Patents

Literature

32results about How to "Increase design size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

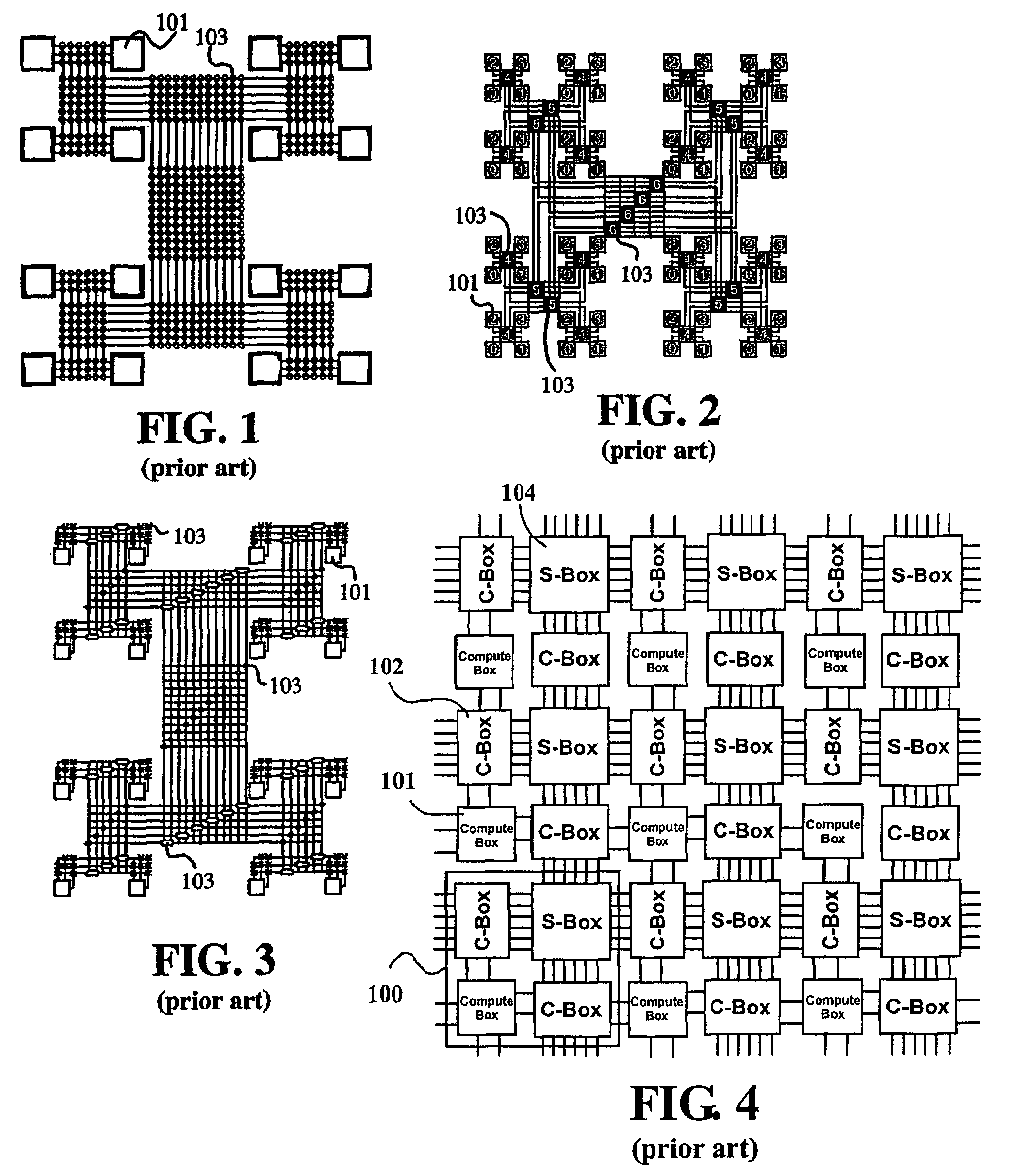

Method and apparatus for network with multilayer metalization

InactiveUS20050063373A1Fast and guaranteed routingEfficient layoutMultiplex system selection arrangementsSingle instruction multiple data multiprocessorsParallel computingInterconnection

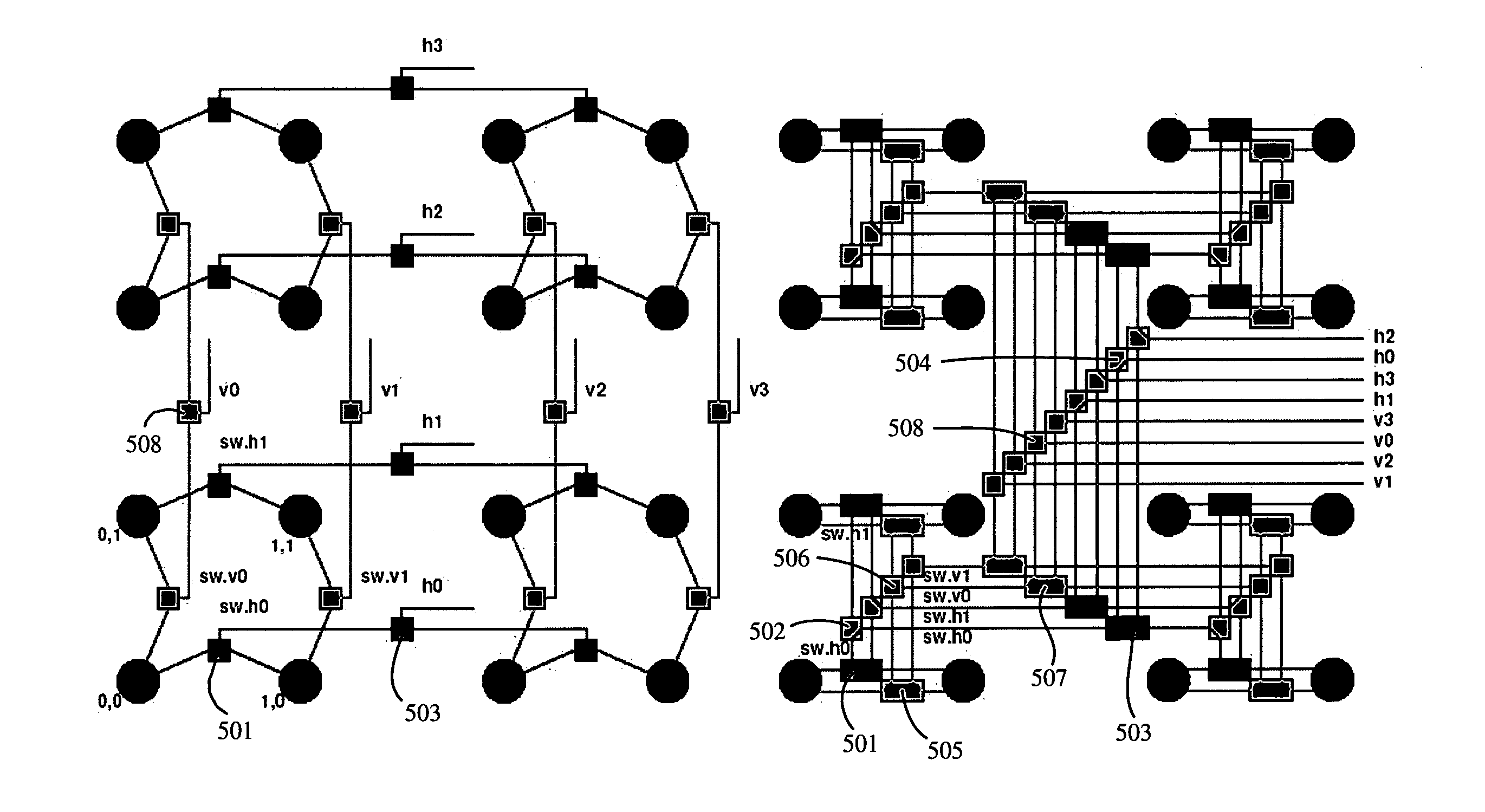

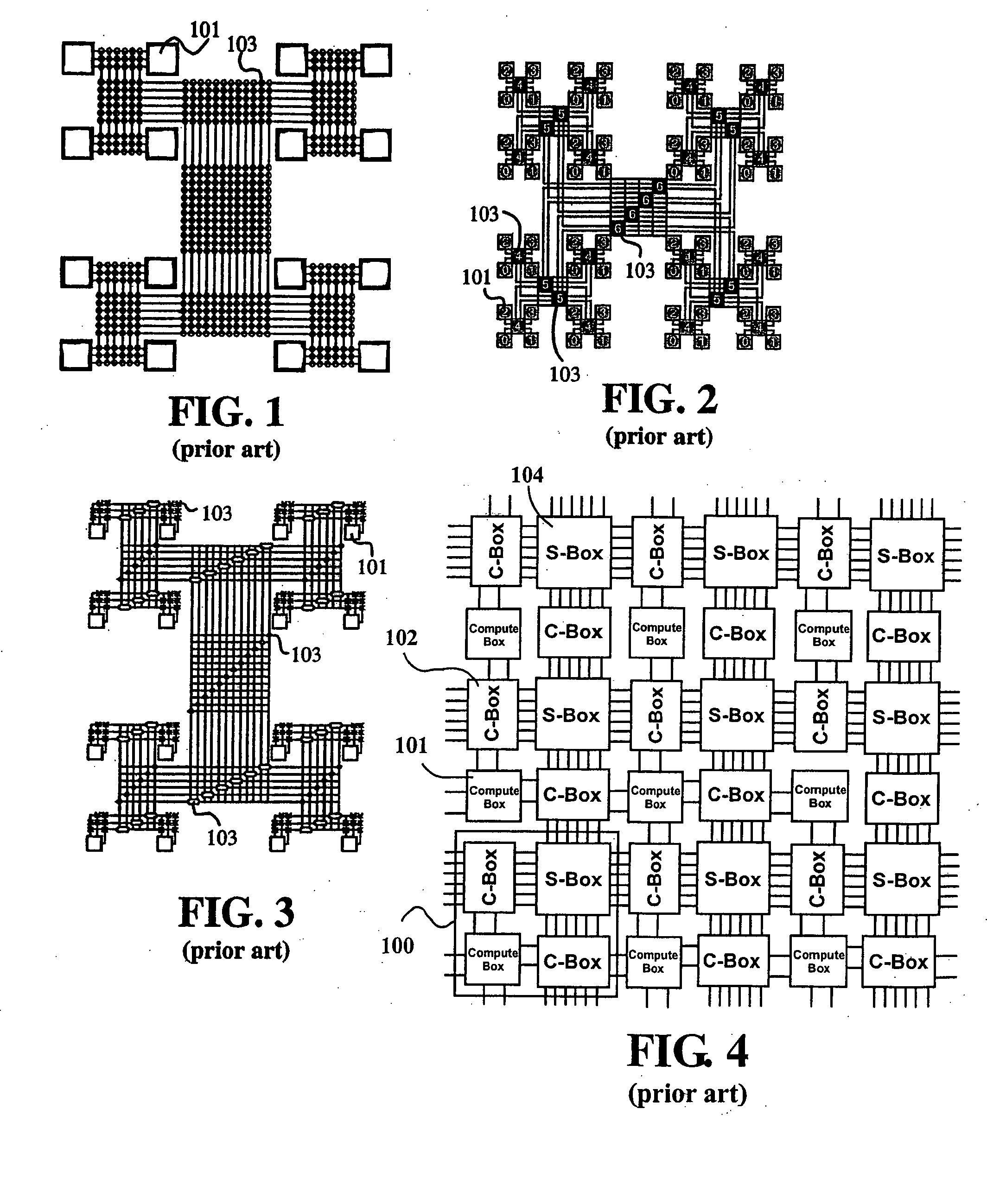

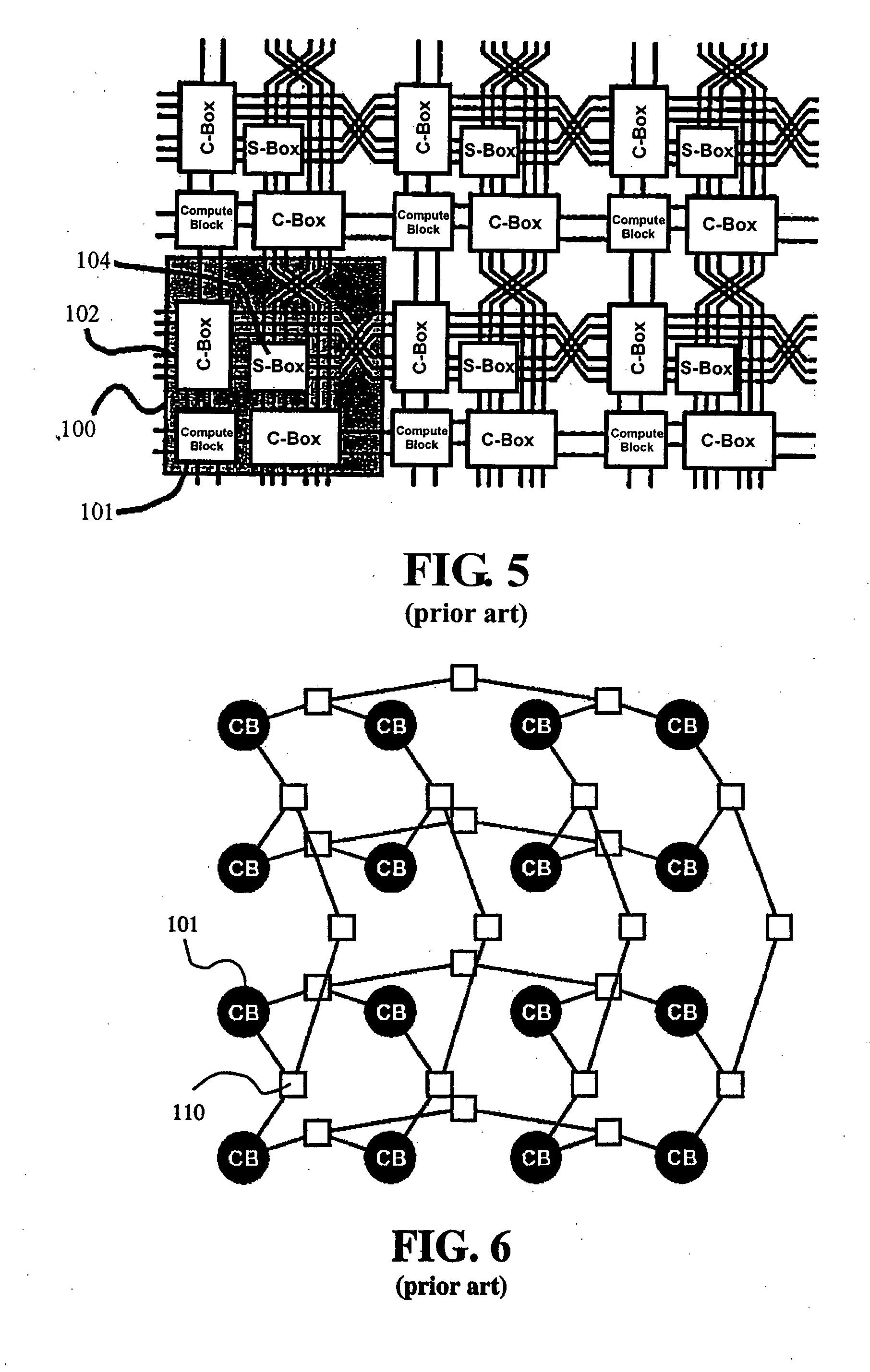

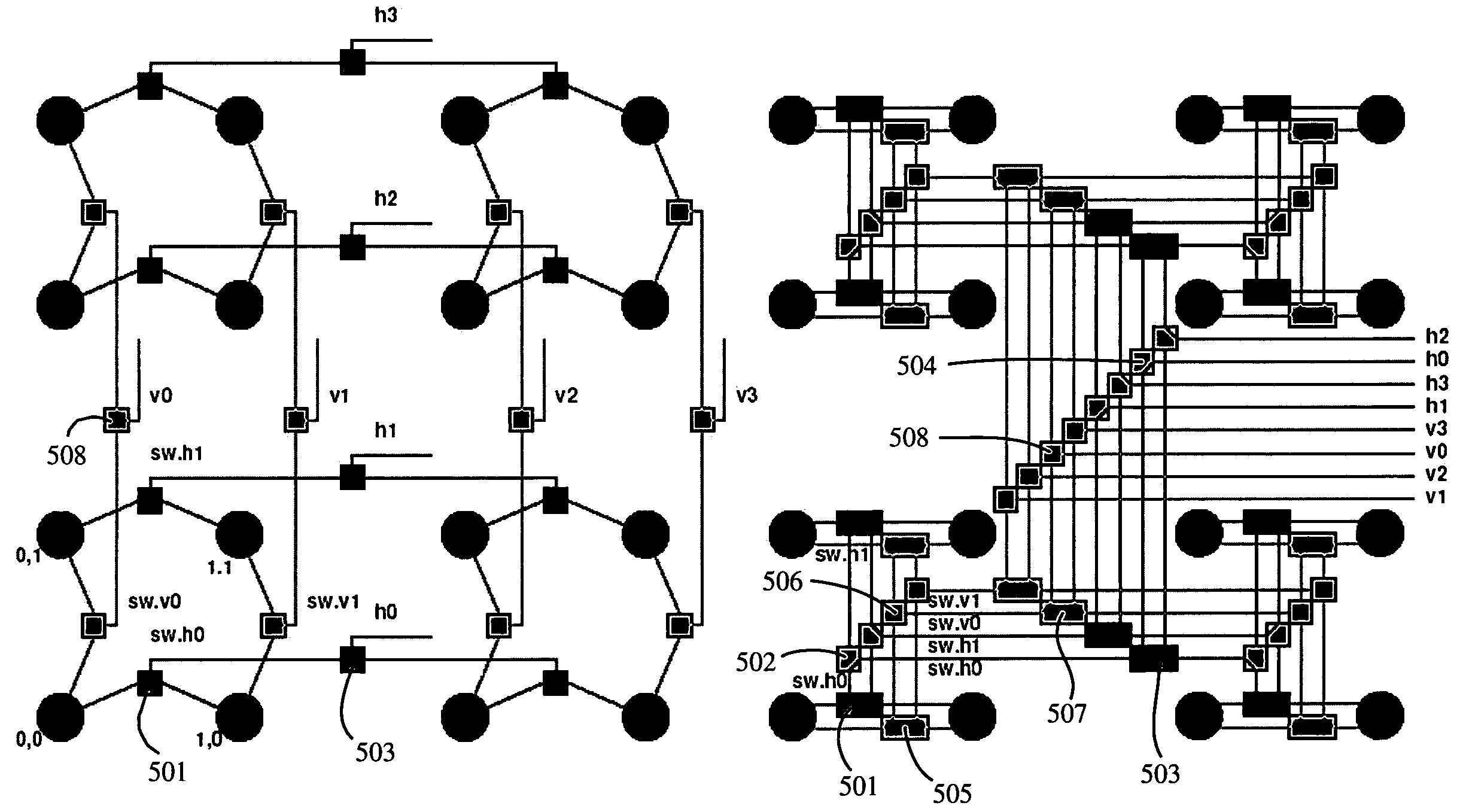

A network for interconnecting processing element nodes which supports rich interconnection while having a number of switching elements which is linear in the number of processing elements interconnected. Processing elements connect to the lowest level of the tree and the higher levels of the tree make connections between the processing elements. The processing elements may be laid out in a two dimensional grid and one or more horizontal and vertical trees may be used to connect between the processing elements with corner switches used to connect between the horizontal and vertical trees. The levels of the tree can be accommodated in multiple layers of metalization such that the entire layout requires a two-dimensional area which is linear in the number of processing elements supported.

Owner:CALIFORNIA INST OF TECH

Method and apparatus for network with multilayer metalization

InactiveUS7285487B2Improved BFT/HSRA layoutImprove good performanceMultiplex system selection arrangementsSingle instruction multiple data multiprocessorsParallel computingInterconnection

A network for interconnecting processing element nodes which supports rich interconnection while having a number of switching elements which is linear in the number of processing elements interconnected. Processing elements connect to the lowest level of the tree and the higher levels of the tree make connections between the processing elements. The processing elements may be laid out in a two dimensional grid and one or more horizontal and vertical trees may be used to connect between the processing elements with corner switches used to connect between the horizontal and vertical trees. The levels of the tree can be accommodated in multiple layers of metalization such that the entire layout requires a two-dimensional area which is linear in the number of processing elements supported.

