A small polypropylene lithium battery diaphragm simulation production equipment

A lithium battery diaphragm and production equipment technology, which is applied in the field of simulated production equipment for small polypropylene lithium battery diaphragms, can solve problems such as the inability to realize simulated production, achieve the effects of increasing the upper limit of the width, increasing the design size, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

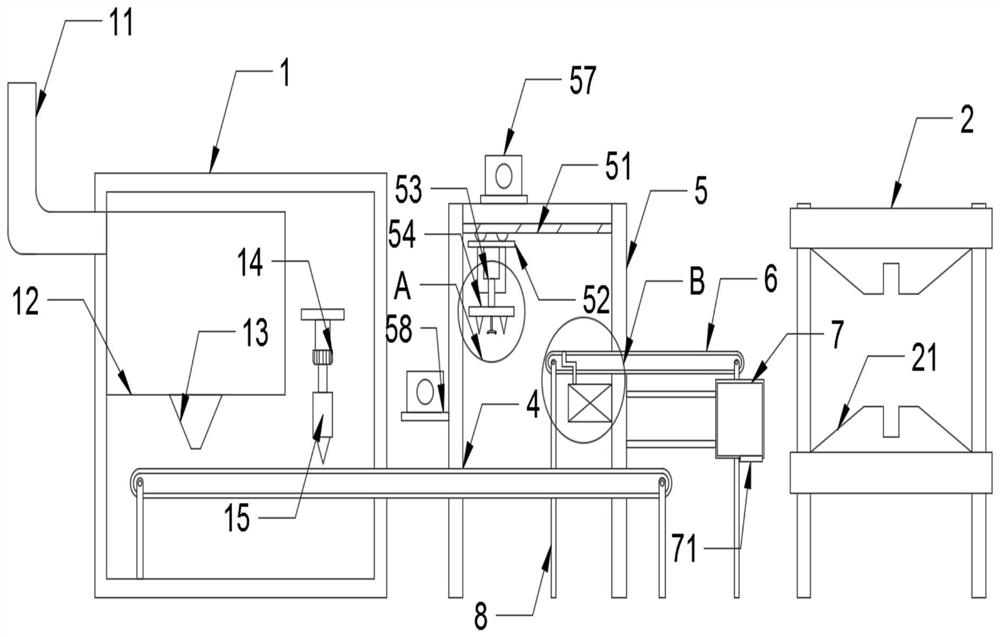

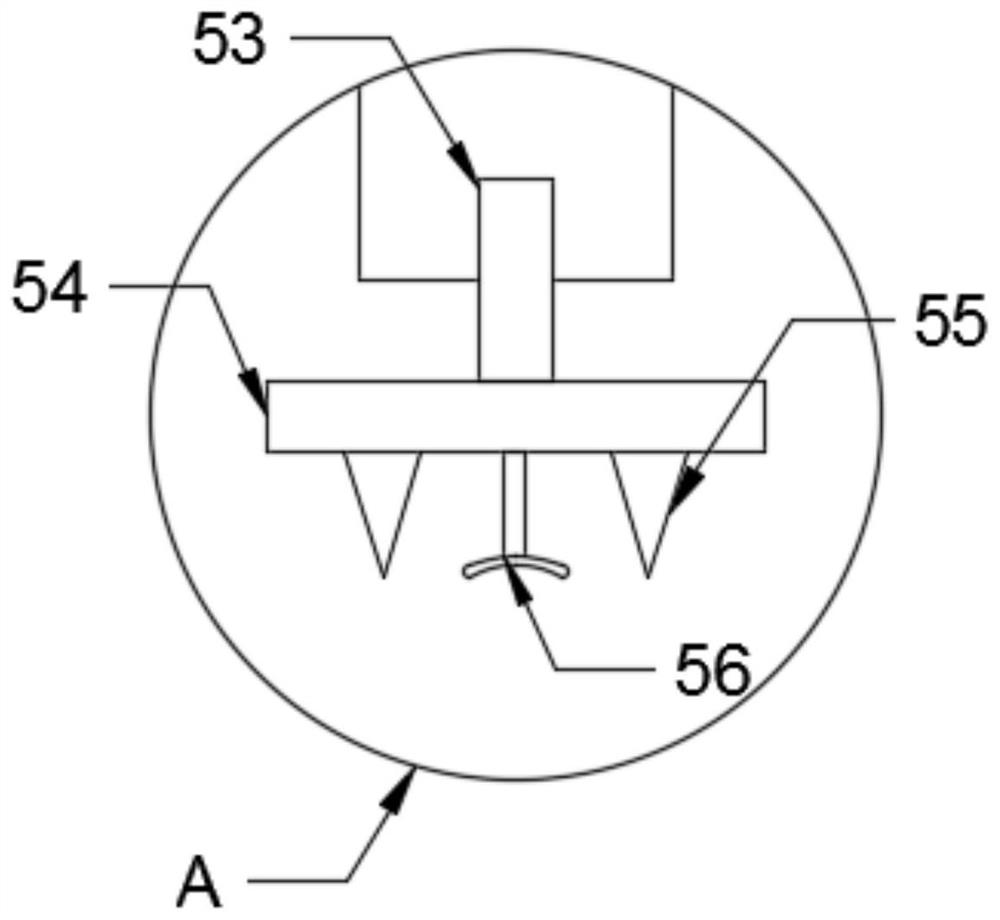

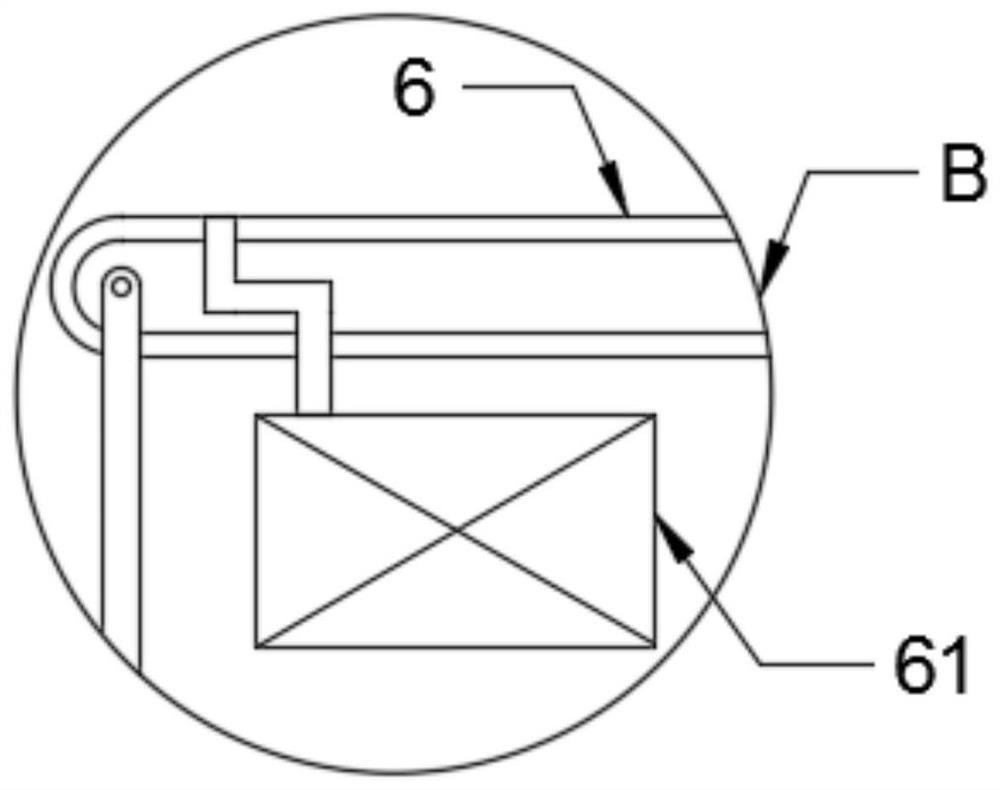

[0019] see Figure 1-3 , a small polypropylene lithium battery diaphragm simulation production equipment, including a small casting machine 1, a universal tensile testing machine 2, the universal tensile testing machine 2 is fixed at one end of the small casting machine 1, and the small casting machine One end of the machine 1 away from the universal tensile testing machine 2 is fixedly provided with a feed pipe 11, the inner side of the small caster 1 close to the feed pipe 11 is fixedly provided with an extruder 12, and the lower end of the extruder 12 is fixedly provided with an outlet A feed port 13, the lower end of the discharge port 13 is movable to install the first conveyor belt 4 through a rotating shaft, the end of the extruder 12 away from the feed pipe 11 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com