Mechanized planting management device for grapery

A management device and vineyard technology, applied in horticulture, climate change adaptation, botanical equipment and methods, etc., can solve problems such as being easily interfered by external factors, poor adjustment effect, grape coloring and insignificant increase in sugar content, etc., to achieve The effects of increasing the rate of photosynthesis, increasing the temperature difference between day and night, and accelerating the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

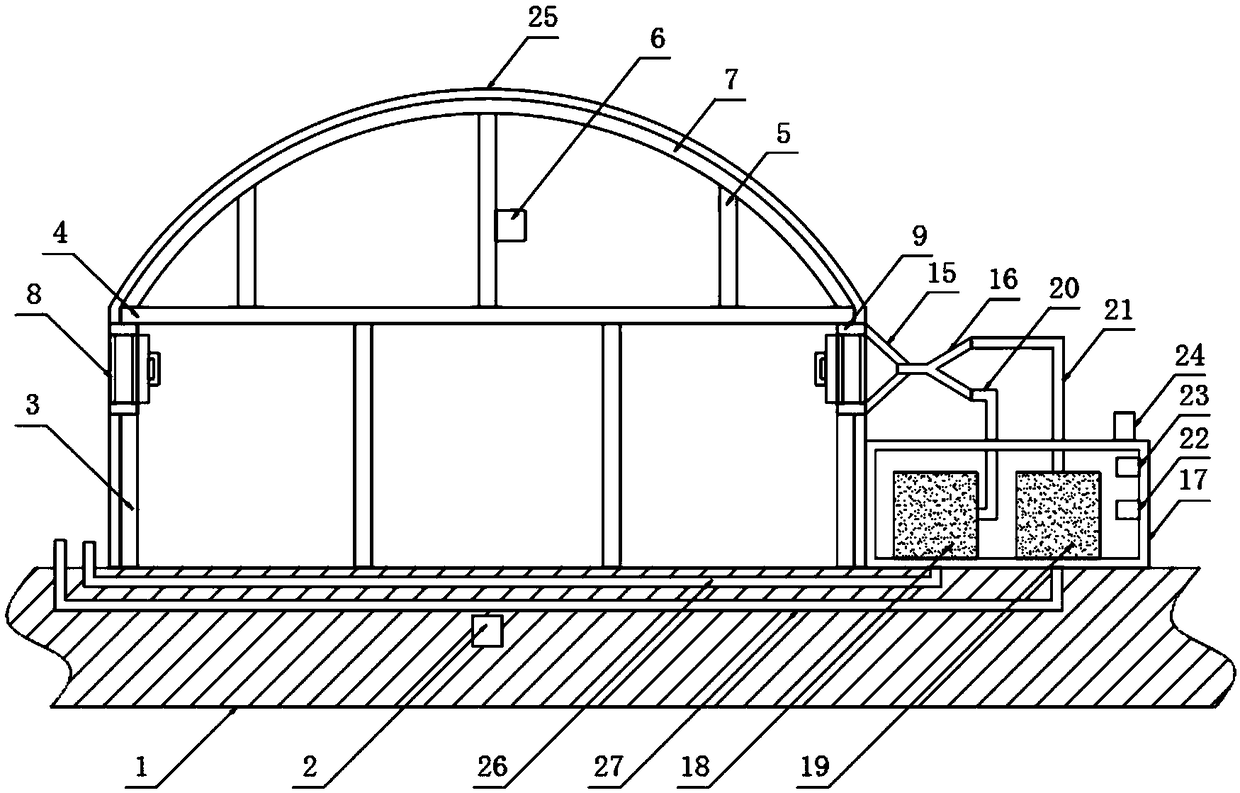

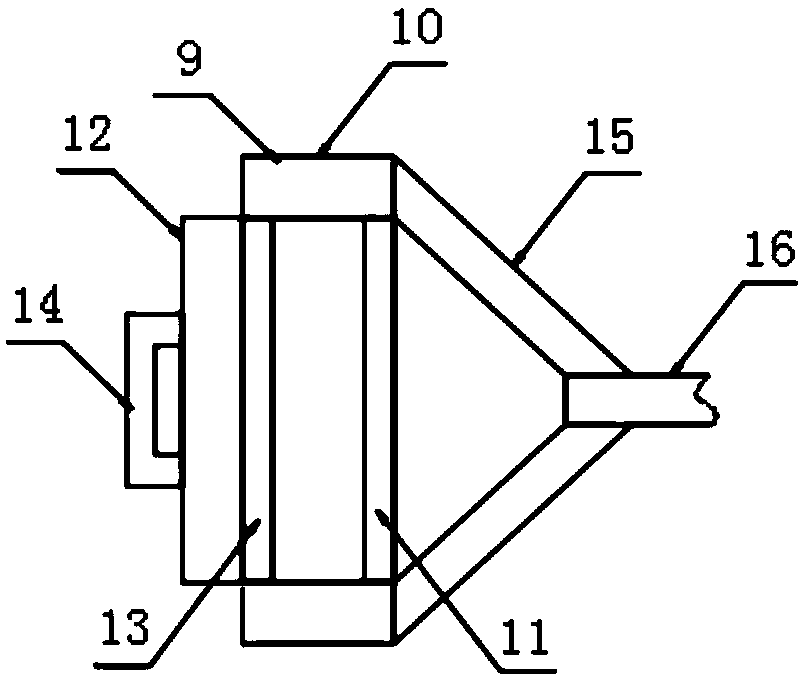

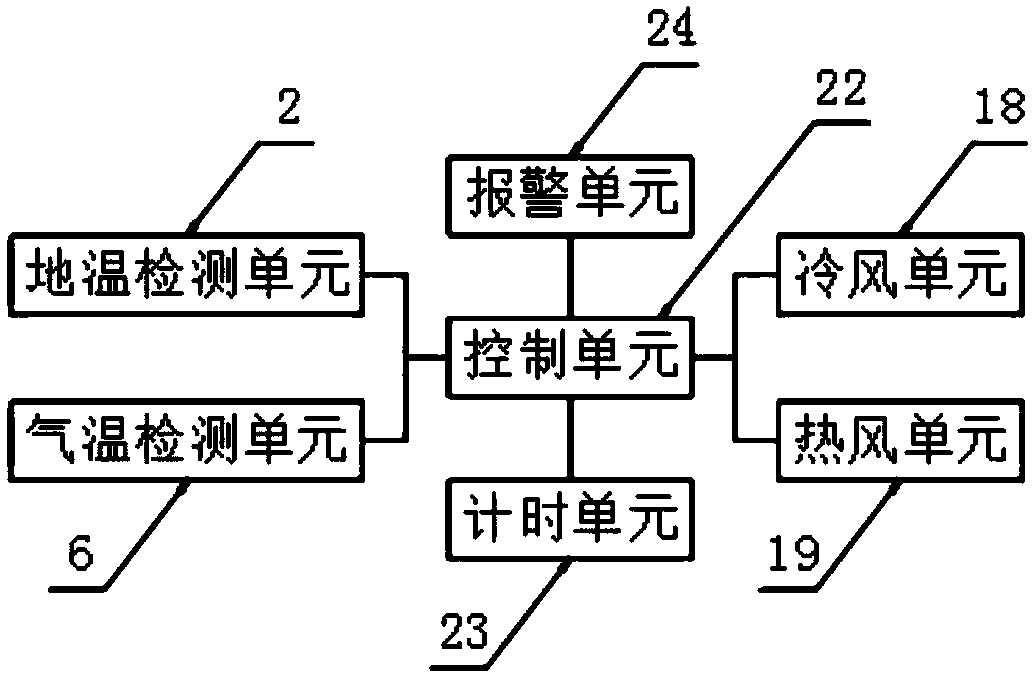

[0024] The present invention provides such Figure 1-3 A vineyard mechanized planting management device shown includes a ground surface 1, a ground temperature detection unit 2 is arranged inside the ground surface 1, and a first buried pipe 27 is arranged on the top of the ground temperature detection unit 2. The top of the pipe 27 is provided with a second underground pipe 26, the top of the surface 1 is fixed with a lower support rod 3, the top of the lower support rod 3 is fixed with a cross bar 4, and the top of the cross bar 4 is fixed with an upper support Rod 5, the side of the upper support rod 5 is provided with an air temperature detection unit 6, and the lower support rod 3 is fixed with a plurality of exhaust windows 8 and intake windows 9, and the intake windows 9 are arranged on the exhaust windows 8 side, the side of the air intake window 9 is fixed with a connecting bucket 15, the connecting bucket 15 is provided with a confluence pipe 16, the side of the lowe...

Embodiment 2

[0027] Further, in the first embodiment above, one end of the first buried pipe 27 is connected to the hot air unit 19 and the other end extends to the top of the ground surface 1 .

[0028] Further, in the first embodiment above, one end of the second underground pipe 26 is connected to the cold air unit 18 and the other end extends to the top of the ground surface 1 .

[0029] Further, in the first embodiment above, the top of the upper support rod 5 is fixed with a curved rod 7 , and the outside of the lower support rod 3 and the curved rod 7 is provided with a greenhouse film 25 .

[0030] Further, in the above-mentioned embodiment 1, the exhaust window 8 and the air intake window 9 both include a fixed frame 10, the inner side of the fixed frame 10 is provided with a filter screen 11 and the side is provided with a sealed door 12, and the sealed door 12 is movably connected to the fixed frame 10 through a hinge, and one side of the airtight door 12 is provided with an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com