Owner:CALIFORNIA INST OF TECH

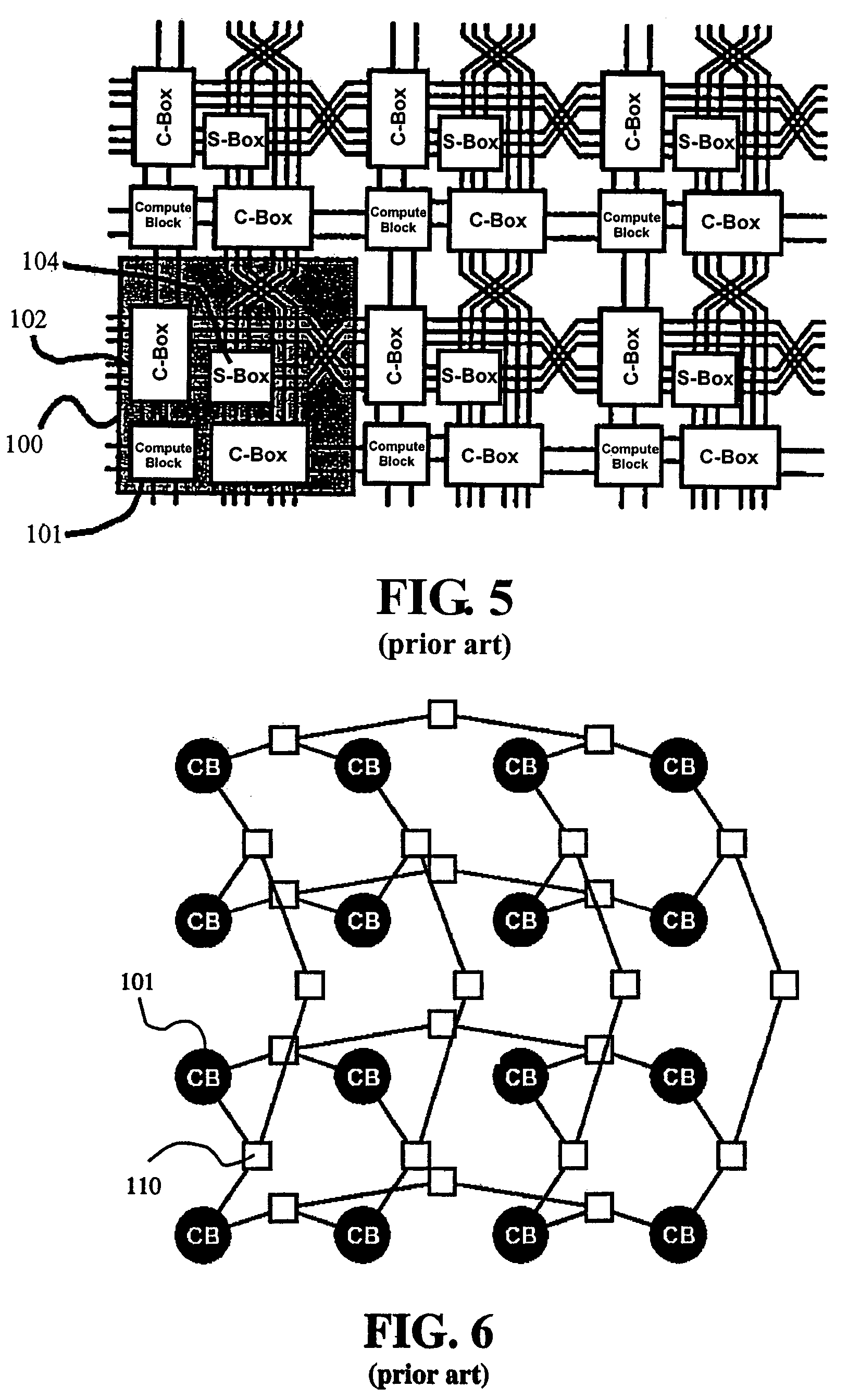

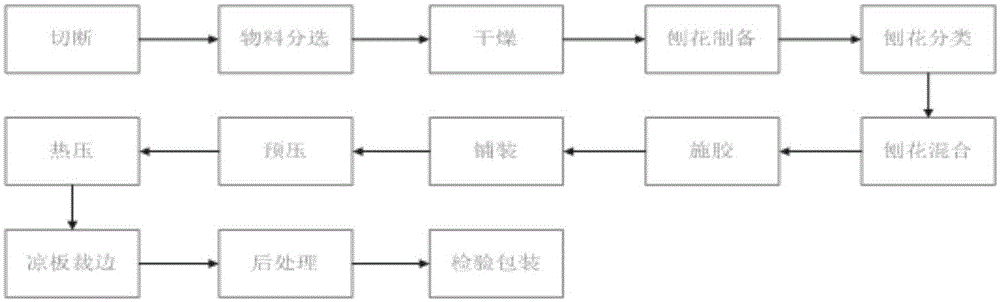

Shaving board manufacturing method

InactiveCN105171890AWidely usedBroaden the field of applicationDomestic articlesFlat articlesControl levelSizing

A shaving board manufacturing method includes the following steps of (1) cutting-off and sorting, (2) shaving preparation and classification, (3) shaving mixing, (4) sizing, (5) laying, (6) hot pressing and (7) after-treatment. Shaving boards are manufactured through puelia production. Compared with the prior art, the method has the advantages that (1) raw materials are widely used, puelia can be used independently for board manufacturing and can be mixed with other raw materials for board manufacturing, the application field of the puelia is widened, the problems of the deficiency and uncertainty of non-wood shaving board raw materials are solved, the design scale of a single production is enlarged, and production cost can be reduced; (2) various raw materials are precisely mixed through independent equipment, and the control level of the production line can be improved; (3) puelia shaving guarantees the uniformity and consistency of fibers by means of a smashing and precise grinding two-stage manufacturing mode, and the product yield is increased and subsequent processing performance is improved; (4) by means of distribution of the overall technology and equipment, the problem caused when puelia is applied to industrialization of board manufacturing is solved.

Owner:HUNAN WANHUA ECOLOGICAL PLATE IND CO LTD

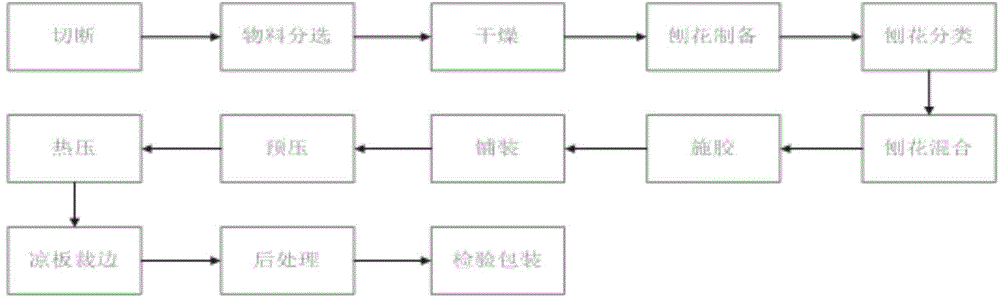

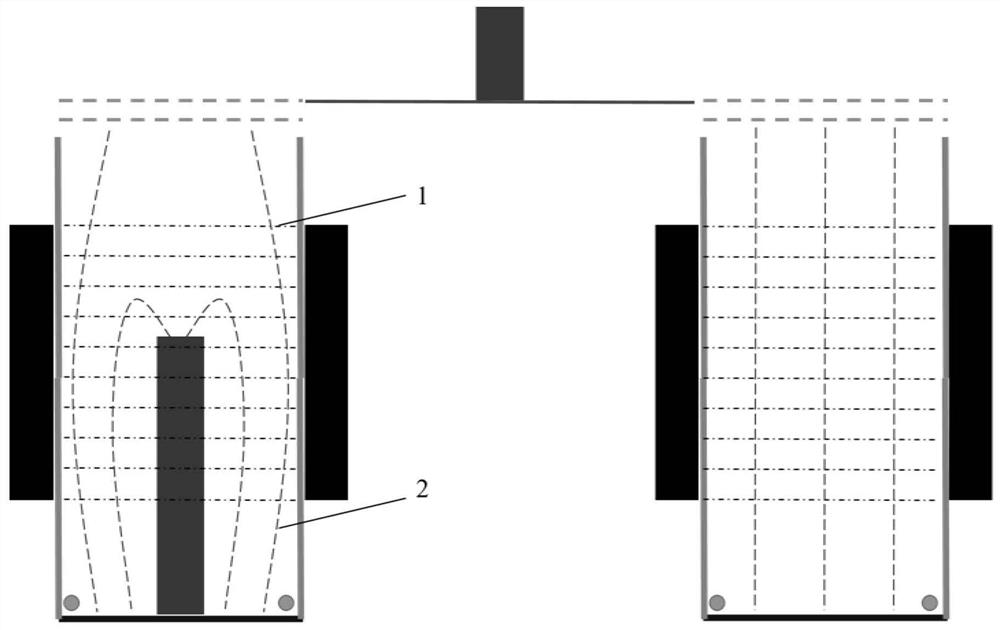

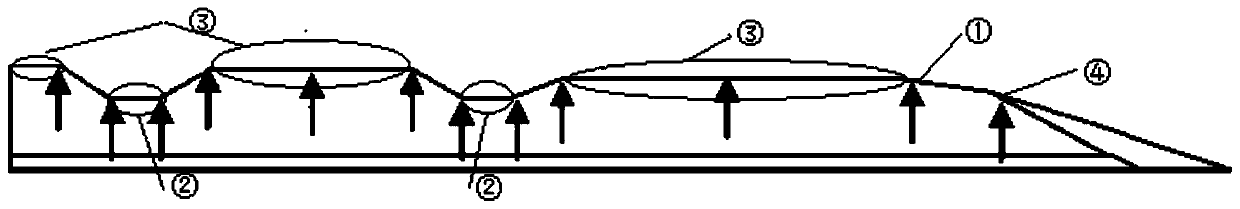

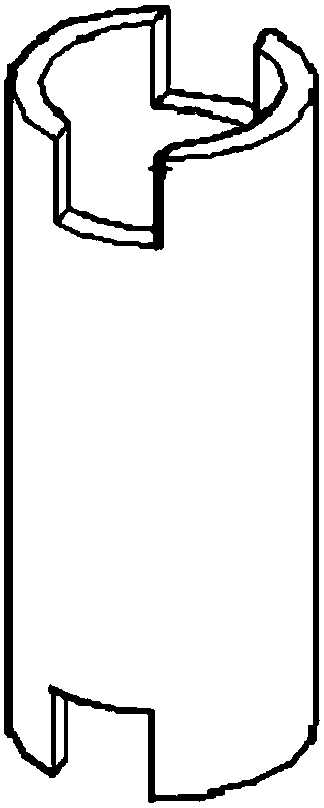

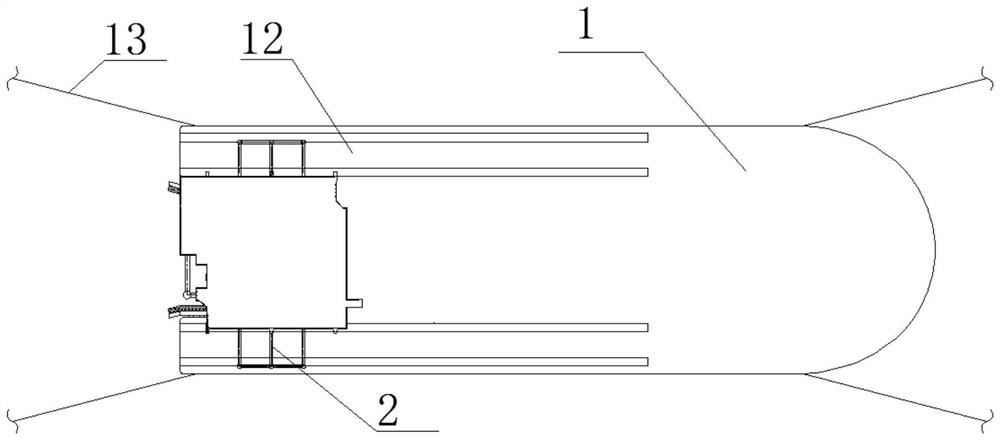

Hall effect ringlike ion thruster

ActiveCN111852802AReduce spanReduce manufacturing difficultyMachines/enginesUsing plasmaPlasmaElectric field

The invention discloses a Hall effect ringlike ion thruster and belongs to the technical field of ion thrusters. The ringlike ion thruster comprises a bottom positive pole, a ringlike grid electrode,ringlike permanent magnets, insulating sleeves, a working medium distributor set, a bias discharging negative pole and a neutralizer. Working medium gas enters a discharging chamber through bottom working medium distributors. Nozzles of the working medium distributors are oriented along the wall face so that the gas can be more uniform in a cavity. An axial electric field is formed among the positive pole, the negative pole and the grid electrode. A radial magnetic field is formed by the inner ringlike permanent magnet and the outer ringlike permanent magnet, and an E*B orthogonal field is formed by the radial magnetic field and the axial electric field. Electrons sprayed out of the negative pole are subjected to Hall drift under the effect of the orthogonal field, and the working medium gas is ionized to generate plasmas. Then, the plasmas are extracted and accelerated by the ringlike grid electrode and neutralized by electrons emitted by the neutralizer to generate thrust. The ionization rate and input power of the thrust generated by the Hall effect ringlike ion thruster are far higher than those of a traditional ion thruster, and performance of the ion thruster can be remarkably improved.

Owner:DALIAN UNIV OF TECH

Method for preparing shaving board by using Jujuncao

InactiveCN105128114AEasy to useSolve problemsDomestic articlesFlat articlesProduction lineWood shavings

The invention discloses a method for preparing a shaving board by using Jujuncao. The method comprises the steps of: (1) cutting and sorting; (2) shaving preparation and classification; (3) shaving mixing; (4) sizing; (5) pavement; (6) hot pressing; and (7) post-treatment step, that is, the shaving board is prepared by the Jujuncao. Compared with the prior art, the method has the following advantages: (1) raw materials are wide in use; the Jujuncao can be singly used for preparing the board, or can be mixed with other raw materials for preparing the board, so that the application field of the Jujuncao is widened, the problems of insufficient raw materials and uncertainty in a non-wood shaving board are solved, the design scale of single production line is widened, and the production cost can be reduced; (2) precise mixing of various raw materials is realized through single equipment; the control level of the production line can be promoted; (3) the Jujuncao shaving adopt a crushing and finish polishing second-level preparation mode to guarantee the fiber uniformity and consistency and to improve the product pass percent and the subsequent machinability; and (5) the problem of applying the Jujuncao to the board manufacturing industrialization is solved through arranging the whole process and equipment.

Owner:HUNAN WANHUA ECOLOGICAL PLATE IND CO LTD

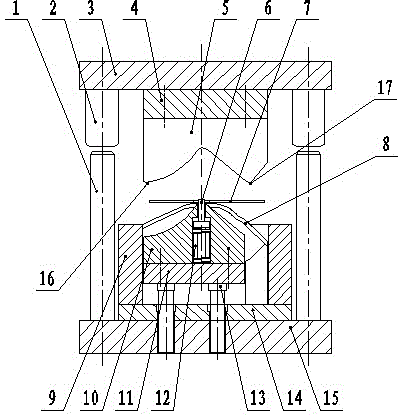

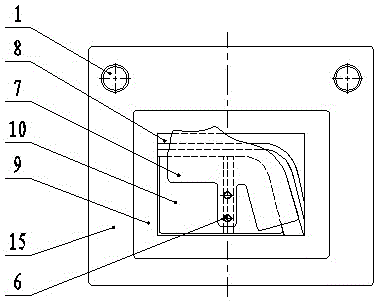

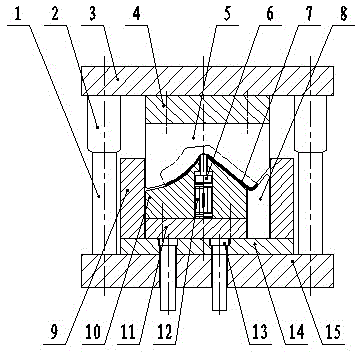

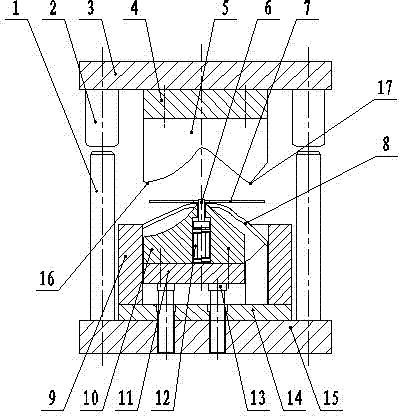

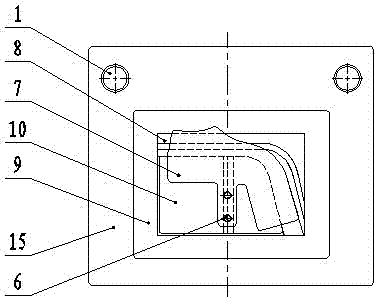

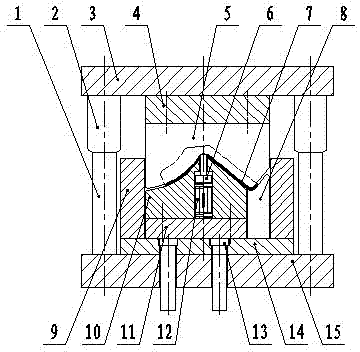

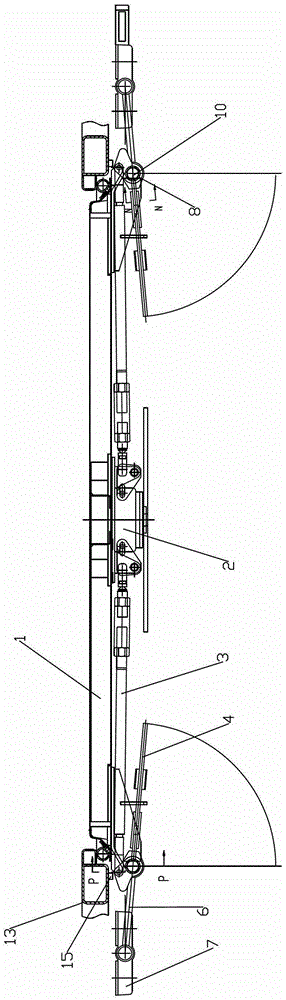

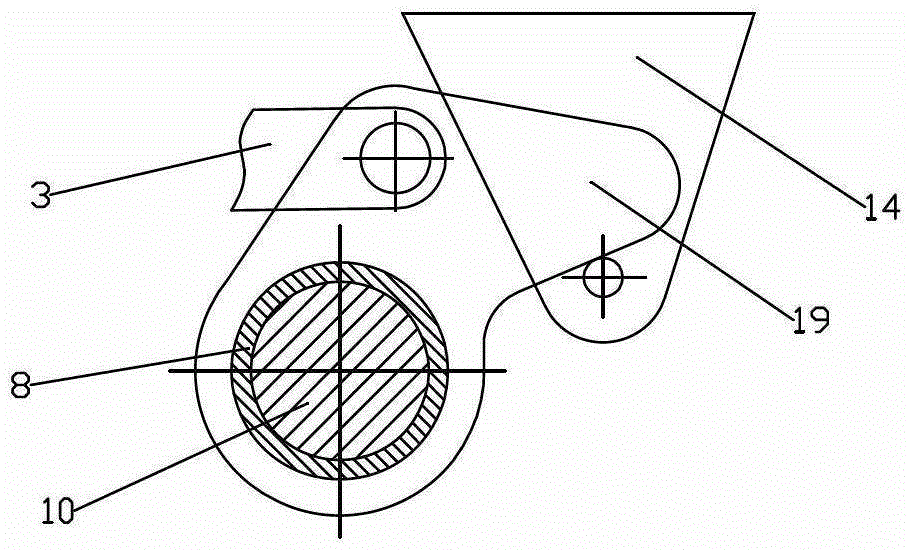

Punch forming process and mould for vehicle load sensing proportional valve support

The invention discloses a punch forming process and mould for a vehicle load sensing proportional valve support. The process comprises the following steps of feeding, blanking, auxiliary hole punching, forming, cutting and assembly hole punching; and a forming mould is divided into an upper die and a lower die, and the forming mould comprises an upper mould board (3), a terrace die (5), a lower mould board (15), a female die fixed plate (9), a guide column (1) and a guide sleeve (2). According to the process and the mould, by the adoption of a novel cold punching process, the difficult problem of finished piece positioning is solved, and one-time forming through the forming mould is realized. By the adoption of the process and the mould, the design size and the use performance of a product can be continuously and stably ensured, the capacity is promoted, the production cost is lowered, the quality and the fatigue life of an irregular and complex forming piece are improved, an outlook of the product is excellent, and the requirements on design and use are totally met.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

