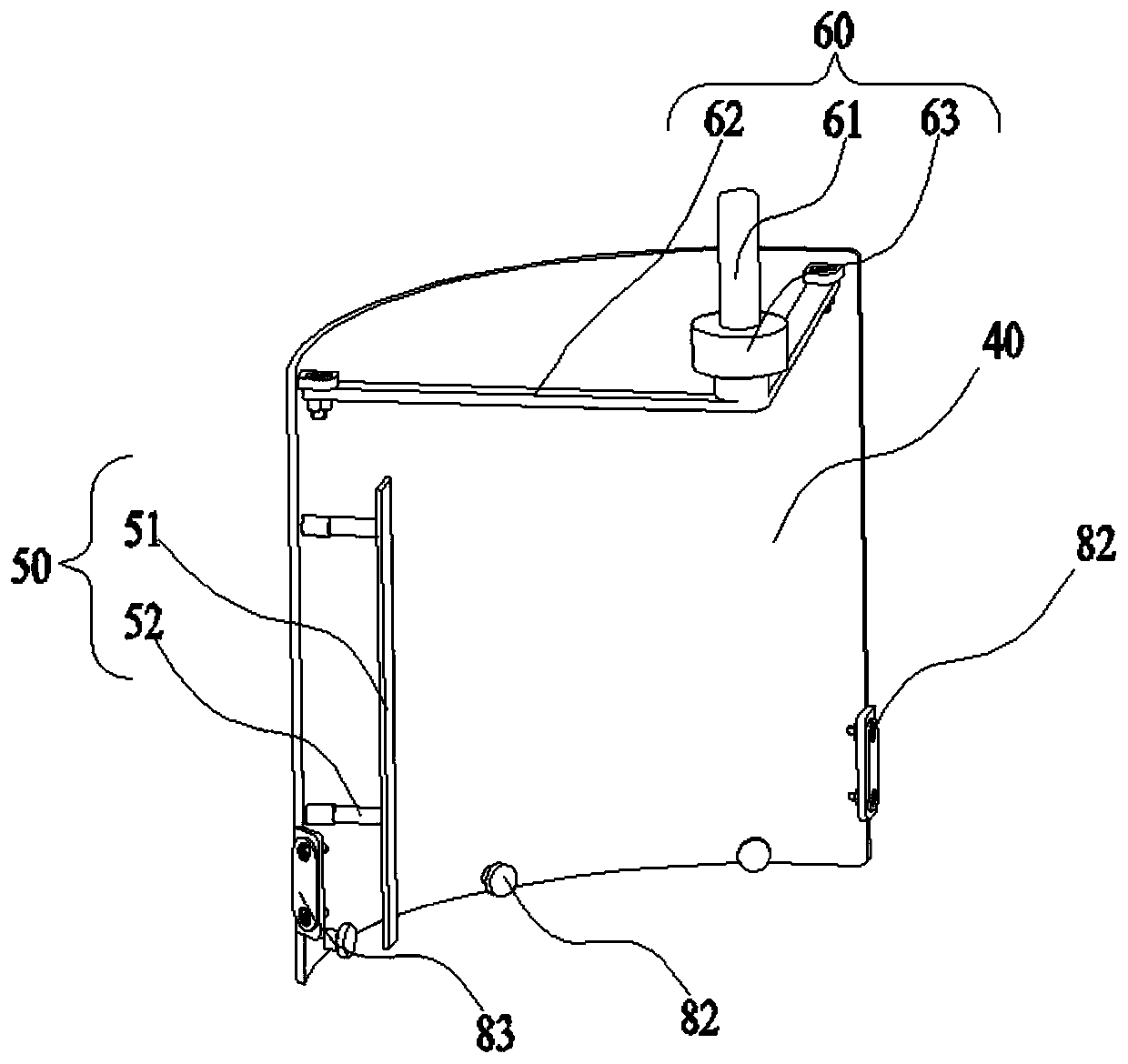

[0056] figure 1 It is a structural schematic diagram of the FOUP in an embodiment of the present invention when the box cover is in a closed state, figure 2 It is a structural schematic diagram of the FOUP in an embodiment of the present invention when the box cover is in an open state. refer to figure 1 and figure 2 , the wafer transfer box includes a wafer storage frame 10, a base 20, a cover 30, a lid 40 and a rotary connection mechanism 60 ( figure 1 and figure 2 not shown). The wafer storage frame 10 is used for storing wafers. The base 20 and the cover 30 are fixedly connected, and the base 20 and the cover 30 enclose a cavity 71 for accommodating the wafer storage frame 10 . The cover 30 is provided with an opening 72 for picking and placing wafers. The box cover 40 is rotatably connected to the housing 30 through the rotary connection mechanism 60 , and when the rotary connection mechanism 60 is rotated, the box cover 40 slides on the base 20 to close and ope...

Embodiment 2

[0082] Different from Example 1, as Figure 6 As shown, the frame positioning mechanism in this embodiment is a frame positioning protrusion 332, and the frame positioning protrusion 332 can be connected with the bottom of the wafer storage frame 10 to limit the position of the wafer storage frame 10. role.

[0083]Optionally, the automatic wafer transfer system using the FOUP described in Embodiment 2 also includes a FOUP platform, and the carrying surface of the FOUP is connected to the lower surface of the base 20 of the FOUP. The surface can be limitedly connected, specifically, a positioning platform 34 is set on the lower surface of the base 20, such as Figure 7 As shown, correspondingly, a positioning seat matching the positioning platform is provided on the carrying surface of the wafer cassette carrier, and vice versa.

[0084] The wafer transport box of the present invention can be used to transport wafers of various specifications, including but not limited to 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com