Swivel chair leg

A technology for chair legs and swivel chairs, applied in the field of swivel chair accessories, can solve the problems of difficult mold development, high material input, and high production costs, and achieve the effects of reducing mold opening costs and material input costs, improving structural strength, and extending service life.

Pending Publication Date: 2019-01-04

ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Although the above-mentioned structure can meet the requirements of service strength, the disadvantages of the chair foot of this structure are:

[0006] Mold development is more difficult, resulting in higher initial investment costs

[0007] Secondly, the material input is relatively high, resulting in high production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

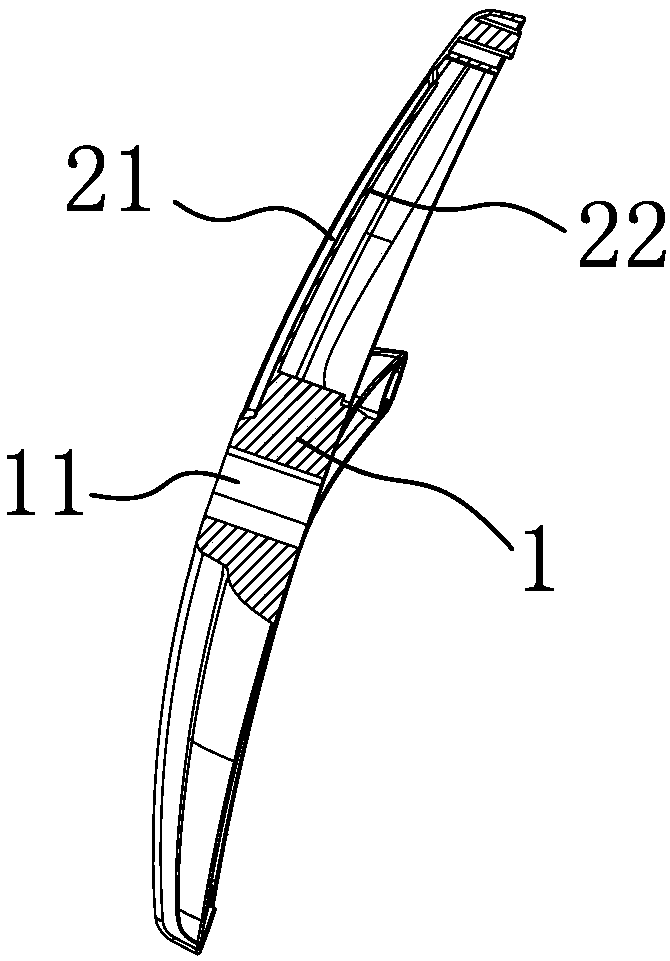

[0054] The working principle and structure of this embodiment are basically the same as those of Embodiment 1, and the different structures are:

[0055] The notch of the strip-shaped groove 21 is provided with a decorative closing cover.

[0056] The upper surface of the decorative closure cover is spliced with the upper surface of the support foot 2 in a smooth transition.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