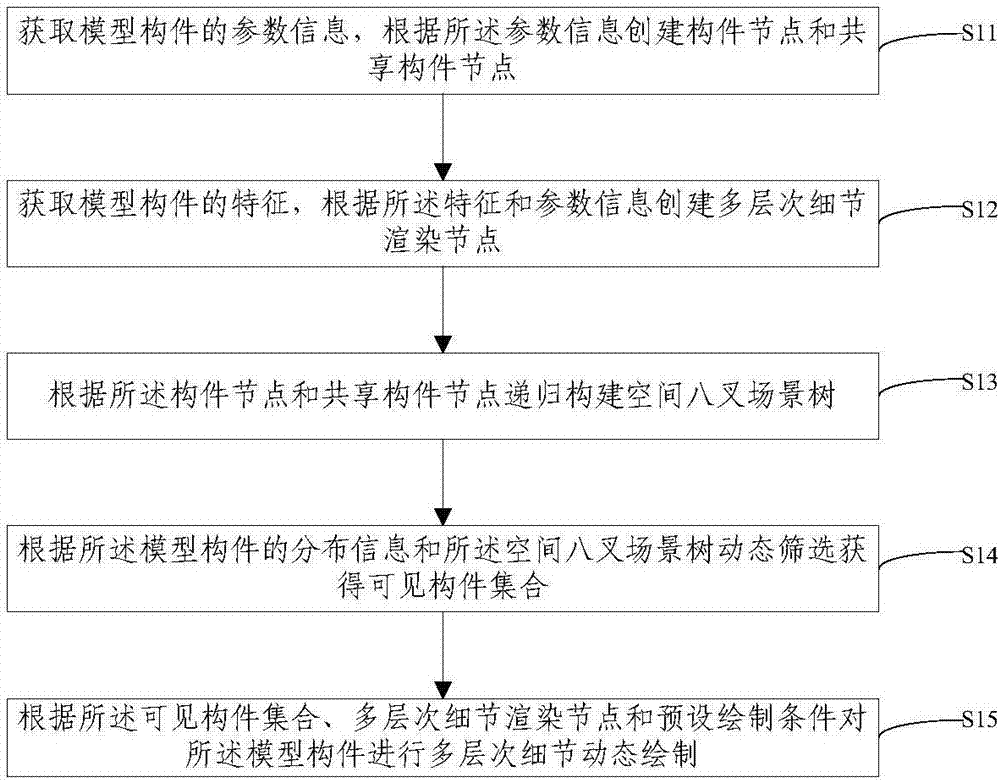

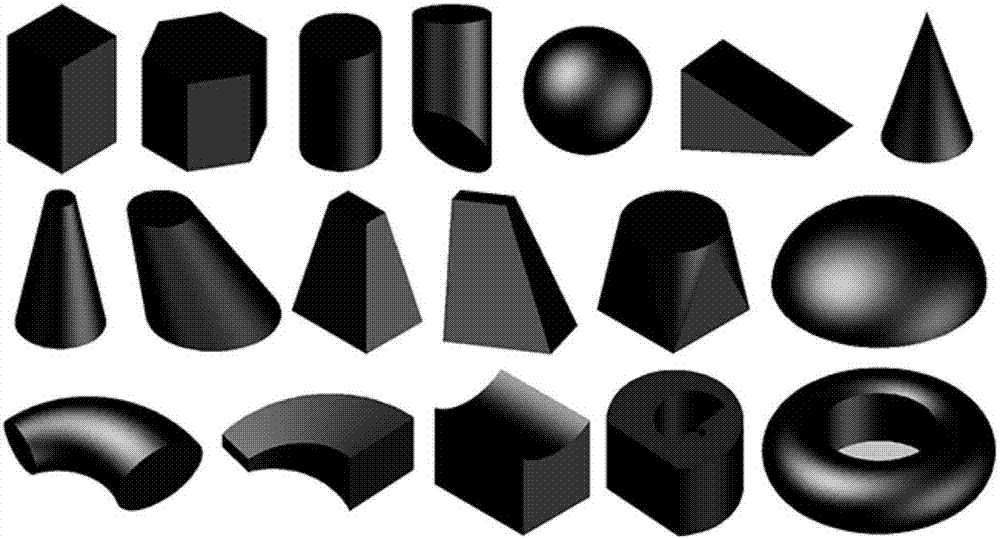

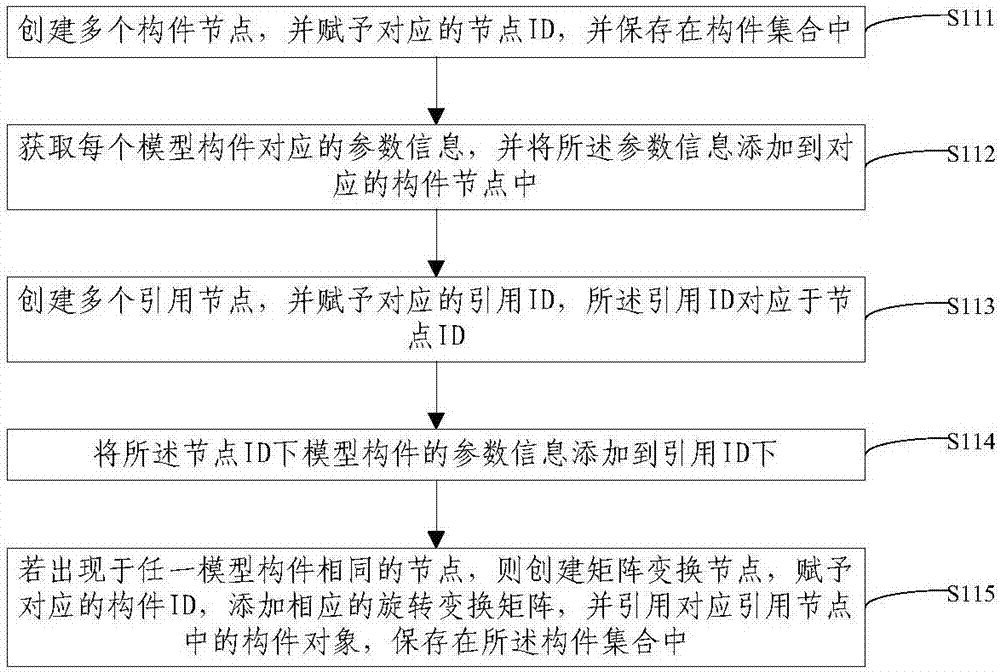

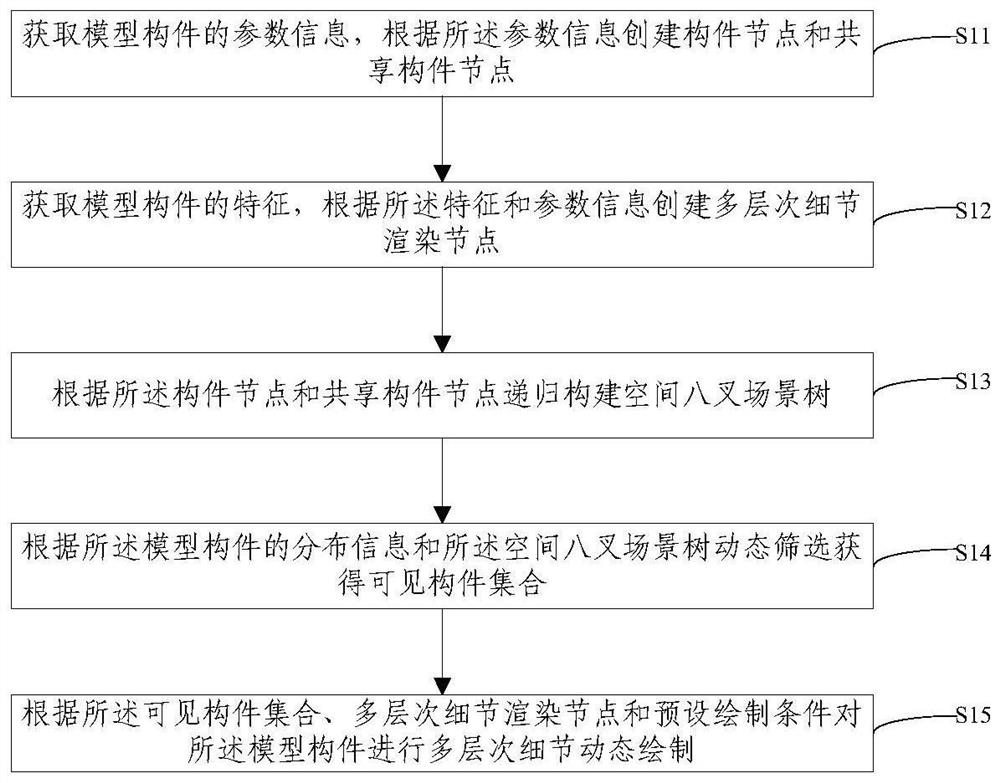

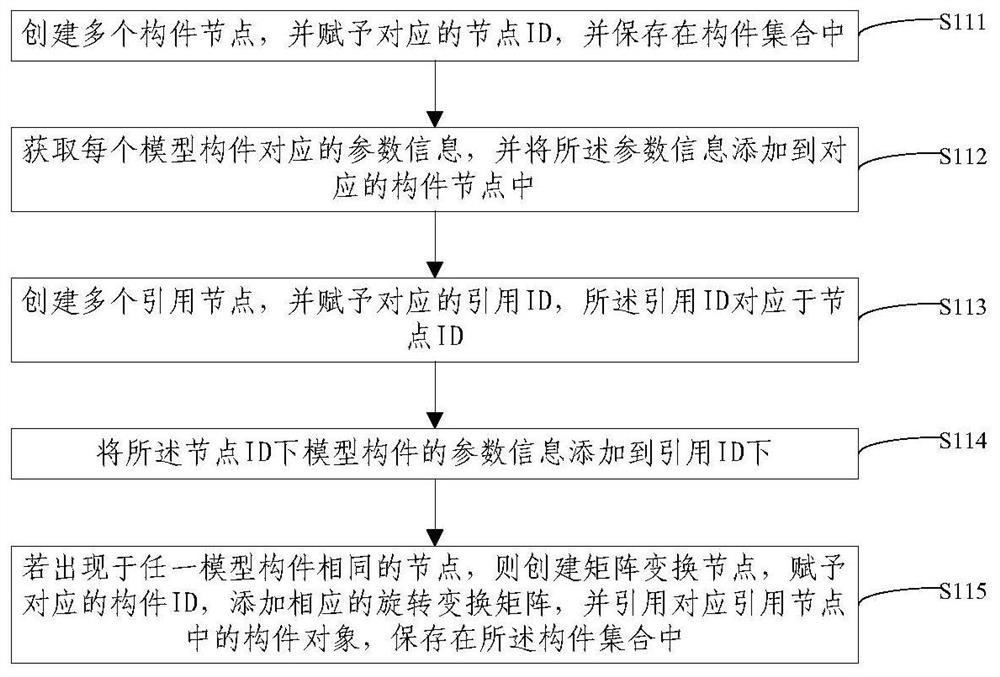

Method and device for drawing large-scale scene at fixed frame rate based on features of model components

ActiveCN107025684AReach load designImplement loading designDesign optimisation/simulationSpecial data processing applicationsNODALAlgorithm

The invention provides a method and a device for drawing a large-scale scene at fixed frame rate based on the features of model components. The method comprises the following steps: acquiring parameter information of model components, and creating component nodes and shared component nodes according to the parameter information; acquiring the features of the model components, and creating multi-level detail rendering nodes according to the features and the parameter information; recursively building a spatial octree scene tree according to the component nodes and the shared component nodes; carrying out dynamic screening according to the distribution information of the model components and the spatial octree scene tree to get a visible component set; and carrying out multi-level detail dynamic drawing of the model components according to the visible component set, the multi-level detail rendering nodes and preset drawing conditions. A large-scale process plant model can be loaded and designed through a process plant design platform, and the frame rate can be displayed and controlled. Moreover, the design scale and the interaction frame rate can both be improved significantly.

Owner:北京中科辅龙智能技术有限公司

Method for preparing high-density ITO target on conditions of reducing sintering temperature

Provided is a method for preparing a high-density ITO target on conditions of reducing sintering temperature. According to the method, in preparation of ITO slurry during the initial period, first premixing liquid needs to be prepared first and a ball mill is used; an oven is used in low-temperature drying preparation of a secondary material; in preparation of the ITO slurry, second premixing liquid needs to be prepared first and the ball mill is used again, a grouting forming method is adopted in the forming processing of ITO blank and compressed air serves as a pressure transmitting medium, and normal pressure oxygen atmosphere conditions are adopted in the sintering processing of the ITO blank. The ITO slurry with a high solid phase content is one requirement for preparing the high-density ITO blank, the relative density of the prepared ITO blank can be as high as 74-76% through measurement in a mercury emission method, the solid content of the ITO slurry is 89-91% through ball milling of the secondary material, and the high-density ITO target with the relative density as high as 99.50-99.67% can be prepared through good viscosity mobility and the low sintering temperature.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

