Hydraulically-driven reaming-while-drilling tool

A technology of reaming while drilling and hydraulic drive, which is applied to drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems affecting the reaming efficiency of tools and the energy loss of drilling fluid, etc., and achieves easy manufacturing, installation and maintenance, and small flow loss , the effect of small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

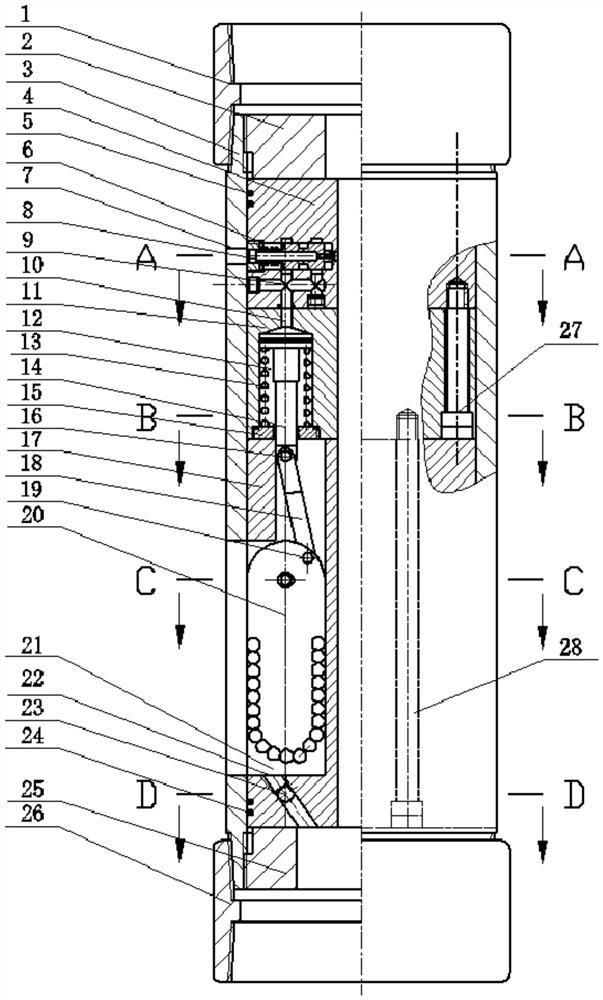

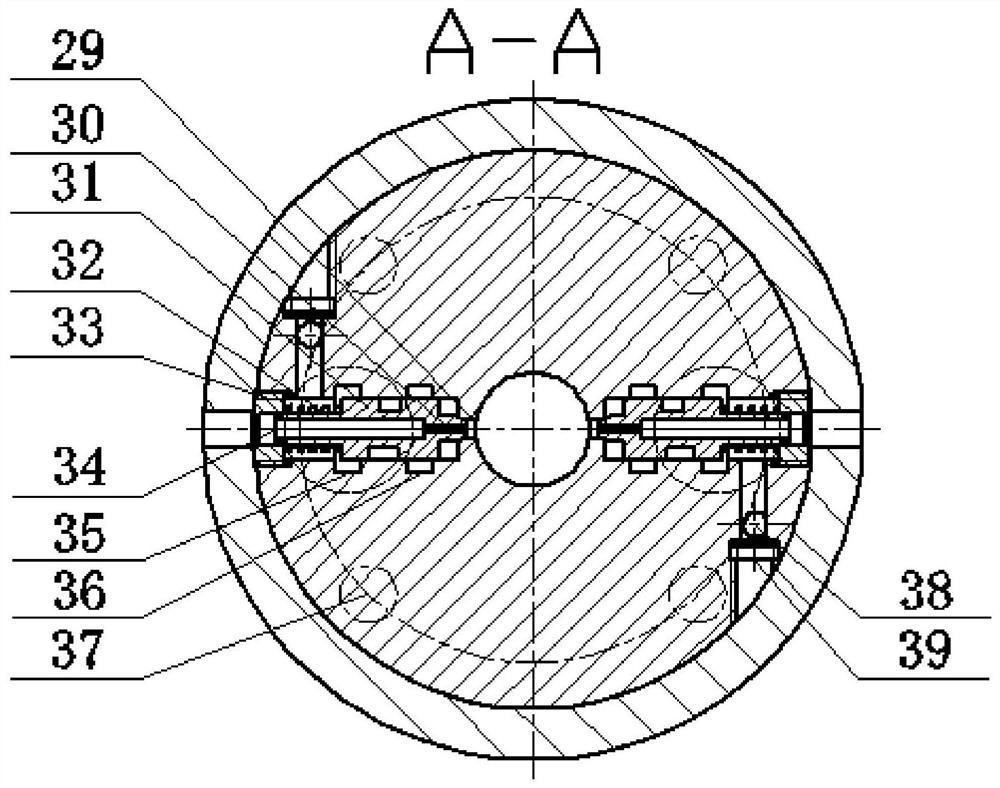

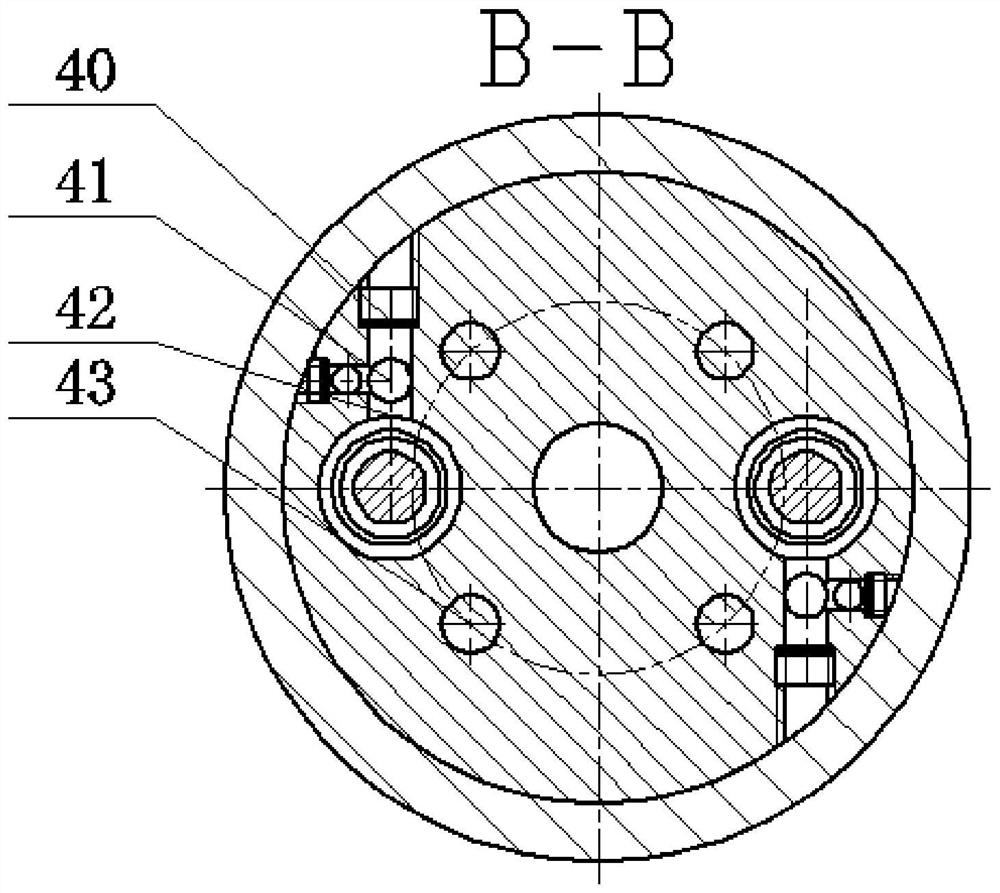

[0019] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-Figure 5 As shown, the hydraulically driven reaming tool mainly consists of three parts, including the main body 4 of the starting device, the main body 11 of the driving device and the main body 17 of the actuator. Among them, the starting device main body 4 and the driving device main body 11 are connected by four M8 upper connecting bolts 27, and the driving device main body 4 and the actuator main body 17 are connected by four M8 lower connecting bolts to form a unified whole by the upper gland 2 and the lower gland. 25 is packaged in the reaming tool housing 3. The end of the upper gland 2 is provided with an end sealing ring 5, and the bottom of the lower gland 25 is provided with a bottom sealing ring 24 to ensure that bad hollow cuttings cannot enter the drilling fluid circulation channel. Both ends of the reaming tool housing 3 are connected with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com