Novel non-flash foaming mold structure and forming method thereof

A technology of foaming mold and molding method, which is applied in the field of new-type non-flash foaming mold structure and its molding, which can solve problems such as product flashing, achieve good product appearance, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

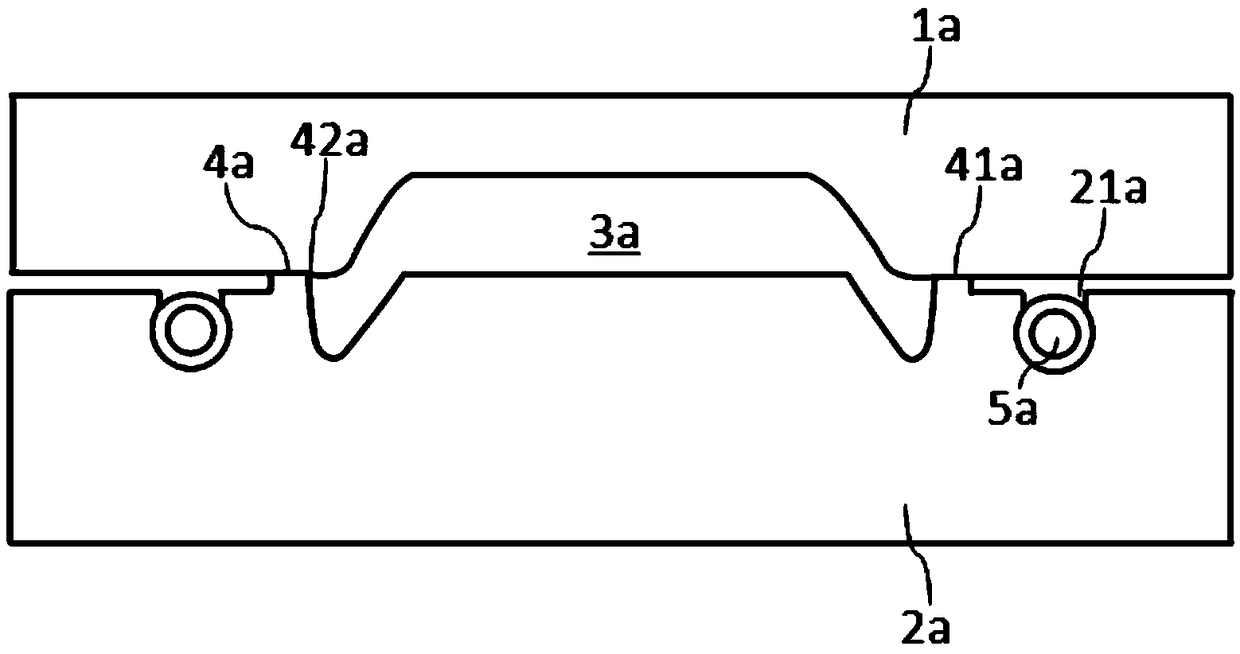

[0028] Such as image 3 As shown, according to a preferred embodiment of the present invention, the novel non-flash foaming mold structure comprises an upper mold 1a and a lower mold 2a, and the upper mold 1a and the lower mold 2a are closed to form a mold cavity 3a, and the upper mold 1a and the lower mold The opening and closing position of 2a has a contact surface 4a, the upper mold 1a and the lower mold 2a have a slit 41a at the position of the contact surface 4a, and the contact surface 4a has an adjoining seam 42a adjacent to the mold cavity 3a.

[0029] In this embodiment, the lower mold 2a has a groove 21a arranged around the mold cavity 3a, and the elastic body ring 5a as a deformation device is fixedly connected in the groove 21a. Such as Figure 4 As shown, the elastic body ring 5a is a circumferentially continuous soft material, which includes five elastic body sub-pieces 51a, and adjacent elastic body sub-pieces 51a are connected by connecting blocks 52a. In thi...

Embodiment 2

[0038] Such as Figure 6 As shown, according to a preferred embodiment of the present invention, the novel no-flash foaming mold structure includes an upper mold 1b and a lower mold 2b, and the upper mold 1b and the lower mold 2b are molded together to form a mold cavity 3b, and the upper mold 1b and the lower mold The opening and closing position of 2b has a contact surface 4b, the upper mold 1b and the lower mold 2b have a slit 41b at the position of the contact surface 4b, and the contact surface 4b has an adjoining seam 42b adjacent to the mold cavity 3b.

[0039] In this embodiment, the lower mold 2b has a first groove 21b disposed around the mold cavity 3b, and the elastic body ring 5b as a deformation device is fixedly connected in the first groove 21b. Such as Figure 7As shown, the elastic body ring 5b is a circumferentially continuous structure, which includes five elastic body sub-pieces 51b, and adjacent elastic body sub-pieces 51b are connected by connecting bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com