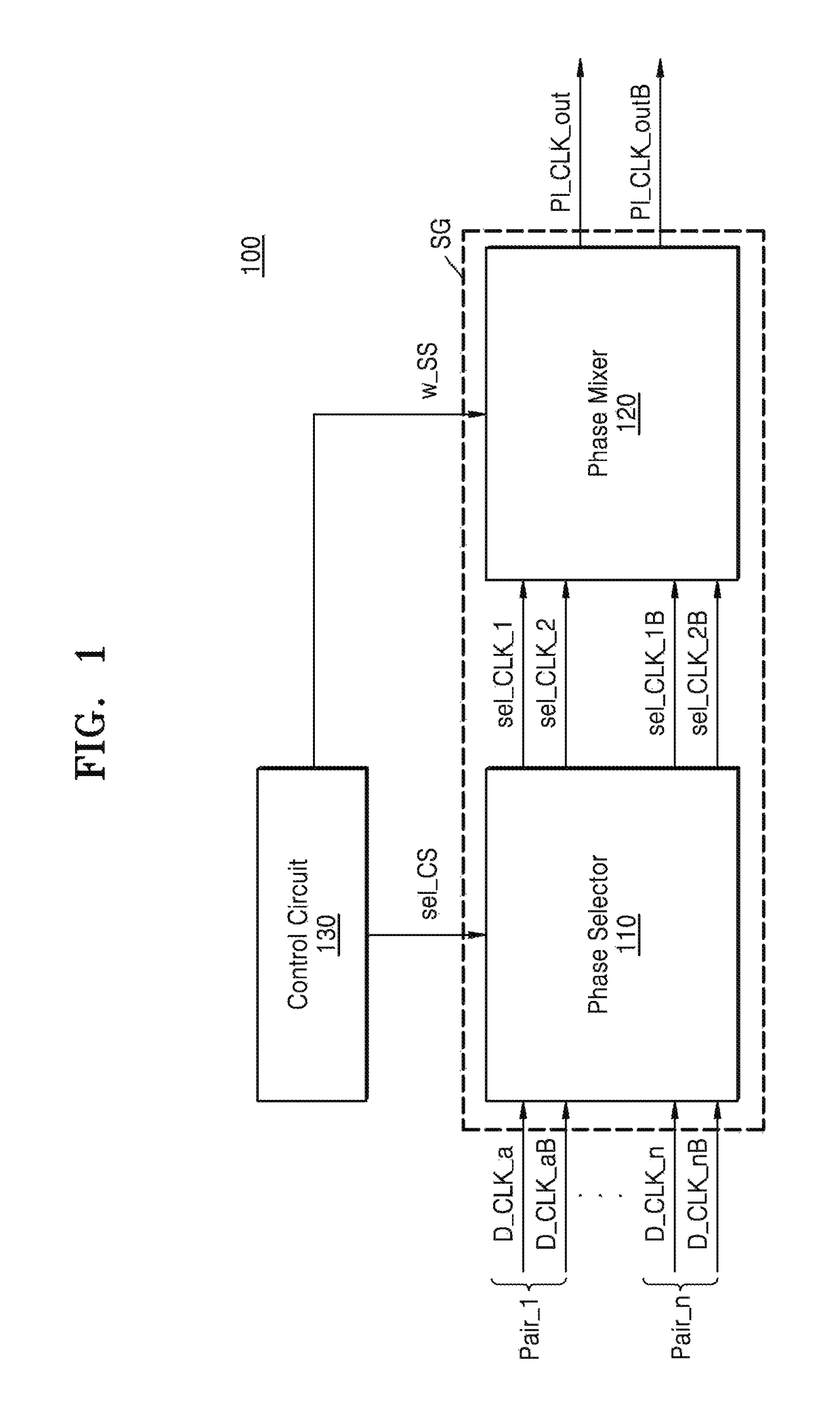

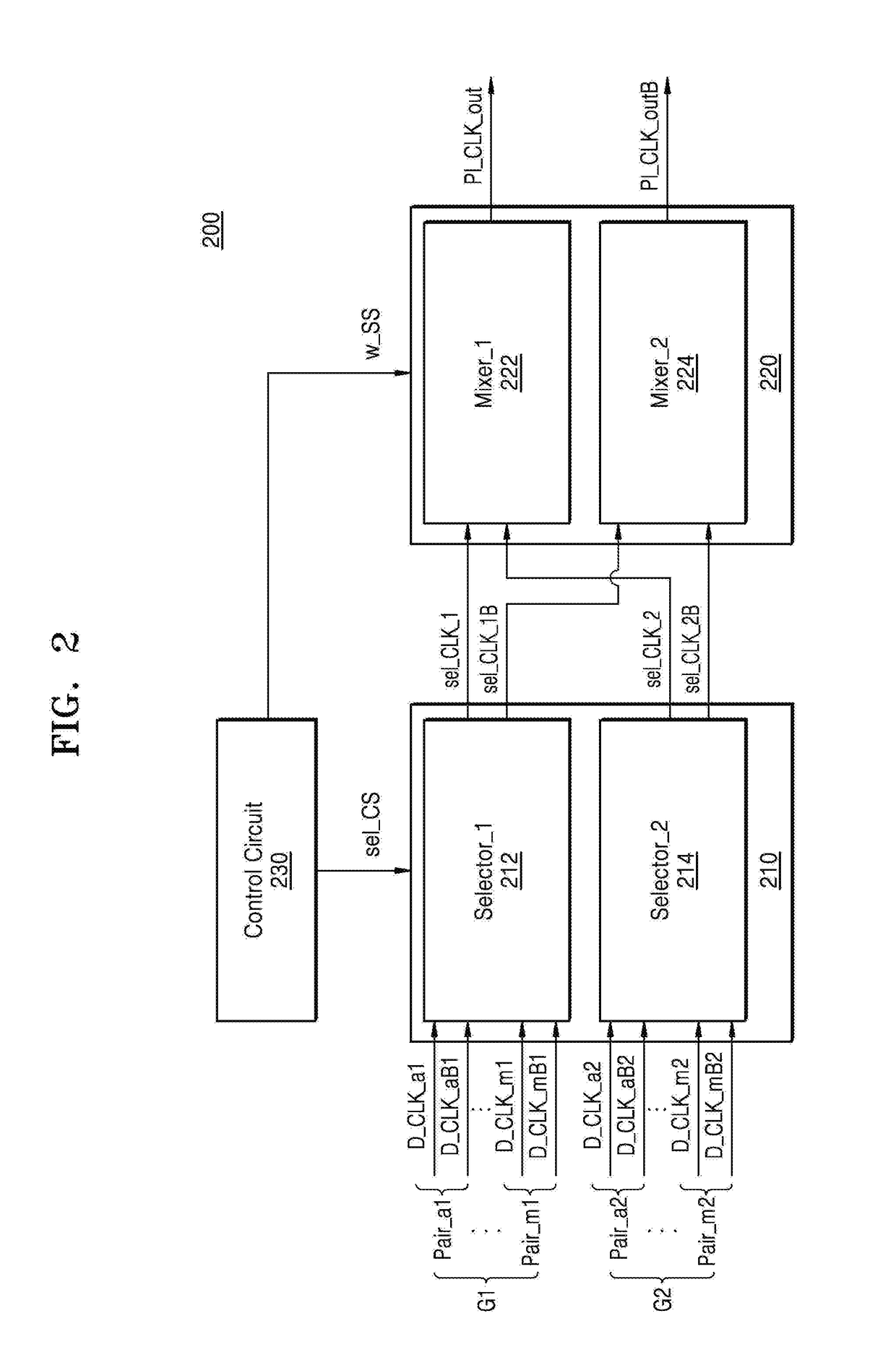

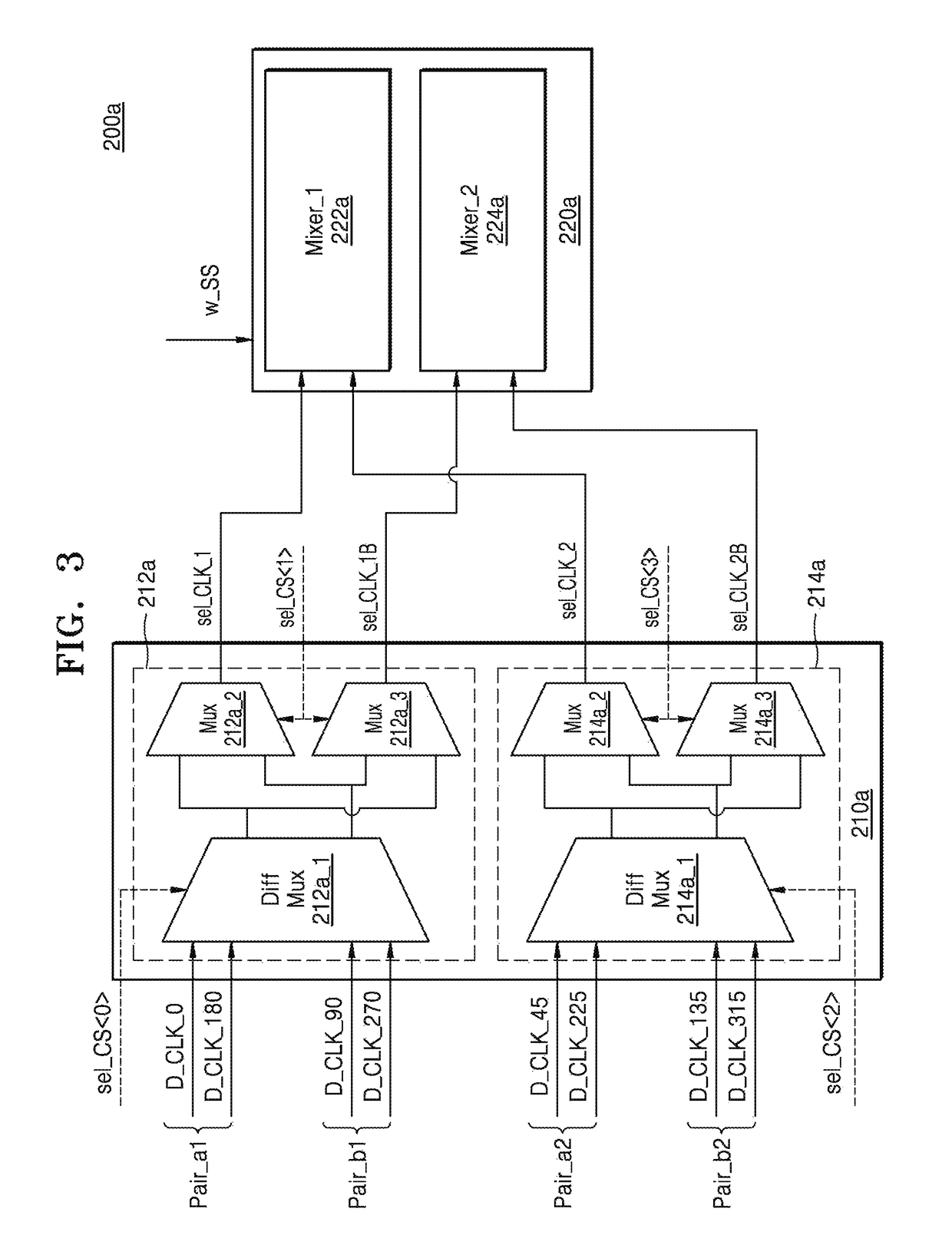

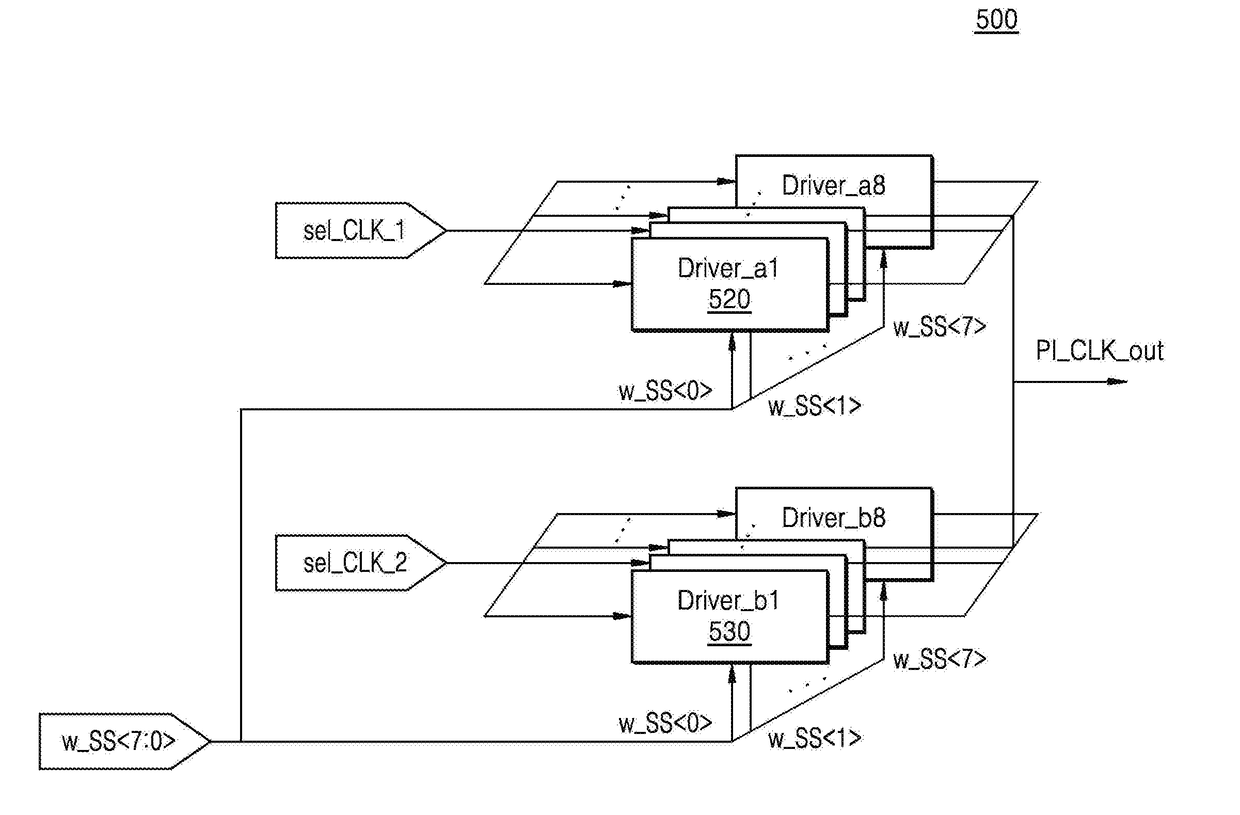

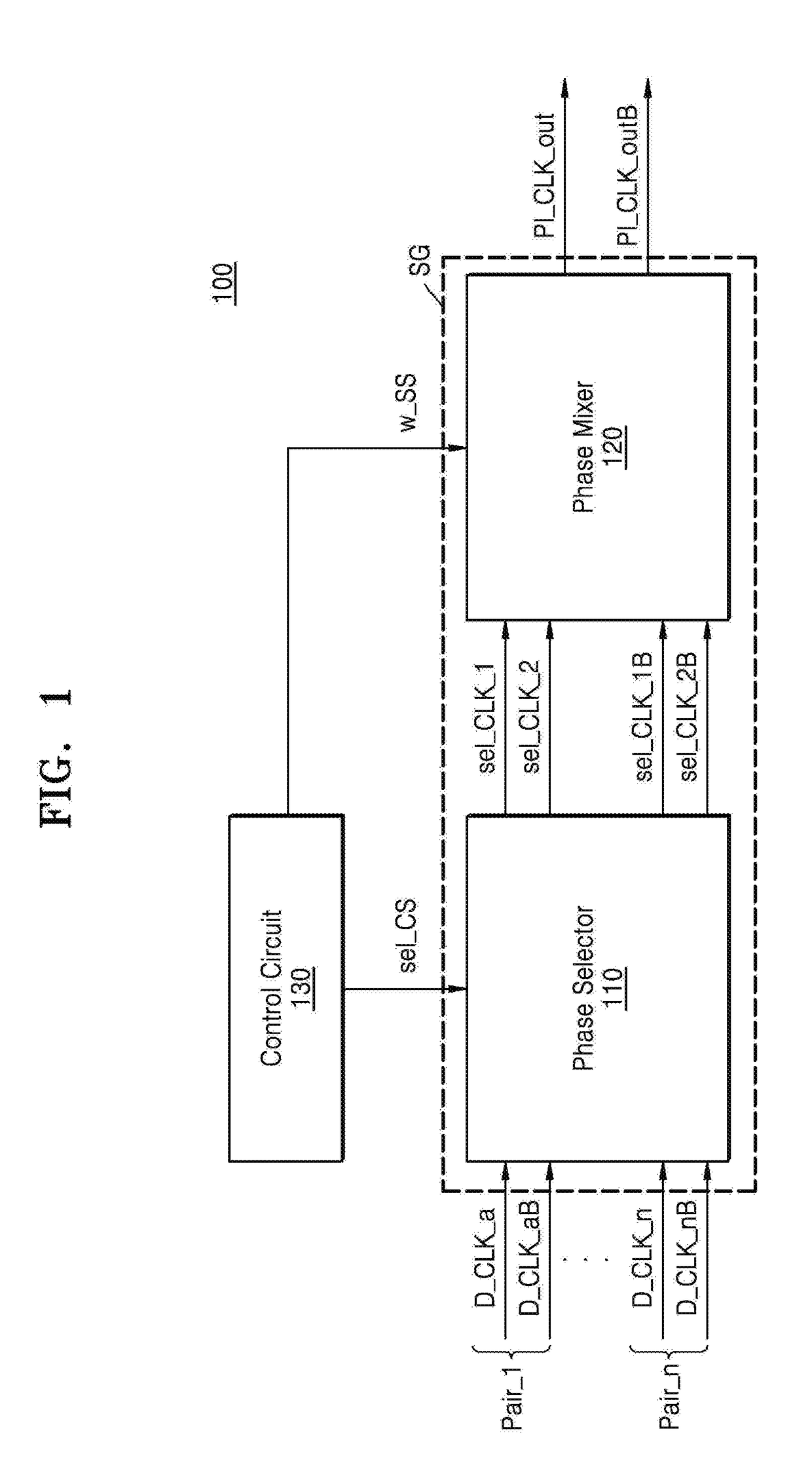

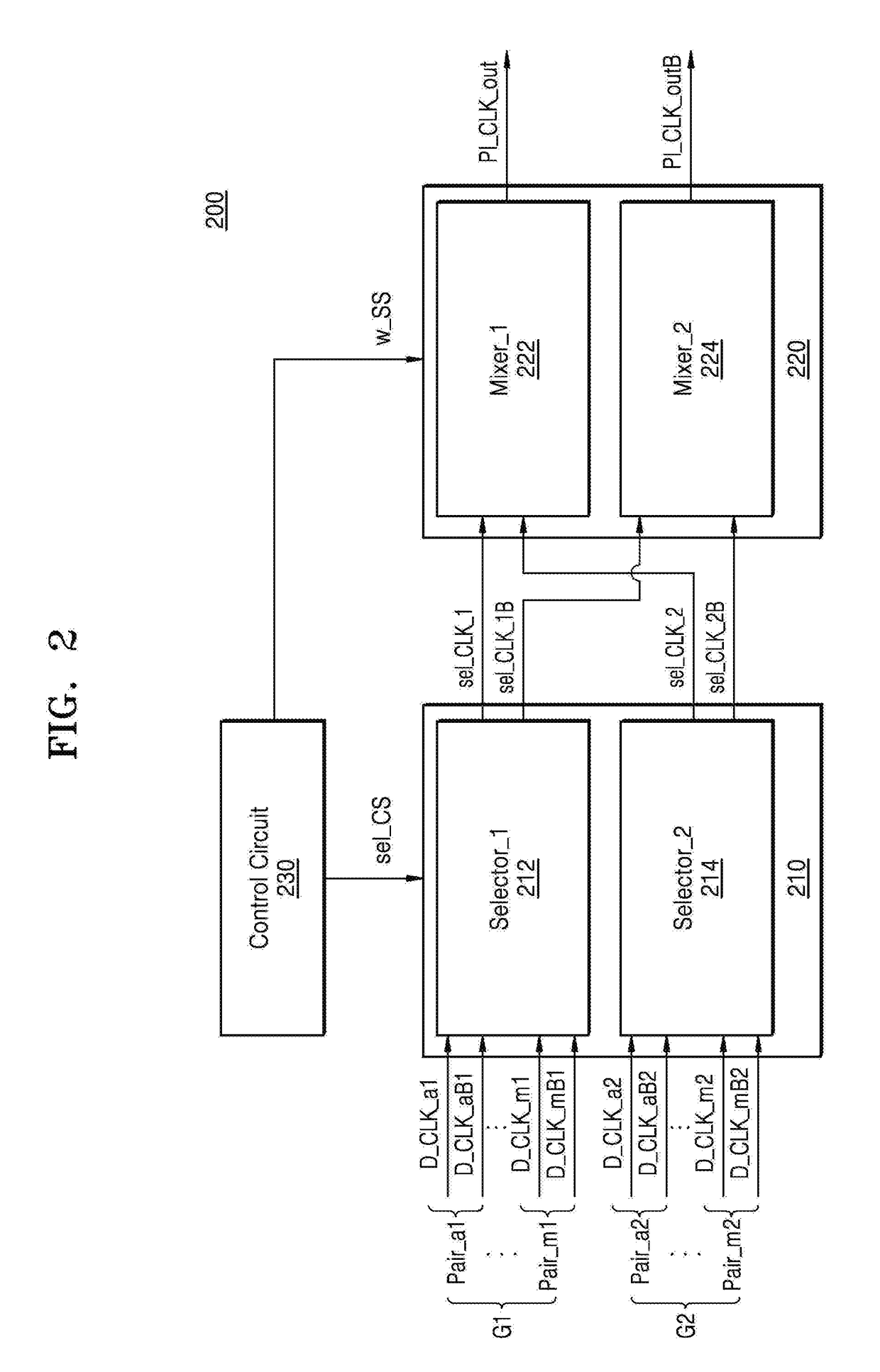

Phase interpolator for interpolating phase of delay clock signal and device including the same and for performing data sampling by using phase interpolated clock signal

ActiveUS10171091B2Reduce glitchesIncrease design sizePulse automatic controlSynchronisation signal speed/phase controlControl signalEngineering

A phase interpolator includes a control circuit configured to generate a selection control signal that corresponds to a selected coarse phase interval, and generate a weight setting signal for generating a phase interpolation clock signal with an interpolated phase within the coarse phase interval; a phase selector configured to receive a plurality of inversion delay clock signal pairs, select at least two inversion delay clock signal pairs from the plurality of inversion delay clock signal pairs based on the selection control signal, select and output a selection delay clock signal pair corresponding to the coarse phase interval from the selected at least two inversion delay clock signal pairs; and a phase mixer configured to receive the selection delay clock signal pair from the phase selector and generate the phase interpolation clock signal based on the weight setting signal.

Owner:SAMSUNG ELECTRONICS CO LTD

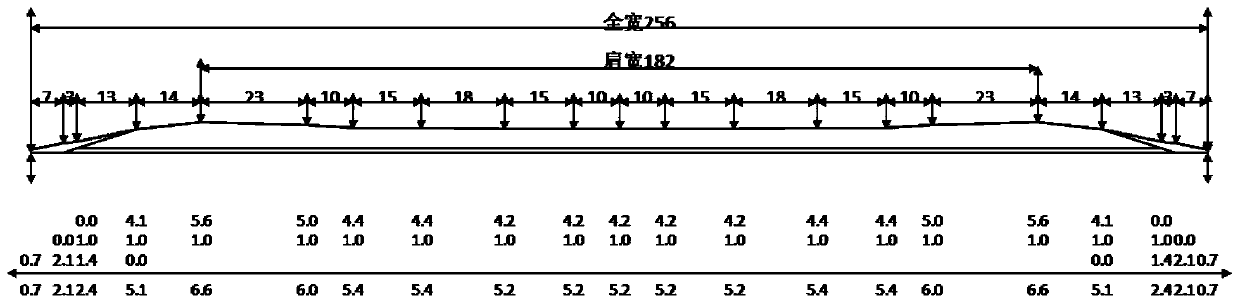

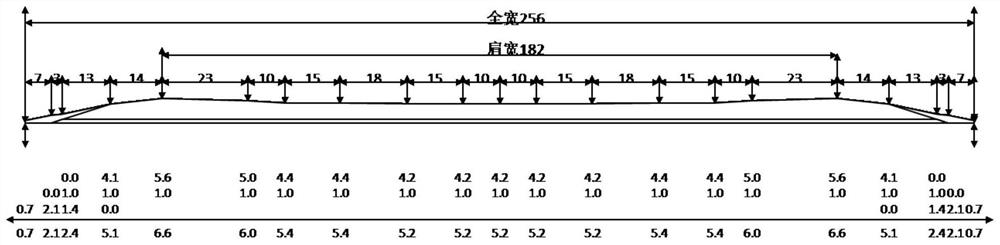

Design method for development size of novel extruded die plate

The invention discloses a design method for the development size of a novel extruded die plate. The design method comprises the two main steps of (1), determining the width of the opening plate of a die plate, wherein the width of the opening plate comprises a shoulder width and a full width; (2) determining the thickness of the opening plate of the die plate, wherein when the thickness of the opening plate of the die plate is determined, on the basis of the determined width of the opening plate, glue types in different extruding machines, preform die of different sizes, and expansion rate inthe die plate of different shapes are researched, a computational formula of the expansion rate of rubber materials and the development size of the die plate is formulated, according to the formula obtained, the design size of the die plate with high precision can be obtained, and the qualified rate of one-time opening plate of the die plate is greatly improved; further, the mouth type developer does not need to perform design and development of the size of the die plate by virtue of empirical values, the culture period of mouth type workers is greatly reduced, the production cost of enterprises can be effectively reduced, the production efficiency can be improved, and the method has relatively high popularization and practical application values.

