Punch forming process and mould for vehicle load sensing proportional valve support

A load-sensing proportional valve, stamping and forming technology, applied in the field of machining, can solve problems such as sharp corners, failure to meet product design and use requirements, and easy deformation of bolt holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Take the example of our company's processing of the load-sensing proportional valve bracket in the Nissan C16A torsion beam:

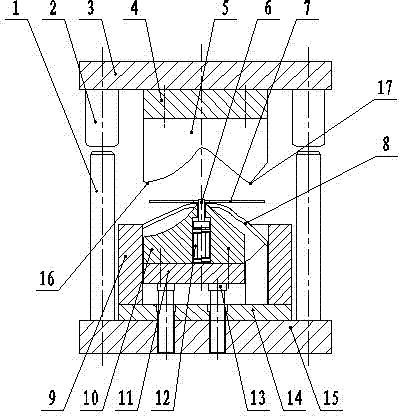

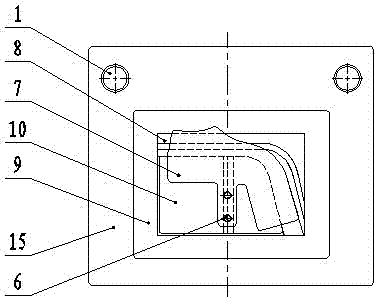

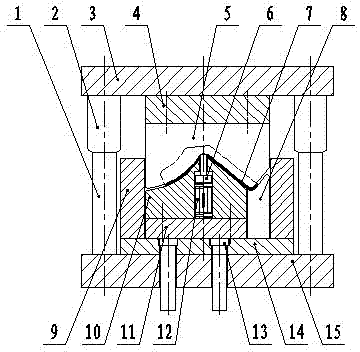

[0030] The Nissan C16A load-sensing proportional valve support molding die adopts the positioning method of "increasing the process length and process holes" to realize the positioning of the two pin holes on the complex curved surface. The positioning reference is set at the highest point of the movable insert, which can well avoid the blank When forming on a complex and irregular surface, the part is unilaterally caused by movement. The mold structure of the load-sensing proportional valve support molding die is as follows: Figure 1-4 Shown:

[0031] The structural relationship of the upper mold is: the punch 5 and the upper backing plate 4 are installed on the upper template 3 through bolts in the order shown in the figure, and are fixed together with fastening pins; the guide sleeve 2 is driven into the corresponding upper templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com