I-type integral oil ring wire working method and equipment for piston ring industry

A processing method and piston ring technology, applied in the field of wire processing, can solve problems such as complex cross-sectional shape, difficult breakthrough, and inability to produce such products, and achieve the effects of avoiding mutual influence, ensuring shape requirements, and high shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

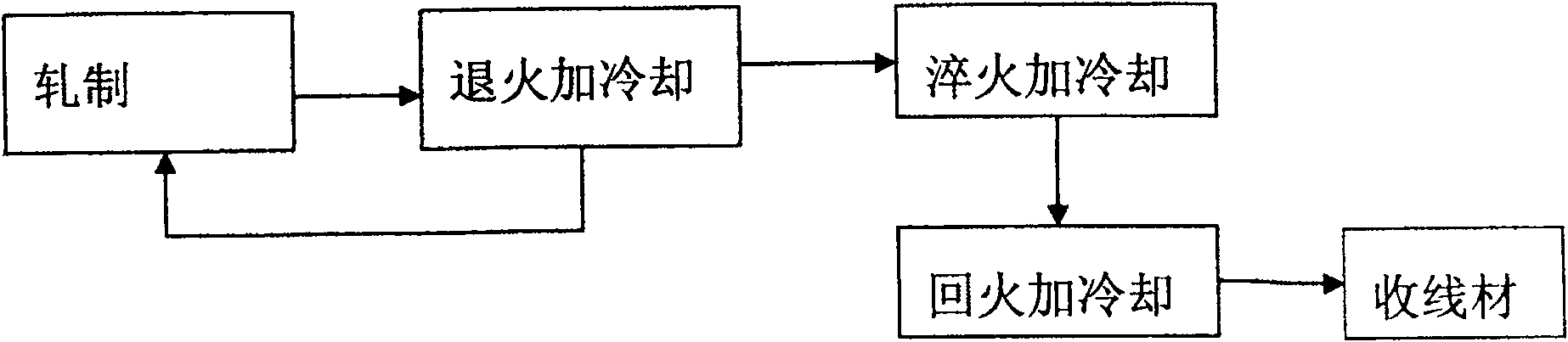

[0019] The processing method of I-type integral oil ring wire used in the piston ring industry:

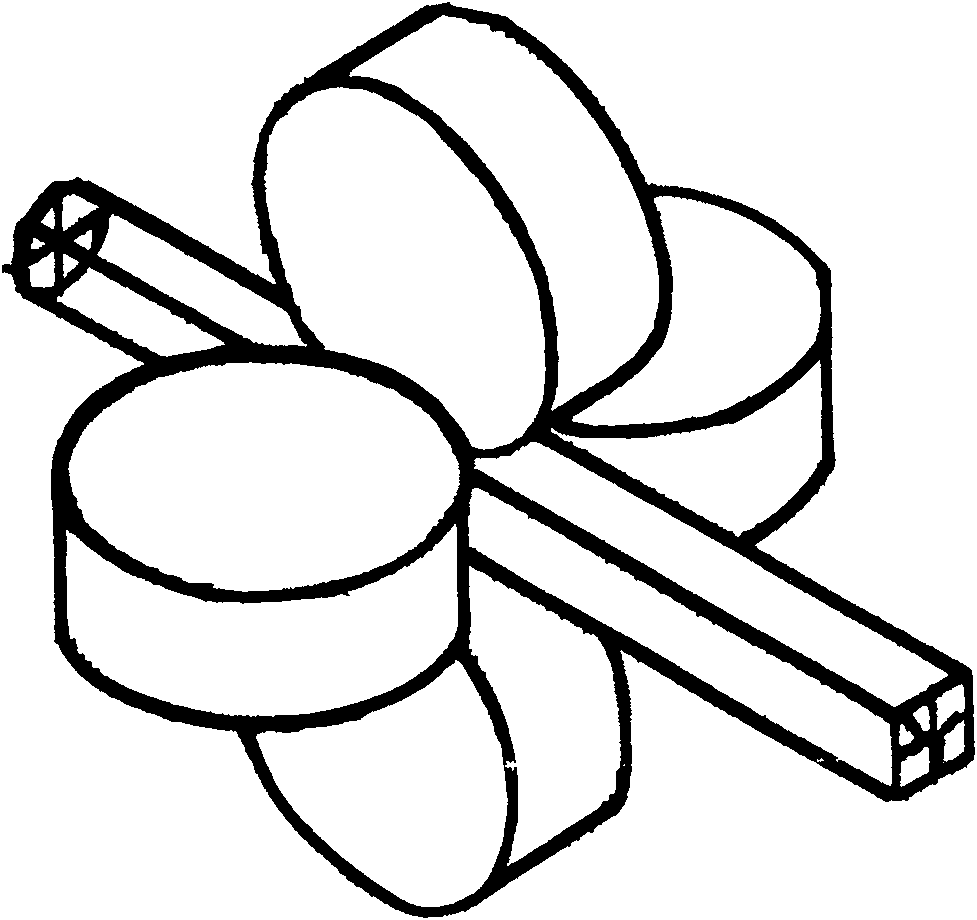

[0020] The first step of rolling: the raw material wire rod is linearly routed through the rolling equipment, and rolled on the four sections of the upper, lower, left, and right sides at the same time to obtain the required I-shaped section shape;

[0021] The second step of annealing: the rolled wire rod is linearly routed through the annealing furnace for annealing, and then rolling and annealing are performed after annealing, and this is repeated 3-8 times to obtain a type I integral oil ring wire rod without quenching and tempering;

[0022] The third step: quenching and tempering heat treatment: the steel wire is linearly and continuously routed and quenched, and the continuous linear route is tempered in an inert protective gas atmosphere. After quenching and tempering, there is a linear continuous water-cooled rapid cooling treatment, and the quenching temperature is 860 ℃ ...

Embodiment 2

[0025] The processing method of the I-type integral oil ring wire with holes for the piston ring industry:

[0026] The first step of rolling: the raw material wire rod is linearly routed through the rolling equipment, and rolled on the four sections of the upper, lower, left, and right sides at the same time to obtain the required I-shaped section shape;

[0027] The second step of annealing: the rolled wire rod is linearly routed through the annealing furnace for annealing, and then rolling and annealing are performed after annealing, and this is repeated 3-8 times to obtain a type I integral oil ring wire rod without quenching and tempering;

[0028] The third step of punching: punching the wire rod on the punching machine to obtain a non-tempered I-type integral oil ring wire rod with holes;

[0029] The fourth step: quenching and tempering heat treatment: the steel wire is linearly and continuously routed and quenched, and then linearly and continuously routed in an inert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com