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

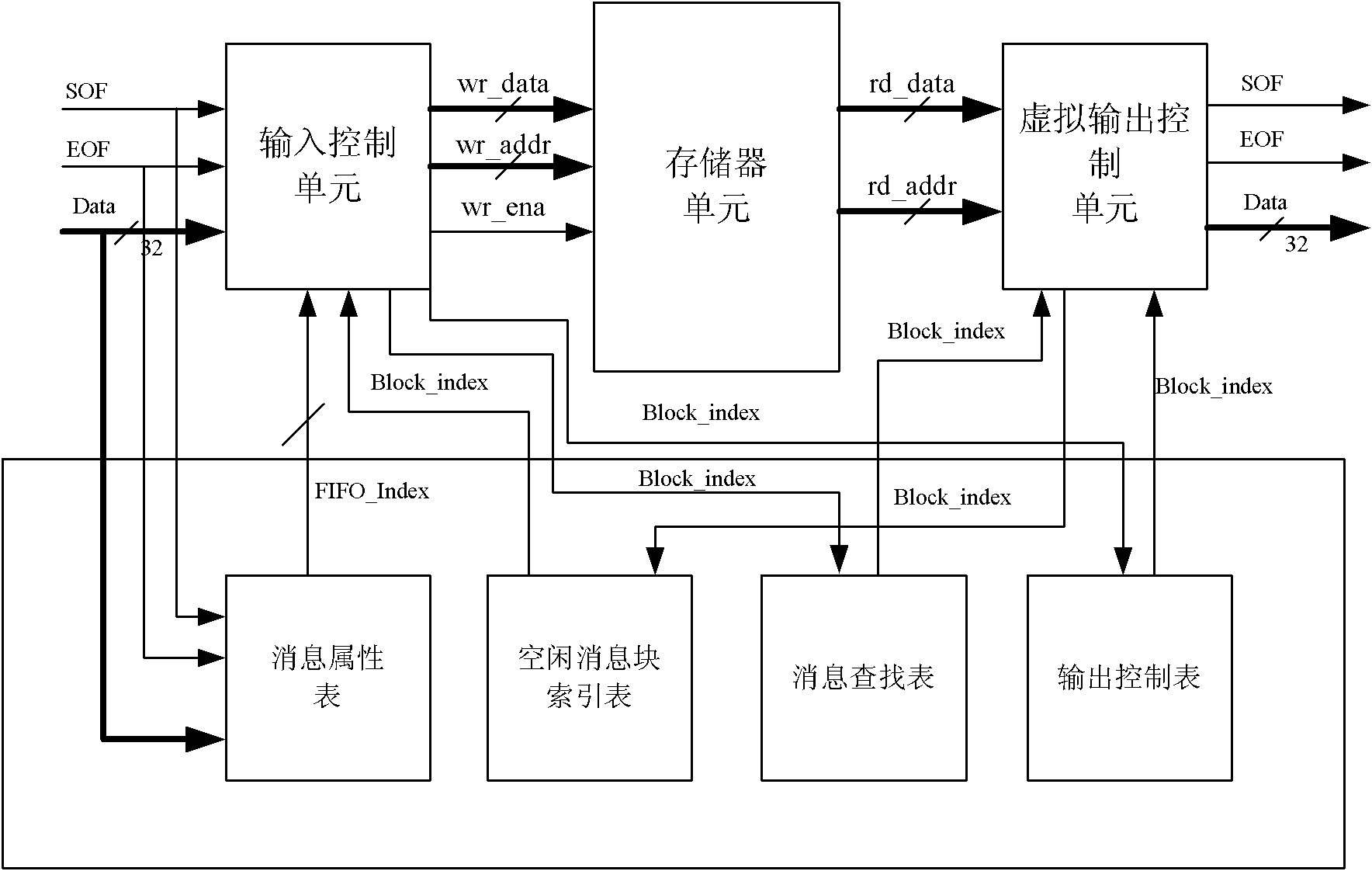

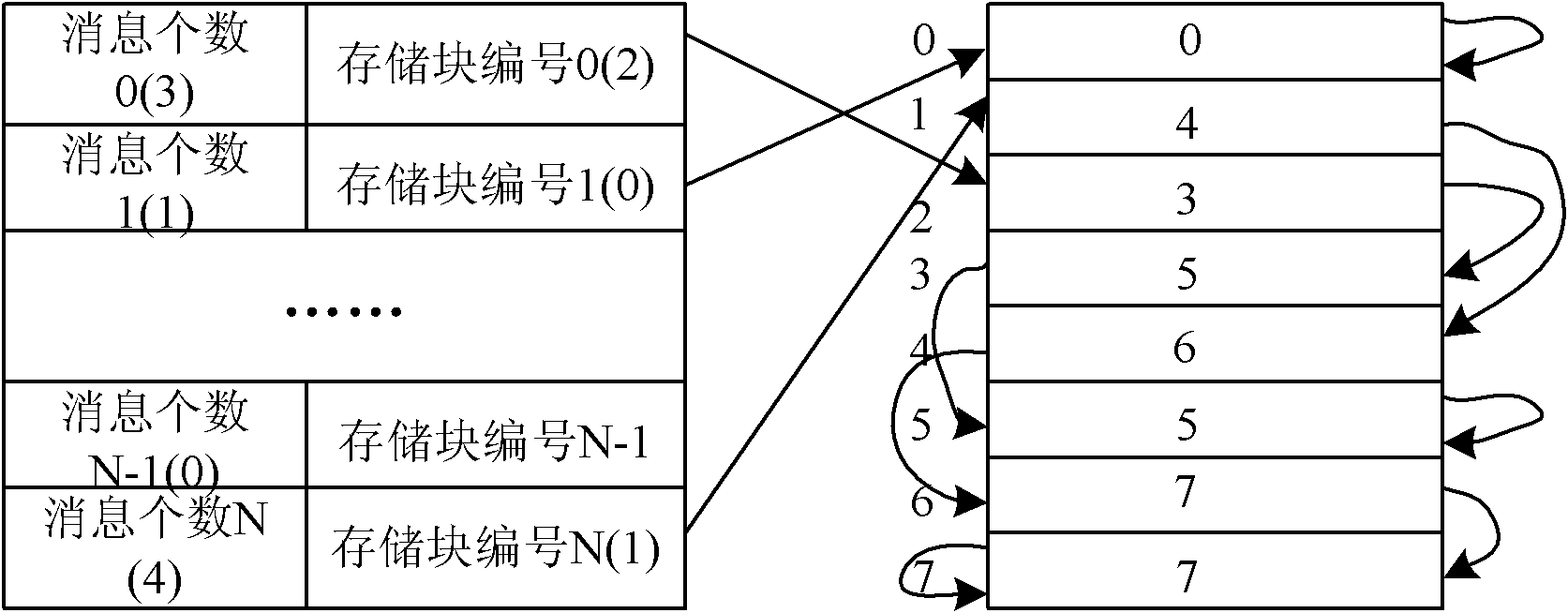

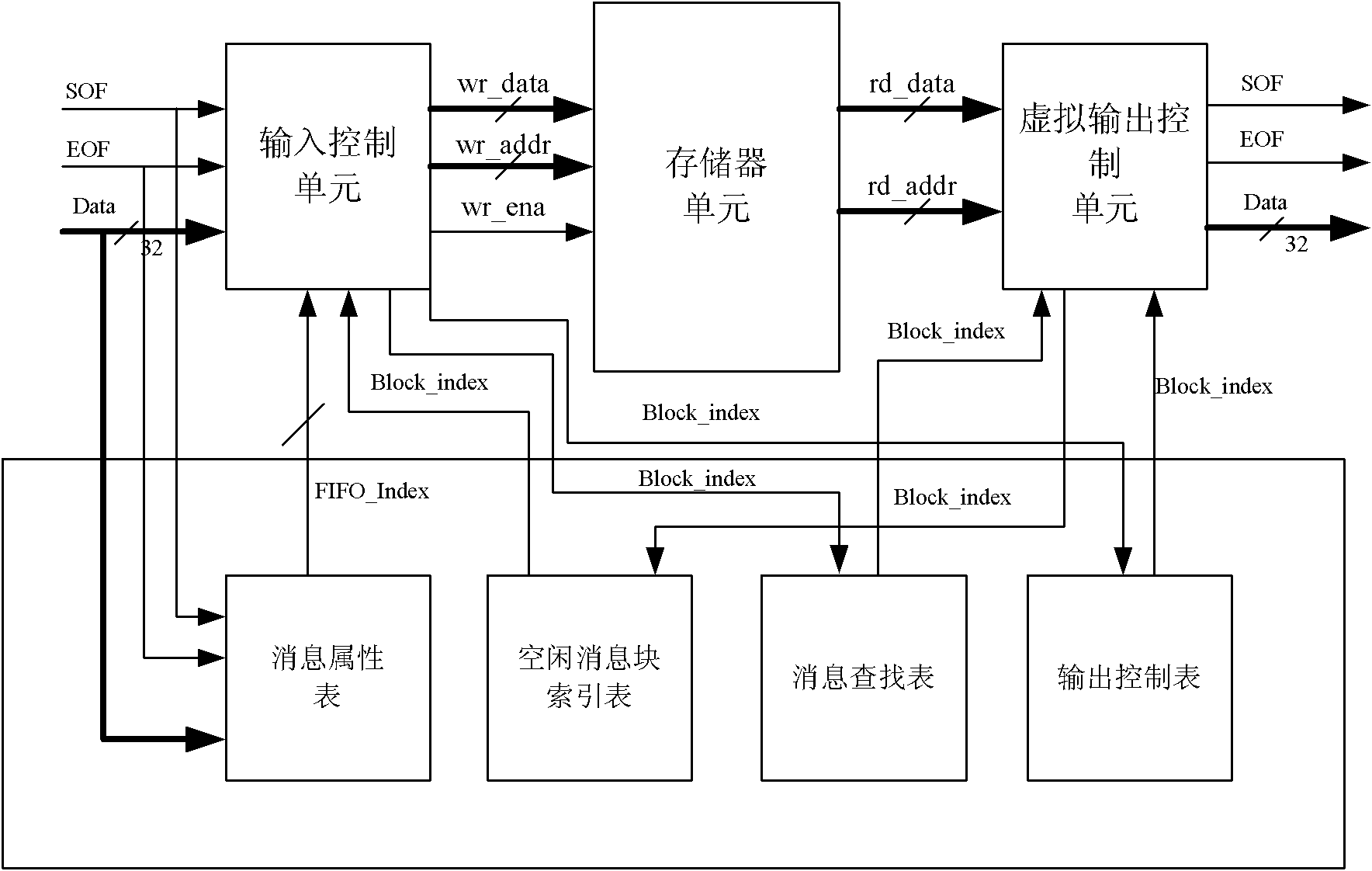

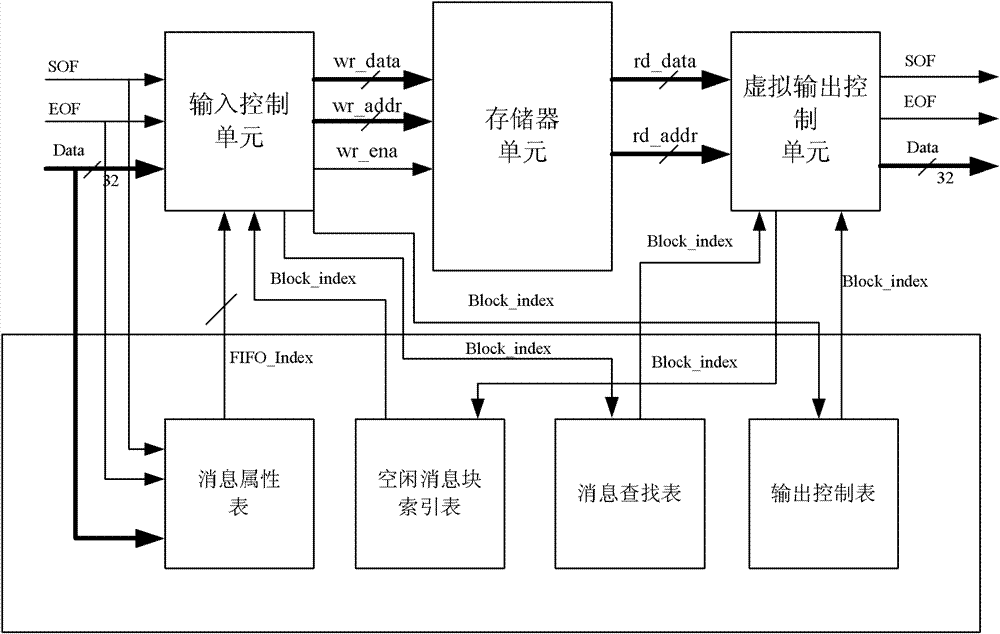

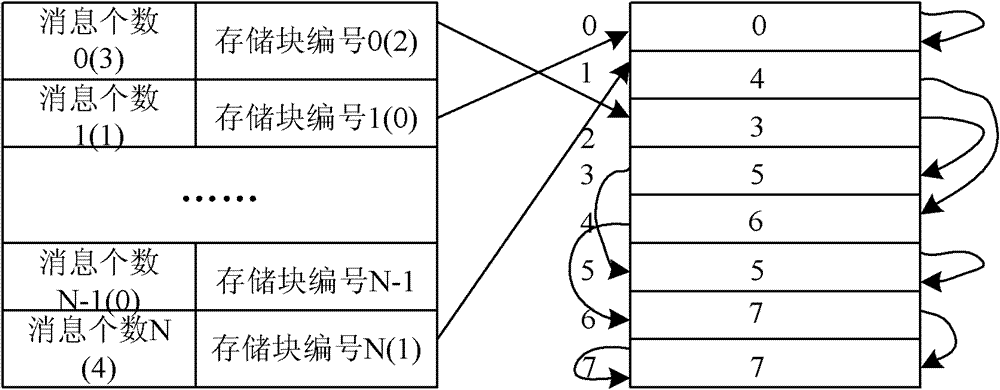

Method and controller for classified output of messages in communication system

ActiveCN102111332AImprove transmission service qualityReduce design difficultyData switching networksMessage queueCommunications system

The invention provides a method and a controller for the classified output of messages in a communication system, and mainly solves the problems that that a conventional method and a conventional controller have high demand on storage resources and high cost, and are low in utilization ratio and difficult to implement. The method for the classified output of the messages in the communication system comprises three steps, namely, system initialization, message writing and message reading. The controller for the classified output of the messages in the communication system comprises an input control unit, a memory unit, an output control unit, a message attribute list unit, an idle message block concordance list unit, a message searching list unit and an output control list unit. The methodand the controller for the classified output of the messages in the communication system, which are provided by the invention, have good flexibility, the number of output ports of a message queue management controller for classification is configurable, and the depth of output queue is configurable.

Owner:AVIC NO 631 RES INST

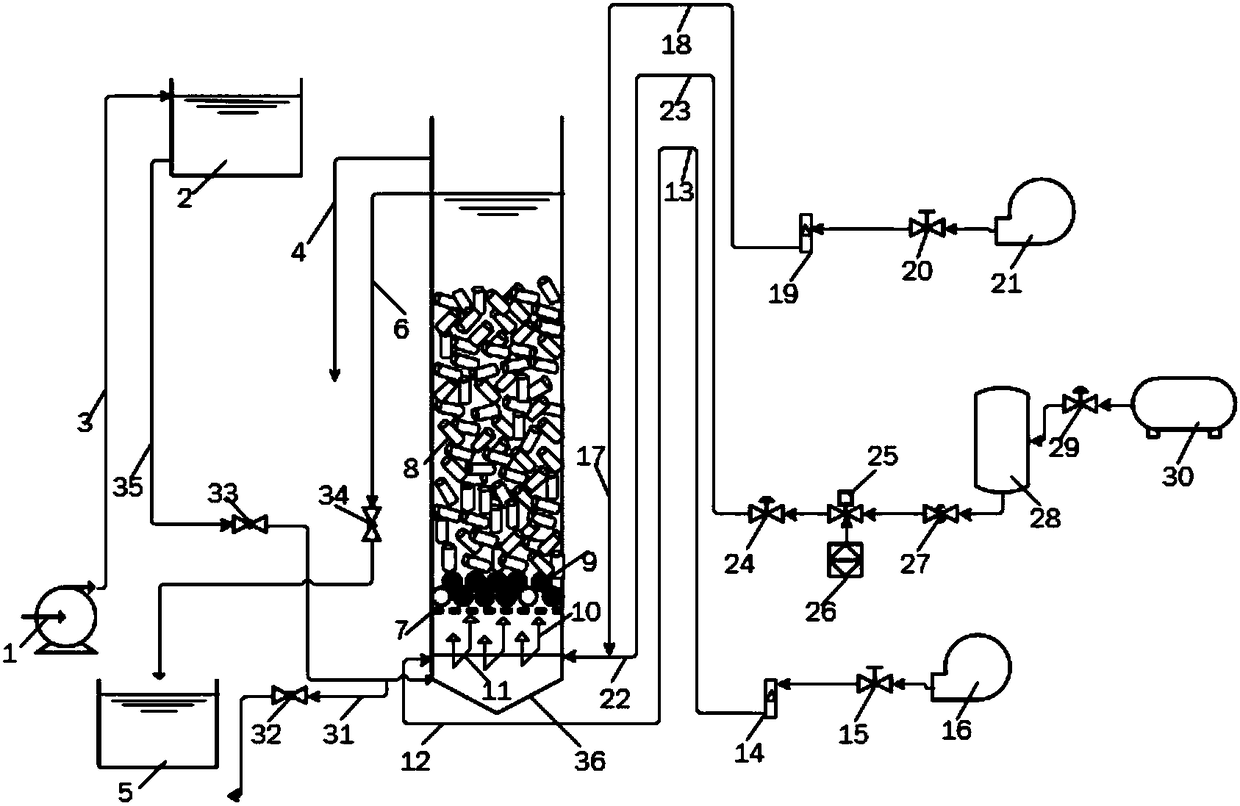

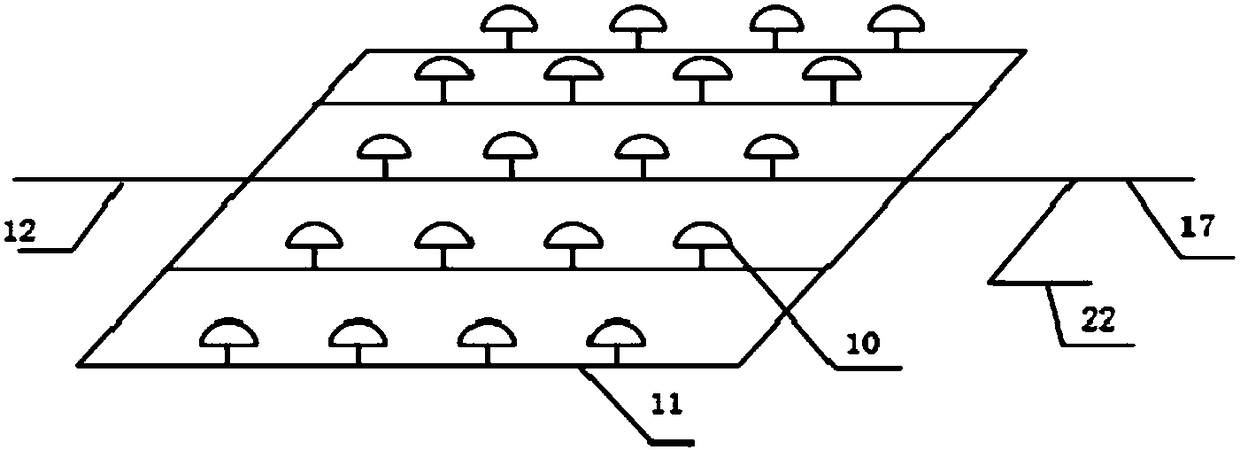

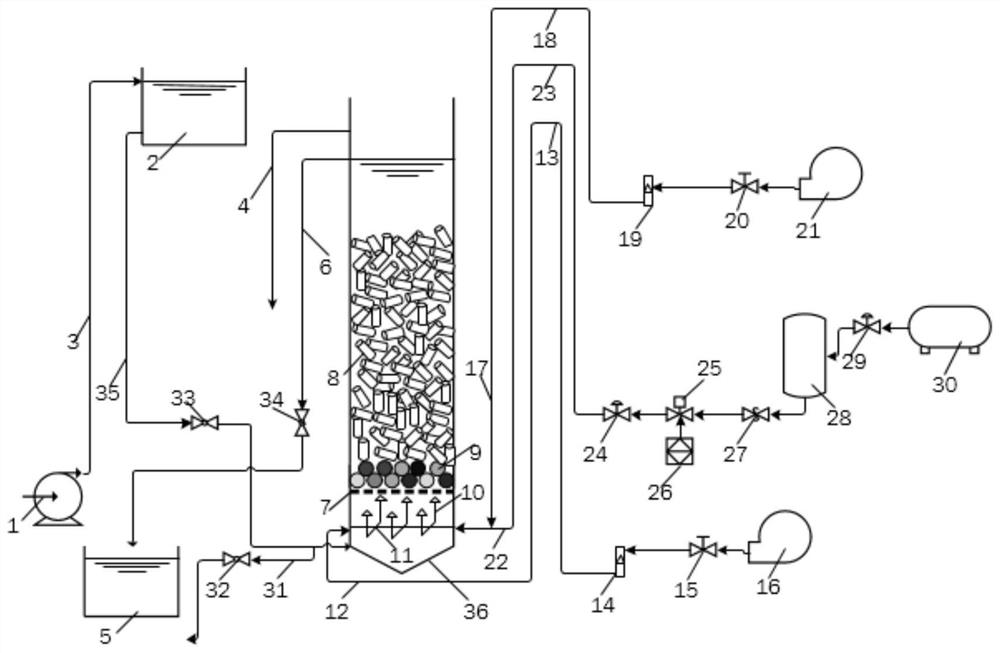

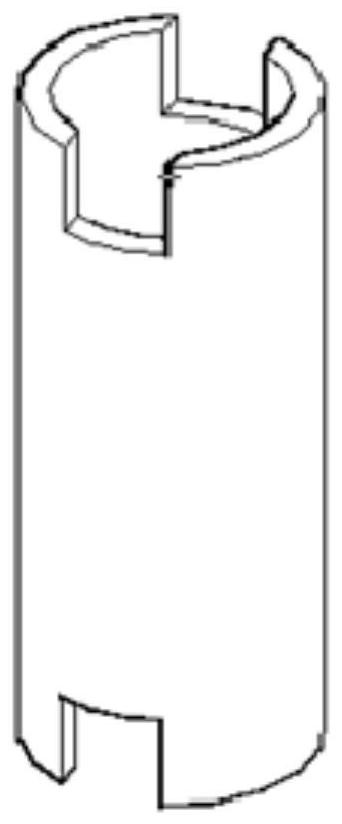

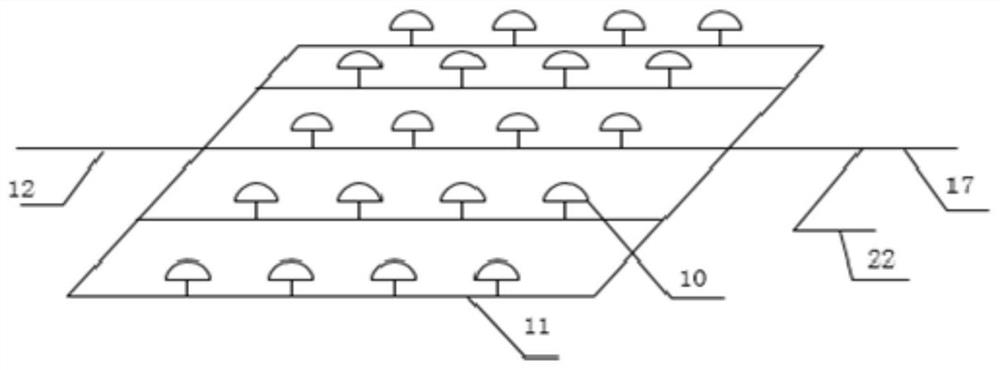

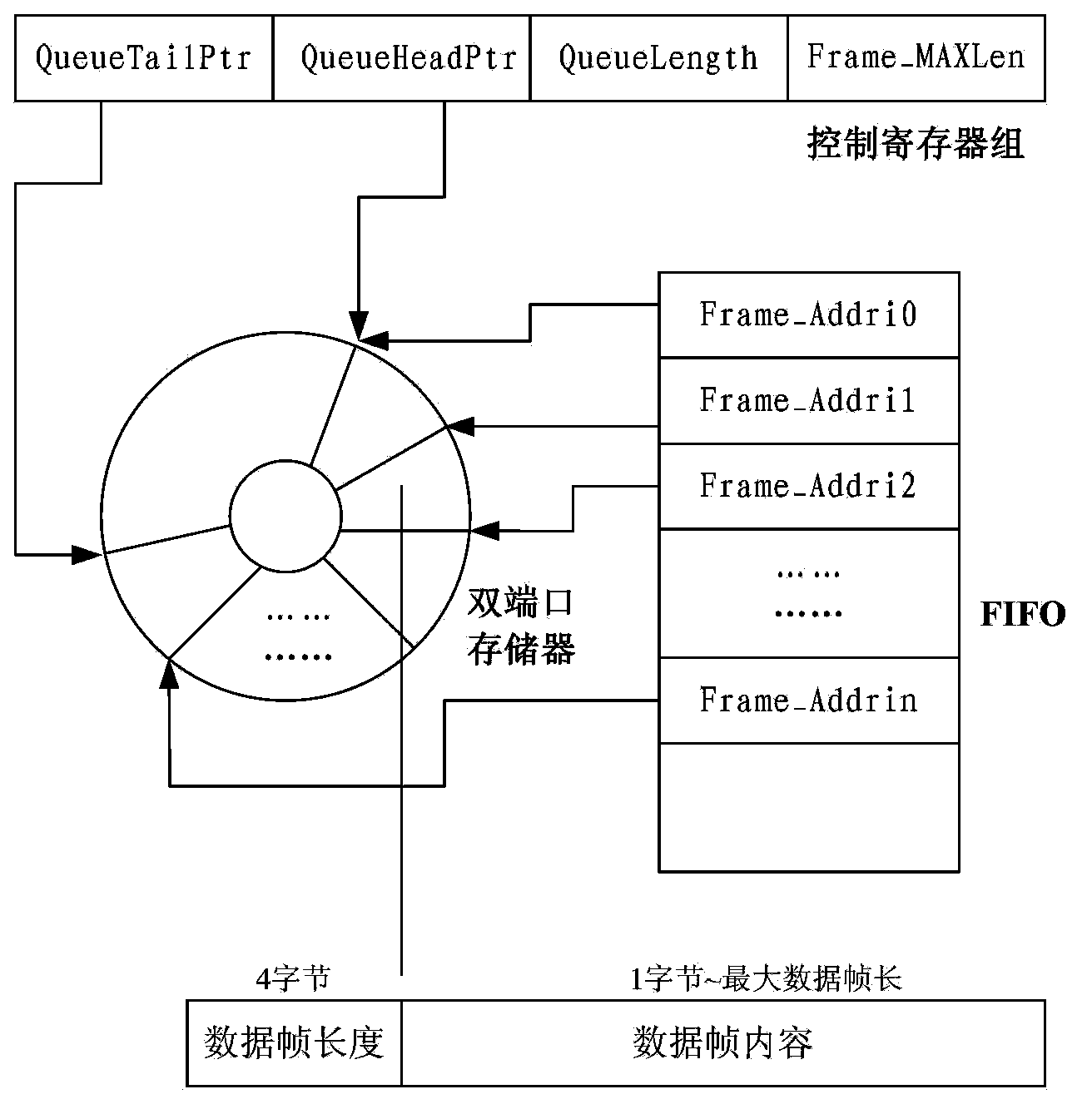

Water treatment device comprising circular pipe filling and use method

ActiveCN108059243ASimultaneous realization of nitrification and denitrification reactionsStable biological stateTreatment with aerobic and anaerobic processesWater qualityPolyvinyl chloride

The invention discloses a water treatment device comprising circular pipe filling and a use method and belongs to the technical field of water treatment. The water treatment device comprises a tank body reaction system, a gas distribution system and a water distribution system, wherein gas is supplied to a gas distribution pipe via adjustment and opening of an aeration pipe, the gas distribution pipe and a pulse pipe in a gas distribution area; the pulse pipe is connected with a gas storage tank from a high pressure fan via an adjustment valve; an outlet is connected with the pulse pipe via areducing valve, an electromagnetic valve and an adjustment valve; the circular pipe filling is 3-6mm in outer diameter D, 10-30mm in length L, 0.5-1mm in pipe wall thickness h and 1.05-1.2g / cm<3> in density rho; U-shaped notches are formed at the two ends of circular pipes; and the circular pipes are made from PVC (polyvinyl chloride). An operating state of the filling can be changed by adjustinga gas distribution valve according to influent quality. The device is used for biochemical sewage treatment and has a good synchronous treatment effect on C, N and P; the working state of the fillingcan be adjusted according to different C / N ratios; back flushing is easy and low in energy consumption; the possibility of blocking is low; the surface area per unit volume is large; and the device issimple to manufacture.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

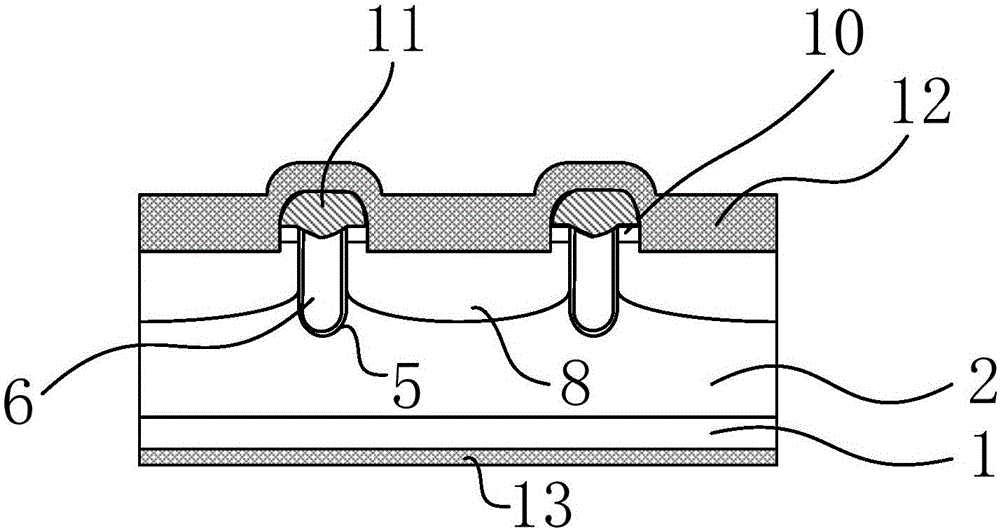

Low-voltage trench DMOS device of high integrated level and manufacture method of device

InactiveCN106340537AAvoid failureAvoid short circuitSemiconductor/solid-state device manufacturingSemiconductor devicesLow voltageEngineering

The invention provides a manufacture method of a low-voltage trench DMOS device of high integrated level. A first insulating dielectric layer is reserved over a gate electrode during etching of the gate electrode, a second insulating dielectric layer is back-etched to reserve part of the sidewall of the gate electrode, so that source electrode metal is electrically insulated from the gate electrode, the cellular size is reduced, and the integrated degree of the unit area is improved. The device and method of the invention can solve the problem that the registering precision of a contact hole is insufficient when the cellular size of Trench DMOS is reduced, the cellular size can be reduced to the largest degree, and the conducting resistance of the unit area is reduced.