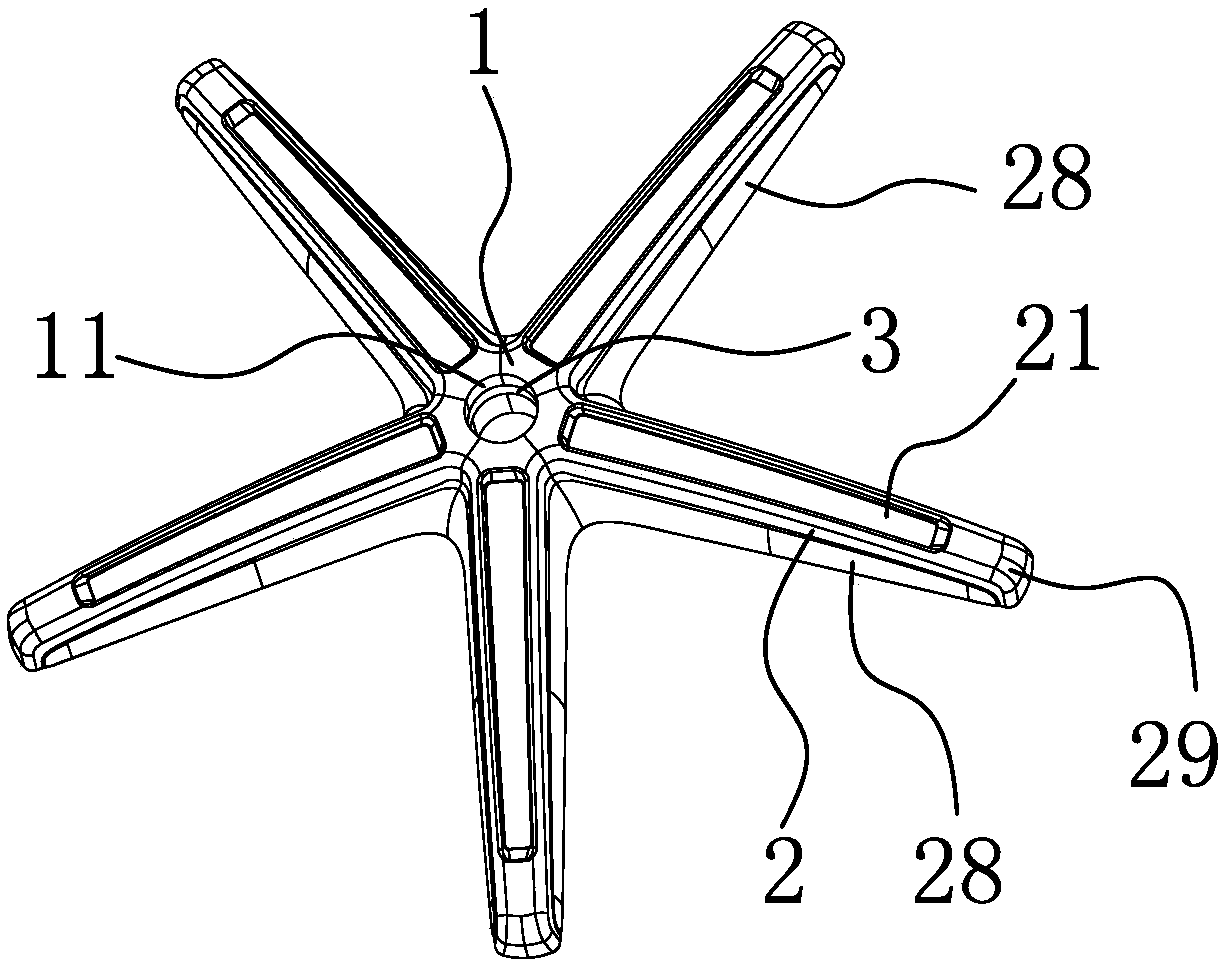

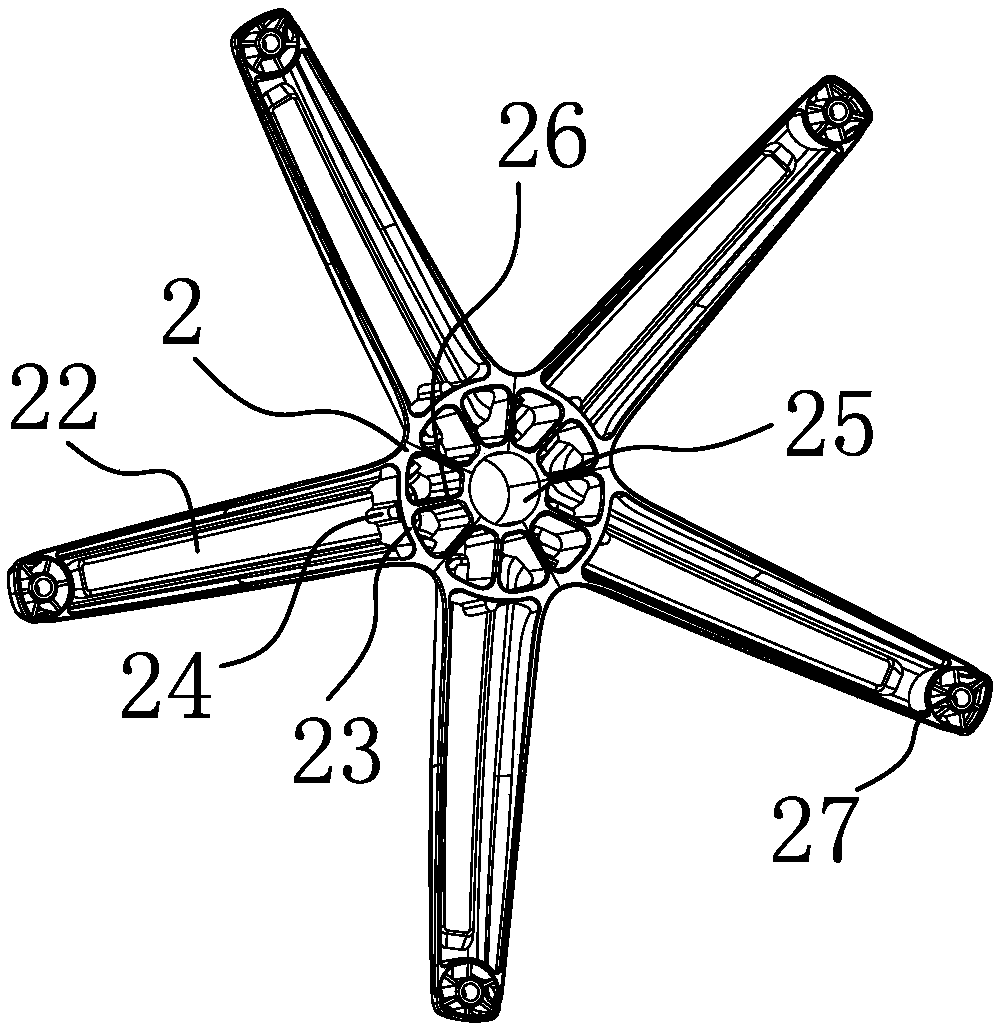

The invention belongs to the technical field of swivel chair fittings, particularly relates to a swivel chair leg, and aims at solving the problem that the design is unreasonable in the prior art. Theswivel chair leg comprises a five-foot body; an axle hole is formed in the center of the five-foot body; strip-shaped grooves which are formed along the length directions of supporting feet of the five-foot body are formed in the supporting feet; recessed bulges corresponding to the strip-shaped grooves are arranged on the lower surfaces of the supporting feet; arc-shaped reinforcing blocks are arranged between the ends, close to the axle hole, of the recessed bulges and the supporting feet; reinforcing ribs are arranged between the arc-shaped reinforcing blocks and the recessed bulges; the arc-shaped reinforcing blocks form a ring; the lower end of the axle hole is connected with an extension cylinder; reinforcing rib bodies are respectively arranged between the arc-shaped reinforcing blocks and the extension cylinder and between the extension cylinder and the ends, close to the axle hole, of the supporting feet; and the reinforcing rib bodies are circumferentially and uniformly distributed. The swivel chair leg has the advantages of reducing the cost and providing relatively high structural strength.

Description

technical field [0001] The invention belongs to the technical field of swivel chair accessories, in particular to a swivel chair foot. Background technique [0002] Swivel chairs, including chair legs, cushions and backrests and other parts. [0003] The chair legs are made of metal and plastic, or a combination of metal and plastic. [0004] In the chair legs made of plastic, the chair legs are generally hollow structures, and in order to enhance the structural strength, generally a lot of grid reinforcing ribs are added on the lower surface of the chair legs, especially the lower surface of the legs of the chair legs. [0005] Although the above-mentioned structure can meet the requirements of service strength, the disadvantages of the chair foot of this structure are: [0006] Mold development is more difficult, resulting in higher initial investment costs. [0007] Second, the material input is relatively high, resulting in high production costs. Contents of the inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47C7/00

CPCA47C7/004

Inventor 彭汉强

Owner ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com