Owner:WUXI NCE POWER

Phase interpolator for interpolating phase of delay clock signal and device including the same and for performing data sampling by using phase interpolated clock signal

ActiveUS20180152190A1Reduce glitchesIncrease design sizePulse automatic controlSynchronising arrangementControl signalControl circuit

A phase interpolator includes a control circuit configured to generate a selection control signal that corresponds to a selected coarse phase interval, and generate a weight setting signal for generating a phase interpolation clock signal with an interpolated phase within the coarse phase interval; a phase selector configured to receive a plurality of inversion delay clock signal pairs, select at least two inversion delay clock signal pairs from the plurality of inversion delay clock signal pairs based on the selection control signal, select and output a selection delay clock signal pair corresponding to the coarse phase interval from the selected at least two inversion delay clock signal pairs; and a phase mixer configured to receive the selection delay clock signal pair from the phase selector and generate the phase interpolation clock signal based on the weight setting signal.

Owner:SAMSUNG ELECTRONICS CO LTD

A method for preparing high-density ito target by reducing sintering conditions

Provided is a method for preparing a high-density ITO target on conditions of reducing sintering temperature. According to the method, in preparation of ITO slurry during the initial period, first premixing liquid needs to be prepared first and a ball mill is used; an oven is used in low-temperature drying preparation of a secondary material; in preparation of the ITO slurry, second premixing liquid needs to be prepared first and the ball mill is used again, a grouting forming method is adopted in the forming processing of ITO blank and compressed air serves as a pressure transmitting medium, and normal pressure oxygen atmosphere conditions are adopted in the sintering processing of the ITO blank. The ITO slurry with a high solid phase content is one requirement for preparing the high-density ITO blank, the relative density of the prepared ITO blank can be as high as 74-76% through measurement in a mercury emission method, the solid content of the ITO slurry is 89-91% through ball milling of the secondary material, and the high-density ITO target with the relative density as high as 99.50-99.67% can be prepared through good viscosity mobility and the low sintering temperature.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Punch forming process and mould for vehicle load sensing proportional valve support

The invention discloses a punch forming process and mould for a vehicle load sensing proportional valve support. The process comprises the following steps of feeding, blanking, auxiliary hole punching, forming, cutting and assembly hole punching; and a forming mould is divided into an upper die and a lower die, and the forming mould comprises an upper mould board (3), a terrace die (5), a lower mould board (15), a female die fixed plate (9), a guide column (1) and a guide sleeve (2). According to the process and the mould, by the adoption of a novel cold punching process, the difficult problem of finished piece positioning is solved, and one-time forming through the forming mould is realized. By the adoption of the process and the mould, the design size and the use performance of a product can be continuously and stably ensured, the capacity is promoted, the production cost is lowered, the quality and the fatigue life of an irregular and complex forming piece are improved, an outlook of the product is excellent, and the requirements on design and use are totally met.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

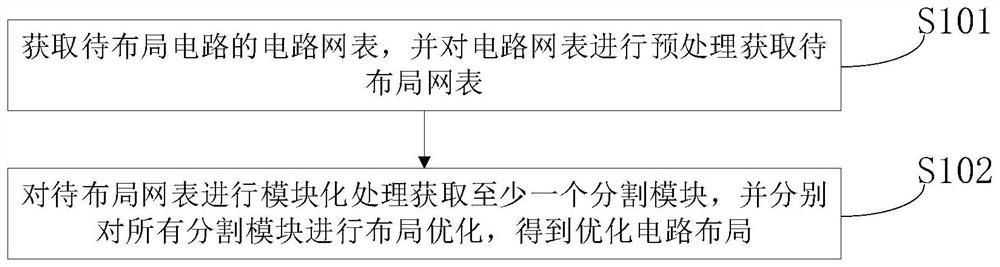

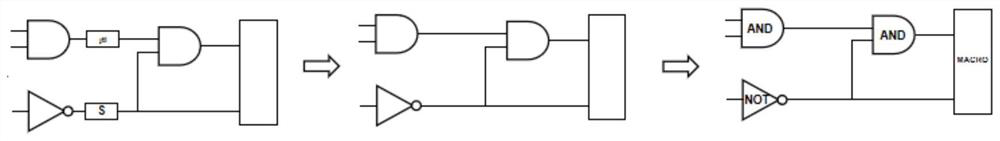

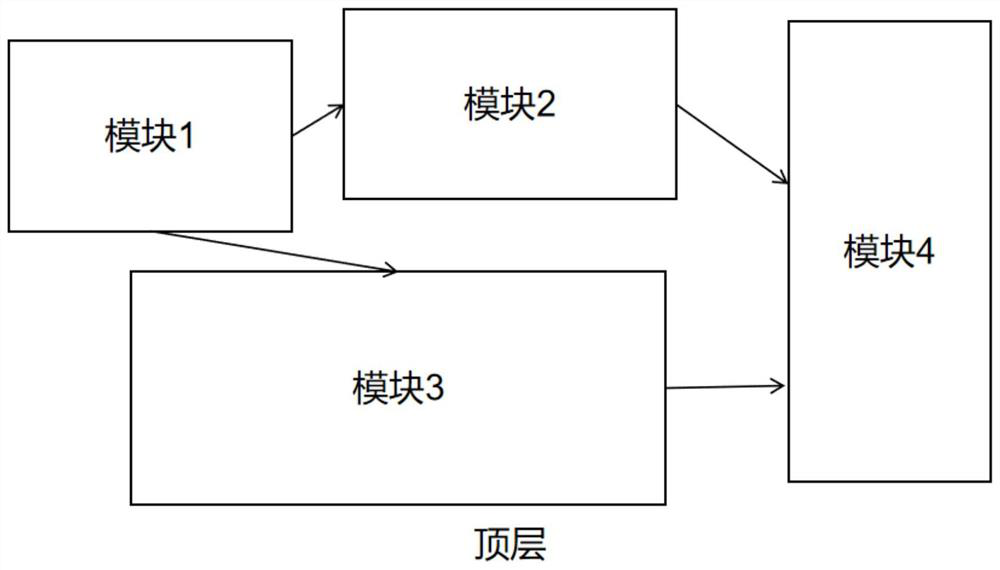

Superconducting integrated circuit layout optimization method and device, storage medium, and terminal

ActiveCN113627120AIncrease design sizeConform to the structureComputer aided designSpecial data processing applicationsLayout planningSoftware engineering

The invention discloses a superconducting integrated circuit layout optimization method and device, a storage medium, and a terminal. The method comprises the following steps: performing modularization on a to-be-laid netlist to obtain segmented modules; performing out layout optimization on all segmented modules to obtain an optimized circuit layout, wherein the layout optimization of the segmented modules comprises the following steps: determining the size of a layout space required by the segmented modules; performing position arrangement optimization on all logic gate units in the segmented modules; mapping a result to layout planning to obtain a layout of the segmented modules; placing all confluence buffer units in the segmented modules in the layout; performing position optimization on all units in the layout through a second global optimizer; performing clock optimization on all the logic gate units containing clocks in the layout. According to the method and device, automatic layout optimization of a large-scale superconducting integrated circuit is realized, and the original manual design process is replaced, so that the design scale of superconducting integrated circuits is improved, and the design iteration period is shortened.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A water treatment device containing round tube packing and its use method

ActiveCN108059243BSimultaneous realization of nitrification and denitrification reactionsStable biological stateTreatment with aerobic and anaerobic processesSolenoid valveSewage

The invention discloses a water treatment device containing a circular tube filler and a use method thereof, belonging to the technical field of water treatment. The water treatment device includes a pool reaction system, a gas distribution system and a water distribution system. The gas distribution area mainly supplies air to the gas distribution pipe by adjusting and opening the three types of pipes: the aeration pipe, the gas distribution pipe and the pulse pipe. The pulse pipe is regulated by a high-pressure fan. The valve is connected to the gas storage tank, and the outlet is connected to it through a pressure reducing valve, a solenoid valve and a regulating valve; the outer diameter D of the round pipe packing is 3-6mm, the length L is 10-30mm, the pipe wall thickness h is 0.5-1mm, and the density ρ is 1.05~1.2g / cm 3 , Both ends of the round tube are U-shaped cuts, and the material of the round tube is PVC. The running state of the filler can be changed by adjusting the gas distribution valve according to the quality of the influent water. The invention is used for sewage biochemical treatment and has a good synchronous treatment effect on C, N, and P, and can adjust the working state of the filler according to different C / N ratios; it is easy to backwash, has low energy consumption for backwashing, and is not easy to block; the surface area per unit volume is high, Easy to make.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

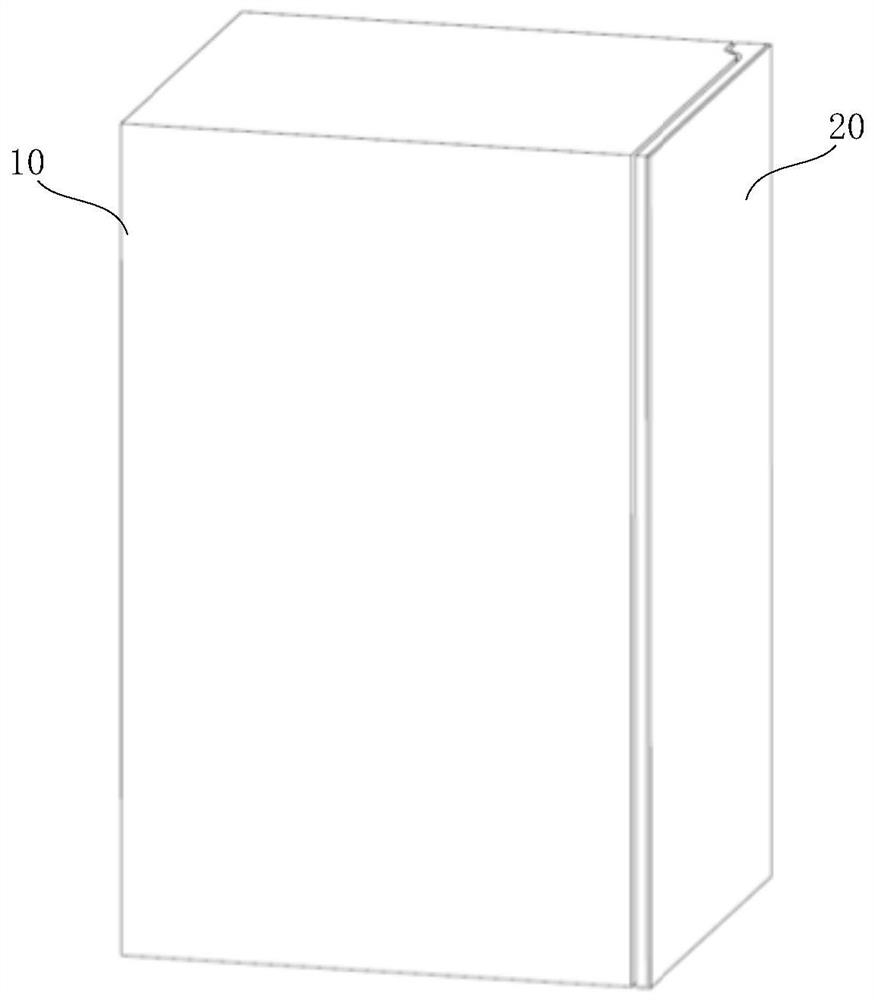

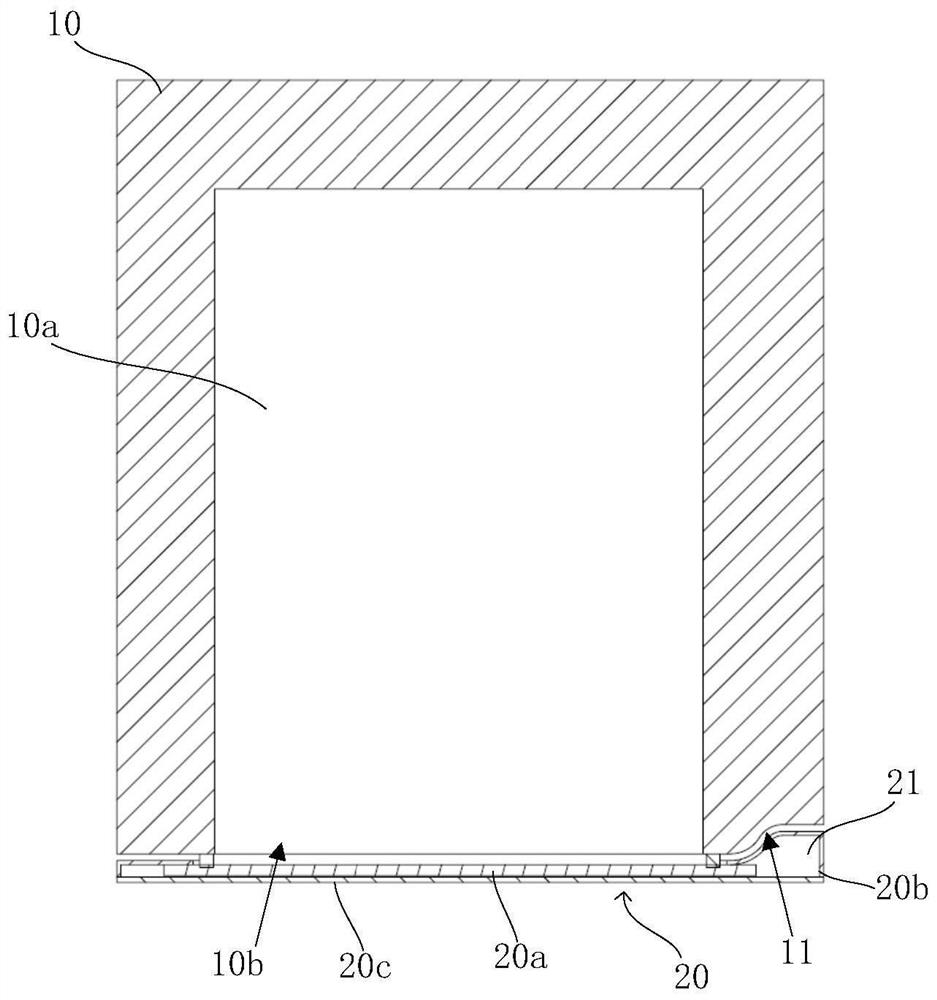

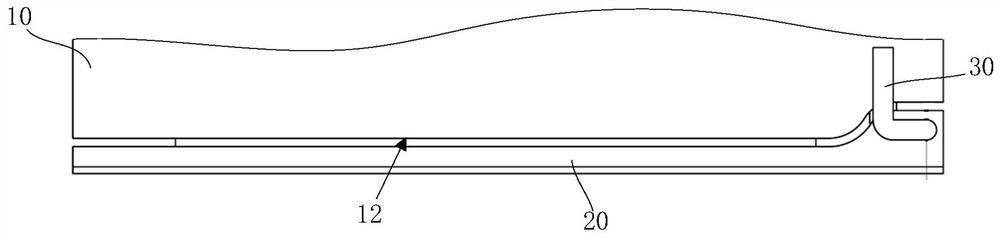

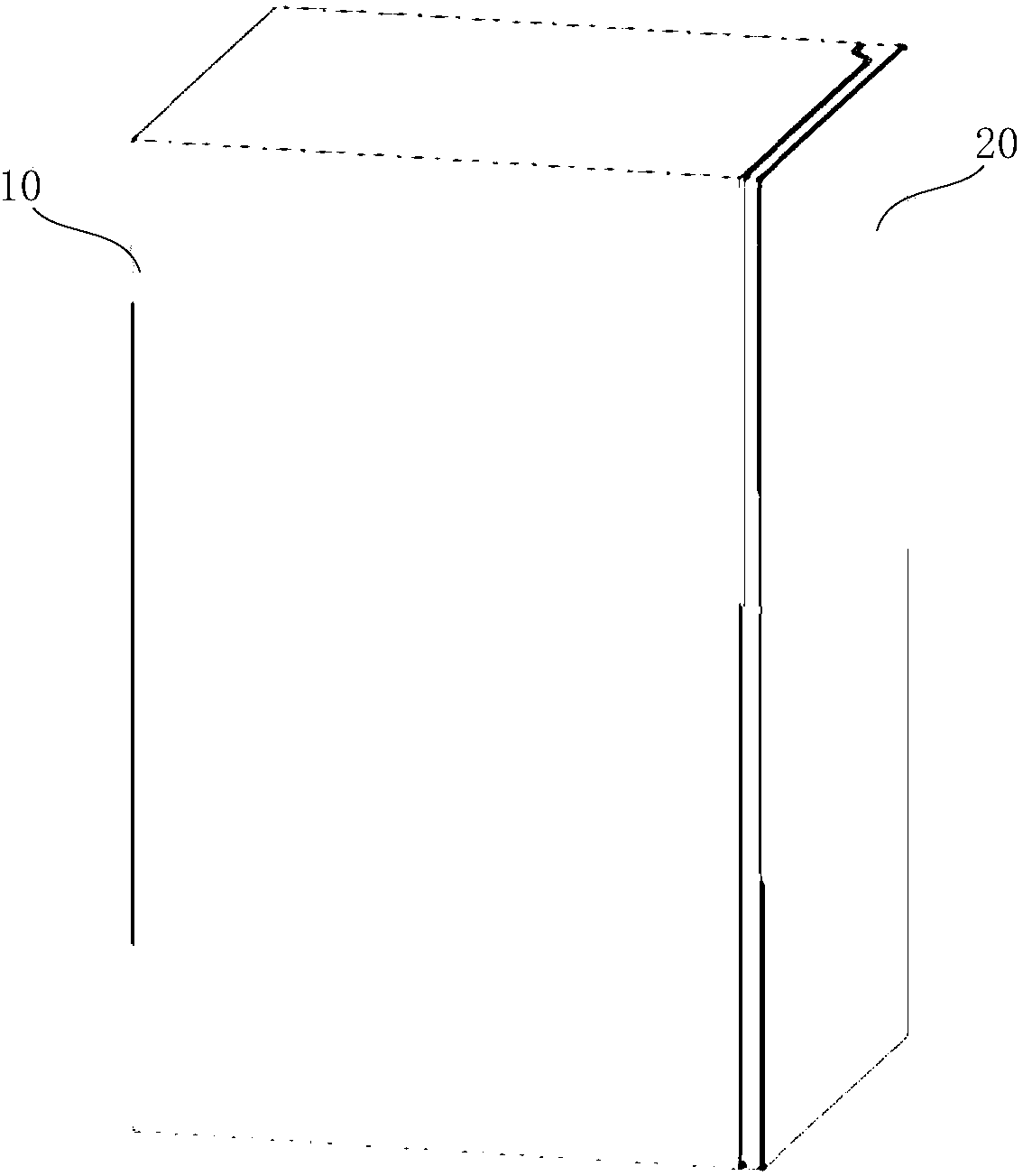

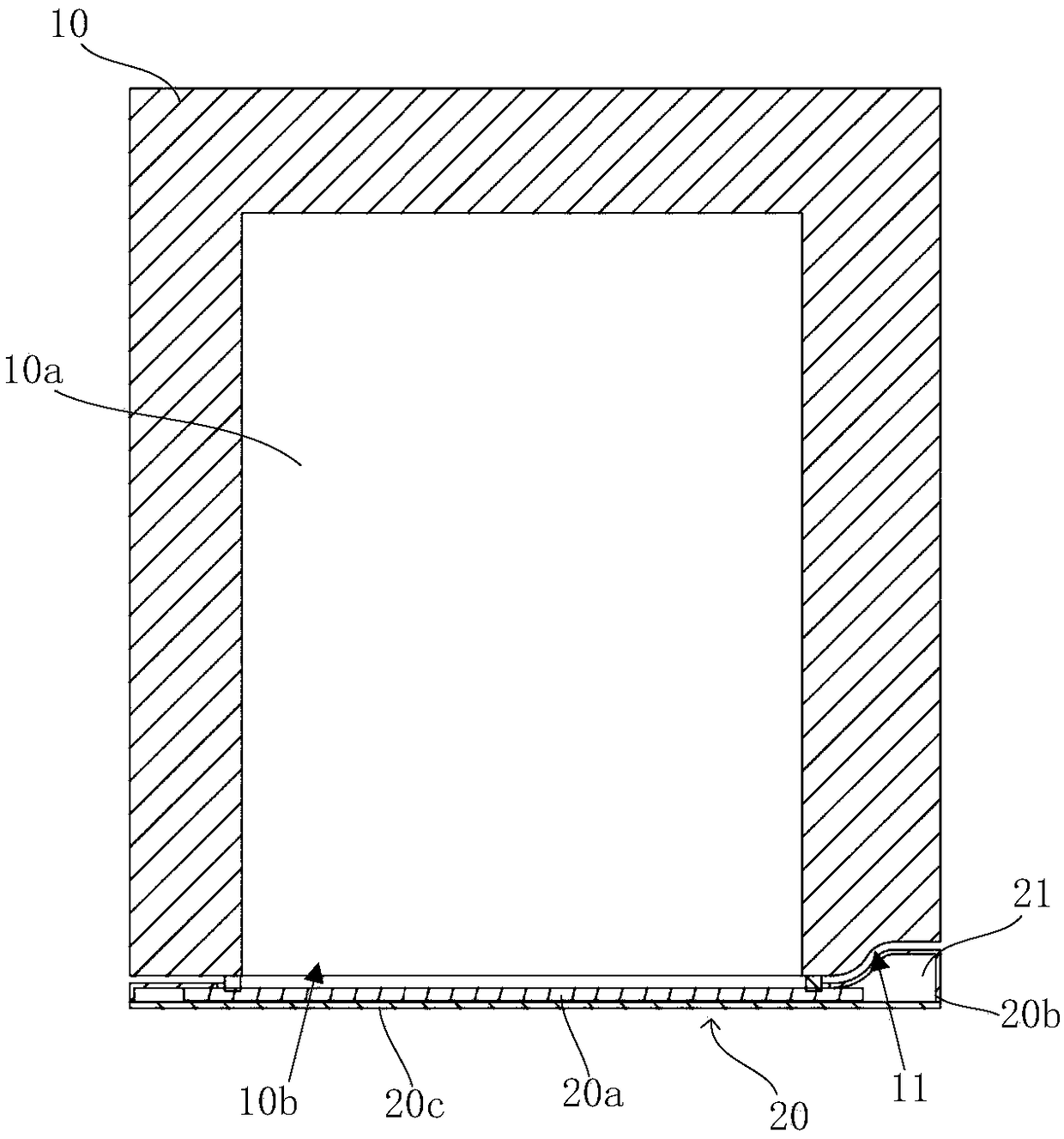

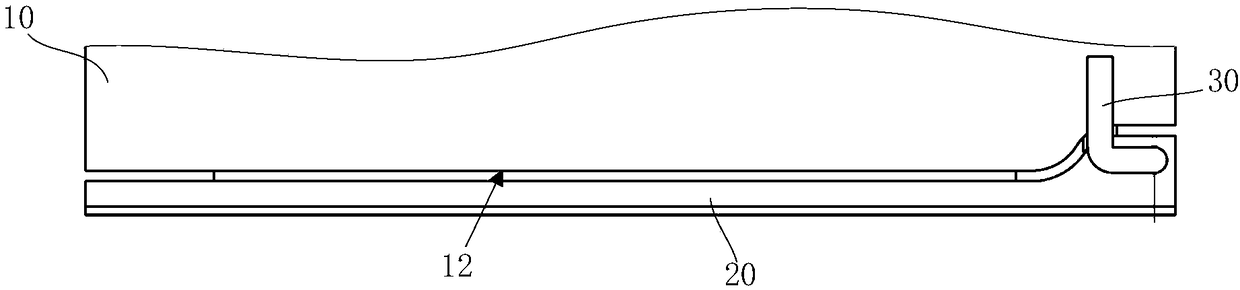

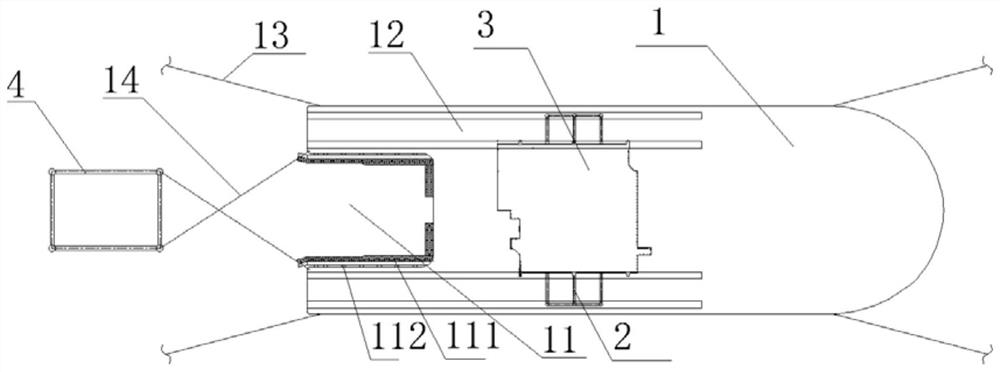

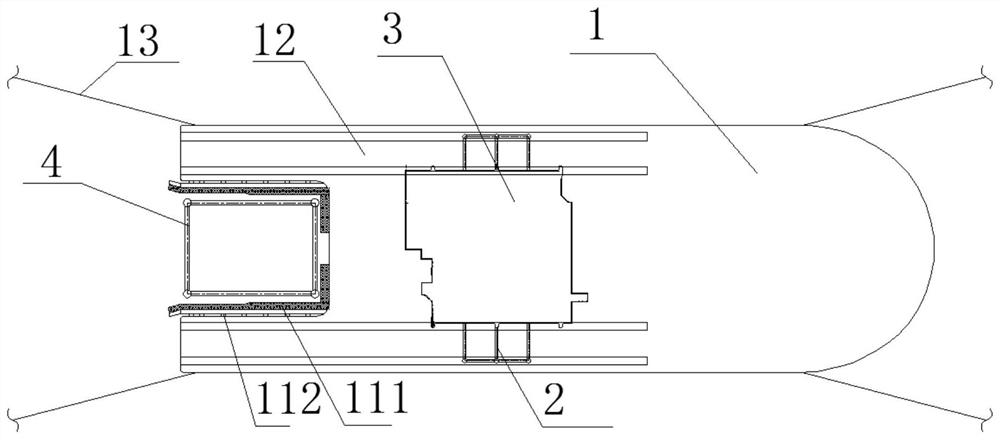

household appliances

ActiveCN108240155BReduce thicknessImprove insulation performanceLighting and heating apparatusInsulation for cooling apparatusMedicineThermal insulation

A household appliance, comprising a storage part (10), including a storage space (10a) with an opening (10b); a door (20), used to close the opening (10b), and the door (20) is hinged (30) is rotatably connected to the storage part (10), the hinge (30) has a first end connected to the door (20), and a second end connected to the storage part (10). Two ends; the door (20) includes a protruding portion (21) protruding backward toward the storage portion (10), and the storage portion (10) has a socket for accommodating the protruding portion (21) The recessed part (11), the first end of the hinge (30) is connected to the protruding part (21). This solution is beneficial to reduce the thickness of the door, increase the storage space of the storage part, improve the heat insulation effect of the door, and reduce energy consumption.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

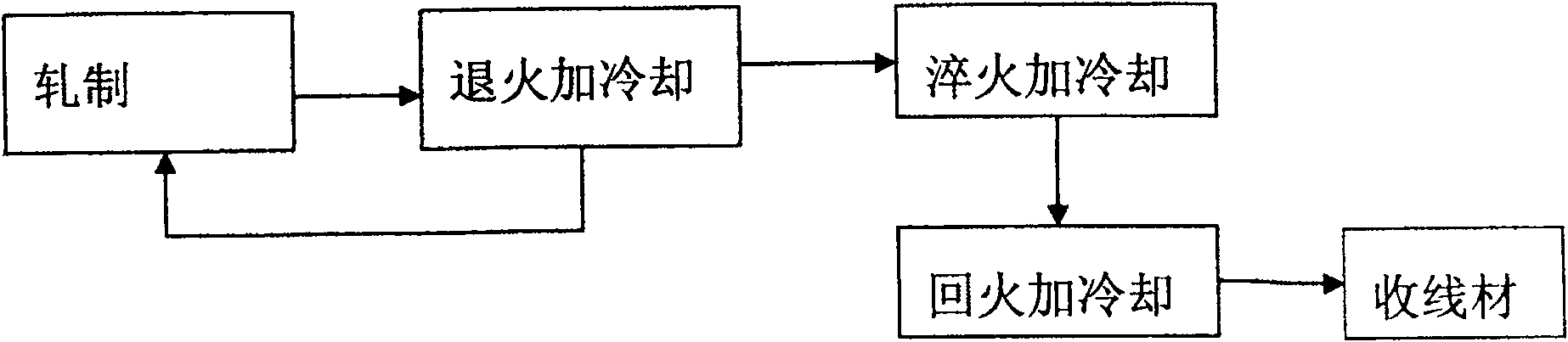

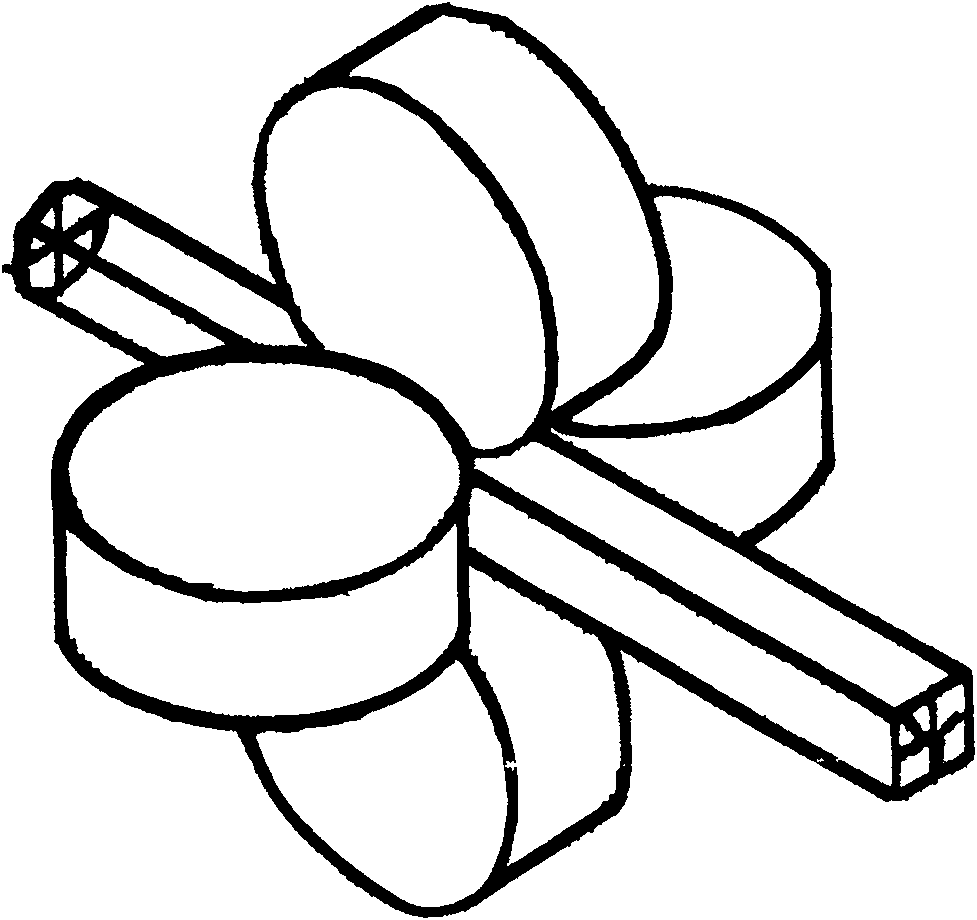

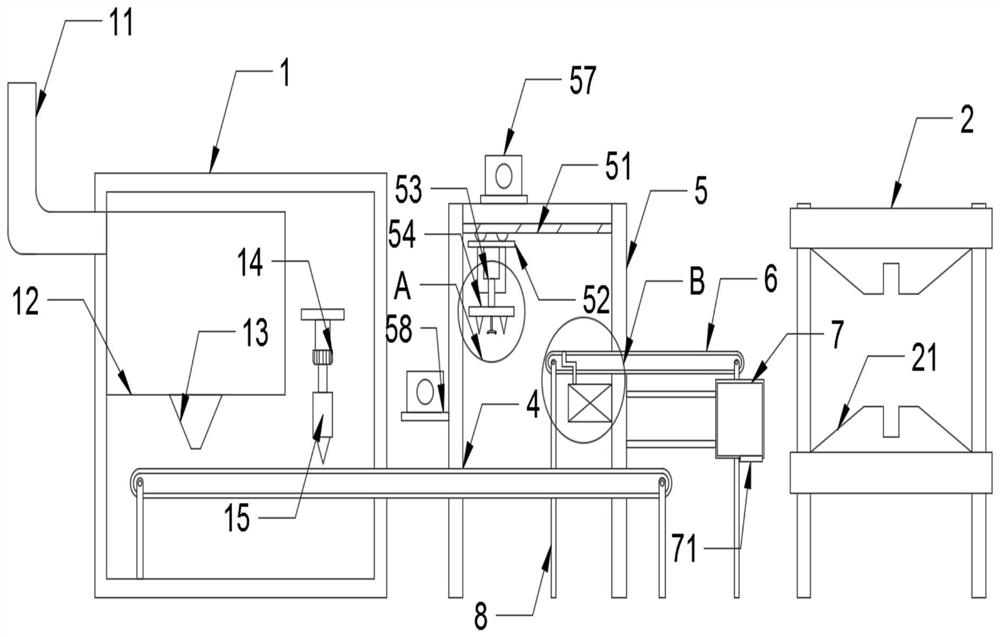

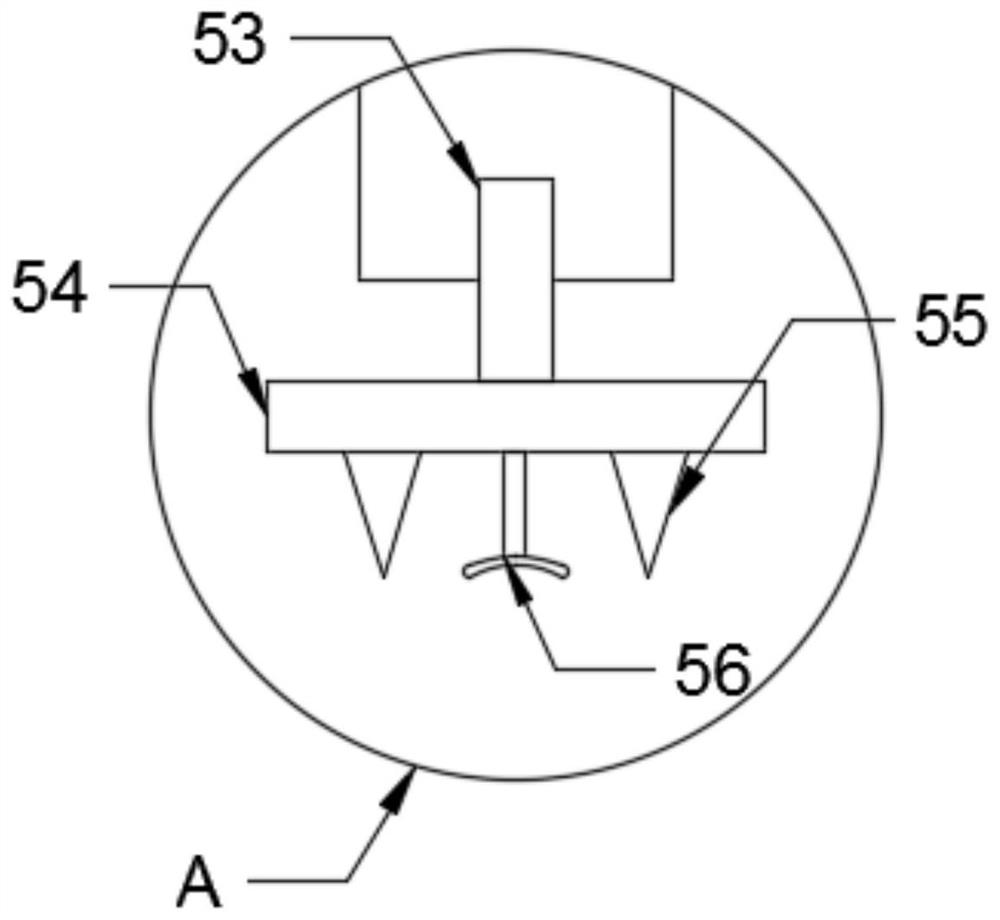

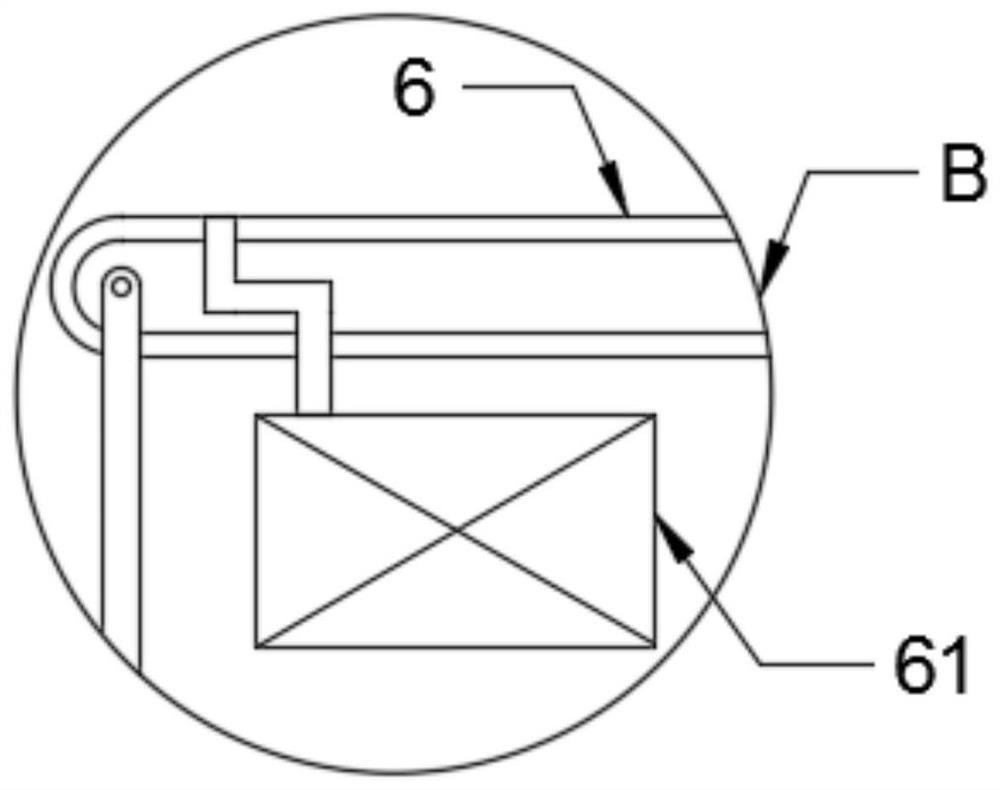

I-type integral oil ring wire working method and equipment for piston ring industry

ActiveCN100566926CAvoid interactionAvoid bendingFurnace typesOther manufacturing equipments/toolsWire rodPiston ring

The invention relates to a wire rod processing method, a processing method for an I-type integral oil ring wire rod used in the piston ring industry: rolling: the raw material wire rod is linearly routed through the rolling equipment, and simultaneously rolled on the four sections of the upper, lower, left, and right sides to obtain the obtained product. Cross-section shape is required; annealing: after rolling, the wire rod is linearly routed through an annealing furnace for annealing, and then rolling and annealing are performed after annealing, and this is repeated 3-8 times to obtain a type I integral oil ring wire rod without quenching and tempering. The present invention adopts rolling in four directions at the same time, rolling directly according to the required cross-sectional shape, reasonable distribution of rolling times and rolling volume, ensuring shape requirements, completely avoiding wire bending, oxidation and decarburization, and matrix hardness and plasticity reaching It is a quenching and tempering treatment method based on certain technical requirements, and the product design has high precision in size and shape, excellent quality, and low cost, which can meet the needs of various shapes in large quantities.

Owner:大连环新新材料科技有限公司

Large-scale scene fixed frame rate rendering method and device based on model component features

ActiveCN107025684BReach load designImplement loading designDesign optimisation/simulationSpecial data processing applicationsAlgorithmFrame rate

The present invention provides a large-scale scene fixed frame rate rendering method and device based on the characteristics of model components. The method includes: acquiring parameter information of model components, creating component nodes and shared component nodes according to the parameter information; acquiring features of model components, and and parameter information to create multi-level detail rendering nodes; recursively construct a spatial octet scene tree according to component nodes and shared component nodes; obtain the visible component set according to the distribution information of model components and the spatial octet scene tree dynamic screening; according to the visible component set, multiple The level-detail rendering nodes and preset drawing conditions dynamically draw the multi-level details of the model components, which can effectively realize the loading and design of large-scale process plant models on the process plant design platform and achieve the effect of display control frame rate. The design scale and interaction frame rate can be significantly improved.

Owner:北京中科辅龙智能技术有限公司

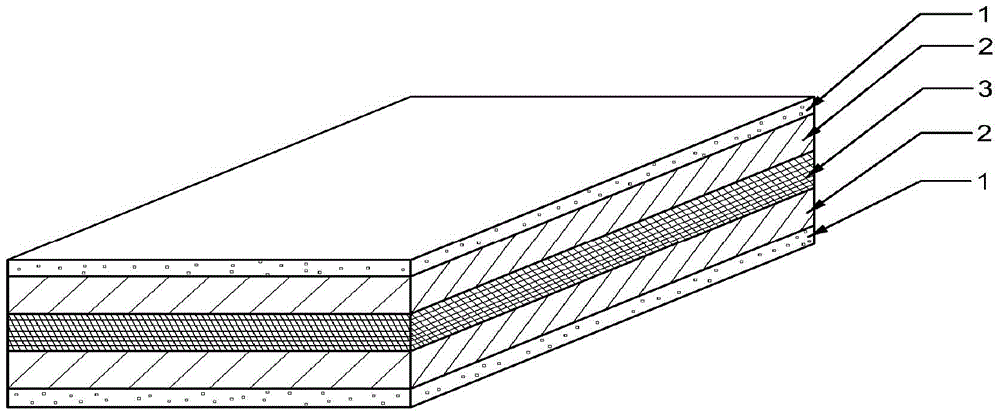

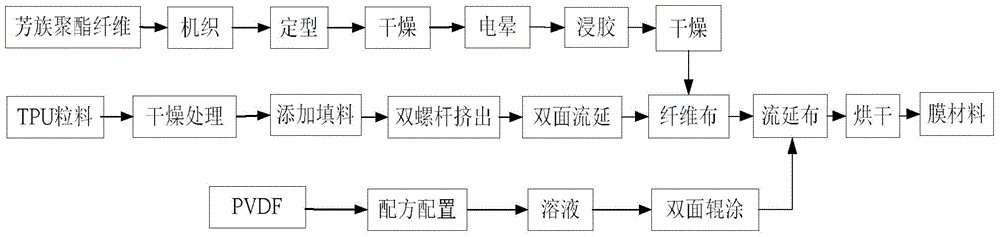

A kind of lightweight high-strength inflatable membrane material and preparation method thereof

ActiveCN104108211BGood gas and water resistanceGood weather resistanceLamination ancillary operationsSynthetic resin layered productsHigh resistanceAnti fungal

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

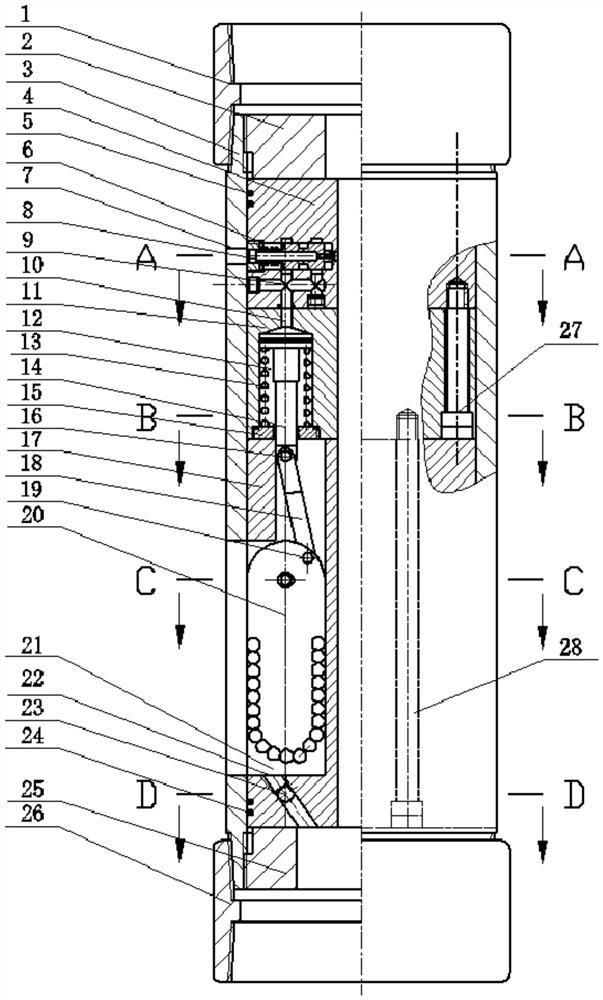

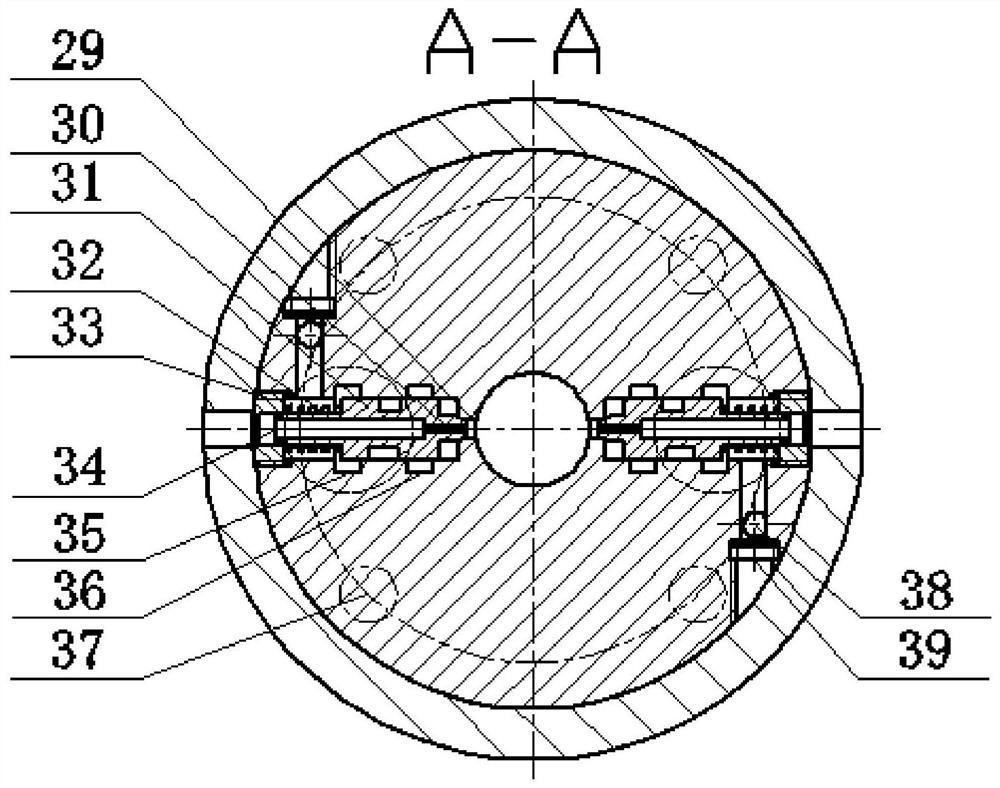

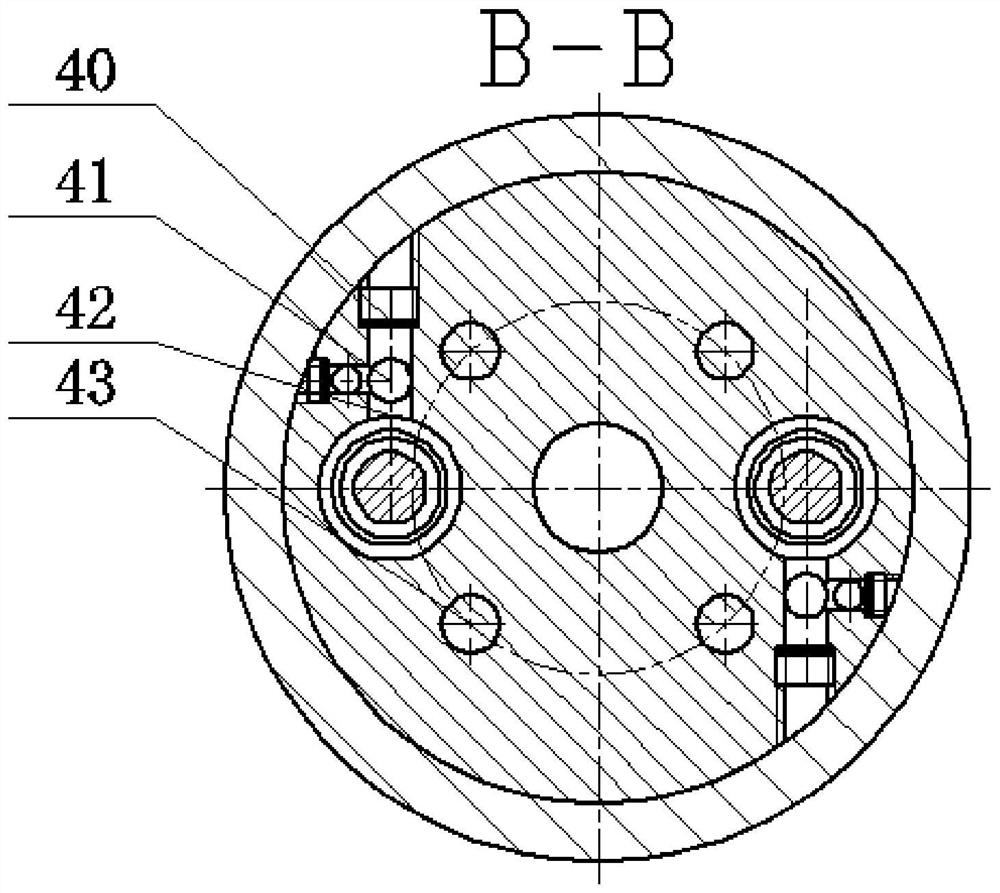

Hydraulically-driven reaming-while-drilling tool

ActiveCN112196468AEasy to replaceEasy to manufacture, install and maintainDrill bitsWell/borehole valve arrangementsHydraulic cylinderWell drilling

The invention discloses a hydraulically-driven reaming-while-drilling tool. The hydraulically-driven reaming-while-drilling tool mainly solves the problem that an existing reaming-while-drilling toolis small in reaming range. The hydraulically-driven reaming-while-drilling tool is characterized by comprising three parts including a starting device main body, a driving device main body and an executing device main body; a throttling reversing valve is arranged in the starting device main body and comprises a throttling reversing valve cavity, a throttling reversing valve element, a throttlingspring and a throttling reversing valve gland; and a throttle reversing valve switch is controlled to be started by the displacement of a drilling pump, and after the throttle reversing valve is opened, a piston of a hydraulic cylinder in the driving device main body descends under the action of liquid pressure to drive a cutter wing of a four-rod mechanism in the executing device main body to extend out to start reaming work. According to the hydraulically-driven reaming-while-drilling tool, under the condition that drilling is not affected, the reaming range can be enlarged, and the reamingrate can reach 60%.

Owner:NORTHEAST GASOLINEEUM UNIV

Domestic appliance

ActiveCN108240155AReduce thicknessImprove insulation performanceLighting and heating apparatusInsulation for cooling apparatusEngineeringEnergy consumption

The invention discloses a domestic appliance. The domestic appliance comprises a storage part (10) and a door (20), wherein the storage part is provided with a storage space (10a) with an opening (10b), the door (20) is used for sealing the opening (10b), the door (20) is rotatably connected with the storage part (10) through a hinge (30), and the hinge (30) is provided with a first end connectedto the door (20) and a second end connected to the storage part (10). The door (20) comprises a bulged part (21) which bulges backwards toward the storage part (10), the storage part (10) is providedwith a concave part (11) used for containing the bulged part (21), and the first end of the hinge (30) is connected to the bulged part (21). According to the technical scheme, the thickness of the door is reduced, the storing space of the storage part is increased, at the same time, the heat insulation effect of the door is improved, and the energy consumption is reduced.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

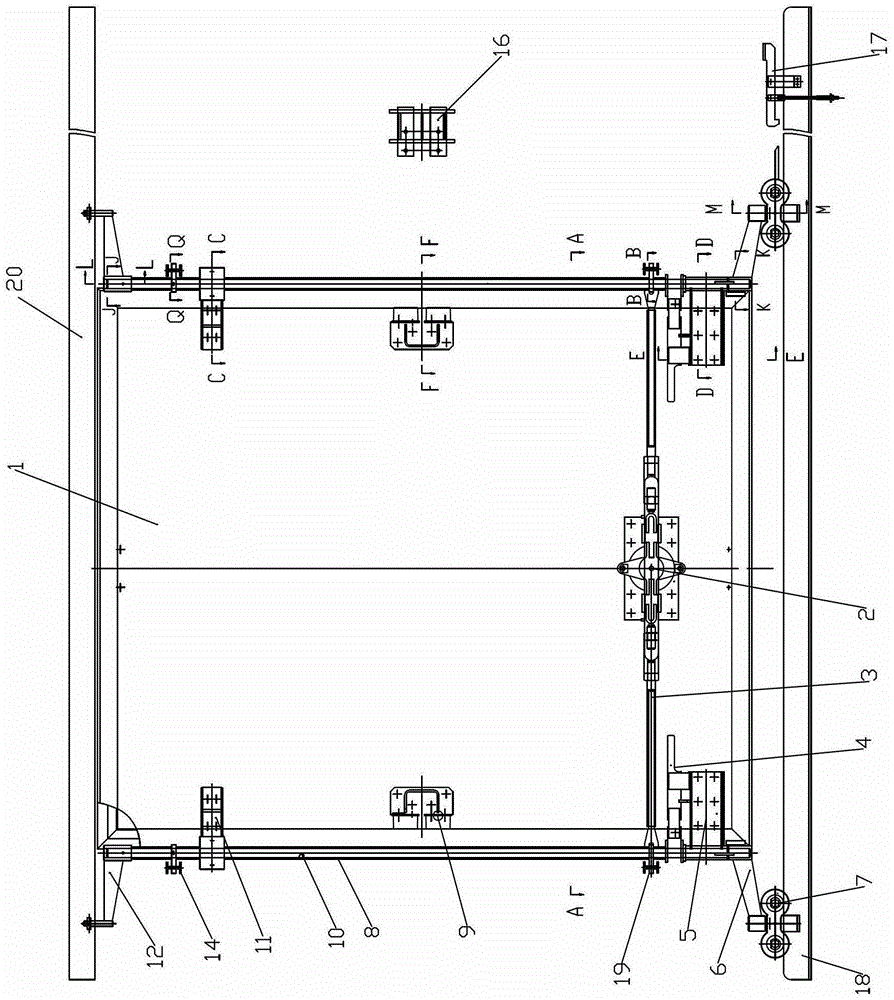

Railway wagon sliding recessed doors

The invention discloses a sliding embedded type car door of a railway freight car. The sliding embedded type car door of the railway freight car comprises a door body, an upper supporting base and a lower supporting base, wherein the upper supporting base and the lower supporting base are arranged on the two sides of the door body, hollow locking rods are arranged in corresponding installation holes of the upper supporting base and the lower supporting base, door pivoted rods are arranged in the hollow locking rods, the upper end and the lower end of each door pivoted rod are matched with an upper slide way and a lower slide way through an upper crank and a lower crank, a handle is fixed on each door pivoted rod, and the handles are rotated to enable the door body to transversely move in the direction of a door frame. A bi-directional door lock is installed in the middle of the door body, the telescopic control ends on the two sides of the bi-directional door lock are respectively connected with one end of a matched pull rod, the other end of each pull rod is connected with one locking cam, each locking cam is fixed on the hollow locking rod corresponding to the position of each pull rod, the door frame on the outer side of each locking cam is provided with a lock base matched with the locking cam, the pull rods drive the locking cams and the hollow locking rods to rotate, the locking cams and the lock bases can be meshed, and accordingly the door body is locked. The sliding embedded type car door of the railway freight car is simple and reliable in structure, the load-carrying performance of a car body to the car door is good, and the sealing performance is excellent.

Owner:CRRC YANGTZE CO LTD

Maritime work module installation device and maritime work module mounting system

The invention provides a maritime work module installation device and a maritime work module installation system. The device comprises a ship body and a supporting structure, wherein the ship body includes a ballast device and a notch, the notch is suitable for accommodating a second maritime work module and achieving alignment installation of a first maritime work module and the second maritime work module, and the ballast device is suitable for adjusting the draft of the ship body; and the supporting structure is arranged on the ship body, is suitable for supporting the first maritime work module, is provided with a mounting position located at the notch, and is detachably connected with the first maritime work module at the mounting position. By means of the arrangement, on one hand, stable positioning between the ship body and the second maritime work module is achieved, installation between the maritime work modules is facilitated; on the other hand, limitation on a ship width isreduced, a selection range of available ship bodies is enlarged, a selection space of later construction schemes is increased, and a size and weight of the second maritime work module are reduced; andthe manufacturing and mounting difficulty and cost are decreased.

Owner:HUADIAN HEAVY IND CO LTD

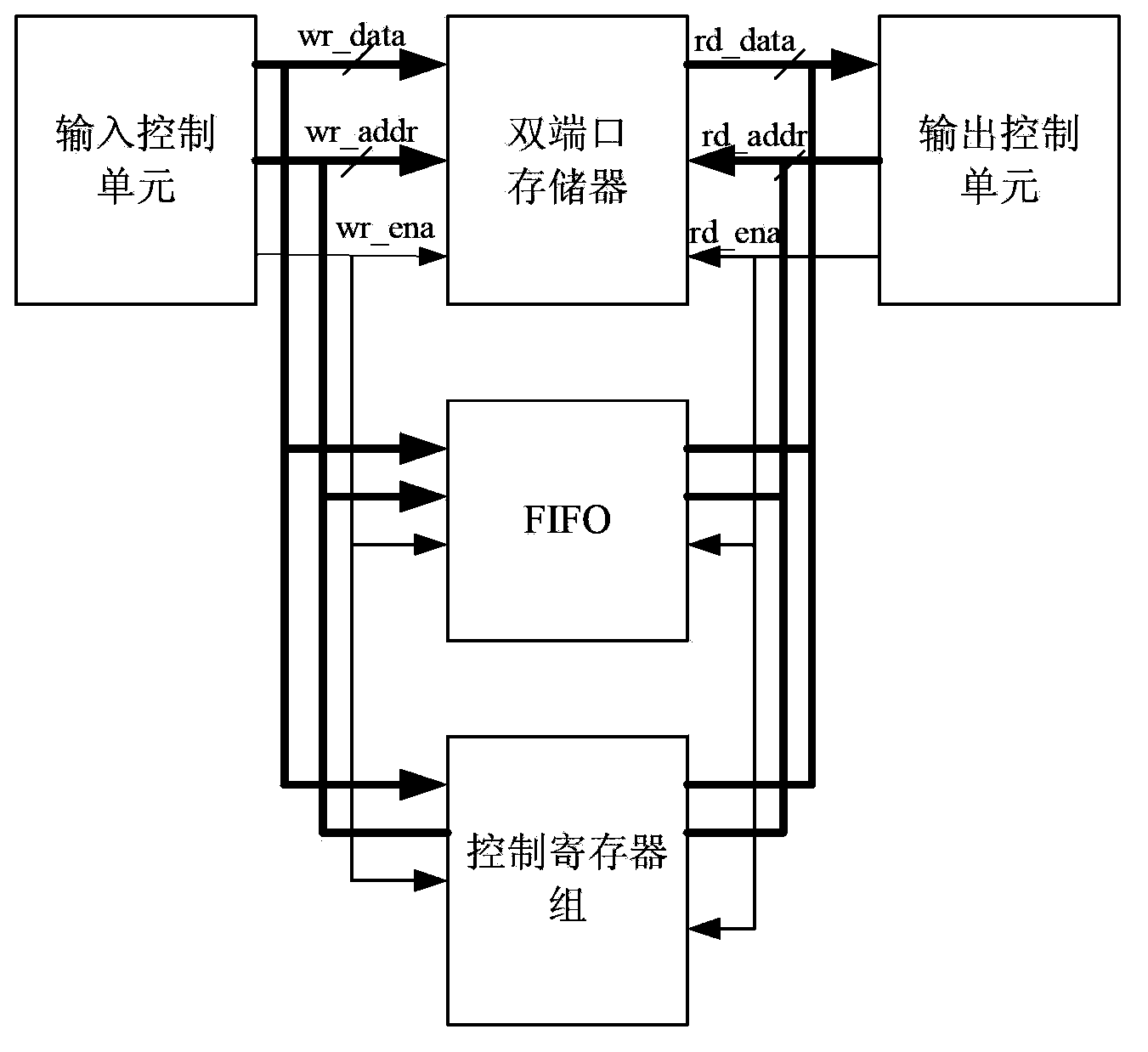

Controller and controlling method for intensive data frame queues

ActiveCN103902249AImprove resource utilizationAchieving Tight Storage ArrangementData conversionResource utilizationFpga chip

The invention relates to a controller and a controlling method for intensive data frame queues. The controller for the intensive data frame queues comprises an FIFO used for storing initial addresses of all data orderly, a sharing storage source double-port storer used by a storer to store the length and the content of data frames and dedicated control logic used for realizing data frame queue control management, wherein the FIFO and the double-port storer are connected with the dedicated control logic respectively. The controller and the controlling method for the intensive data frame queues can realize tight storage and array of data frames, can improve the utilization rate of limited storage resources, effectively solve the bottleneck problems of resource storage, are favorable to realizing a high-performance interchanger and communication ports on the basis of an existing FPGA chip and can reduce hardware designing difficulty and cost.

Owner:AVIC NO 631 RES INST

A Design Method for the Development and Dimensions of Extrusion Mouth Plates

ActiveCN110228151BIncrease design sizeImprove the qualified rate of one-time board openingDesign methodsExpansion rate

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

Method and controller for classified output of messages in communication system

ActiveCN102111332BImprove resource utilizationReduce design difficultyData switching networksMessage queueCommunications system

The invention provides a method and a controller for the classified output of messages in a communication system, and mainly solves the problems that that a conventional method and a conventional controller have high demand on storage resources and high cost, and are low in utilization ratio and difficult to implement. The method for the classified output of the messages in the communication system comprises three steps, namely, system initialization, message writing and message reading. The controller for the classified output of the messages in the communication system comprises an input control unit, a memory unit, an output control unit, a message attribute list unit, an idle message block concordance list unit, a message searching list unit and an output control list unit. The methodand the controller for the classified output of the messages in the communication system, which are provided by the invention, have good flexibility, the number of output ports of a message queue management controller for classification is configurable, and the depth of output queue is configurable.

Owner:AVIC NO 631 RES INST

A small polypropylene lithium battery diaphragm simulation production equipment

ActiveCN109927224BEasy to testLess materialPreparing sample for investigationMaterial strength using tensile/compressive forcesPolypropyleneTensile testing

This invention relates to the field of special materials for polypropylene lithium battery diaphragms, in particular to a small polypropylene lithium battery diaphragm simulation production device. Asmall casting machine and a universal tensile testing machine are included, and the universal tensile testing machine is fixedly arranged at one end of the small casting machine; the end, away from the universal tensile testing machine, of the small casting machine is fixedly provided with a material entering pipe; the end, close to the material entering pipe, of the inner side of the small casting machine is fixedly provided with an extruding machine; a discharging port is fixedly formed in the lower end of the extruding machine; the lower end of the discharging port is movably provided witha first conveying belt through a rotating shaft; the end, away from the material entering pipe, of the extruding machine is fixedly provided with a telescopic rod; and a tool bit is fixedly arranged at the lower end of the telescopic rod. According to the small polypropylene lithium battery diaphragm simulation production device, by arranging the small casting machine and the universal tensile testing machine, firstly simulation production is performed on materials needed for producing a diaphragm, then the diaphragm after being produced is detected, and batch production can be performed if noproblems exist, so that resources needed for production can be saved.

Owner:NORTH HUAJIN CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com